OK, folks, let's get started. Welcome to the Hack Chat, I'm Dan and I'll be moderating today along with Dusan for Andrew Sink. As you can probably tell from the pre-Chat, we'll be talking about Resin Printing today -- stereolithography or SLA if you want to be proper about it.

OK, folks, let's get started. Welcome to the Hack Chat, I'm Dan and I'll be moderating today along with Dusan for Andrew Sink. As you can probably tell from the pre-Chat, we'll be talking about Resin Printing today -- stereolithography or SLA if you want to be proper about it.

Welcome Andrew, thanks for joining us today. Can you fill us in a little on your background?

Looks like @Thomas Shaddack picked up a good bit of slack and started doing a deep dive here; thanks Thomas!

Looks like @Thomas Shaddack picked up a good bit of slack and started doing a deep dive here; thanks Thomas!

Hello and welcome!

Hello and welcome!

Thanks for the introduction, @Dan Maloney!

Thanks for the introduction, @Dan Maloney!

I've been involved in the additive industry for about 9 years, first as a student, then a hobbyist, and currently a full-time additive engineer!

I've been involved in the additive industry for about 9 years, first as a student, then a hobbyist, and currently a full-time additive engineer!

Hi @Andrew Sink !

Hi @Andrew Sink !

I turned my attention to resin 3D printing earlier this year, and I've been absolutely fascinated with it since!

I turned my attention to resin 3D printing earlier this year, and I've been absolutely fascinated with it since!

To answer the question I posed earlier, that part was printed hollow and upside down using a flexible resin with a 3mm thick wall!

To answer the question I posed earlier, that part was printed hollow and upside down using a flexible resin with a 3mm thick wall!

It is pretty awesome!

It is pretty awesome!

You can see the deformation is lateral in the print, and squishing from top to bottom results in FAR less deformation

You can see the deformation is lateral in the print, and squishing from top to bottom results in FAR less deformation

An interesting side-effect of the layer-by-layer exposure process of an MSLA 3D printer!

An interesting side-effect of the layer-by-layer exposure process of an MSLA 3D printer!

I'd like this chat to focus on resin printing, with an emphasis on questions from beginners on the "How-To" of MSLA 3D printing!

I'd like this chat to focus on resin printing, with an emphasis on questions from beginners on the "How-To" of MSLA 3D printing!

Is there as wide a range of material types in resins as there is in filaments?

Is there as wide a range of material types in resins as there is in filaments?

Let's start with a quick definition of the term

Let's start with a quick definition of the term

There sure are! We'll dive into those in a just moment!

There sure are! We'll dive into those in a just moment!

"MSLA" stands for "Masked SLA (Stereolithography)"

"MSLA" stands for "Masked SLA (Stereolithography)"

![]() The breaking depends on the mechanical properties of the resin. Again, degree of crosslinking and the nature of the diluent and the main oligomer. The more the matrix can deform and absorb energy, the tougher it is, the less brittle it will be. ABS, acrylonitrile-butadiene-styrene, uses the butadiene rubber parts of the polymer chains to make softer domains in the material where the stresses dissipate. That's the impact toughening principle in general. I also saw a trick with graphene addition into the matrix, where the graphene particles do crack pinning - cracks going through the material are attracted to the particles, and then they get stuck there as the energy for the crack propagation shoots insanely up. Small fraction of percent, if I rememer correctly, increased impact toughness by almost order of magnitude.

The breaking depends on the mechanical properties of the resin. Again, degree of crosslinking and the nature of the diluent and the main oligomer. The more the matrix can deform and absorb energy, the tougher it is, the less brittle it will be. ABS, acrylonitrile-butadiene-styrene, uses the butadiene rubber parts of the polymer chains to make softer domains in the material where the stresses dissipate. That's the impact toughening principle in general. I also saw a trick with graphene addition into the matrix, where the graphene particles do crack pinning - cracks going through the material are attracted to the particles, and then they get stuck there as the energy for the crack propagation shoots insanely up. Small fraction of percent, if I rememer correctly, increased impact toughness by almost order of magnitude.

