-

How to Solve the Problem That the Servo Motor Cannot Keep Up With the Expected Speed?

01/14/2025 at 05:31 • 0 comments1. Possible Causes

1.1. Mechanical problems: If the servo motor cannot keep up with the expected speed, it may be due to problems in the mechanical system. For example, mechanical parts are damaged, the transmission device fails, or the machine is overloaded.

1.2. Electrical problems: Another possible reason why the servo motor cannot keep up with the expected speed is electrical problems. If the power supply voltage of the motor is too low or the AC power supply is unstable, the output voltage of the servo motor will also be unstable, resulting in the speed not keeping up with expectations.

![]()

1.3. Parameter adjustment problems: Another common problem is incorrect parameter settings. If the parameters of the servo motor are not set correctly, it may cause the motor to fail to reach the expected speed.

2. Solutions

2.1. Check the mechanical system: If there is a problem in the mechanical system, check and repair the damage to the mechanical parts, clean and lubricate the machine, and ensure the normal operation of the transmission. If these problems cannot be solved by yourself, you can consider seeking professional mechanical repair services.

2.2. Solve electrical problems: If the servo motor cannot keep up with the expected speed due to electrical problems, you should ensure that the power supply voltage of the servo motor meets the equipment requirements, check the wiring of all electrical components and clean the contaminated contacts. If necessary, you can use a device such as a voltage stabilizer or UPS to provide power stability.

2.3. Adjust parameter settings: The last solution is to check and adjust the parameter settings of the servo motor. Make sure all parameters meet the machine requirements and use the correct accessories. You can also use professional software for parameter optimization.

3. Conclusion

By understanding the reasons and solutions for the servo motor not keeping up with the expected speed, you can solve the problem yourself or get a better solution. If you can't solve it, you can consider seeking professional mechanical repair services.

-

Can I Set Torque Stop While the Servo Motor Is Running?

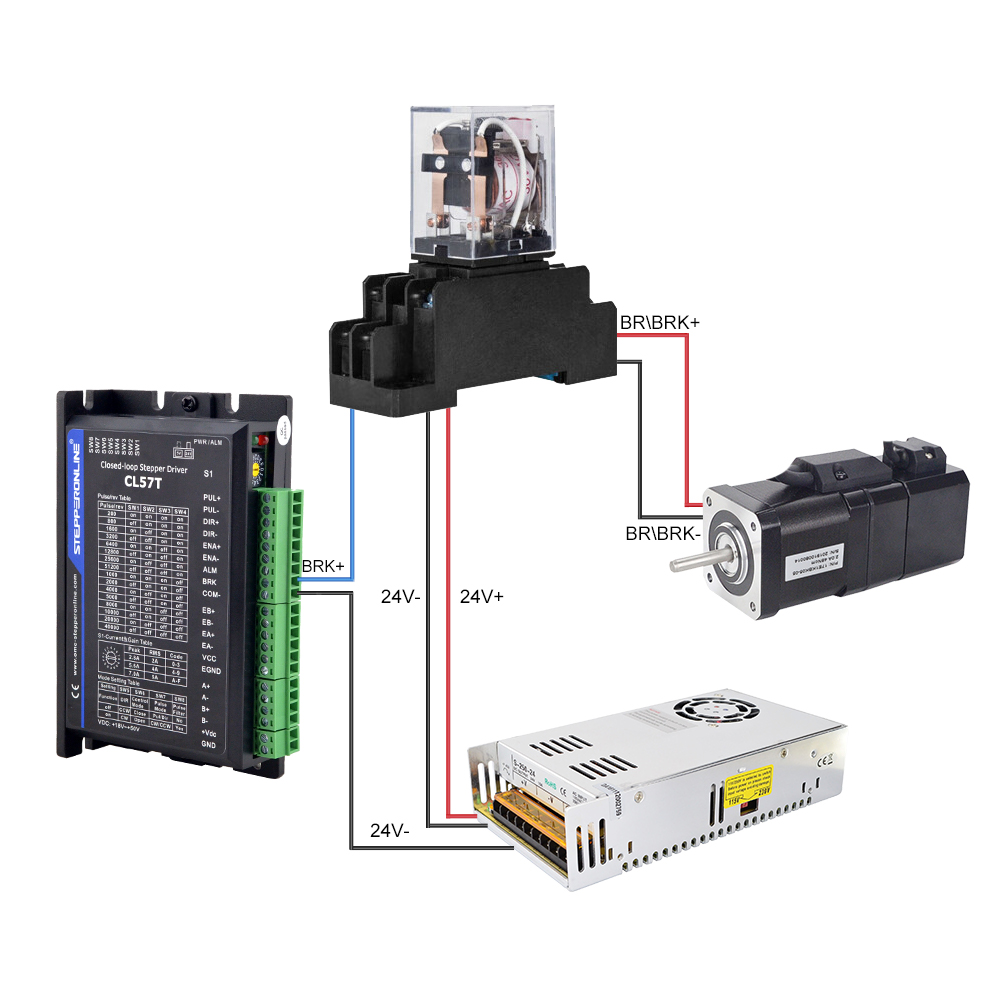

01/14/2025 at 05:30 • 0 commentsYes, the torque stop function can be achieved by adjusting the torque setting in the closed loop when the servo motor is running.

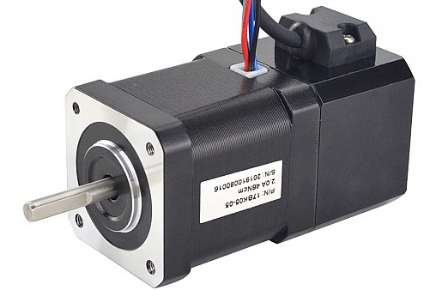

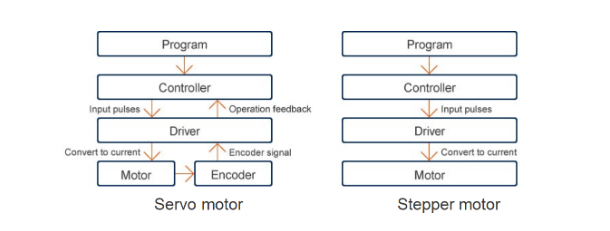

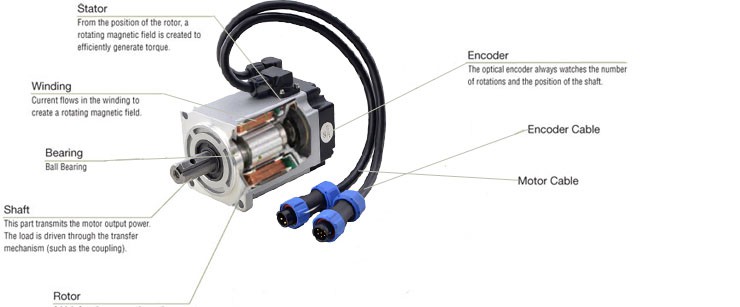

1. Working principle of servo motor

A servo motor is a motor that converts electrical energy into mechanical motion. Unlike ordinary motors, it monitors the motion state in real time through feedback devices such as encoders, and the control circuit controls the motor more accurately.

The main working principle of the servo motor is: the control circuit reads the feedback signal, compares it with the target position, calculates the error, and sends the control signal to the motor so that it can move according to the preset motion trajectory.

![]()

2. The principle of setting the torque stop function

During the operation of the servo motor, the torque stop function needs to be set in many application scenarios to ensure that the device can stop moving more accurately.

The principle of achieving torque stop is: in most cases, there is a torque limiter inside the servo controller. By adjusting the torque setting in the closed loop, the purpose of stopping the motor can be achieved after reaching a certain torque.

However, it should be noted that if the set torque is too small, it may affect the normal operation of the device, so it needs to be flexibly set according to the actual application situation.

3. Advantages and application scenarios of servo motors

Servo motors have the following advantages:

1. High precision: Due to the use of closed-loop control, the servo motor can monitor its own motion state in real time and accurately control it, ensuring higher accuracy and precision.

2. Fast response speed: Due to the support of a large number of special electronic technology equipment inside the servo motor, it can achieve fast response in an instant, thereby improving work efficiency.

