Over the course of last month, the parts I ordered arrived so I tried some things out.

C clamp and TM-5 magic arm

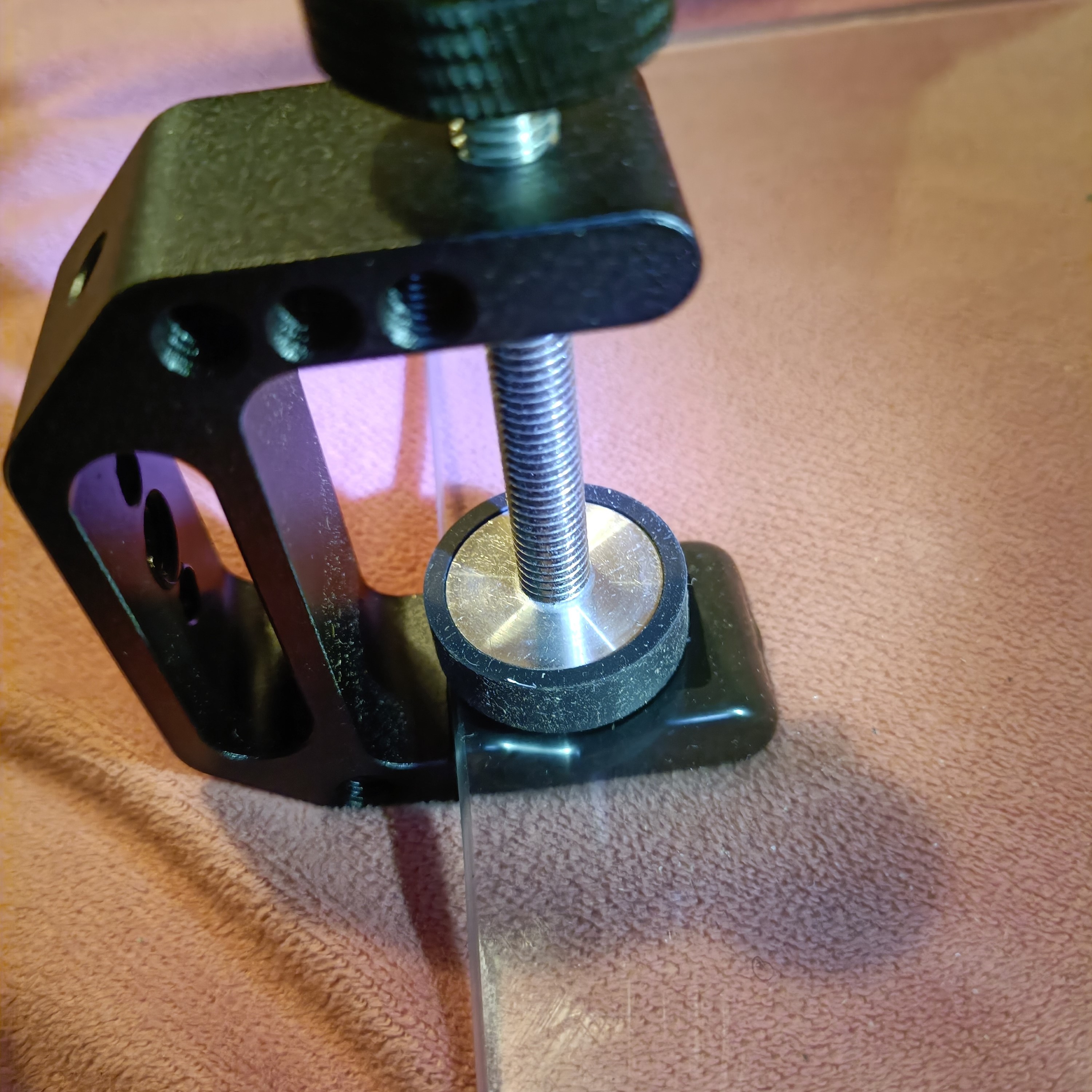

The c-clamp was very nice, being able to securely clamp to a 5mm glass worktop saver and a 42mm pipe:

There is just one very unfortunate problem (that I already knew was going to be an issue but I went ahead with the purchase anyway) which is that the vast majority of tubes out-and-about are larger than 42mm.

I took my calipers outside to measure them. The most abundant size was 76mm for things like lamp-posts and signs, followed by railings that are 48 - 51mm in diameter. If only the c-clamp was designed to be 20% larger.

TM-5

This was disappointing as it still spun in place where the threads are. One reason could be that the rubber surface is just a thin embossed grid which folds over at minimal torque:

1-inch Ball Accessories

I noticed that the ball joints themselves were very solid, so I was able to find some 1-inch ball accessories:

- https://vi.aliexpress.com/item/1005005160312819.html

- https://vi.aliexpress.com/item/1005008473928934.html

- https://vi.aliexpress.com/item/1005006394021014.html

The idea is that I get 3 ball mounts; 2 for the front and back of Tetizmol (for mounting options) and one to somehow attach to the c-clamp. This one would stay inside while the tube clamp with built-in ball will be used outdoors:

Without much effort, the handle of the arm can be twisted and movement of the joints is completely locked. Additionally, the handle of the tube clamp is easy to quickly spin to open/close the jaws.