It's a VERY interesting process, and the low cost of these machines have made them very popular in the past few years

It's a VERY interesting process, and the low cost of these machines have made them very popular in the past few years

Newbie Q: What is the average cost of admission for SLA printing?

Newbie Q: What is the average cost of admission for SLA printing?

Essentially, instead of a motor and motion system for each axis, the average MSLA 3D printer only has one moving part; the Z axis

Essentially, instead of a motor and motion system for each axis, the average MSLA 3D printer only has one moving part; the Z axis

Great question @controlmypad !

Great question @controlmypad !

I recently saw an MSLA 3D printer from Voxelab that sold new for $111

I recently saw an MSLA 3D printer from Voxelab that sold new for $111

They also sell a model for about $150 or so, and it's a surprisingly decent machine!

They also sell a model for about $150 or so, and it's a surprisingly decent machine!

But it's sort of like buying a bike; you also need a helmet, a pump, and a few other things

But it's sort of like buying a bike; you also need a helmet, a pump, and a few other things

When a part is made on a resin 3D printer, it needs to be rinsed in a solvent to clear off any excess resin

When a part is made on a resin 3D printer, it needs to be rinsed in a solvent to clear off any excess resin

and then it has to be fully polymerized in a curing chamber

and then it has to be fully polymerized in a curing chamber

So you'll want to either buy / build one of those yourself!

So you'll want to either buy / build one of those yourself!

It can be as simple or as complex as you'd like!

It can be as simple or as complex as you'd like!

A coworker of mine got an Elgoo when Covid started and he says he never uses it because its a pain to clean up and maintain - Do you have any shortcuts/advice for maintaining/cleaning SLA printers?

A coworker of mine got an Elgoo when Covid started and he says he never uses it because its a pain to clean up and maintain - Do you have any shortcuts/advice for maintaining/cleaning SLA printers?

Absolutely, great question @joshua.vader !

Absolutely, great question @joshua.vader !

I use a silicone baking mat that stays under my printer during printing

I use a silicone baking mat that stays under my printer during printing

So when I remove the part, any resin that drips will stay on the silicone mat, which I can bring outside and allow to cure, followed by breaking off the resin and disposing of it

So when I remove the part, any resin that drips will stay on the silicone mat, which I can bring outside and allow to cure, followed by breaking off the resin and disposing of it

I've been loving resin printing - and the cleanup process has been far less messy than I thought, perhaps because I'm very methodical in how I do things - always have gloves and paper towels at the ready, have my isopropyl alcohol at the ready, etc., etc. Interestingly, I tried the water soluable resins and the results, for me, were terrible. I use Siraya Fast ABS-like resin and it has been a champ.

I've been loving resin printing - and the cleanup process has been far less messy than I thought, perhaps because I'm very methodical in how I do things - always have gloves and paper towels at the ready, have my isopropyl alcohol at the ready, etc., etc. Interestingly, I tried the water soluable resins and the results, for me, were terrible. I use Siraya Fast ABS-like resin and it has been a champ.

Also, you'll need a lot of paper towels

Also, you'll need a lot of paper towels

Excellent feedback, @David Geller !

Excellent feedback, @David Geller !

Do all MSLA printers use an LCD, or does MSLA include ones that may say use a laser + galvos/...? (i'd not heard the 'masked' part of the acroynym before)

Do all MSLA printers use an LCD, or does MSLA include ones that may say use a laser + galvos/...? (i'd not heard the 'masked' part of the acroynym before)

There is certainly a lot of work involved in the clean-up process, but there are a handful of shortcuts that make life more bearable!

There is certainly a lot of work involved in the clean-up process, but there are a handful of shortcuts that make life more bearable!

