![]() I saw somewhere printing dye into gel, for jello shots.

I saw somewhere printing dye into gel, for jello shots.

Yeah, I think there were a few specialty chocolate shops that actually had them. In general, Brooke kind of moved on towards more bespoke 3D printers for specific industries, I remember for awhile he had a couple machines custom made for printing prosthetic limbs.

Yeah, I think there were a few specialty chocolate shops that actually had them. In general, Brooke kind of moved on towards more bespoke 3D printers for specific industries, I remember for awhile he had a couple machines custom made for printing prosthetic limbs.

This is an entire new side of it that I haven't worked on yet! I've been so focused on chocolate because I think it is the most difficult, especially with respect to temperature control, that once Chocolate becomes easier, some of these other applications are also possible.

This is an entire new side of it that I haven't worked on yet! I've been so focused on chocolate because I think it is the most difficult, especially with respect to temperature control, that once Chocolate becomes easier, some of these other applications are also possible.

Oh that's cool @Tom Nardi. I wonder what he's currently working on. I know he had a couple of machines in the works, but I never saw if they shipped or not

Oh that's cool @Tom Nardi. I wonder what he's currently working on. I know he had a couple of machines in the works, but I never saw if they shipped or not

Now I'm going to go down the new idea rabbit hole haha

Now I'm going to go down the new idea rabbit hole haha

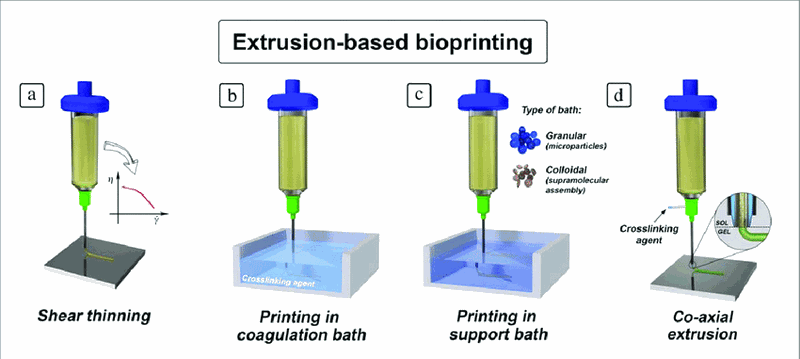

![]() Bioprinting is a fun area, certainly. And shares problems with many other materials.

Bioprinting is a fun area, certainly. And shares problems with many other materials.

The Hack Chat is a good rabbit-hole maker

The Hack Chat is a good rabbit-hole maker

coextrusion or a tool changing chocolate printer would also be really fun. I'm working on making colorful chocolate (dyed white chocolate). That could work really well in the tool changing settings

coextrusion or a tool changing chocolate printer would also be really fun. I'm working on making colorful chocolate (dyed white chocolate). That could work really well in the tool changing settings

Haha @Dan Maloney I can see that 😄

Haha @Dan Maloney I can see that 😄

![]() My machine is hacked with the head mounted on a load cell. The cell is a rectangular bar that could be friendly for tool exchange.

My machine is hacked with the head mounted on a load cell. The cell is a rectangular bar that could be friendly for tool exchange.

![]() Some wearable tech uses magnetic connectors. Phone chargers too. That can be leveraged for the electrical wiring to the head.

Some wearable tech uses magnetic connectors. Phone chargers too. That can be leveraged for the electrical wiring to the head.

Have you mentioned yet about the nozzle? Are different sizes planned?

Have you mentioned yet about the nozzle? Are different sizes planned?

![]() Multihead machine would also allow having one nozzle big and fat, for the bulk, and the other fine, for the surface details. But the slicer would be likely a nightmare to write.

Multihead machine would also allow having one nozzle big and fat, for the bulk, and the other fine, for the surface details. But the slicer would be likely a nightmare to write.

