when's the hackchat? Don't want to miss it =(

1h?

1h?

![]() in 50 minutes :)

in 50 minutes :)

26 minutes now. Hack Chat coming up with Drew and Chris from OSH Park!

26 minutes now. Hack Chat coming up with Drew and Chris from OSH Park!

![]() Yes!

Yes!

![]() We are excited to talk about the Flex PCB contest and our Flex PCB service

We are excited to talk about the Flex PCB contest and our Flex PCB service

60 winners, but only 49 contestants so far, sounds like it is not very difficult to win :-)

60 winners, but only 49 contestants so far, sounds like it is not very difficult to win :-)

Oh man, I should hurry up an make something then.

Oh man, I should hurry up an make something then.

flex PCB Cthulhu

flex PCB Cthulhu

hi

hi

soon to be 50 contestants

soon to be 50 contestants

@Alex Klimaj - You don't even have to make anything! Just an idea will do.

@Alex Klimaj - You don't even have to make anything! Just an idea will do.

that's what i did, just an idea

that's what i did, just an idea

unfortunately i did not expand upon it or implement anything

unfortunately i did not expand upon it or implement anything

i'd have to make a text to gerber converter somehow, possibly Eagle

i'd have to make a text to gerber converter somehow, possibly Eagle

don't want to get too creative at $10/square inch

don't want to get too creative at $10/square inch

I've been rush learning KiCad for this contest

I've been rush learning KiCad for this contest

that's not overly expensive for the application

that's not overly expensive for the application

even one page could hold a few favorite verses of the bible

even one page could hold a few favorite verses of the bible

?

?

wouldn't that combust in contact with with the chemicals used for etching?

wouldn't that combust in contact with with the chemicals used for etching?

:)

:)

My idea was to print some the bible in kapton. lol that could be an issue

My idea was to print some the bible in kapton. lol that could be an issue

why waste good kapton?

why waste good kapton?

utilize the flex PCB to make a scroll

utilize the flex PCB to make a scroll

maybe that's the thing to do: if (detect == satanism) self(destruct);

maybe that's the thing to do: if (detect == satanism) self(destruct);

lol I could see making a microTorah out of flex...

lol I could see making a microTorah out of flex...

OMG a scroll, not a book! very cool!

OMG a scroll, not a book! very cool!

![]()