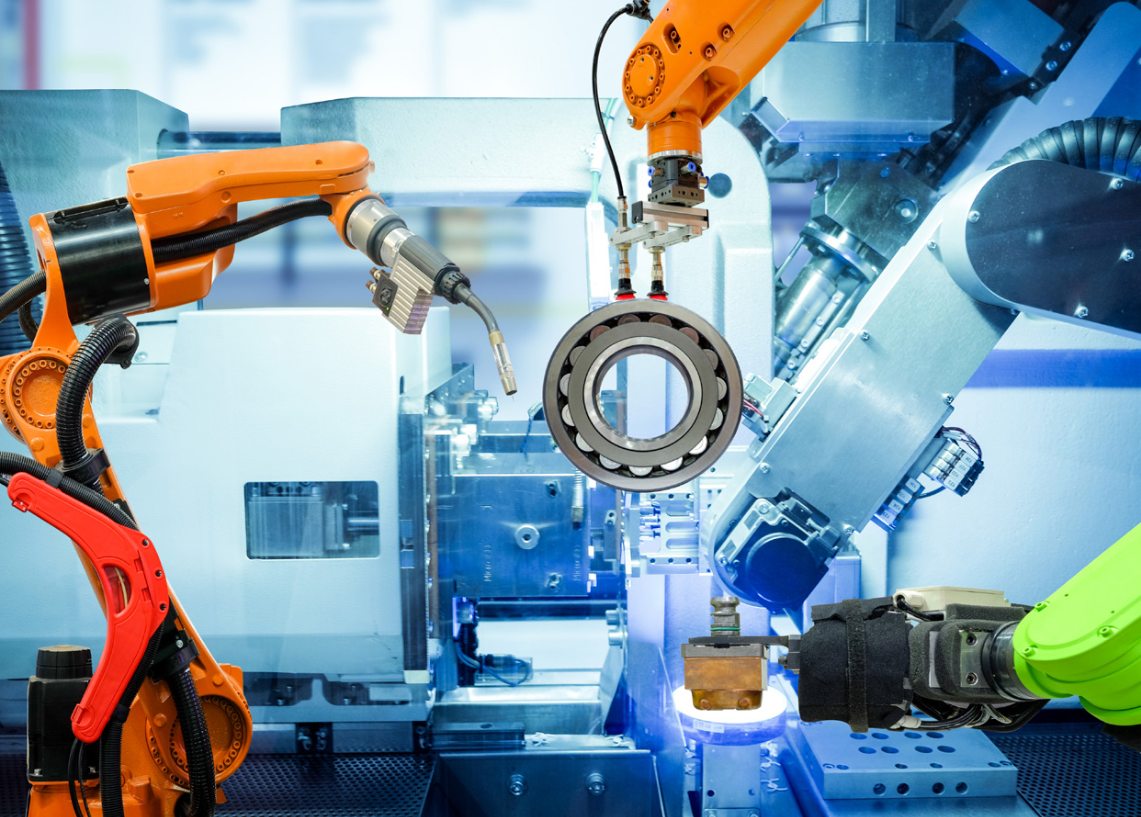

3. Adaptable to a variety of application scenarios: Servo motors are widely used and can be applied to equipment in various industries, such as CNC machine tools, punching machines, robots, etc.

In summary, setting the torque stop function can effectively ensure the stability and safety of the equipment, and is widely used and easy to implement in the operation of servo motors.

-

Detailed Introduction of the Input Shaft and Output Shaft of the Planetary Gearbox

12/05/2024 at 05:03 • 0 commentsThe input shaft of the planetary gearbox is the shaft where power is input, and the output shaft is the shaft where power is output. They achieve the functions of deceleration, speed increase or change of transmission direction through the interaction of components such as the planetary gearbox carrier, sun gear and planetary gear.

In the field of mechanical transmission, the planetary gearbox system has attracted much attention for its unique transmission method and high efficiency. Among them, the input shaft and output shaft are two indispensable key parts of the planetary gearbox system. This article will deeply analyze the input shaft and output shaft of the planetary gearbox to show you their working principles and applications.

![]()

1. Basic structure of planetary gearbox system

Before understanding the input shaft and output shaft, let's briefly review the basic structure of the planetary gearbox system. The planetary gearbox system is mainly composed of sun gear, planetary gear, planetary gearbox carrier and inner and outer gear rings. Among them, the sun gear is located in the center, the planetary gearbox revolves around the sun gear and rotates on its own, and the planetary gearbox carrier supports the planetary gearbox and enables it to revolve. The inner and outer gear rings mesh with the planetary gearbox and sun gear respectively to achieve power transmission.

2. Function and characteristics of input shaft

The input shaft is the shaft through which power is transmitted in the planetary gearbox system. It is usually connected to the driving device (such as motor, engine, etc.) to transmit power to the planetary gearbox system. In the planetary gearbox system, the input shaft transmits power to the planetary gearbox and the inner and outer ring gears through the sun gear, thereby driving the entire system to operate.

The characteristics of the input shaft mainly include:

2.1. Bearing large torque: Since the input shaft is directly connected to the driving device, it needs to bear large torque. Therefore, the input shaft is usually made of high-strength materials to ensure that it can withstand large loads.

2.2. High-precision processing: In order to ensure transmission efficiency and transmission accuracy, the input shaft needs to be processed with high precision. This includes the processing accuracy requirements of the shaft diameter, keyway, thread and other parts.

2.3. Lubrication and sealing: The input shaft needs good lubrication and sealing during operation to reduce wear and leakage. Therefore, lubrication and sealing measures need to be considered during the design and manufacturing process.

![]()

3. Function and characteristics of the output shaft

The output shaft is the shaft that transmits power in the planetary gearbox system. It converts the power of the input shaft into a specific speed and torque output through the interaction of components such as the planetary gearbox carrier, sun gear, and inner and outer ring gears. The output shaft is usually connected to the driven equipment to drive it to operate.

The characteristics of the output shaft mainly include:

3.1. Stable output performance: The output shaft needs to have stable output performance to ensure that the driven equipment can operate smoothly. This requires the planetary gearbox system to have high transmission accuracy and stability.

3.2. Strong adaptability: The output shaft needs to adapt to the output requirements of different speeds and torques. Therefore, the planetary gearbox system needs to have a variety of transmission ratios to choose from to meet the needs of different application scenarios.

3.3. Compact structure: The output shaft usually needs to be closely integrated with the planetary gearbox system, so its structure needs to be compact and lightweight for easy installation and commissioning.

-

Planetary Gearbox Fault Signal Analysis and Fault Diagnosis

12/05/2024 at 05:00 • 0 comments1. Composition and working principle of planetary gearbox

The planetary gearbox is composed of planetary gears, sun gears, internal gears, external gears, etc. Its working principle is that the sun gear, planetary gears and internal gears transmit the driving force to the external gears through the cam to achieve the transmission of different speeds and torques.

2. Fault signal characteristics of planetary gearbox

2.1. Significant increase in noise: After a fault occurs in the planetary gearbox, the noise will increase significantly, which is caused by the friction and wear of the faulty gear.

2.2. Temperature increase: After the planetary gearbox fails, the operating efficiency decreases, which will cause excessive heat and cause the temperature of the entire system to rise.

2.3. Abnormal vibration signal: Abnormal vibration signal is one of the most significant fault characteristics. The increase in friction of the faulty gear will cause a larger vibration signal.![]()

3. Experimental method for fault diagnosis of planetary gearbox

3.1. Vibration analysis method: By analyzing the vibration signal, the location and type of the fault can be determined, so as to locate the problem and deal with it.

3.2. Sound analysis method: By analyzing the sound signal, the abnormal sound emitted by the faulty gear can be detected, and the severity of the fault can be judged according to the type and size of the sound.

3.3. Temperature analysis method: Monitor the operating temperature of the planetary gearbox. When it rises abnormally, it means that the fault is serious and needs to be repaired or replaced.

3.4.Edge filtering waveform analysis method: This method can analyze the edge of the faulty gear to determine the type and degree of the gear fault.![]()

4. Experimental technology for fault diagnosis of planetary gearbox

4.1. Feature extraction technology: Determine the location and type of fault by analyzing the characteristics of the signal, such as using wavelet analysis, Fourier analysis and adaptive filtering to extract features.

4.2. Pattern recognition technology: Establish a fault pattern recognition model through training samples to obtain more accurate fault judgment results.

4.3. Artificial intelligence technology: Neural networks, genetic algorithms and other technologies can be used for fault prediction and diagnosis.

In summary, the analysis of planetary gearbox fault signals and the introduction of fault diagnosis experimental methods and technologies can effectively improve the operating efficiency and reliability of planetary gearboxes. -

Why the servo motor rotates forward and reverse at one time?

11/12/2024 at 06:27 • 0 comments1. Circuit failure

The circuit of the servo motor control system is composed of multiple components. The working problem of any component may cause the servo motor to malfunction. For example: controller internal fault, motor drive board fault, etc.

2. Sensor failure

The motion status of the servo motor needs to be detected and fed back through the sensor. When the sensor is faulty, it will cause the servo motor motion to be distorted. For example, the error of the feedback signal is too large, the sensor is aging, the contact is poor, etc.

![]()

3. Mechanical failure

The servo motor and the mechanical device are matched, and mechanical problems will seriously affect the work of the servo motor. For example, the driving device is aging, mechanical parts are loose, etc.

In view of the above possible reasons, the problem of the servo motor rotating forward and reverse can be solved by troubleshooting the specific reasons and performing corresponding repairs and replacements.

Conclusion

Through the above analysis of the servo motor rotating forward and reverse, we can see that this problem is caused by a variety of possible reasons. Therefore, when operating the servo motor, you must pay attention to safety and usage methods to avoid problems.

-

Analysis and Solution of Servo Motor Start-stop Impact Problem

11/12/2024 at 06:25 • 0 comments1. Problem analysis

In actual use, shock may occur when the servo motor starts or stops. This impact usually takes the form of a violent shaking of the motor or a sudden stop or start of the machine. This situation will not only affect the normal operation of the equipment, but also shorten the life of the equipment.

There are many reasons for such problems, mainly including the following aspects:

1.1. The power supply fluctuates or the voltage is unstable. Servo motors require stable power to operate properly. If the power supply is unstable, shocks may easily occur.

1.2. Program control error. The operation of the servo motor requires program control. If there is an error in the program, it may cause impact problems.

1.3. Sudden change in load. Servo motors are often used in dynamic load applications. When the load changes suddenly, the motor is prone to shock.

1.4. The parameter settings are incorrect. The servo motor has many parameters that need to be set, including speed, acceleration, deceleration, tracking error, etc. If the parameters are set incorrectly, shock may easily occur.

![]()

2. Solution

For the above reasons, we can take the following measures to solve the problem of servo motor start and stop impact:

2.1. Stable power supply. It is recommended to use a stable power supply when using servo motors. You can use UPS power supply or voltage stabilizer and other equipment to solve the power supply problem.

2.2. Check program controls. The program control of the servo motor needs to be carefully checked to ensure that the program runs stably.

2.3. Balance the load. In response to the problem of sudden load changes, the occurrence of shocks can be reduced by adjusting the structure of the equipment or balancing the load.

2.4. Set the parameters correctly. Correctly setting the parameters of the servo motor can effectively avoid the occurrence of impact. It is recommended to adjust the motion parameters of the motor according to the characteristics and requirements of the equipment.

