Power electronics design is an essential aspect of modern engineering, as it enables the efficient conversion of electrical power from one form to another. This technology plays a crucial role in many industries, including automotive, aerospace, renewable energy, and consumer electronics. In this blog, we will explore some of the innovative approaches to power electronics design, using case studies and success stories to showcase the latest developments in this field.

Case Study 1: Tesla’s Power Electronics Design for Electric Vehicles

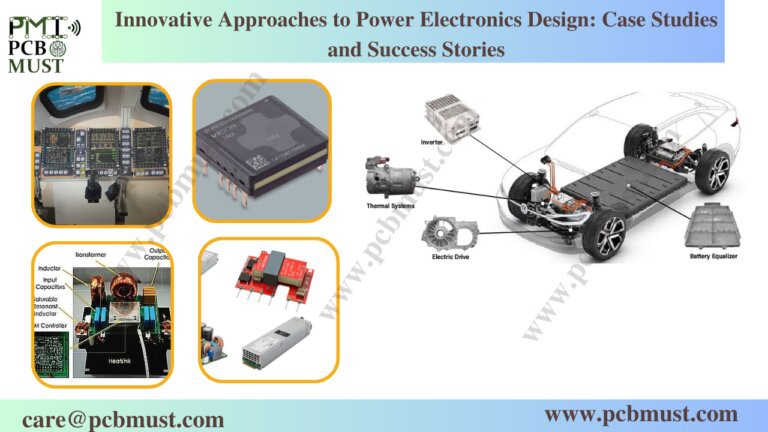

Tesla is a well-known electric vehicle manufacturer that has gained widespread recognition for its innovative power electronics design. The company’s electric vehicles use a unique powertrain design that includes a power electronics module, an electric motor, and a battery pack. The power electronics module is responsible for converting the DC power from the battery into the AC power required by the electric motor.

Tesla’s power electronics design is based on the use of silicon carbide (SiC) MOSFETs, which are more efficient than traditional silicon MOSFETs. This approach has allowed Tesla to reduce the size and weight of its power electronics module while increasing its efficiency. As a result, Tesla’s electric vehicles have longer ranges and faster acceleration than many other electric vehicles on the market.

Case Study 2: NASA’s Power Electronics Design for Spacecraft

Power electronics design is also critical for space applications, where power efficiency and reliability are essential. NASA’s Mars Science Laboratory (MSL) mission, which landed the Curiosity rover on Mars in 2012, used a unique power electronics design that enabled the rover to operate for an extended period on the harsh Martian surface.

The power electronics system used in the MSL mission was based on a modular design that allowed for redundancy and fault tolerance. The system used a combination of silicon and gallium nitride (GaN) MOSFETs, which are more efficient than traditional silicon MOSFETs. The power electronics system also included advanced thermal management systems, which allowed for efficient heat dissipation in the harsh Martian environment.

Success Story:

Vicor’s Power Electronics Design for High-Density Data Centers

Vicor is a power electronics company that specializes in high-density power systems for data centers. The company’s power electronics design approach is based on the use of a modular power system (MPS), which allows for flexible and scalable power delivery. The MPS consists of a range of power components, including DC-DC converters, AC-DC converters, and filters, that can be combined in various configurations to meet the power requirements of different applications.

Vicor’s power electronics design approach has been successful in reducing the size, weight, and cost of power systems for data centers. The company’s MPS technology has been used in many high-profile data center installations, including those operated by Google, Facebook, and Amazon.

Conclusion

Power electronics design is a critical aspect of modern engineering, enabling the efficient conversion of electrical power from one form to another. The latest developments in power electronics design are focused on improving efficiency, reducing size and weight, and increasing reliability. The case studies and success stories highlighted in this blog demonstrate the innovative approaches being taken in this field, from Tesla’s use of SiC MOSFETs to NASA’s modular power system for space applications and Vicor’s MPS technology for high-density data centers. As this technology continues to evolve, we can expect to see even more exciting developments in power electronics design in the years to come.

About the Author:

Avi Gupta, Founder of PCB Must Innovations, is a dynamic force in the world of electronics design. With a wealth of industry experience, Avi thrives on solving intricate problems and delivering dependable solutions. A tech enthusiast, Avi stays ahead of trends while cherishing precious moments with family.

Avi could be reached at care@pcbmust.com

Avi Gupta

Avi Gupta

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.