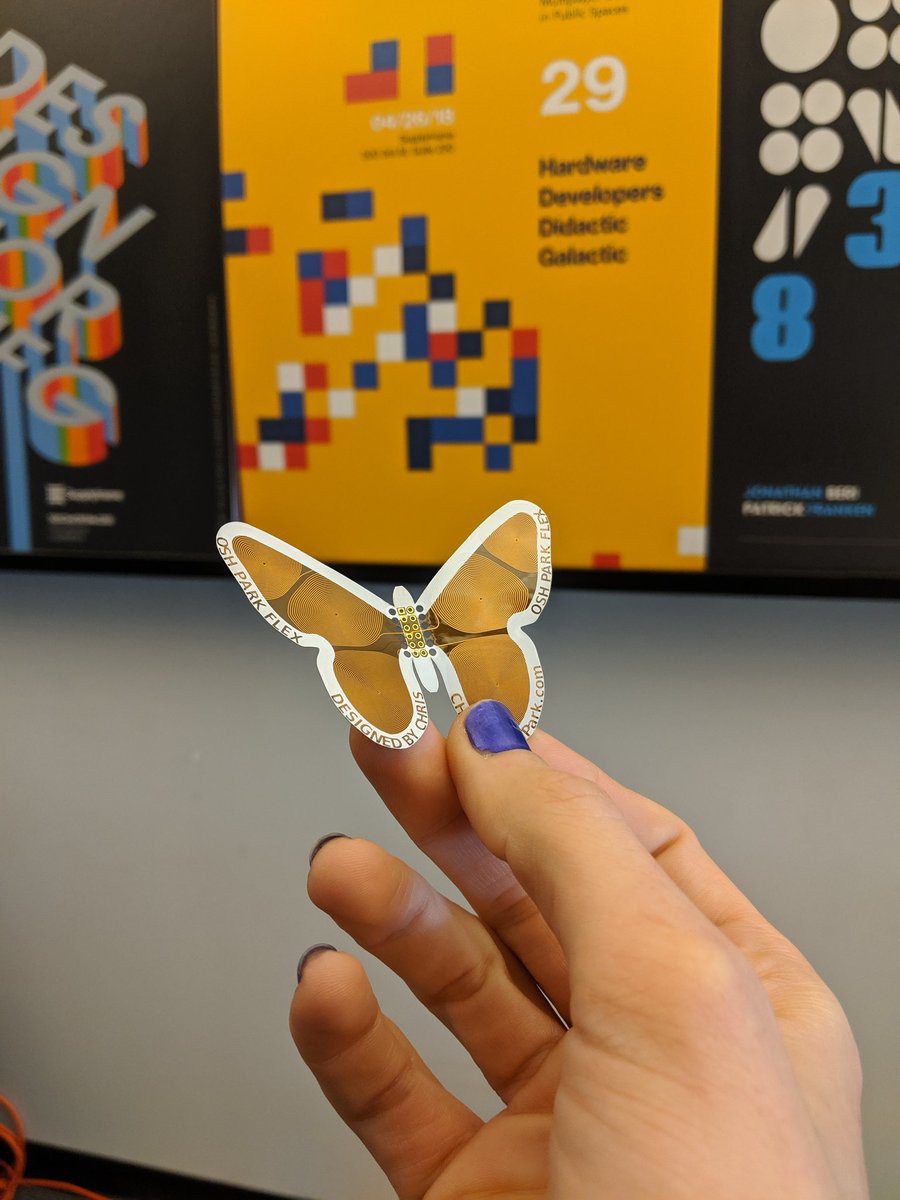

![]() Hello from Supplyframe SF :)

Hello from Supplyframe SF :)

does it fly?

does it fly?

flex PCB glider would be sick

flex PCB glider would be sick

It can move :) Flying may take just a little longer ;)

It can move :) Flying may take just a little longer ;)

are we limited to kapton? are there other materials? I was thinking polyester?

are we limited to kapton? are there other materials? I was thinking polyester?

pretty sure there is only one substrate

pretty sure there is only one substrate

hmmm, origami in flex with creases where fill is not...

hmmm, origami in flex with creases where fill is not...

![]() @oshpark just got a really nice pcb for my Unisolder from you ;)

@oshpark just got a really nice pcb for my Unisolder from you ;)

OK, it's noon here in UTC-7, so let's kick it off!. We're pleased to welcome Drew and Chris from OSH Park to the Hack Chat today, to discuss the details on flexible PCBs.

OK, it's noon here in UTC-7, so let's kick it off!. We're pleased to welcome Drew and Chris from OSH Park to the Hack Chat today, to discuss the details on flexible PCBs.

Drew, can you kick us off?

Ha, you made a butterfly... :)

Ha, you made a butterfly... :)

Hi Dan

Hi Dan

Hey Bil!

Hey Bil!

!

!

OSHPark rocks.

OSHPark rocks.

![]() Thanks @Dan Maloney . At OSH Park, we are very excited about the Flex PCB contest currently on Hackaday

Thanks @Dan Maloney . At OSH Park, we are very excited about the Flex PCB contest currently on Hackaday

Great to see everyone today for Flex! Chris here.

Great to see everyone today for Flex! Chris here.

![]() Chris is joining us as OSH Park

Chris is joining us as OSH Park

Hi Chris

Hi Chris

![]() We hope everyone will checkout the Flex PCB contest:

We hope everyone will checkout the Flex PCB contest:

![]()

https://hackaday.io/contest/163267-flexible-pcb-concept-contest

Flexible PCB Concept Contest

Flex your circuit's power!