-

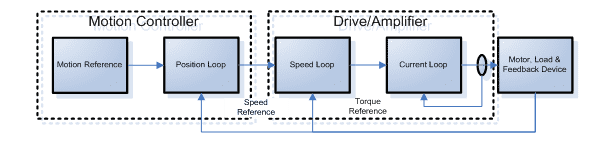

Can Stepper Motors Achieve Infinite Speed Change?

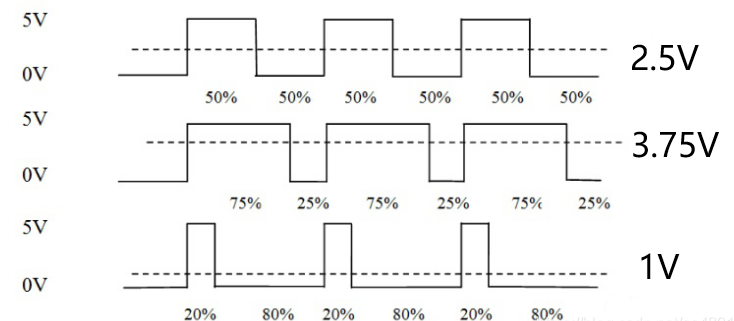

10/10/2024 at 05:13 • 0 commentsStepper motors cannot achieve infinite speed change, but they can achieve a certain degree of speed change by changing the step angle and driving method.

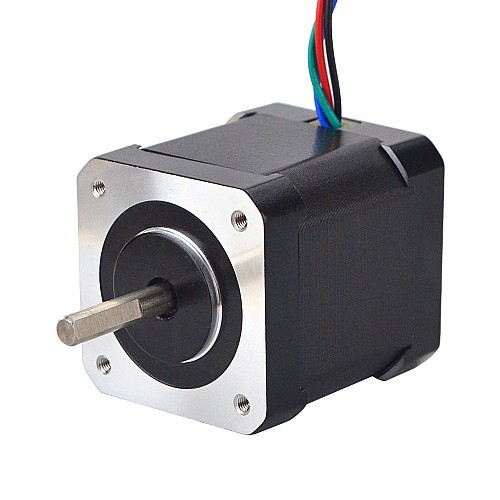

1. Working principle of stepper motor

A stepper motor is a motor controlled by different phases, which can achieve precise positioning and rapid acceleration and deceleration. The principle is to make the motor rotor rotate according to a fixed step angle under the changing phase sequence modulation. The movement of a stepper motor is discrete and can only produce a fixed step distance and cannot achieve seamless and continuous rotation.

2. Definition and implementation of infinitely variable speed

Continuously variable speed refers to achieving stepless speed change by changing the motor output torque and speed. It can achieve very delicate adjustments, so that the motor's speed and torque can be seamlessly switched, and almost any change can be achieved. There are two main ways to achieve infinite speed: frequency converter and speed regulator. The frequency converter uses the speed regulation function of the frequency converter to achieve stepless speed change, and the speed regulator realizes stepless speed change by adjusting the mechanical transmission ratio or changing the motor voltage flow.

![]()

3. Reasons why stepper motors cannot achieve infinite speed change

Although stepper motors have great advantages in terms of accuracy and stability, due to their inherent motion discreteness, they cannot achieve stepless changes in motor output torque and speed, so stepless speed changes cannot be achieved. The speed of the stepper motor can only be adjusted by changing the pulse frequency and phase sequence, and the number of steps is also fixed, so the stepper motor has the defect of "step by step".

4. Change the step angle and driving mode to achieve a certain degree of speed change

Although the stepper motor cannot achieve infinite speed change, it can achieve a certain degree of speed change by changing the step angle and driving method. The smaller the step angle, the faster the motor rotates, and the larger the step angle, the slower the motor rotates. Therefore, changing the step angle can achieve a certain degree of speed change. In addition, driving methods such as open-loop control, closed-loop control, and micro-step control can also affect the motor's speed and torque. For example, microstep control can be used to divide the step distance of a stepper motor into many small steps, thereby reducing the vibration of the motor and improving accuracy.

Conclusion

Although stepper motors cannot achieve infinite speed change, a certain degree of speed change can be achieved by changing the step angle and driving mode. Therefore, stepper motors are still an important driving method in automation fields that require fine positioning and rapid acceleration and deceleration.

-

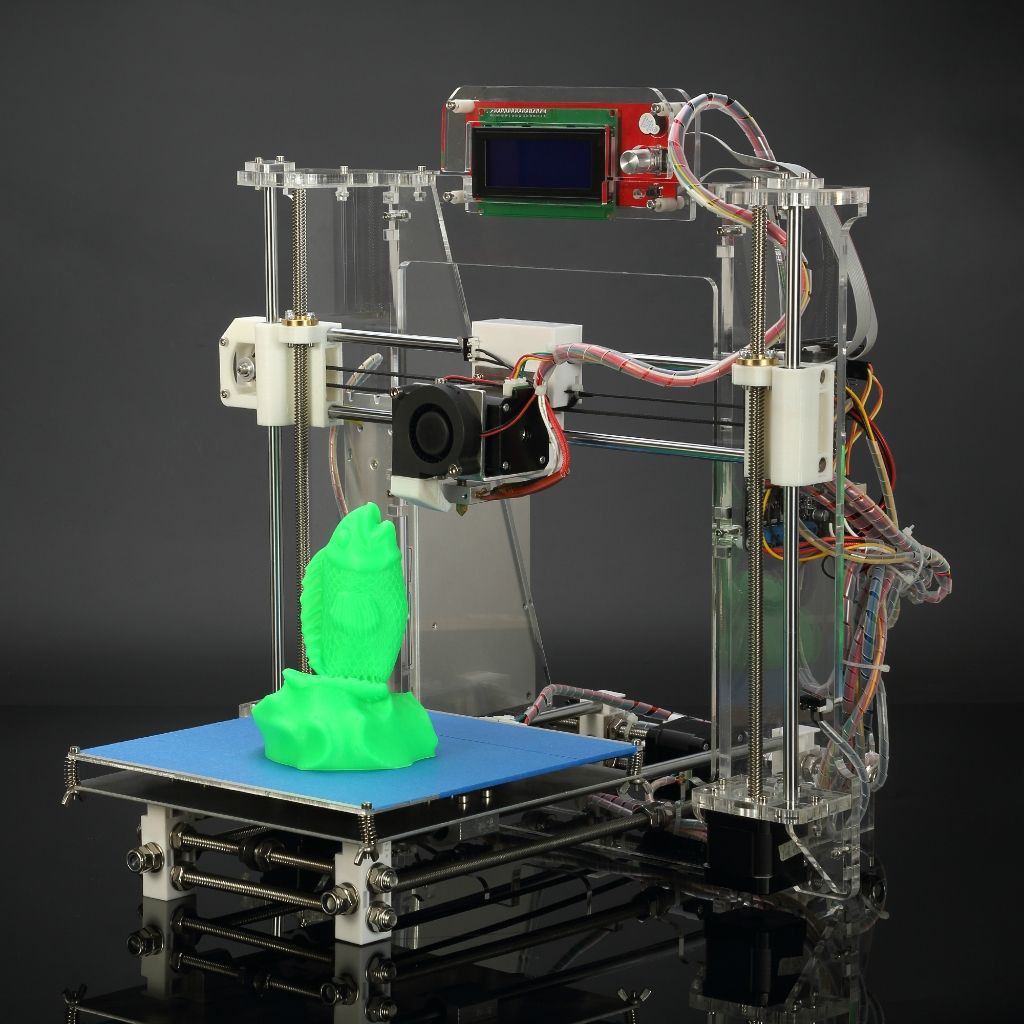

How Stepper Motors Achieve Linear Motion?

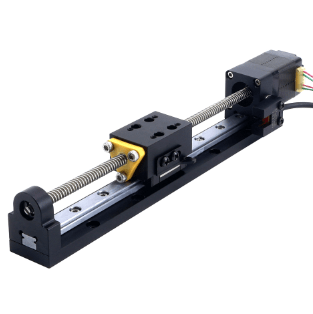

10/10/2024 at 05:12 • 0 comments1. Use Screw

A common method of converting the rotary motion of a stepper motor into linear motion is to use a screw. Attaching a stepper motor to a threaded shaft that interacts with a nut-like positioner converts rotational motion into linear motion.

2. Use Guide Rails

Another common method is to use guide rails. The guide rail can convert the rotational motion transmitted by the stepper motor into linear motion. Guide rails are usually made of metal rods or similar materials that ensure continuity and stability of linear motion. Guide rails can be used in many industries, including robotics, CNC machine tools and medical equipment.

![]()

3. Use Belt

The third method is to use straps. By attaching a stepper motor to a pulley and wrapping a strap around the pulley, rotational motion can be converted into linear motion. This method requires ensuring tight contact between the strap and the wheel at all times, and using appropriate tensioners to maintain strap tightness and normal movement.

In summary, the above are three common methods for converting stepper motor rotary motion into linear motion. Depending on the specific application scenario and actual requirements, different methods can be selected to achieve the best results.

-

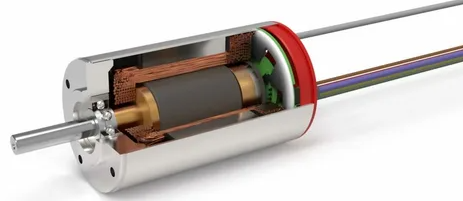

What is the Difference Between a Brushless DC Geared Motor and a Brushed DC Geared Motor?