I would've preferred if the tube clamp was a bit wider than 20mm to better fight against torque forces, but I think it's actually the grippy surface slightly moving / flexing. Everything returns to its original position, so there's no sliding happening. Thus, I think it will be fine for this application.

Joysticks

I measured about 90gf for displacement of the stick, so these are already 50% stiffer than the original L4A joysticks seen in:

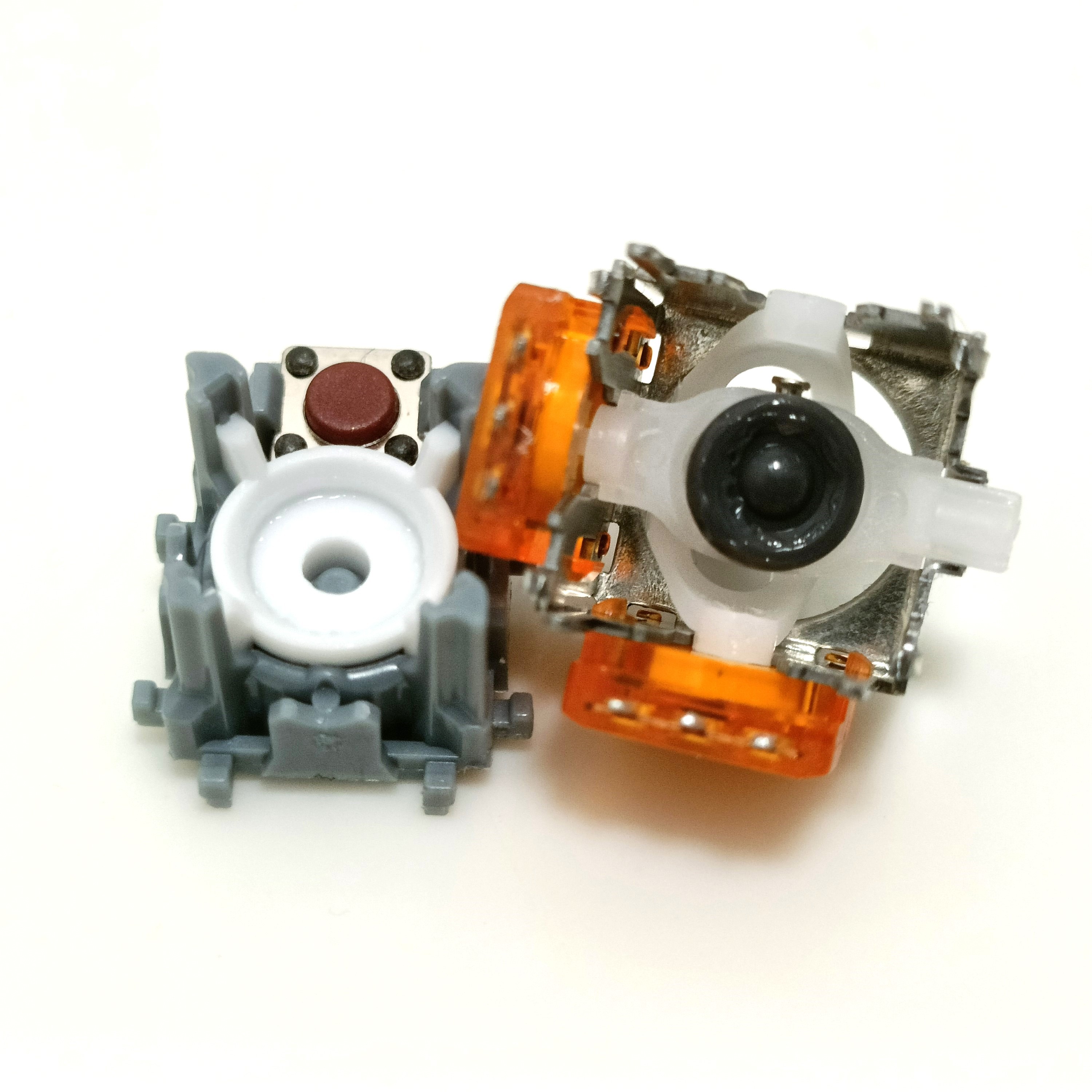

Using the smallest flat-head attachment I had, I was able to fold out the 4 tabs under a joystick and separate the base from the frame:

2 of the 4 legs have very small bumps in them that prevent the plunger from launching out. Pulling them apart allows it to come off.

The spring inside is 0.5 x 8.7 x 11mm and compresses down to 2.05mm height. In contrast, the springs I bought only compressed down to 3.05mm. The stock springs slot around a cylinder on the other side that is 7.6mm diameter.

I had calculated that the difference from 0.5mm to 0.7mm would be a 3X difference, but unfortunately it's more like 10X. I measured about 120g and 1200g respectively when compressing both springs down to 5mm height.

I put the joystick back together, but the axle that rests over the push button now has an airgap. All in all, I don't think spring replacement is a reliable strategy.

Stainless balls and copper bushings

The ball beads (measured 7.92 - 8.03) slide into the bushings (measured 8.03) and they move smoothly without noticeable backlash.

LED Ring

I soldered the ring on a 30cm length of wire and rested them inside the pin holes of the RP2040 board to confirm that they all light up white:

This is because, when assembling the Airberries (see #AirBerries and SpaceExplorer), I didn't check and one of the LEDs in the strip were defective.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.