Hey Chris and Drew.

Hey Chris and Drew.

Hi

Hi

![]() It ends next week so there is still time to enter

It ends next week so there is still time to enter

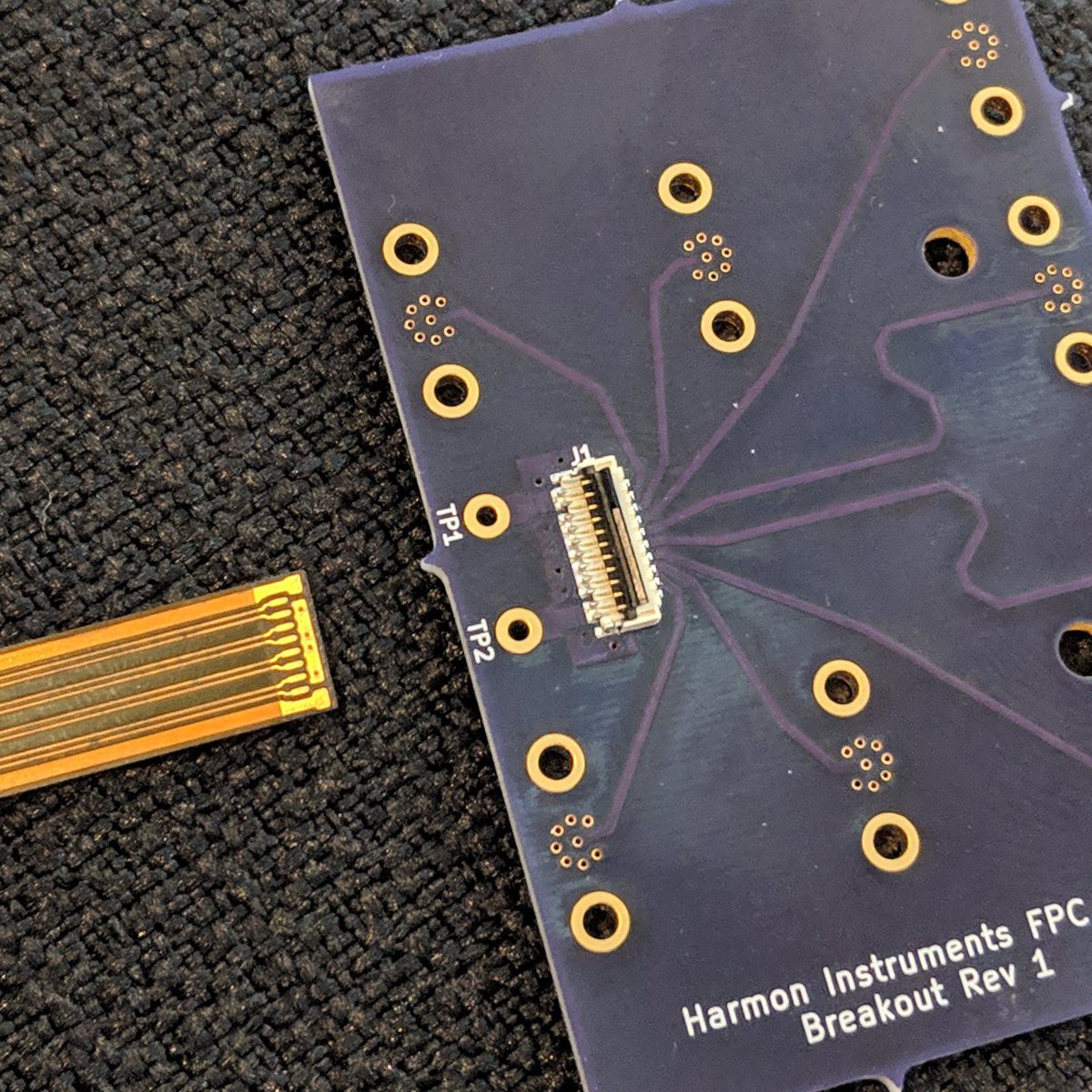

![]() Digi-Key has partnered with Hackaday to provide the opportunity for 60 contest winners to receive 3 flexible circuits of their design! We will have 60 flexible designs (within 2 square inches or 13 square centimeters), manufactured with help from @oshpark and shipped directly to the winners!