Here's the stuff I make (don't worry - I'm not selling here; in fact - if you want want DM me and I'll send it out to you)... https://www.etsy.com/listing/985358329/throttle-switch-for-rad-power-ebikes?ga_order=most_relevant&ga_search_type=all&ga_view_type=gallery&ga_search_query=rad+throttle&ref=sr_gallery-1-8&organic_search_click=1

Here's the stuff I make (don't worry - I'm not selling here; in fact - if you want want DM me and I'll send it out to you)... https://www.etsy.com/listing/985358329/throttle-switch-for-rad-power-ebikes?ga_order=most_relevant&ga_search_type=all&ga_view_type=gallery&ga_search_query=rad+throttle&ref=sr_gallery-1-8&organic_search_click=1

It paid for my resin printer many times over!

It paid for my resin printer many times over!

![]() A lot of the resin can be washed off with running hot water, combination of mechanical and thermal effect. The heat greatly lowers viscosity.

A lot of the resin can be washed off with running hot water, combination of mechanical and thermal effect. The heat greatly lowers viscosity.

@anfractuosity, that's a great question!

@anfractuosity, that's a great question!

An "MSLA" 3D printer will, by definition, use a masking LCD!

An "MSLA" 3D printer will, by definition, use a masking LCD!

i recommend "animal feeding matts" - they always have a nice lips that prevents resin spills

i recommend "animal feeding matts" - they always have a nice lips that prevents resin spills

aha, makes sense, cheers

aha, makes sense, cheers

If it uses galvos or lasers, it's probably an SLA printer, and if it uses a light-based projector, it's a DLP printer!

If it uses galvos or lasers, it's probably an SLA printer, and if it uses a light-based projector, it's a DLP printer!

You're dead-on, great critical thinking!

You're dead-on, great critical thinking!

These are great questions, everyone!

These are great questions, everyone!

@WooDWorkeR - do you mean cafeteria trays kids use? That's what I use.

@WooDWorkeR - do you mean cafeteria trays kids use? That's what I use.

Printing clear parts with resin is another fun strength of this technology!

Printing clear parts with resin is another fun strength of this technology!

"How do I print a water-clear" part is a really common question in resin printing, and the short answer is, "With a lot of effort!"

"How do I print a water-clear" part is a really common question in resin printing, and the short answer is, "With a lot of effort!"

But using a quality clear resin is a great way to skip to the front of the line!

But using a quality clear resin is a great way to skip to the front of the line!

How good is the clarity? is it possible to print any sort of lens yet?

How good is the clarity? is it possible to print any sort of lens yet?

![]() You can even print some rudimentary nonimaging optics. Fresnel lens worked, and focused a LED in usable way.

You can even print some rudimentary nonimaging optics. Fresnel lens worked, and focused a LED in usable way.

Anyone experimenting with dyes and clear resin? I bought both but haven't experimented yet.

Anyone experimenting with dyes and clear resin? I bought both but haven't experimented yet.

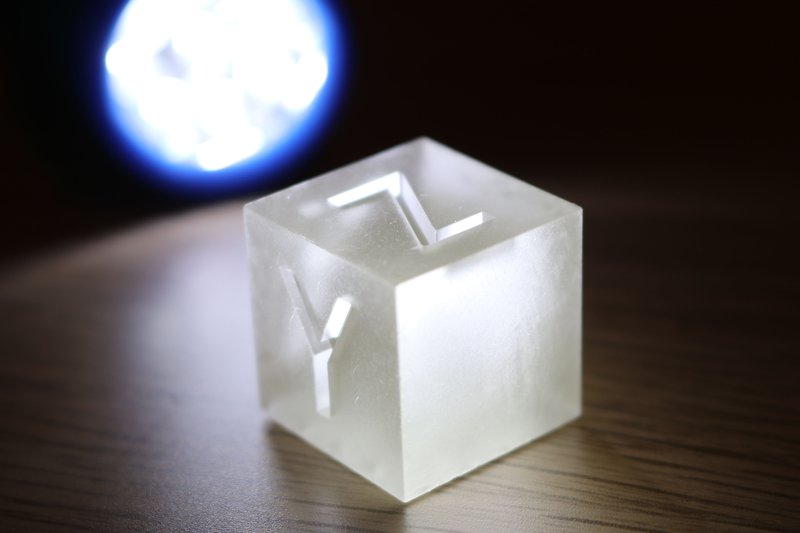

Here's an example of a solid cube, printed and cured, with no post-processing

Here's an example of a solid cube, printed and cured, with no post-processing

Whoops, sorry, those were out of order!