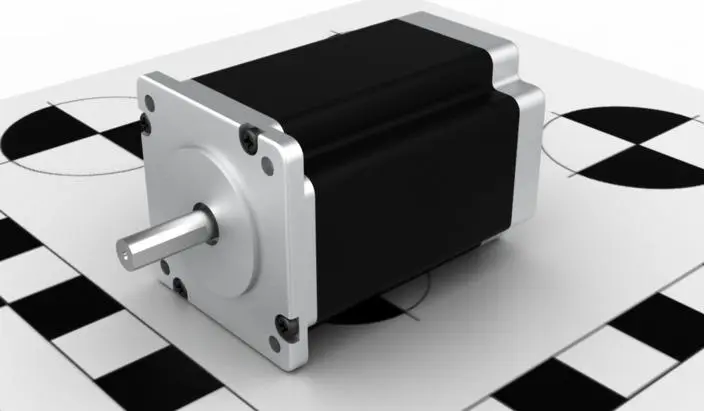

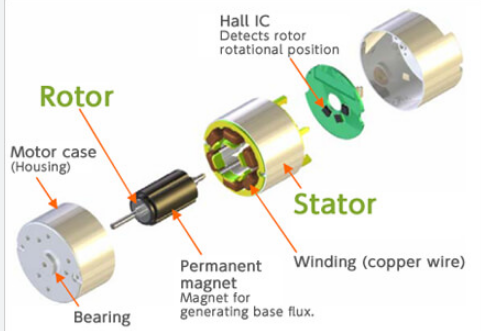

09/14/2024 at 05:47 • 0 commentsThe brushless DC motors with gearboxed are advanced motors that is also called brushless DC geared motor. It has the advantages of high efficiency, reliability, low noise, and long life. The structure of the brushless DC geared motor is more complex than that of the brushed DC geared motor, but its performance and efficiency are higher. It detects the position of the rotor through the sensor and transmits the position signal to the driver. The driver controls the current direction of the motor based on the position signal, realizes electronic commutation, generates a magnetic field, and drives the rotor to rotate.

![]()

DC brushed geared motor is also a common motor type, which consists of a DC motor and a reducer. This kind of motor has the advantages of simple structure, easy control, and low cost. Therefore, in some applications with simple functions, or on the premise that it can meet the necessary performance, low cost, and sufficient reliability, the DC brushed geared motor is an ideal choice. A very good choice.

![]()

The difference between brushless DC geared motors and brushed DC geared motors mainly lies in the following aspects:

1. Different structures: DC brushed geared motors usually include motor body, brushes, commutator and other components, while DC brushless geared motors usually include motor body, sensors and drivers.

2. Different working principles: DC brushed geared motors rely on the action of brushes and commutators to achieve current commutation through mechanical commutation, thereby generating a magnetic field. The brushless DC geared motor uses electronic commutation instead of mechanical commutation through the cooperation of sensors and drivers to achieve current commutation, thereby generating a magnetic field.

3. Different performances: DC brushed geared motors will have a certain amount of noise and wear due to the friction between the brushes and the commutator, and the output torque is relatively small. The brushless DC gear motor has the advantages of higher efficiency, longer life, smaller noise and smaller size.

4. Maintenance and maintenance methods are different: DC brushed geared motors need to regularly replace brushes and clean the commutator, while DC brushless geared motors do not need to perform these operations and only need to regularly check the operating status of the sensor and driver.

To sum up, the brushless DC geared motor has higher performance and maintenance convenience than the brushed DC geared motor, so it is widely used in some high-precision, high-efficiency, and long-term operation application scenarios.

-

The Purpose of the Five Wires of the Brushless DC Geared Motor

09/14/2024 at 05:39 • 0 comments1. Introduction to the five wires of brushless DC geared motor

1.1 Positive power wire (+5V): This wire provides the working voltage for the motor. It is usually red in color and is used to control the transmission of signals to ensure the normal operation of the motor.

1.2 Power supply negative wire(-5V) or ground wire (GND): As the reference point of the circuit, all signal wires and power wires will be connected to this wire to protect the circuit and other wires from electric shock. Usually the color is black or brown .

1.3 Signal wires (yellow wire and blue wire): These two wires together form a two-way signal, which is used to improve the accuracy and stability of control. They are related to the number of revolutions of the rotor, and the voltage changes in the opposite direction, providing a signal of the motor speed to the controller.

1.4 Hall sensor power wires (+5V and GND): These wires provide power to the Hall sensor and ensure the sensor is working properly. Usually the thin red wire is the +5V power supply and the thin black wire is the ground wire.

![]()

2. The purpose of the five wires of the brushless DC geared motor

2.1 Generator wires

The function of the three generator wires is to output the power of the motor, which is the most basic function of the BLDC motor with gearbox. The motor converts direct current into rotational force through internal electronic components, and at the same time drives the device to complete the work. The three generator wires include one positive wire and two negative wires. The positive wire is connected to the positive pole of the motor, and the two negative wires are connected to the two negative poles of the motor.

2.2 Sensor wires

The purpose of the two sensor wires is to transmit the position and speed information of the motor. These two wires can identify the position and speed of the motor and then control the operating status of the motor. According to the kinematic principle of the motor, the output position and speed of the motor are closely related to the input control signal. The three generator wires and two sensor wires work together to achieve accurate motion control.

-

The Difference Between Static Torque and Dynamic Torque of Stepper Motor

08/21/2024 at 01:26 • 0 comments1. What is a Stepper Motor?

Stepper motor is a commonly used precision motor that can rotate at a certain angle through pulse signals. Stepper motors are widely used in a variety of automation fields, including control systems, photographic equipment, and medical equipment.

2. Characteristics of Stepper Motors

2.1 High precision

Stepper motors can achieve very high positioning accuracy when stopped, so they can be used in applications that require high-precision control and positioning.

2.2 Stability

The output speed of the stepper motor can be very stable, which ensures that it can maintain a relatively constant output torque under load.

2.3 Good low speed adjustment performance

Stepper motors can achieve very small angle control, which also makes speed control very precise, especially when running at low speeds.

![]()

3. Output Torque of Stepper Motor

The output torque of stepper motor includes static torque and dynamic torque.

3.1 Static torque

The static torque of a stepper motor refers to the resistance of the motor shaft to the associated load without increasing the current. During operation, the stepper motor can withstand high static torque and its positioning accuracy is very high.

3.2 Dynamic torque

The dynamic torque of a stepper motor refers to the resistance of the motor shaft to the relevant load after adding current. Dynamic torque is usually lower than static torque and decreases as rotational speed increases.

4. The Difference Between Static Torque and Dynamic Torque

The main difference between static torque and dynamic torque is whether current is applied. The static torque of a stepper motor refers to the maximum torque it can withstand without increasing the current, while the dynamic torque refers to the maximum torque it can withstand after adding current. In practical applications, dynamic torque is often lower than static torque and decreases as the rotational speed increases.

5. Precautions for Stepper Motors

1. The driving method of the stepper motor is achieved through pulse control. When selecting the driver, you need to pay attention to its performance and quality.

2. Stepper motors have high accuracy and stability, but careful debugging and control are required during actual application to ensure that their performance is consistent with expectations.

3. When installing the stepper motor, you need to pay attention to protecting its bearings and performing appropriate lubrication to extend its service life.

6. Summarize

This article introduces the characteristics and output torque of stepper motors, and explains in detail the difference between static torque and dynamic torque. Stepper motors have the characteristics of high precision, stability and good low-speed adjustment performance. In practical applications, attention needs to be paid to issues such as driving methods, careful debugging, and bearing protection.

-

Can a Stepper Motor be Used as a Brake?

08/21/2024 at 01:24 • 0 comments1. Working principle of stepper motor

A stepper motor is a motor that converts electrical energy into rotational motion. It converts electrical signals into mechanical motion. The motor is controlled through a driver to achieve precise position control and speed control. There are two control methods for stepper motors: open-loop control and closed-loop control. Among them, open-loop control means that the controller sends instructions to the stepper motor, and the motor rotates according to the instructions; closed-loop control adds a feedback system for monitoring and adjustment based on open-loop control, improving accuracy and stability.

2. The connection between stepper motor and brake

A brake is a device that converts kinetic energy into heat or other forms of energy, which can reduce or stop the movement of a vehicle or machinery. In some cases, it is necessary to stop mechanical equipment or vehicles at a precise position. In this case, electronic brakes or electronic locking devices can be used. The stepper motor can generate reverse torque by controlling the driver to achieve the function of tightening or locking an object, so it can be used as an electronic brake or electronic locking device.

![]()

3. Can stepper motors be used as brakes?

Although the torque and braking functions of the stepper motor can tighten or lock an object, due to its structural characteristics, once the power supply is lost, the motor shaft will lose braking force, thus making it impossible to ensure the stable parking of the machine. Therefore, although the stepper motor can achieve a certain degree of braking, it is not an ideal braking device and cannot completely replace the mechanical or hydraulic braking device. In practical applications, the braking device needs to be reasonably selected according to specific needs, and the stepper motor cannot be relied upon to achieve the braking function.

In short, although the stepper motor has a certain braking function, it cannot be used as an ideal braking device. In practical applications, it is necessary to select the appropriate braking device according to specific needs.

-

Can Stepper Motors be Powered by Batteries?

06/06/2024 at 06:41 • 0 comments1. Basic principles and characteristics of stepper motors

A stepper motor is a precision motor that can accurately control position according to a preset number of steps. The working principle of a stepper motor is to use magnetic field rotation to control the position and speed of the rotor. It consists of stator, rotor, drive circuit and sensor. Whenever the drive circuit gives a pulse signal, the rotor will rotate at a certain angle according to the set number of steps. Stepper motors have the advantages of precise control and high positioning accuracy, and are widely used in robots, CNC machine tools, electronic equipment and other fields.

2. Can stepper motors be powered by batteries?

The answer is yes. Stepper motors can be powered by batteries, but you need to pay attention to whether the voltage and current of the battery meet the requirements of the stepper motor. The voltage and current of stepper motors are generally relatively large, so a suitable battery needs to be selected for power supply. At the same time, the stepper motor needs to be connected to the drive circuit to work properly, so the drive circuit needs to be selected to match the battery to ensure that the stepper motor can work properly.

