Like many, I often buy the Shenzhen special when it comes to jumper wires. They often do good enough when it comes to signaling, but when using them to deliver power to anything requiring more than a minute amount of power you start to have problems. The two problems with them is the wire diameter tends to be extremely small and connector resistance.

On account of being too cheap to buy more expensive ones, I decided to try my hand at making my own.

Materials needed:

24 AWG speaker wire

single pin press-fit female pin headers (can of course use press-fit male pin headers for male ends)

heat shrink tubing

of course normal soldering equipment/supplies

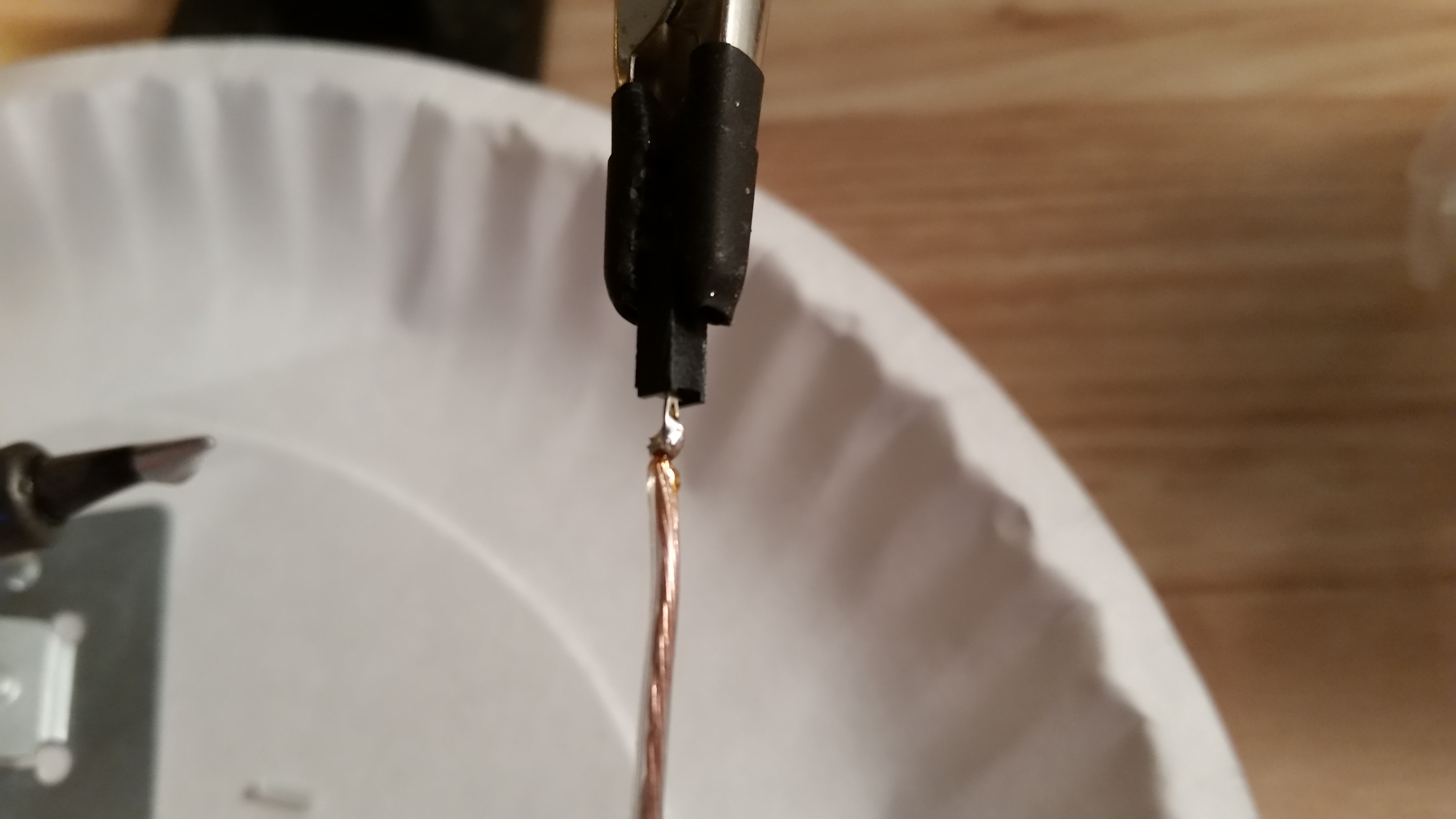

I specifically chose press-fit pin headers as they have "needle eyes" on them vs. just a straight section of metal. The "needle eye" allows one to "thread" the speaker wire and thus keeps it nicely held in place so one doesn't have to hold the wire in place for soldering. The the on-label purpose of the "needle eyes" are to compress when pushed in a plated thru-hole and expand on the other-side, holding the pin headers in-place.