Digi-Key has partnered with Hackaday to provide the opportunity for 60 contest winners to receive 3 flexible circuits of their design! We will have 60 flexible designs (within 2 square inches or 13 square centimeters), manufactured with help from @oshpark and shipped directly to the winners!

Hi @Dan Maloney @Bil Herd and @Alex!

Hi @Dan Maloney @Bil Herd and @Alex!

![]() A friend wants to make a sphere out of flex pcb ~25-30cm so 9 3/4-11 3/4"

A friend wants to make a sphere out of flex pcb ~25-30cm so 9 3/4-11 3/4"

how far can that stuff flex in 3D?

![]() We launched our 2 Layer Flex service at the beginning of the year. Here are details:

We launched our 2 Layer Flex service at the beginning of the year. Here are details:

https://docs.oshpark.com/services/flex/\

![]() oops: https://docs.oshpark.com/services/flex/

oops: https://docs.oshpark.com/services/flex/

@Aaron_Kraus The Panasonic Felios substrtae we use is very flexible but also has good spring-back which should help it keep a more-rounded shape for an object that size.

@Aaron_Kraus The Panasonic Felios substrtae we use is very flexible but also has good spring-back which should help it keep a more-rounded shape for an object that size.

@Aaron_Kraus It'll flex all the way, so this is totally doable. It doesn't stretch though, so it'd have tessellation effects. Like a beach ball, soccer ball, or volleyball.

@Aaron_Kraus It'll flex all the way, so this is totally doable. It doesn't stretch though, so it'd have tessellation effects. Like a beach ball, soccer ball, or volleyball.

is it possible to solder flex PCB in a reflow oven? what are the temperature specs?

is it possible to solder flex PCB in a reflow oven? what are the temperature specs?

Increased use of copper will cause the flex to become more ductile and retain it's shape. That's something you might want to avoid on flex cables where you want more spring, but for a sphere it might also help keep the final shape better.

Increased use of copper will cause the flex to become more ductile and retain it's shape. That's something you might want to avoid on flex cables where you want more spring, but for a sphere it might also help keep the final shape better.

@Frank Buss Absolutely! Our Flexible PCBs have the highest temperature ratings of any of our services, and can handle lead-free reflow with no problem.

@Frank Buss Absolutely! Our Flexible PCBs have the highest temperature ratings of any of our services, and can handle lead-free reflow with no problem.

cool

cool

what's the operating temperature limit?

what's the operating temperature limit?

can we crease the PCB?

can we crease the PCB?

![]() How about regular iron soldering and soldering egde to egde?

How about regular iron soldering and soldering egde to egde?

@Les Hall sounds breaky. The oshpark specs page has a recommended bend radius

@Les Hall sounds breaky. The oshpark specs page has a recommended bend radius

Panasonic specs 288ºC for 1 min soldering for our R-F775. The full data sheet can be found here https://docs.oshpark.com/resources/flex-panasonic-felios-F775.pdf

Panasonic specs 288ºC for 1 min soldering for our R-F775. The full data sheet can be found here https://docs.oshpark.com/resources/flex-panasonic-felios-F775.pdf

@Les Hall Yeah. We have a relatively springy substrate, but it'll still hold a shape if you bend it sharply. If you have copper in a bend, it'll hold shape better, but you can't bend it quite as sharply and expect the signal to hold together. It's a pretty tight bend radius.