![]()

3. Precautions when using battery power supply for stepper motors

3.1 Choose the right battery: Stepper motors require relatively large voltage and current, so you need to choose a high-capacity, high-power battery for power supply. At the same time, it is necessary to select a suitable protection circuit for the battery to prevent battery over-discharge, over-charge, over-current and other problems.

3.2 Choose the appropriate drive circuit: Stepper motors require a drive circuit to work properly, and you need to choose a stable and reliable drive circuit. The power supply of the drive circuit needs to match the battery to ensure that the stepper motor can work properly.

3.3 Control power supply: Stepper motors require a stable and reliable control power supply to ensure that the position and speed of the stepper motor can be accurately controlled.

3.4 Avoid over-discharging the battery: Over-discharging will greatly shorten the life of the battery, and may cause battery short circuit, leakage and other problems. Therefore, a protection circuit needs to be used to control the over-discharge of the battery so as not to affect the normal operation of the stepper motor.

In short, stepper motors can be powered by batteries, but attention needs to be paid to the selection of appropriate batteries and drive circuits to ensure the normal operation of the stepper motor.

-

Does a Stepper Motor Need to Use a Relay?

06/06/2024 at 06:40 • 0 comments1. The relationship between stepper motors and relays

Stepper motors are controlled electronically to achieve precise position control and motion control. The stepper motor can be directly connected to the power supply and the rotation is controlled by controlling the voltage, so in theory there is no need to use a relay.

However, in actual use, it is necessary to use relays in some cases. For example, when a larger current needs to be used to start or stop a stepper motor, a relay can be used to provide auxiliary control of the motor. In addition, if direct control of the stepper motor will have a negative impact on the main control board or high level, using a relay can play a role in isolation and protection.

![]()

2. Matters needing attention

2.1 When selecting a relay, you need to consider that the rated voltage and current of the relay must match the actual voltage and current of the stepper motor, otherwise it will easily cause failure to operate normally.

2.2 A suppression circuit needs to be added between the relay and the stepper motor to reduce possible electromagnetic interference and ensure the stability and reliability of the system.

2.3 The quality of the relay and suppression circuit directly affects the performance and life of the stepper motor, so it is necessary to choose better quality hardware equipment.

In summary, the use of relays can enhance the control capability of the stepper motor and the reliability of the system, but the actual needs of the system and the quality of the hardware equipment need to be considered when selecting relays and suppression circuits.

-

The Role of Stepper Motor Inductance and Selection Considerations

05/11/2024 at 07:20 • 0 commentsStepper motor inductance is a crucial parameter that influences motor performance. Its primary functions are as follows:

1. Energy Storage

When voltage is applied to the motor, the inductance stores energy, generating a magnetic field. Upon voltage removal, the inductance releases energy, sustaining the magnetic field's decay for a period.

- Limiting Current Change Rate

- Impacting Motor Response Speed

- Influencing Motor Heat Generation

Inductance impedes abrupt current changes. According to Lenz's law, when current changes, the inductance generates a counter-electromotive force (CEMF) that opposes the current change. This is essential for stepper motor control as the motor requires rapid current direction changes to achieve stepping motion.

Inductance reduces the motor's response speed to control signals. This is because the inductance takes time to store and release energy. For high-speed applications, choose motors with lower inductance to enhance response speed.

Inductance increases the motor's copper losses, leading to heat generation. Therefore, consider inductance value and ambient temperature when selecting motors to prevent overheating and damage.

![]()

How to Select Proper Stepper Motor Inductance

Stepper motor inductance selection involves considering several factors:

1. Motor Speed

For high-speed applications, choose motors with lower inductance to improve response speed.

- Motor Load

- Ambient Temperature

- Control Method

For heavier loads, select motors with higher inductance to achieve greater torque.

For high ambient temperatures, choose motors with lower inductance to reduce heat generation.

For control methods requiring rapid current direction changes, select motors with lower inductance.

Generally, stepper motors with inductance values between 0.5mH and 5mH are suitable for most applications. If you have any questions regarding inductance value selection, consult the motor manufacturer or the motor driver's technical support.

Summary

Stepper motor inductance is a critical parameter affecting motor performance. Choosing the appropriate inductance value is essential for ensuring proper motor operation. When selecting inductance, consider factors such as motor speed, load, ambient temperature, and control method.

-

How to Choose the Right Stepper Motor Based on Resistance?

05/11/2024 at 07:19 • 0 commentsThe resistance value of astepper motor has a significant impact on its performance, including current, heat generation, torque, and speed. Therefore, selecting the appropriate resistance value is crucial. Here are some principles to consider when selecting resistors for stepper motors:

1. Determine the Appropriate Resistance Value Based on Motor Voltage and Current

The resistance value of a stepper motor can be calculated using the following formula:

R = U / I

Where:

R: Resistance value (unit: ohm)

U: Motor voltage (unit: volt)

I: Motor current (unit: ampere)

When selecting the resistance value, ensure that the motor current does not exceed its rated current. Otherwise, the motor may overheat and damage.

![]()

2. Determine the Appropriate Resistance Value Based on Motor Torque and Speed Requirements

The relationship between motor torque and speed with the resistance value is as follows:

Torque is directly proportional to current and inversely proportional to resistance.

Speed is directly proportional to voltage and inversely proportional to resistance.

Therefore, for applications requiring higher torque, choose a smaller resistance value. For applications requiring higher speed, choose a larger resistance value.

3. Consider the Motor's Heat Resistance

A lower resistance value leads to higher motor current and increased heat generation. Therefore, consider the motor's heat resistance when selecting the resistance value to prevent overheating and damage.

Specific Selection Recommendations:

For low-speed, high-torque applications, choose a stepper motor with a higher resistance value.

For high-speed, low-torque applications, choose a stepper motor with a lower resistance value.

For applications requiring frequent starting and stopping, choose a stepper motor with a lower resistance value.

For high-temperature environments, choose a stepper motor with better heat resistance.

In practical applications, consider the specific application requirements and select the appropriate stepper motor resistance value based on the factors mentioned above.

-

Why Do Stepper Motors Lose Steps When They Get Hot?

04/11/2024 at 03:06 • 0 commentsWhen a stepper motor gets hot, it loses steps and fails to rotate. Under no-load conditions, the following may be the reasons:

- Excessive load or stuck: If the motor load is too large or the motor bearings are stuck, it will cause the motor controller to continuously output current, causing the motor to overheat, and it will easily lead to loss of steps and the motor not rotating.

- Drive circuit problems: Unreasonable drive circuit design or unstable drive voltage will cause the motor to heat up and affect its normal operation.

- Poor heat dissipation of the motor shell: When working in a high temperature environment for a long time, poor heat dissipation of the motor will cause the motor temperature to be too high and easily damage the motor.

- The stepper motor generates serious heat: The stepper motor itself generates a certain amount of heat due to its working principle. However, if the motor heats up severely, there may be a problem with the motor's internal windings or iron core, which requires inspection and repair.

![]()

To solve this problem, the following measures can be taken:

- Check the load: Make sure the motor load is within the normal range to avoid overload or underload. At the same time, check whether the motor bearings are normal. If any abnormalities are found, they need to be replaced in time.

- Check the drive circuit: Make sure the drive circuit design is reasonable and the drive voltage is stable. If there is a problem with the drive circuit, it needs to be repaired or replaced in time.

- Optimize heat dissipation: Ensure that the motor casing has good heat dissipation conditions. You can install heat sinks or fans and other heat dissipation equipment on the motor casing to help the motor dissipate heat quickly.

- Check the motor: If the motor heats up severely or other abnormalities occur, the motor needs to be inspected, repaired or replaced in time.

-

Several Types of DC Stepper Motors with High Waterproof Levels

04/11/2024 at 03:03 • 0 comments1. IP65 DC stepper motor

DC stepper motors with protection class IP65 have a high degree of dust and water tightness and are suitable for some special working areas, such as production halls, sewage treatment plants, etc. This type of motor has a tightly sealed housing that can prevent the ingress of dust, sand and splashing water, and has the ability to adapt to harsh environments.

2. IP67 DC stepper motor

The DC stepper motor with IP67 protection has a fully enclosed structure, is waterproof, can work underwater and is dustproof. This type of motor is generally used in applications that require long-term operation in harsh environments. These include rain and snow weather, swamps, hot springs and other places.

![]()

3. IP68 DC stepper motor

The IP68 DC stepper motor is a fully enclosed, waterproof structure that can completely isolate the ingress of water molecules and will not be damaged even if immersed in water for a long time. such as underwater detection and other fields.

4. IP69K class DC stepper motor

The IP69K-rated DC stepper motor is a fully enclosed high-temperature and high-pressure structure with very high waterproof, dustproof, high-temperature resistance and corrosion resistance. Such motors are commonly used in the food and beverage processing industry, medical equipment, shower equipment and other applications where high hygiene standards are required.

In general, DC stepper motors with different waterproof levels have different characteristics and application ranges. When selecting, users should determine the required waterproof level based on the specific working environment and needs.

-

What are the components of a DC motor?

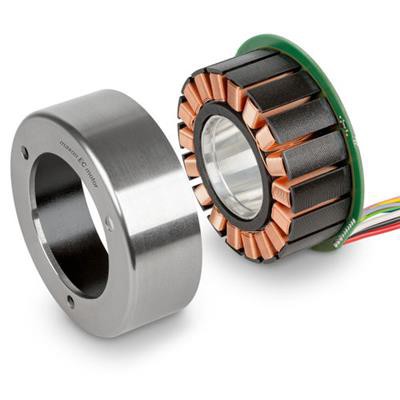

03/12/2024 at 06:48 • 0 comments1. Structure of brushless DC motor

Brushless DC motors are complex mechanical system composed of multiple parts. Its main components include the motor body, rotor, stator, bearings, end covers, magnets, encoders, drivers, etc.