After soldering it in place:

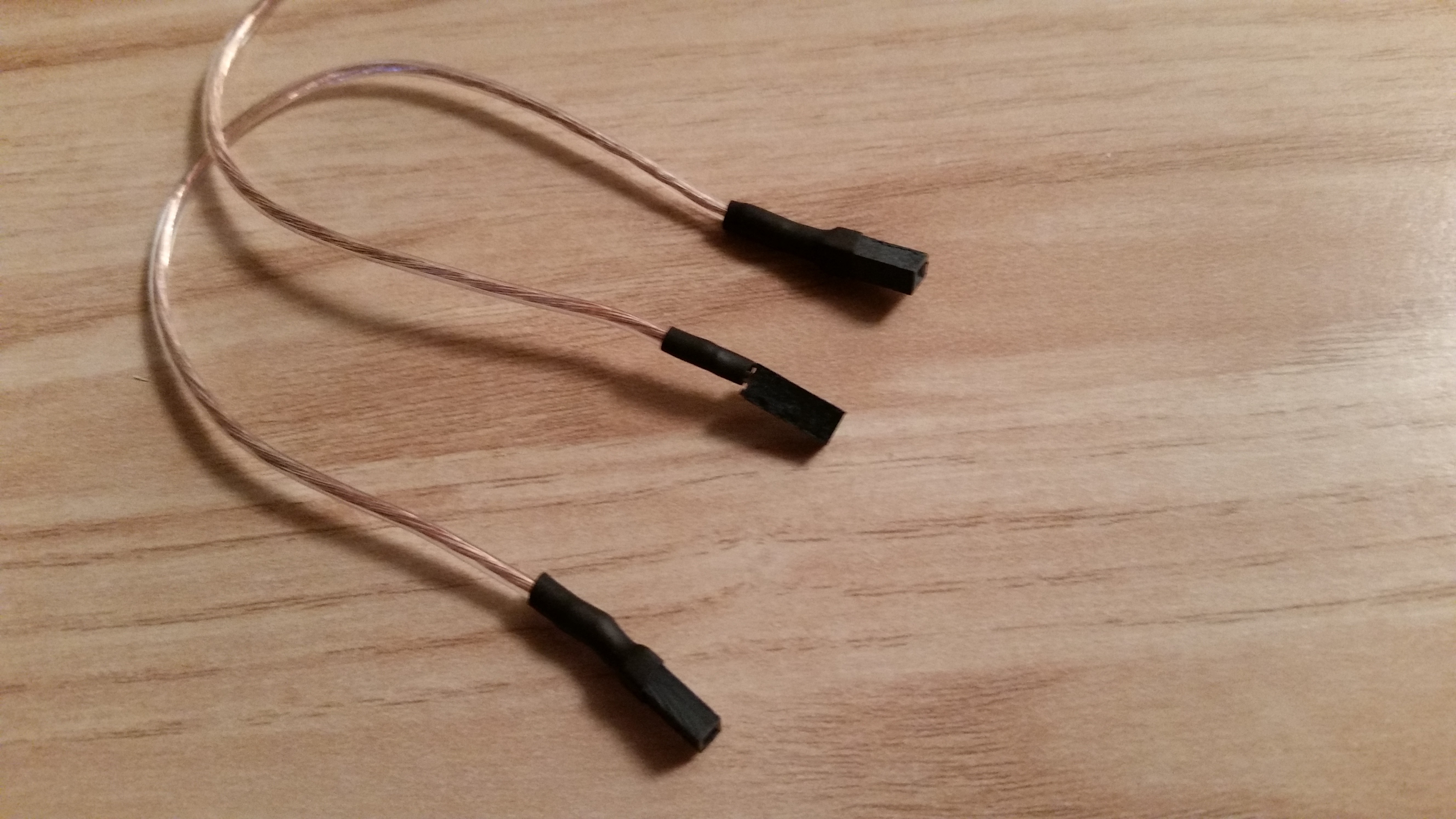

And with some heat-shrink tubing:

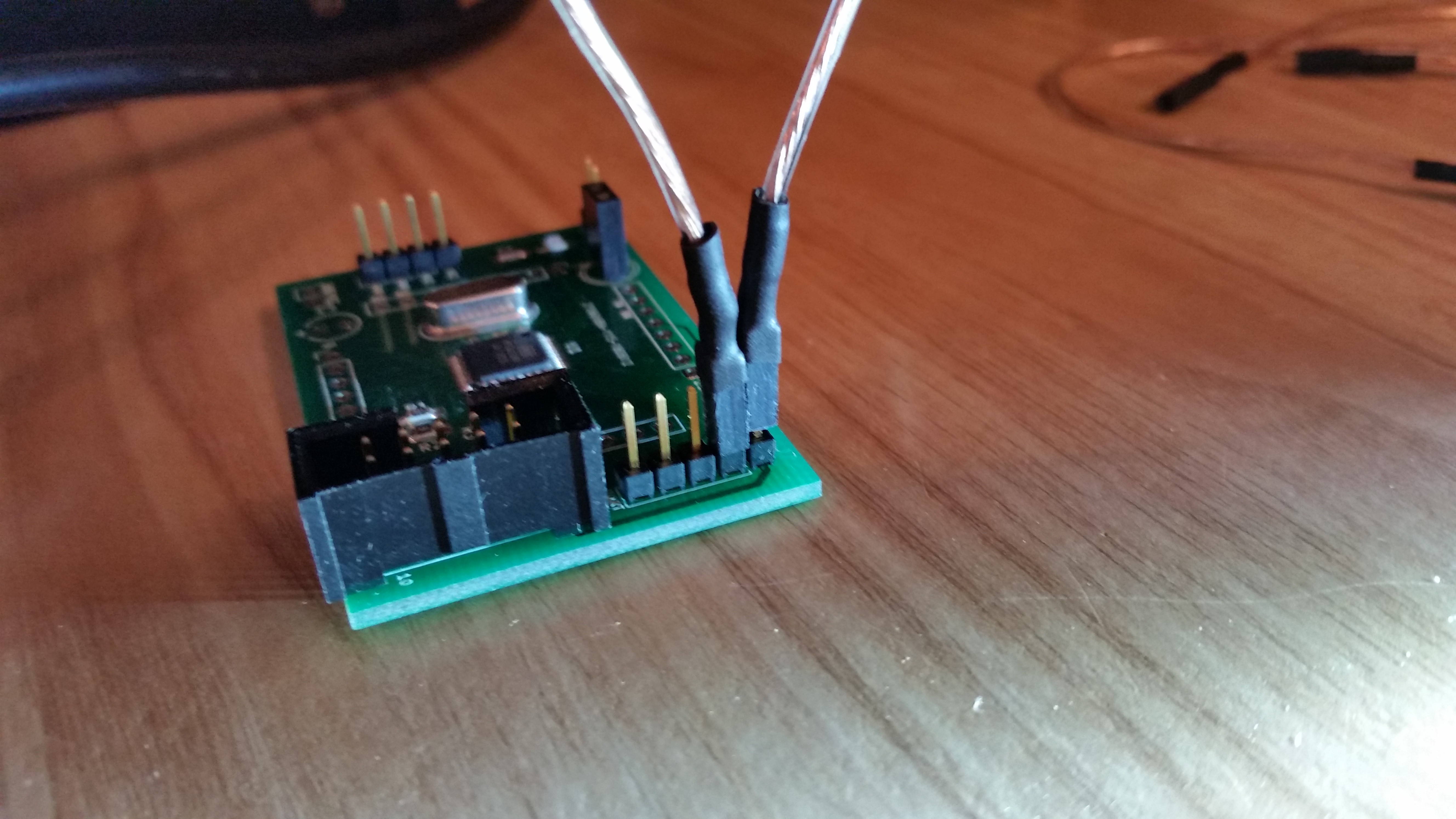

I did experiment with putting an additional piece of heat-shrink tubing over part of the pin-header housing and wire to make it more robust, but as I expected it the additional thickness causes issues when being plugged in side-by-side:

The pin headers that I got were more rectangular than square. That could cause problems when plugging in to double-row headers. Going to look around and see if I can find some completely square ones.

Based on some very crude testing, there does seem to be an improvement over the cheapie dupont connectors.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.