@Les Hall Yeah. We have a relatively springy substrate, but it'll still hold a shape if you bend it sharply. If you have copper in a bend, it'll hold shape better, but you can't bend it quite as sharply and expect the signal to hold together. It's a pretty tight bend radius.

Do you have specs on website for the flex such as Dk, Df , and whether Tg applies like in epoxy-glass PCBs?

Do you have specs on website for the flex such as Dk, Df , and whether Tg applies like in epoxy-glass PCBs?

@Nicolas Tremblay Yep. Both of those are OK. You can get copper pretty close to the edge, so you can use exposed pads to weld two pieces together.

@Nicolas Tremblay Yep. Both of those are OK. You can get copper pretty close to the edge, so you can use exposed pads to weld two pieces together.

![]() @oshpark @Dan Sheadel So More Copper gets me a "Less Flexible, more robust" structure?

@oshpark @Dan Sheadel So More Copper gets me a "Less Flexible, more robust" structure?

how is this effecting bigger structures like the 10" sphere? Any guesses how many sections i need to get a halfway decent ball?

And Edge soldering would be quite interesting

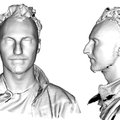

![]() There is great information about the RF characteristics of OSH Park 2 layer flex in this KiCon talk"

There is great information about the RF characteristics of OSH Park 2 layer flex in this KiCon talk"

"Microwave Design with KiCad" - Darrell Harmon (KiCon 2019)

ty @Dan Sheadel was wondering about making a scroll as someone else here suggested, thinking ahead of a crease in each end or not.

ty @Dan Sheadel was wondering about making a scroll as someone else here suggested, thinking ahead of a crease in each end or not.

@Aaron_Kraus Exactly. Flooding both sides with a copper fill would make the board malleable and hold it's shape reasonably well after bending.

@Aaron_Kraus Exactly. Flooding both sides with a copper fill would make the board malleable and hold it's shape reasonably well after bending.

The copper is annealed and soft, which is specific and necessary to flexible circuits.

The copper is annealed and soft, which is specific and necessary to flexible circuits.

@Aaron_Kraus Basically. It's actually a bit stiff when you have a copper plane or two, and really bendy with no copper. Most boards will be in the middle. Hatched copper pours are really great to get a fairly consistent bend across the board.

@Aaron_Kraus Basically. It's actually a bit stiff when you have a copper plane or two, and really bendy with no copper. Most boards will be in the middle. Hatched copper pours are really great to get a fairly consistent bend across the board.

Thanks. Your standard Isola FR-408 rocks, I was going to mention that in my next vid.

Thanks. Your standard Isola FR-408 rocks, I was going to mention that in my next vid.

![]() @Bil Herd Harmon Instruments has some measurements here: https://twitter.com/HarmonInst/status/1084142351210037249

@Bil Herd Harmon Instruments has some measurements here: https://twitter.com/HarmonInst/status/1084142351210037249

To add to the barrage of questions; I get that this is a polymide film, has anyone (ultrasonically) welded it together?

To add to the barrage of questions; I get that this is a polymide film, has anyone (ultrasonically) welded it together?

Thanks @Drew Fustini

Thanks @Drew Fustini

![]() There is more information in the datasheet for our flex https://docs.oshpark.com/resources/flex-panasonic-felios-F775.pdf

There is more information in the datasheet for our flex https://docs.oshpark.com/resources/flex-panasonic-felios-F775.pdf

Ah, thats what I was looking for, thanks!

Ah, thats what I was looking for, thanks!

![]() @David Troetschel that is an interesting idea, but I don't believe we have seen anyone try that yet

@David Troetschel that is an interesting idea, but I don't believe we have seen anyone try that yet

@Les Hall If you make this let us know! That sounds awesome. I think any anchoring method at the ends will be fine if you're not passing active circuitry between the roll and the "paper". If you are, perhaps consider a wire-specific region in the middle that has more room to "bend" rather than crease.