1.1 Motor body: The motor body is the core part of the brushless DC motor and usually consists of two parts: the rotor and the stator. The rotor can be an inner rotor or an outer rotor, which is composed of magnetic poles, shafts, bearings, etc.; the stator is the fixed part of the motor and is composed of coils, iron cores, and motor brackets.

1.2 Rotor: The rotor is the rotating part of the motor, which consists of permanent magnets, shafts and other components. The permanent magnets of the inner rotor are located inside the rotor, while the permanent magnets of the outer rotor are located outside the rotor.

1.3 Stator: The stator is the directional component of the motor. It is composed of coils and iron cores and is the immovable part of the motor.

1.4 Bearings: Bearings are the core components that support the rotating part of the motor. Rolling bearings or sliding bearings are usually used.

1.5 End cover: The end cover includes the front cover and the back cover. It is a component used to seal the motor. It is usually installed at both ends of the motor body.

1.6 Magnetic steel: Magnetic steel is a component used to generate a magnetic field in a motor. It is usually composed of permanent magnets or electromagnets.

1.7 Encoder: Encoder is a component in the motor used to detect the rotor position and motion status. It usually includes photoelectric encoders, magnetic encoders and other types.

1.8 Driver: The driver is the core component of the motor control system. It can control the speed and steering of the motor based on signals.

![]()

2. Working principle of brushless DC motor

The working principle of the brushless DC motor is to generate a magnetic field between the stator and rotor through permanent magnets and current, thereby generating electromagnetic torque. Specifically, when current passes through the stator winding, a magnetic field is generated in the stator, and at this time, the rotor permanent magnets are subjected to magnetic forces and start to rotate. When the rotor rotates to a certain position, the driver changes the direction of the current so that the rotor continues to rotate. By continuously changing the direction of the current, the motor can be continuously rotated.

3. Advantages of brushless DC motor

Brushless DC motors have many advantages, such as high efficiency, high torque, low energy consumption, lightweight, low noise, etc. In addition, since brushless DC motors do not require the use of carbon brushes, their lifespan is also longer. These advantages make brushless DC motors widely used in robotics, electric vehicles, medical equipment and other fields.

-

How to commutate a brushless DC motor?

03/12/2024 at 06:38 • 0 comments- Commutation principle of brushless DC motor

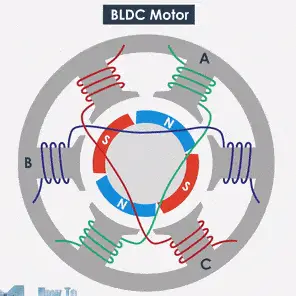

A brushless DC motors are an electric motor with multiple permanent magnets on its rotor and multiple sets of windings on its stator. The speed and direction of the motor are controlled by controlling the direction and size of the current through an electronic speed regulator. Since the brushless DC motor does not require a mechanical commutator, it can achieve the advantages of high efficiency, low noise, and long life. However, when the speed is high, the load is large, or the load changes suddenly, the reverse direction of the commutation current is required, otherwise the motor will not work properly. The commutation principle of the brushless DC motor is to use the Hall sensor or electric speed regulator inside the motor to control the direction and magnitude of the current, thereby realizing the commutation of the motor.

2. Commonly used brushless DC motor commutation methods

2.1 Hall sensor commutation

Hall sensors for brushless DC motors are divided into three types: single-axis Hall sensors, three-axis Hall sensors and linear Hall sensors. These sensors can measure the position and speed of motor rotation, thereby controlling the direction and magnitude of the current to achieve motor commutation. The specific implementation method is: when the motor moves, the Hall sensor detects the change in the magnetic field and sends the signal to the ESC control chip, which is processed in the chip and drives the power sensor to output to the motor. Make sure the coils are positioned correctly so the motor operates properly. Hall sensor commutation has the advantages of simple structure and low cost, and is suitable for low-power motors.

![]()

2.2 Electric speed regulator reversal

The electric speed regulator uses the back electromotive force principle in the DC motor to control the commutation of the motor by adjusting the direction and magnitude of the current. During reversal, the ESC control chip will automatically determine the front and rear position of the motor and the direction of the magnetic field, and control and adjust the current direction to achieve the running direction of the motor. Compared with Hall sensor commutation, electric speed regulator commutation does not require external sensors, making the design more flexible. However, electric speed regulator commutation also has some shortcomings, such as complex structure and high price.

-

Resonance of a Stepper Motor

02/18/2024 at 07:49 • 0 commentsStepper motors are known to vibrate or resonate at certain speeds, especially at low speeds. At low speeds, the motor's motion is more like a stepper, with the motor's rotor tending to oscillate back and forth between each step. This oscillation causes mechanical resonance in the motor components such as the rotor, shaft and bearings. Resonance can cause the motor to vibrate, resulting in loss of torque and precision.

For a given stepper motor, its resonance problem is difficult to eliminate, but there are some methods to reduce the vibration to a certain extent.

1. Stay away from the resonance zone

Since the motor only exists in a certain resonance area, the motor should be avoided to run near the resonance area. When the motor accelerates from a lower resonance area, it should accelerate as fast as possible, away from the resonance area, and reduce vibration.

2. Increase the subdivision of the driver

The larger the subdivision, the smaller each step of the motor will be, and the range of motion of the motor will become more delicate, so that the motor will move more smoothly, thereby reducing vibration.

3. Reduce the driving current

In the case of ensuring that the stepper motor has sufficient torque, reduce the drive current as much as possible. The smaller the current, the smaller the change in the coil current in the motor.

4. Install dampers or shock absorbers

Add a shock absorber between the motor and the mounting part, such as a rubber or silicone coupling or a tuned mass damper, which absorb the motor's vibration and reduce the resulting vibration.

If the above methods still cannot meet your vibration requirements, you need to replace a motor. You can contact the technical team of STEPPERONLINE and tell us the speed range that needs to work, and we will help you choose a motor whose resonance area is not in this speed range. -

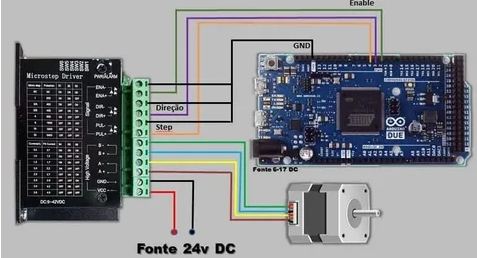

Stepper Motor Does Not Rotate After Connecting to the Driver

02/18/2024 at 07:46 • 0 commentsFirstly, you can perform the following steps to troubleshoot the problem:

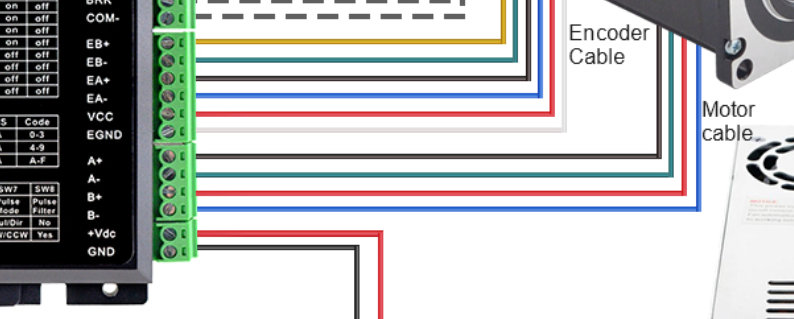

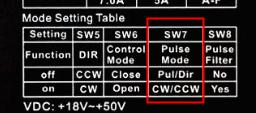

1. Double-check all the wiring. You may need to refer to the manuals of both the stepper motor and driver.

Note: It's better to test the motor and driver separately instead of installing them in your production equipment to eliminate other interfering factors.![]()

Note: The wire colors in the picture are for display only. For the actual correct wiring sequence, please refer to the motor drawing !

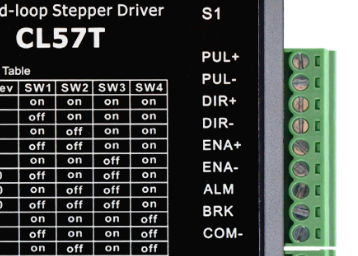

2. Check if the power voltage and signal voltage of the driver are correct. In particular, make sure the signal voltage set by the driver matches the voltage provided by the controller. According to our feedback records, 40-50% of the motors do not turn because of this reason. Because the control signal voltage is 5V, and the driver defaults to 24V.![]()

3. Try disconnecting the ENA+/- interface if you have connected it.

4. Power on the driver without sending any pulse signals and check whether the motor is locked. If it is a closed-loop motor, you can set the driver to open-loop mode, usually by setting SW6 to on, and then check whether the motor can run. If it can run, then there is probably a problem with the encoder part.

5. Power on the driver and send pulse signals to see if the driver gives an alarm. Record the number of alarms displayed on the driver and refer to the "Troubleshooting Table" in the driver's manual to check each potential problem. Usually, you can find the "Troubleshooting Table" in the driver's manual.

6. If you have other motors or drivers, you can perform a cross-test to determine if the problem lies with the motor or driver.

7. Check whether the pulse mode setting is correct. Some drivers can be set to the type of input pulse signal (usually SW7), so you need to select the corresponding pulse mode according to the signal type provided.![]()

-

What is the relationship between phase resistance and phase inductance and stepper motor?

01/08/2024 at 04:48 • 0 comments1. What are phase inductance and phase resistance?