I generally print in a 0.8mm nozzle, but I am planning a 1.6mm nozzle too! Not sure if/when I'll launch that. I am curious how cooling time will be affected with 4x the flow rate

I generally print in a 0.8mm nozzle, but I am planning a 1.6mm nozzle too! Not sure if/when I'll launch that. I am curious how cooling time will be affected with 4x the flow rate

![]() Thought that may work with relative ease. Manually swappable heads. Print the part with one chocolate, swap head, print the surface details.

Thought that may work with relative ease. Manually swappable heads. Print the part with one chocolate, swap head, print the surface details.

![]() Consider a thermal camera, to watch the material behavior at the nozzle?

Consider a thermal camera, to watch the material behavior at the nozzle?

I think Prusa Slicer already has some variable layer height stuff written in. Not sure about that one yet, but with their 5 tool tool changer coming out soon, I wouldn't be surprised if that gets added at some point

I think Prusa Slicer already has some variable layer height stuff written in. Not sure about that one yet, but with their 5 tool tool changer coming out soon, I wouldn't be surprised if that gets added at some point

![]() I saw somewhere a trick with ZnSe lasercutter lens for making a macro from a FLiR One.

I saw somewhere a trick with ZnSe lasercutter lens for making a macro from a FLiR One.

I use Prusa Slicer for all of my chocolate slicing!

I use Prusa Slicer for all of my chocolate slicing!

![]() I use SuperSlicer which is a fork with some added features. Easier inspection of the g-code. (Or I didn't find how to make it easy enough in PrusaSlicer.)

I use SuperSlicer which is a fork with some added features. Easier inspection of the g-code. (Or I didn't find how to make it easy enough in PrusaSlicer.)

I think we are going to see a lot more camera/lidar based AI coming to printers in the future. I'm so ready for it

I think we are going to see a lot more camera/lidar based AI coming to printers in the future. I'm so ready for it

![]() Same here!

Same here!

Also I have about 25 more minutes, so if you haven't asked anything yet, please feel free to pop in!

Also I have about 25 more minutes, so if you haven't asked anything yet, please feel free to pop in!

I was just about to barge in and call time, but if you want to keep going, that's fine too

I was just about to barge in and call time, but if you want to keep going, that's fine too

![]() Not just for printers. CNC machines too. Imagine one that knows where the fixtures are, that sees when the workpiece moved, that will never crash the tool by a stupid operator mistake.

Not just for printers. CNC machines too. Imagine one that knows where the fixtures are, that sees when the workpiece moved, that will never crash the tool by a stupid operator mistake.

![]() ...a poor man's vibration agitator is a small fan with a screw in one of its blades.

...a poor man's vibration agitator is a small fan with a screw in one of its blades.

or in my case an old Makerbot replicator (wood one) where I would break one fin off of a fan blade and it would all vibrate

or in my case an old Makerbot replicator (wood one) where I would break one fin off of a fan blade and it would all vibrate

![]() Sometimes the blade breaks on its own. Or when you adjust something in the machine and stick in a finger. Don't ask how I know-ow-ow.

Sometimes the blade breaks on its own. Or when you adjust something in the machine and stick in a finger. Don't ask how I know-ow-ow.

hahaha that definitely made me laugh out loud

hahaha that definitely made me laugh out loud

Had to change both fans on my Replicator 2X

Had to change both fans on my Replicator 2X

![]() A good thing to have around the printer, for boosting of workpiece cooling for eg. a more finicky object from PLA, is a pair of fans that you can place on the bed, side to side on the workpiece, outside of reach of the head.

A good thing to have around the printer, for boosting of workpiece cooling for eg. a more finicky object from PLA, is a pair of fans that you can place on the bed, side to side on the workpiece, outside of reach of the head.

![]() After the piece starts printing and you know where the head will not go.

After the piece starts printing and you know where the head will not go.

![]() Have a barrel jack with 12v on the machine for such accessories. And some USB ports with 5v power for other accessories.

Have a barrel jack with 12v on the machine for such accessories. And some USB ports with 5v power for other accessories.

![]() ...and some system ground connected accessible wires to clip on the multimeter or scope probe once the machine inevitably breaks under the modifications and demands maintenance/debugging/troubleshooting...