Whoops, sorry, those were out of order!

You could also print a master, make silicone mold from it, then cast with clear resin.

You could also print a master, make silicone mold from it, then cast with clear resin.

![]() The clearness depends on both the precursors, which are usually yellowish naturally, and the photoinitiator, which by the virtue of having to be sensitive to 405nm has to be yellowish at least a little bit (but some can photobleach to near-colorless).

The clearness depends on both the precursors, which are usually yellowish naturally, and the photoinitiator, which by the virtue of having to be sensitive to 405nm has to be yellowish at least a little bit (but some can photobleach to near-colorless).

The first one has been wetted down, and the second one is the original!

The first one has been wetted down, and the second one is the original!

You can see the difference in the clarity of the part

You can see the difference in the clarity of the part

Hey @Thomas Shaddack! Thanks for all the extra information!

Hey @Thomas Shaddack! Thanks for all the extra information!

Clarity depends on many things, but here's a good explanation

Clarity depends on many things, but here's a good explanation

When a part is printed, the cloudy surface is due to rough imperfections in the upward-facing surface

When a part is printed, the cloudy surface is due to rough imperfections in the upward-facing surface

Think of it like a mirror, covered in sand

Think of it like a mirror, covered in sand

would sanding the surface help with the cloudiness or are the flaws deeper?

would sanding the surface help with the cloudiness or are the flaws deeper?

@David Geller something like this https://www.amazon.com/-/en/dp/B01MEHV8YR/

@David Geller something like this https://www.amazon.com/-/en/dp/B01MEHV8YR/

As you reduce the overall roughness, it becomes clearer!

As you reduce the overall roughness, it becomes clearer!

So, sanding is a GREAT way to get a clear part

So, sanding is a GREAT way to get a clear part

But, it's time-consuming

But, it's time-consuming

So a quick way to cheat is a thin coat of Acrylic Clear Coat!

So a quick way to cheat is a thin coat of Acrylic Clear Coat!

I use Krylon Crystal Clear

I use Krylon Crystal Clear

![]() We're encroaching on the field of UV-vis spectrometry. Anything with enough conjugated aromatic bonds will tend to be at least yellowish. If it will tend to make them over time, it will yellow later.

We're encroaching on the field of UV-vis spectrometry. Anything with enough conjugated aromatic bonds will tend to be at least yellowish. If it will tend to make them over time, it will yellow later.

This will help fill the valleys between the layers, and give the part a more uniform surface

This will help fill the valleys between the layers, and give the part a more uniform surface

@Andrew Sink awesome, thanks!

@Andrew Sink awesome, thanks!

![]() I think you can use the resin itself. Thin coat, and cure in place. Or skip on the washing if the part's design allows.

I think you can use the resin itself. Thin coat, and cure in place. Or skip on the washing if the part's design allows.

Eric Strebel has a video on post-processing CLA prints to make them water clear:

Eric Strebel has a video on post-processing CLA prints to make them water clear:

https://www.youtube.com/watch?v=nvNXCyDyTTI

Like most 3D printers, the resolution and repeatability is a function of price and control software. It would be nice to print lens assembles. I was working on the microscope industry this morning and thinking how expensive it is to machine, cast metals, hand assemble. And the chaos and expense of al those threads, adapters, connectors - more cost to connect than the pieces.