Phase resistance refers to the resistance in each phase coil of a stepper motor. Inside the stepper motor, there are two or more phase coils. Each coil has a phase resistance, and its size depends on the material of the coil. , wire diameter and coil length;

Phase inductance is the static electrical parameter of the motor, which refers to the inductance of the internal winding coil of the motor. It is an important parameter that affects the torque-frequency characteristics of the motor. Generally speaking, the attenuation of the motor output torque is inversely proportional to the phase inductance (that is, the larger the phase inductance, the smaller the torque attenuation. The smaller the phase inductance, the greater the torque attenuation);

![]()

2. The impact of phase resistance and phase inductance on stepper motors;

Inductance will affect the vibration, speed and heat of the motor. Under the condition of equal resistance and guaranteed torque, the smaller the inductance, the better. In this way, the motor speed can be higher and the vibration will be smaller accordingly.

The size of the resistor mainly affects the heating and efficiency of the motor: larger phase resistance will cause the motor to generate more heat when working, because resistance losses will occur when the current passes through the resistor. This may require better cooling systems to keep motor temperatures within acceptable limits. In addition, larger phase resistance will also cause the efficiency of the motor to decrease.

3. What factors will affect the phase resistance and phase inductance of the stepper motor?

1). Coil material: The material of the coil will affect the phase resistance and phase inductance. Different materials have different electrical and magnetic conductivities, which affect the resistance and inductance of the coil.

2). Coil length and cross-sectional area: The length and cross-sectional area of the coil will also affect the phase resistance and phase inductance. Longer coils increase resistance and inductance, while larger cross-sectional areas reduce resistance and inductance.

3). Number of coil turns: The number of coil turns indicates the number of coils in the coil. More turns generally result in higher inductance values.

4). Core material and structure: The core material and structure in the stepper motor will also affect the phase resistance and phase inductance. The permeability and shape of the core affect the magnetic field distribution in the coil and thus the inductance.

5). Motor lead length: The motor outlet mainly affects resistance and has little impact on inductance. The longer the wire, the greater the resistance.![]()

4. Characteristics of motors with high inductance and low inductance/high resistance and small resistance

High inductance and large resistance motor:

Its advantage is that it can achieve the required torque by using a relatively small current, so you can choose one with a smaller current.The driver, the heating, stability and noise of the driver and motor will be much better.

Its disadvantage is that it cannot go up at high speed, and the torque decays quickly at high speed.

Low inductance and small resistance motor:Its advantages are that the driver has higher voltage and current at high speed, and its no-load starting and operating frequency are both higher.The hardness of the machine is relatively good, and the torque decays very slowly with speed.

Its disadvantages are that the current is very large, the voltage is relatively high, the heat is large, and the noise is difficult to control; the driver performance requirements are also relatively high.

Note: It does not mean that the greater the phase resistance and inductance, the greater the holding torque! Rather, under the same voltage and current conditions, the larger the inductor and resistance, the greater the driving capability.

-

How to deal with the heating problem of stepper motor?

01/08/2024 at 03:10 • 0 comments1. Causes of motor heating

For any stepper motor, it is normal to generate heat during operation, and the same is true for stepper motors. The inside of the stepper motor is composed of an iron core and a winding coil. The resistance of the operation and maintenance winding exists, and the current flowing through the motor will cause loss. The loss is proportional to the square of the resistance and the current. This is called "copper loss". In addition, there is a hysteresis eddy current effect in the iron core, which will also cause losses in the alternating magnetic field. Its size is related to material, current, frequency, and voltage. This is called "iron loss". Both copper loss and iron loss will appear in the form of heat, affecting the efficiency of the motor. Because stepper motors generally pursue positioning accuracy and torque output, they have low efficiency, large current, and high harmonic components. The alternating frequency of the current also changes with the rotation speed, so stepper motors generally generate heat.

![]()

2. Normal phenomenon of motor heating

The allowable degree of motor heating mainly depends on the internal insulation level of the motor. Only at high temperatures (above 130 degrees) will the internal insulation performance be destroyed. So as long as the internal temperature does not exceed 130 degrees, the motor will not be damaged and the surface temperature is below 90 degrees. Therefore, it is normal for the surface temperature of the stepper motor to be 70-80 degrees, which can be roughly judged with a point thermometer. This normal heating will not affect the life of the stepper motor.

![]()

3. Countermeasures for motor heating

(1) Check whether the current setting of the driver is appropriate. If the setting is too high, you can reduce the current appropriately and turn on the half-current holding function of the driver.

(2) Check whether the driver is overloaded or overheated. If necessary, add cooling measures or replace the driver with a higher power one.

(3) Check whether the stepper motor works for too long. If so, consider increasing the cooling time or using a fan for heat dissipation.

(4) Check whether the ambient temperature is too high, and increase ventilation or lower the operating temperature if necessary.

(5) Check the power cord and its connecting wires: Check the power cord and its connecting wires to make sure there is no high impedance in them, so as not to affect the flow of current and make the stepper motor hot to the touch. -

What is motor insulation made of?

01/08/2024 at 02:04 • 0 commentsIn electrical equipment such as stepper motors, closed-loop motors, and servo motors, equipment using different insulation materials has different abilities to withstand high temperatures. Therefore, general motors have a maximum allowable temperature for their operation. Now let’s take a look at insulation materials and the temperatures they withstand.

![]()

Class A insulation materials: including impregnated cotton yarn, silk, paper and other organic fiber materials, as well as enamel on ordinary enameled wires, etc., and are currently only used on transformers. The maximum allowable operating temperature is 105°C. The temperature rise of the wire group is 60℃, and the performance reference temperature is 80℃.

Class B insulation materials: including mica, asbestos, glass fiber and other organic matter; materials and compositions made of organic paint or resin with improved heat resistance as a binder; enamel on polyester high-strength enameled wire; maximum allowable work The temperature is 130℃. The temperature rise of the wire group is 80℃, and the performance reference temperature is 100℃. It has good heat resistance, solvent resistance, adhesion performance, high mechanical strength, etc., and is suitable for small ordinary motors, electrical appliances, instruments, and telecommunications materials.

Class C insulation materials: including mica, quartz, glass, etc.; asbestos, glass fiber fabrics or their products treated with silicone resin, polyimide impregnating paint, etc. with particularly excellent thermal stability; polyimide based Enameled wire enamel, polyimide film, etc., Class C insulation grade is an insulating material with higher requirements and is being promoted and used in production. Its maximum allowable working temperature has not yet been determined, but it is probably above 180°C.

Class F insulation materials: including mica, asbestos, glass fiber and other inorganic materials, made of synthetic resin paint modified with silicone organic compounds, or alkyd, epoxy and other synthetic resins whose heat resistance meets this requirement as a binder. Material or its composition, the maximum allowable operating temperature is 155°C. The temperature rise of the wire group is 100℃, and the performance reference temperature is 120℃. Its characteristics are that it has good heat shock resistance, mechanical and electrical properties and high softening temperature. It is suitable for high temperature resistant electronics, instruments, meters and telecommunications equipment.

![]()

Class H insulation materials: Materials including silicone organic matter and inorganic materials such as mica, asbestos, glass fiber, etc., with silicone organic paint as a binder. The maximum allowable working temperature is 180°C. The temperature rise of the wire group is 125℃, and the performance reference temperature is 145℃. It is characterized by excellent friction, heat and solvent resistance. Its scope of application is general motors, transformers, four-way valves, igniters, automotive relays, etc.

Class E insulation materials: including films made of polyester resin, epoxy resin, triacetate fiber, etc., polyvinyl acetal, enamel on high-strength enameled wire, etc. The maximum allowable operating temperature is 120°C. The temperature rise of the wire group is 75℃, and the performance reference temperature is 95℃.

In addition, it should be noted that the insulation level and insulation temperature resistance are closely related, because the higher the temperature, the worse the insulation performance of the material will be. Therefore, different grades of insulation materials have a maximum allowable operating temperature, and within this temperature range, they can be used safely. If the working temperature of the insulating material exceeds its own insulation heat-resistant temperature, the insulating material will age rapidly and become unusable, which may also cause safety hazards.

-

What is the Difference between Linear Motors and Linear Actuators?

01/02/2024 at 04:50 • 0 commentsThe structural differences are:

A linear motor is a mechanical device that converts rotational motion into linear motion. From the perspective of motion principles, to convert a stepper motor from rotational motion to linear motion, the simplest design is to integrate the screw nut into the stepper motor, and realize the entire linear transformation inside the motor. This method greatly simplifies the entire structural design, and in many application fields can directly use linear motors for precise linear transmission without installing external mechanical linkage devices. The basic principle is to install a nut in the center of the rotor of the linear motor, and accordingly use a screw rod to mesh with the nut. In order to move the screw rod forward and backward, some method must be used to prevent the screw rod and the rotor assembly from rotating together. Since the rotation of the screw is constrained, the screw achieves linear motion when the rotor rotates.

![]()

Linear Motor Actuators usually consist of linear guide rails, aluminum alloy profiles, supports, motors, photoelectric switches, etc. It is a transmission device that directly converts electrical energy into linear motion mechanical energy without any intermediate conversion mechanism. It has the advantages of simple structure, convenient long stroke, high acceleration, fast response and high precision. The linear actuators currently on the market can be roughly divided into two categories: synchronous belt type linear modules and ball screw linear modules. The former installs the belt on the transmission shafts on both sides of the linear module, which serves as the power input shaft. A slide block for adding equipment workpieces is fixed on the belt. When there is input, the slide block is moved by driving the belt; the latter The motor drives the screw to make the slider run. Our company is currently selling this type, but the structure is simpler. We have canceled the coupling and integrated the linear motor into the module as a whole. Please explain whether the actuators has a coupling or not.

![]()

The performance difference is:

Linear Actuators usually include the linear motor itself and its supporting control system, sensors and mechanical structure. This integrated design allows linear motor modules to be deployed faster and easier t

-

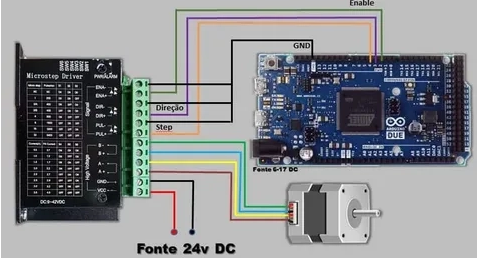

Brake stepper motor--a brief overview

01/02/2024 at 03:20 • 0 commentsWhat is a brake stepper motor?