...and some system ground connected accessible wires to clip on the multimeter or scope probe once the machine inevitably breaks under the modifications and demands maintenance/debugging/troubleshooting...

that definitely reminds me of my very first chocolate print, which was a Hershey kiss. Everyone called it the 💩 emoji though.

that definitely reminds me of my very first chocolate print, which was a Hershey kiss. Everyone called it the 💩 emoji though.

fans on the side and all

fans on the side and all

![]() YESSS! Exactly like that!

YESSS! Exactly like that!

![]() Well, both are made by extrusion...

Well, both are made by extrusion...

![]() Another trick for food. Laser.

Another trick for food. Laser.

![]()

https://www.improwis.com/projects/food_LaserEngravedCandy/

Laser engraved candy

Tests of laser cutting of pressed sugar candy

recently I have been trying to laser engrave chocolate. The gameboy advance was just directly layering onto chocolate while the pride one was an attempt at using cocoa butter transfer sheets to put color on the chocolate in specific places

recently I have been trying to laser engrave chocolate. The gameboy advance was just directly layering onto chocolate while the pride one was an attempt at using cocoa butter transfer sheets to put color on the chocolate in specific places

both were fun experiments! I don't think they will go anywhere, but goo to know that they kinda work

both were fun experiments! I don't think they will go anywhere, but goo to know that they kinda work

![]() I saw somewhere transfer of a hologram texture to chocolate surface.

I saw somewhere transfer of a hologram texture to chocolate surface.

yes! You can use that on top of the bed for sure

yes! You can use that on top of the bed for sure

![]()

https://www.youtube.com/watch?v=UsDnkrDvkBo

I think I’m going to sign off in a couple mins. Thanks for asking questions and for following the chat! If you want to look up more stuff, you can follow me on Twitter https://twitter.com/elianarose66, or on just about any other social media site. You can check out more on cocoapress.com and email me at hello@cocoapress.com if you have any more thoughts or questions!

I think I’m going to sign off in a couple mins. Thanks for asking questions and for following the chat! If you want to look up more stuff, you can follow me on Twitter https://twitter.com/elianarose66, or on just about any other social media site. You can check out more on cocoapress.com and email me at hello@cocoapress.com if you have any more thoughts or questions!

![]() Re laser and food... I saw somewhere a paper from Wisconsin about lasercutting cheese. Turned out the UV laser is the best, the IR ones were melting the cut too much.

Re laser and food... I saw somewhere a paper from Wisconsin about lasercutting cheese. Turned out the UV laser is the best, the IR ones were melting the cut too much.

Thanks Ellie, great spending time with you today, I really appreciate it. Great chat, really fun topic. Thanks all for the great discussion!

Thanks Ellie, great spending time with you today, I really appreciate it. Great chat, really fun topic. Thanks all for the great discussion!

Thanks again for inviting me!

Thanks again for inviting me!

![]() Random thought. Thermal analysis of the chocolate. How much energy goes in during slow heating.

Random thought. Thermal analysis of the chocolate. How much energy goes in during slow heating.

![]()

https://en.wikipedia.org/wiki/Differential_thermal_analysis

Differential thermal analysis - Wikipedia

From Wikipedia, the free encyclopedia Differential thermal analysis ( DTA) is a thermoanalytic technique that is similar to differential scanning calorimetry. In DTA, the material under study and an inert reference are made to undergo identical thermal cycles, (i.e., same cooling or heating programme) while recording any temperature difference between sample and reference.

![]() like this. would show the temperature and magnitude of phase transitions within the material.

like this. would show the temperature and magnitude of phase transitions within the material.

![]() Could make adjustments for a new material easier, by knowing where the key temperature points are.

Could make adjustments for a new material easier, by knowing where the key temperature points are.

![]() My first time here. Very interesting and informative chat with Ellie. Possible to have a copy of this entire session?

My first time here. Very interesting and informative chat with Ellie. Possible to have a copy of this entire session?

Yep, transcript coming right up

Yep, transcript coming right up

![]() Thank you very much.

Thank you very much.

Dan Maloney

Dan Maloney

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.