Like most 3D printers, the resolution and repeatability is a function of price and control software. It would be nice to print lens assembles. I was working on the microscope industry this morning and thinking how expensive it is to machine, cast metals, hand assemble. And the chaos and expense of al those threads, adapters, connectors - more cost to connect than the pieces.

The idea of printing optics as you need them. Want to change, them, make a new one, and throw the other one away or give it to a good cause.

Guess it depends on how clear you like your water ;-)

Guess it depends on how clear you like your water ;-)

This is also visible in the parts themselves, when they are coated with resin, they are highly transparent!

This is also visible in the parts themselves, when they are coated with resin, they are highly transparent!

@RichardCollins, that's a great point!

@RichardCollins, that's a great point!

Printing a lens assembly would be a HUGE win for 3D printing, but currently, there is a lot of post-processing involved in getting those parts to an acceptable level of light transmission and clarity!

Printing a lens assembly would be a HUGE win for 3D printing, but currently, there is a lot of post-processing involved in getting those parts to an acceptable level of light transmission and clarity!

![]() As Andrew said clearness depends on many variables. The surface is one major one. If surface finish is an issue some clear paints can help. They generally have a self-leveling effect that will smooth out micro roughness.

As Andrew said clearness depends on many variables. The surface is one major one. If surface finish is an issue some clear paints can help. They generally have a self-leveling effect that will smooth out micro roughness.

Clarity is a lot of fun to experiment with, there are LOTS of creative ways to solve the problem of making clear prints!

Clarity is a lot of fun to experiment with, there are LOTS of creative ways to solve the problem of making clear prints!

Speaking of which!

Speaking of which!

![]() I succeeded in printing a M12x0.5 thread that didn't need chasing with a tap. (Needs a lil' adjustment, making a little bigger or smaller to account for the process variables. Print a couple of threaded holes with different adjustment factors, choose by test.

I succeeded in printing a M12x0.5 thread that didn't need chasing with a tap. (Needs a lil' adjustment, making a little bigger or smaller to account for the process variables. Print a couple of threaded holes with different adjustment factors, choose by test.

Here's a thumbnail from a video I published recently (that was actually featured on Hackaday!)

Here's a thumbnail from a video I published recently (that was actually featured on Hackaday!)

This was an experiment in printing hollow resin parts, and filling them with paint to provide an opaque backing to the clear nature of the parts

This was an experiment in printing hollow resin parts, and filling them with paint to provide an opaque backing to the clear nature of the parts

I worry about global education. Low cost optics for schools leaves most without anything to use, eats up budgets and requires fairly costly human teachers. If the kids can print the experiments themselves, or as needed, it might be possible to teach the two billion first time learners at present, and more later.

I worry about global education. Low cost optics for schools leaves most without anything to use, eats up budgets and requires fairly costly human teachers. If the kids can print the experiments themselves, or as needed, it might be possible to teach the two billion first time learners at present, and more later.

This allowed the otherwise difficult-to-see details show right through!

This allowed the otherwise difficult-to-see details show right through!

![]() Technically, using two-photon polymerization, it could be possible to get to 100nm resolution. Then even with the ridged surface we could have optical components, as we'd be at quarter-wavelength of blue light anyway.

Technically, using two-photon polymerization, it could be possible to get to 100nm resolution. Then even with the ridged surface we could have optical components, as we'd be at quarter-wavelength of blue light anyway.

So, let's keep talking about getting started!

So, let's keep talking about getting started!

What are some obstacles you've ran into when resin printing?

What are some obstacles you've ran into when resin printing?

![]() I saw school-grade optics with jello cast into moulds.

I saw school-grade optics with jello cast into moulds.

@Thomas Shaddack I was looking for one of those this morning and wondering if they could be 3D printed. It just has to hold for many setups. Thanks!

@Thomas Shaddack I was looking for one of those this morning and wondering if they could be 3D printed. It just has to hold for many setups. Thanks!

Dan Maloney

Dan Maloney

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.