@Les Hall If you make this let us know! That sounds awesome. I think any anchoring method at the ends will be fine if you're not passing active circuitry between the roll and the "paper". If you are, perhaps consider a wire-specific region in the middle that has more room to "bend" rather than crease.

![]() For those interested in connectors, Harmon Instruments found a connector on Digi-Key that works well:

For those interested in connectors, Harmon Instruments found a connector on Digi-Key that works well:

https://twitter.com/HarmonInst/status/1095448040243003392

![]()

![]()

@Drew Fustini I happen to have access to a machine...

@Drew Fustini I happen to have access to a machine...

![]() very interesting... we would love to hear the results

very interesting... we would love to hear the results

@Bil Herd The Dk on Panasonic's Felios substrate is nominally 3.2 which also makes it an excellent candidate for RF work. In fact our current stack-up was partly chosen to enable making common impedances relatively easy. https://docs.oshpark.com/services/flex/

@Bil Herd The Dk on Panasonic's Felios substrate is nominally 3.2 which also makes it an excellent candidate for RF work. In fact our current stack-up was partly chosen to enable making common impedances relatively easy. https://docs.oshpark.com/services/flex/

@Drew Fustini and those connectors are without backing on the flex?

@Drew Fustini and those connectors are without backing on the flex?

I'm assuming this is almost identical to Kaptan? I think I have some lying around. I'll give it a shot next time I'm around the machine.

I'm assuming this is almost identical to Kaptan? I think I have some lying around. I'll give it a shot next time I'm around the machine.

![]() Please submit an idea to the Flex PCB contest. You should be able to get a gift code given the current number of entries

Please submit an idea to the Flex PCB contest. You should be able to get a gift code given the current number of entries

![]() DK part: https://www.digikey.com/product-detail/en/te-connectivity-amp-connectors/2-2328724-1/A141393CT-ND/9565592

DK part: https://www.digikey.com/product-detail/en/te-connectivity-amp-connectors/2-2328724-1/A141393CT-ND/9565592

@David Troetschel Correct! It's basically the same as DuPont Pyralux, etc.

@David Troetschel Correct! It's basically the same as DuPont Pyralux, etc.

![]() @morgan the flex has no stiffner but is rigid enough to insert into the connector

@morgan the flex has no stiffner but is rigid enough to insert into the connector

cool

cool

![]() how concistent is the thickness (variation) of the flex PCB over a bigger area?

how concistent is the thickness (variation) of the flex PCB over a bigger area?

nice, that connector is cheaper than what I was looking at

nice, that connector is cheaper than what I was looking at

Also has Tan loss of .002 at 1Mhz looks like which is the other factor dragging on high speed.

Also has Tan loss of .002 at 1Mhz looks like which is the other factor dragging on high speed.

@morgan You can adjust the thickness somewhat by choosing which layers to use at the connector, such as adding copper or not on the bottom, etc.

@morgan You can adjust the thickness somewhat by choosing which layers to use at the connector, such as adding copper or not on the bottom, etc.

@Aaron_Kraus The substrate thickness spec is +/- 0.4mil . That's over on our flex specs if you need it later.

@Aaron_Kraus The substrate thickness spec is +/- 0.4mil . That's over on our flex specs if you need it later.

Recently found some HP 5082-7415 5x7segment led modules from over 40 years ago. Anyone still having some around or ideas what to do with it? They got pretty rare.

Recently found some HP 5082-7415 5x7segment led modules from over 40 years ago. Anyone still having some around or ideas what to do with it? They got pretty rare.

Sadly half of them have damaged segments. Probably loose bondwires.

Made a simple interface board if you want to use them: https://hackaday.io/project/165710-hp-5082-74xx-7-segment-display-revived

Maybe a geiger counter, a watch or some other readout. :) I love the glow

Lutetium

Lutetium

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.