Stepper motors are equipped with encoders, reducers, brakes and other configurations to improve the motor's application range and performance. So what is a brake stepper motor? The so-called brake stepper motor is to install a brake device, that is, a braking device, at the end of the stepper motor. When the stepper motor is powered on, the brake is also powered on, and the braking device will also break away from the stepper motor output shaft, causing the motor to normal operation. When power is removed, the brake releases tightly to hold the motor shaft. Realize the function of frequently starting and stopping a stepper motor to ensure that the motor is powered on or locked when it is powered off.

![]()

Advantages and characteristics of brake stepper motors

The stepper motor with brake is like a well-trained horse, ready for use at any time. From an industrial development perspective, the stepper motor is a great invention. It is driven by electromagnetic force and can accurately convert electrical energy into mechanical energy to achieve angular or linear displacement. Its step angle is precise, its rotation is smooth, and it responds quickly. With the pulse of current, it completes every action accurately. The addition of the brake device is the icing on the cake. It gives the stepper motor the ability to quickly lock its position when stopped, preventing accidental rotation due to external forces. This kind of locking force is powerful and reliable. No matter how the external environment changes, the stepper motor with brake can maintain its original position and remain unmoved.

Stepper motors with brakes also have many advantages such as energy saving, environmental protection, long life, and easy maintenance.

Its operation is quiet and efficient, producing almost no noise and vibration, providing great convenience for modern industrial production and daily life. In general, stepper motors with brakes are a combination of modern technology and art. It has both strong power and stable braking performance; it can accurately perform complex motion tasks and stop quickly when needed. With its unique advantages and wide range of application fields, it is leading the development of modern automation control field.

![]()

What working conditions require braking stepper motors?

For stepper motors equipped with brakes, the permanent magnet brake used has the characteristics of fast response, large holding force, and long service life. When the motor moves up and down, and when the equipment is powered off, it can maintain the torque so that the working object does not move. Will not fall off, which additionally enhances the diversification of stepper motor convenience in use.

So what are the advantages of brake stepper motors and what industries are they widely used in?

When the motor is working, it can drive the mechanism up. When the motor stops, it cannot guarantee that the platform mechanism will not fall. At this time, we need to use the brake to lock and drag the axis to position the platform height and accuracy. Currently, they are widely used in automated equipment such as dispensing machines, elevators, CNC machine tools, tapering machines, and packaging machines. Because these industries often use start-stop devices during work, they all require the use of brake stepper motors. -

What are sensed brushless motors and senseless brushless motors?

01/02/2024 at 02:56 • 0 commentsWhat are sensed brushless motors and senseless brushless motors?

1. The difference between sensored brushless motors and sensorless brushless motors

The sensor in sensorless brushless refers to "Hall sensor", so what is "Hall"? Hall refers to the Hall effect. Simply put, when a current passes through a conductor perpendicular to the external magnetic field, a potential difference will appear between the two end faces of the conductor perpendicular to the magnetic field and the direction of the current. It can be easily known through the Hall effect. Regardless of high-speed or low-speed motor operating status. It can be seen that the inductive brushless motor is a brushless motor without Hall sensor feedback. It indirectly detects the rotor position commutation through the voltage and current changes of the motor winding.

![]()

2. Characteristics of inductive brushless motors and inductive brushless motors

The position of the rotor can be known when the inductive motor is at rest, but the position of the rotor needs to be rotated for the non-inductive motor. Therefore, the non-inductive motor will shake when it just starts and stops. A brief summary is that it will shake when starting and stopping; Induction motors use Hall element sensing, which is less susceptible to interference and more accurate in judgment. Therefore, it can be applied to fast start and fast stop conditions. It usually provides better low-speed torque performance because they can accurately operate at low speeds or even at rest. Control commutation.

3. Usage scenarios of sensored brushless motors and sensorless brushless motors

When choosing between an inductive motor and a non-inductive motor, you need to consider the following aspects:

![]()

1). Speed range: If the speed is higher, it is recommended to choose a non-inductive motor; if the speed is lower, it is recommended to choose an inductive motor.

2). Control accuracy: If high-precision control is required, it is recommended to choose an inductive motor; if the control requirements are relatively low, it is recommended to choose a non-inductive motor.

3). Cost factor: If the cost requirements are low, it is recommended to choose a non-inductive motor; if the accuracy and operating stability requirements are high, it is recommended to choose an inductive motor.

4). Control distance: If the distance is less than 3 meters, you can use an inductive motor. When the distance is greater than or equal to 3 meters, it is recommended to use a non-inductive motor.

All in all, non-inductive motors are suitable for applications with small to medium power and high speed operation, such as fans, model toys, etc. Inductive motors are suitable for high-precision and high-power applications, such as machine tools, automation equipment, etc. -

How to maintain the AC servo motor control system?

12/25/2023 at 01:09 • 0 commentsFor the maintenance of ACservo motor control systems, the following are some common precautions:

![]()

(1) Clean the servo motor and controller regularly to ensure that their surfaces are clean and to prevent dust, oil and other impurities from entering the equipment. Cleaning can be done with a soft brush or a hair dryer, but be careful not to damage electrical components.

(2) Regularly check whether the cable connection is firm to avoid looseness or poor contact. If damaged or frayed cables are found, they should be replaced promptly.

(3) According to the manufacturer's recommendations, regularly lubricate and maintain the bearings and transmission components of the servo motor. Use appropriate lubricants and follow correct lubrication methods and cycles.

(4) Ensure that the operating temperatures of the servo motor and controller are within the normal range. Avoid excessive temperatures that may cause motor overheating or controller failure. If necessary, a radiator or fan can be installed to reduce the temperature.

(5) Regularly calibrate parameters such as position, speed and torque of the servo motor to ensure its accuracy and stability. Perform appropriate calibration operations according to the manufacturer's recommendations.![]()

(6) If a fault or abnormality is found in the servo motor control system, troubleshoot it in a timely manner. You can refer to the device manual, technical support provided by the manufacturer, or professional help to solve the problem.

(7) Carry out regular maintenance work according to the manufacturer's recommendations, such as replacing parts, checking electrical connections, updating software, etc. Regular maintenance can extend the life of your equipment and maintain its performance -

How to extend the service life of servo motor?

12/25/2023 at 00:57 • 0 commentsServo motoris a common industrial motor that often appears in various fields such as automated production lines, machining centers, medical equipment, and semiconductor equipment. This kind of motor has the advantages of high precision, high speed, and high anti-interference. In order to ensure the normal operation of the servo motor and extend the service life of the servo motor, its maintenance and upkeep work is particularly important. To do this we need to do the following things.

![]()

1. Regularly check the contact and appearance of the motor cable, especially at the interface where the wire enters the servo motor, because interruptions or disconnections may occur during movement.

2. Regularly check the contact of the motor torque cable and maintain good contact. You can insist on checking once every three months.

3. Regularly check the interface between the motor and the power module and ensure that the connection is firm.

4. Check the servo motor system regularly and keep it clean. In order to prevent dust, oil, liquid and other debris from entering the inside of the motor and causing motor failure, we need to clean the air outlet and radiator of the servo motor regularly and ensure good ventilation.

5. Regularly check the indicator lights and fault codes on the servo motor control board and determine any existing faults.

6. Back up the operating program and parameters before and after the normal operation of the servo motor. Backup programs and parameters can help us quickly restore the normal operation of the motor when necessary.

7. Lubrication: Bearings, gears and other components in the servo motor require lubricating oil or grease regularly. The time interval for adding lubricating oil or grease should be determined according to the use of the motor, and should generally be done every quarter or half a year.

8. Stability: The servo motor needs to maintain stability when working. When the power supply voltage is unstable or the motor is overloaded, the motor may experience vibration or noise problems. The power supply voltage should be adjusted in time or a suitable motor should be replaced.

9. Temperature: The servo motor will generate a certain amount of heat when working. The temperature of the motor should be checked in time. If the temperature of the motor is too high, it may cause damage to the motor or unstable operation. It should be stopped in time and the fault should be eliminated.

![]()

During regular maintenance, we need to check the missing and missing parts and repair or replace them in time. If the problem part is not repaired or replaced, further damage to other parts of the motor may result.

In addition, during regular maintenance, we need to conduct a thorough cleaning of the servo motor system. The cables of the servo motor need to be moved and cleaned, usually using a pneumatic electrostatic blower for efficient cleaning.

For servo motors that have not been used for a long time, we need to clean, vacuum and inspect them before restarting them. This ensures that the motor is in optimal condition before restarting, avoiding any problems when starting to use it.

In general, routine maintenance of servo motors is the key to ensuring normal operation of the motor and extending its life. In daily maintenance, attention needs to be paid to issues such as motor cleaning, lubrication, connection inspection, stability and temperature. Regular maintenance and inspection, and timely troubleshooting can effectively protect the normal operation of the motor. At the same time, it can also appropriately extend the service life of the motor and reduce the cost of equipment maintenance and replacement.

-

Getting ready before fixing a brushless DC motor

12/20/2023 at 02:40 • 0 commentsWe'll go over a few things you should know before taking a brushless DC motor apart and fixing it here. I hope it's useful.

![]()

(1) You should dust and wipe the motor's surface to remove any dirt before attempting to disassemble it.

(2) After deciding on a good working location, tidy up the area before disassembling the motor.

(3) Understand the motor's structural features and technical maintenance requirements.

(4) Assemble the equipment and tools needed to disassemble the motor, including any specialized tools.