-

Visualizing the mechanical properties of 3D-printing filaments (BASF Ultrafuse data)

11/16/2022 at 09:15 • 1 commentThe range of filaments for FDM (Fused deposition model) printing is vast. PLA, PETG, ABS, ASA, PA, PP, TPU, etc., each type of plastic has different mechanical characteristics: more or less stiff, more or less resistant to impacts in particular. Manufacturers sometimes provide mechanical test data (in a technical data sheet or TDS). In the BASF Ultrafuse® range ( https://www.ultrafusefff.com/ ), these data are quite rich, with tests of samples printed in 3 directions: flat, on edge or upright, which gives an idea of the performance of the parts in all directions of space, including on a Z axis perpendicular to the printing layers. As the Ultrafuse® range is quite comprehensive, and mechanical tests are provided for each filament, there is a valuable data set available to provide a wide view of the mechanical properties of the main types of plastic.

Sample mechanical data as provided by BASF (datasheet for PLA) One limitation is that these raw figures are not very meaningful and difficult to compare quickly between types of plastic, and as is often the case, a graphical representation would allow a better understanding of how plastics compare to each other. This is the purpose of this article: to summarise the twenty or so data sheets available in a few graphs, to see at a glance the main differences between plastic types.

Analysed filaments:

- PLA (Polylactic acid)

- PLA PRO1 (high quality PLA)

- PET (Polyethylene terephthalate)

- rPET (recycled PET)

- ABS (Acrylonitrile butadiene styrene)

- ABS fusion+ (easy to print ABS)

- ASA (Acrylonitrile styrene acrylate)

- PP (Polypropylene)

- PA (Polyamide = Nylon)

- PC ABS FR (blend Polycarbonate + ABS + fire retardant)

- TPU 85A (Thermoplastic Polyurethane, flexible filament, shore 85A)

- TPU 95A (flexible, shore 95A)

- TPU 64D (semi-flexible, shore 64D)

- TPS 90A (rubber-like flexible SEBS, shore 90A)

Analysed fibre-filled filaments:

- PA6 GF30 (Nylon filled with 30% of glass fibres)

- PAHT CF15 (Nylon filled with 15% of carbon fibres)

- PC GF30 (Polycarbonate filled with 30% of glass fibres)

- PET CF15 (PET filled with 15% of carbon fibres)

- PP GF30 (PP filled with 30% of glass fibres)

The following Ultrafuse® filaments were not included in the mechanical analysis: BVOH and HiPS* (support filaments), PEI and PPSU (filaments to be printed above 300°C), TPC 45D (no mechanical data).

(* HiPS actually has interesting mechanical properties and will be included in a future version of this report)

The mechanical tests carried out by BASF are of three types:

- Tension tests (ISO 527). In this test, the sample is progressively stretched between two clamps, which allows to measure its tensile stiffness, its strength (maximum supported stress), and its maximum elongation before breaking.

- Bending tests (ISO 178). In this test, the sample is progressively bent sideways, to measure its bending (or flexural) stiffness, strength (maximum stress supported) and maximum bending before breaking.

- Impact tests (ISO 179-2 and 180). For these tests, a swinging hammer is used, and the energy absorbed to break the sample is measured. BASF conducts this test using two closely related methods: Charpy and Izod, and for each using a sample with or without a notch.

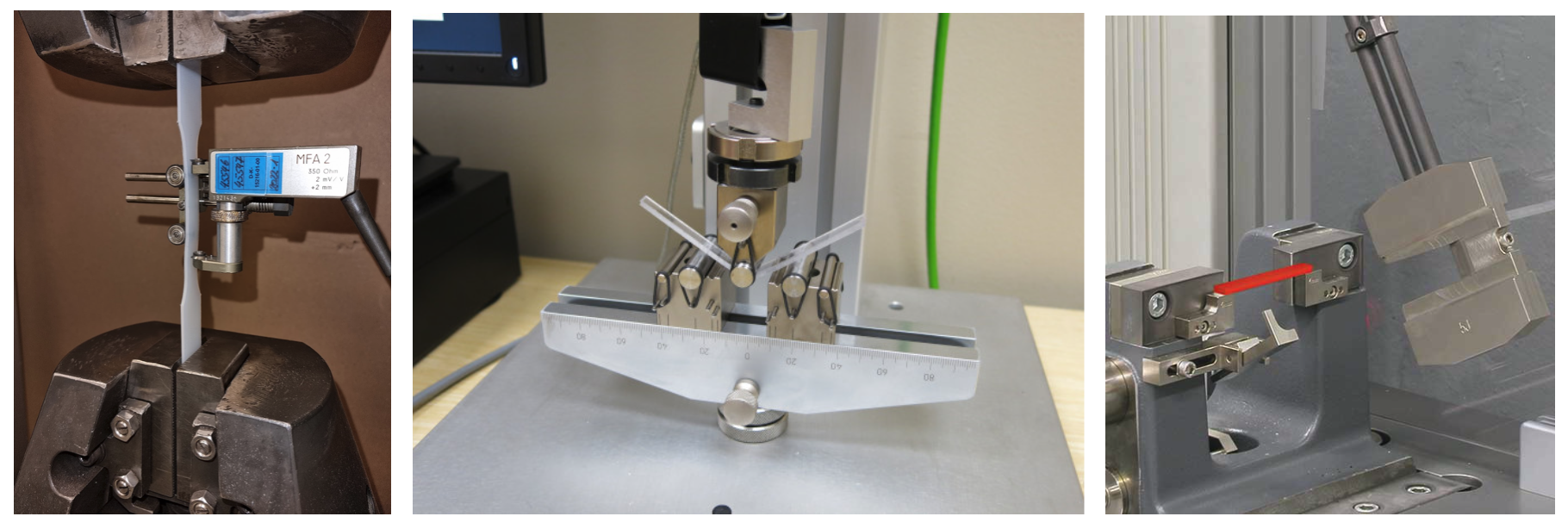

Examples of devices used for mechanical testing. From left to right: tensile test, bending test, Charpy impact test. (sources : iam-approved.com / testresources.net / k-labor.de) Tension test: Stiffness

A first interesting mechanical property of a plastic is its stiffness, i.e. its ability not to deform when a force is applied to it. In a tension test, stiffness is measured by a variable called Young's modulus, in MPa (Megapascal). The modulus is simply the ratio of the applied pressure to the observed deformation. For example, if a weight of 200 N (~20 kg) is suspended from a rod with a cross-section of 1 cm2, and the rod elongates by 0.4%, the Young's modulus is (200 / 0.0001) / 0.004 = 500 MPa. The higher the value of Young's modulus,...

Read more

Emmanuel de Margerie's pages

Scientist working on animal flight. Likes to build devices for science. Also into RC gliders and cars.