-

Power Electronics in Aerospace and Defense: Empowering High-Performance Systems

08/22/2023 at 08:13 • 0 commentsIntroduction:

Power electronics technology plays a critical role in the aerospace and defense industries by enabling efficient power management, control, and conversion in high-performance systems. From aircraft propulsion systems to military vehicles and satellite communications, power electronics empowers the operation and performance of aerospace and defense systems. In this blog, we will explore the significance of power electronics in aerospace and defense applications, its benefits, and other factors that contribute to the advancement of high-performance systems.

![]()

Benefits of Power Electronics in Aerospace and Defense:

1. Efficient Power Conversion: Power electronics enables efficient power conversion in aerospace and defense systems, optimizing energy usage and improving overall system efficiency. By employing power electronic converters, such as inverters and converters, electrical power can be converted from one form to another with minimal losses. Efficient power conversion enhances fuel efficiency, extends mission endurance, and reduces the weight and size of power systems, contributing to improved performance and increased operational range.

2. Motor Control and Drive Systems: Power electronics technology provides precise control over motors and drive systems in aerospace and defense applications. From electric actuators in aircraft control surfaces to propulsion systems in unmanned vehicles, power electronics enables accurate motor control and enhances system responsiveness. Advanced motor control algorithms, coupled with power electronic drives, offer improved efficiency, reliability, and fine-tuned performance characteristics. This level of control is crucial for achieving optimal system operation, reducing maintenance needs, and enhancing overall mission success.

3. Power Quality and Reliability: Power electronics devices, such as uninterruptible power supplies (UPS) and power conditioning units (PCUs), ensure power quality and reliability in aerospace and defense systems. These devices filter out electrical noise, voltage fluctuations, and other power disturbances, providing clean and stable power to critical equipment and sensitive electronics. Power quality and reliability are essential for the operation of navigation systems, communication systems, avionics, and other mission-critical components, ensuring continuous and uninterrupted operation.

4. High Power Density and Lightweight Design: Power electronics advancements have led to the development of high-power density and lightweight systems for aerospace and defense applications. The ability to handle higher power levels within smaller and lighter packages is crucial for reducing weight and maximizing space utilization in aircraft, spacecraft, and military vehicles. Power electronics technologies, such as wide-bandgap semiconductors and advanced cooling techniques, enable the design of compact and lightweight power systems without compromising performance and reliability.

5. Electromagnetic Compatibility (EMC): Power electronics devices are designed with electromagnetic compatibility in mind, ensuring that they do not interfere with or experience interference from other electronic systems. Aerospace and defense applications often involve complex electromagnetic environments, such as radar systems and communication networks. Power electronics systems with effective EMC measures minimize electromagnetic interference (EMI), allowing for reliable and interference-free operation of critical equipment and systems.

Other Factors in Power Electronics for Aerospace and Defense:

1. Thermal Management: Thermal management is a crucial aspect of power electronics in aerospace and defense applications. Power electronics devices generate heat during operation, which needs to be effectively dissipated to maintain optimal performance and reliability. Advanced cooling techniques, such as liquid cooling, heat pipes, and thermal interface...

Read more -

Sustainable Hardware Design: Reducing Environmental Impact through Innovation

08/21/2023 at 08:17 • 0 commentsIntroduction:

In an era of increasing environmental awareness, sustainable practices have become essential in all aspects of our lives, including technology. Hardware design, which encompasses the development and production of electronic devices, plays a significant role in shaping our environmental impact. Sustainable hardware design focuses on minimizing resource consumption, reducing electronic waste, and incorporating eco-friendly materials and manufacturing processes. By adopting sustainable design principles, hardware designers can contribute to a more sustainable future and help mitigate the environmental impact of electronic devices. In this blog, we will explore the importance of sustainable hardware design, the benefits it brings, and other key factors in reducing the environmental impact of electronic devices.

![]()

Benefits of Sustainable Hardware Design:

1. Reduced Resource Consumption: Sustainable hardware design aims to minimize resource consumption throughout the lifecycle of electronic devices. By adopting efficient circuit designs, low-power components, and power management techniques, designers can optimize energy usage, leading to reduced energy consumption and a smaller carbon footprint. Additionally, sustainable design practices consider the selection and sourcing of materials, prioritizing those with lower environmental impacts and promoting responsible resource management. By reducing resource consumption, sustainable hardware design contributes to the preservation of natural resources and helps combat climate change.

2. Extended Product Lifespan: One of the fundamental principles of sustainability is to extend the lifespan of products. Through thoughtful hardware design, devices can be built to withstand the test of time and resist obsolescence. By using durable materials, modular designs, and providing opportunities for software updates, hardware designers can enhance the longevity of devices. Extending the lifespan of electronic devices reduces the need for frequent replacements, conserves resources, and reduces electronic waste. It also promotes a more sustainable consumer culture by encouraging users to value durability and prioritize repair over replacement.

3. E-Waste Reduction: Electronic waste, or e-waste, is a growing environmental concern. The rapid advancement of technology and the short lifespan of many electronic devices contribute to the accumulation of e-waste globally. Sustainable hardware design aims to reduce e-waste by incorporating design elements that promote recycling, repairability, and responsible disposal. By using easily recyclable materials, minimizing the use of hazardous substances, and implementing take-back programs, hardware designers can facilitate the recycling and proper disposal of devices at the end of their lifecycle. This not only reduces the environmental impact of e-waste but also helps recover valuable materials and reduce the need for raw material extraction.

4. Energy Efficiency: Energy efficiency is a critical aspect of sustainable hardware design. By optimizing circuit designs, selecting energy-efficient components, and implementing power management techniques, hardware designers can reduce energy consumption during device operation. Energy-efficient devices not only contribute to lower electricity bills for users but also reduce the overall demand for energy and the associated environmental impact. Additionally, energy-efficient hardware design extends battery life for portable devices, reducing the need for frequent charging and the disposal of worn-out batteries.

5. Eco-Friendly Materials: Sustainable hardware design promotes the use of eco-friendly materials. Designers can prioritize materials with lower environmental impacts, such as recycled plastics, bio-based materials, and non-toxic substances. By selecting eco-friendly materials, hardware designers reduce the extraction of finite resources, minimize pollution...

Read more -

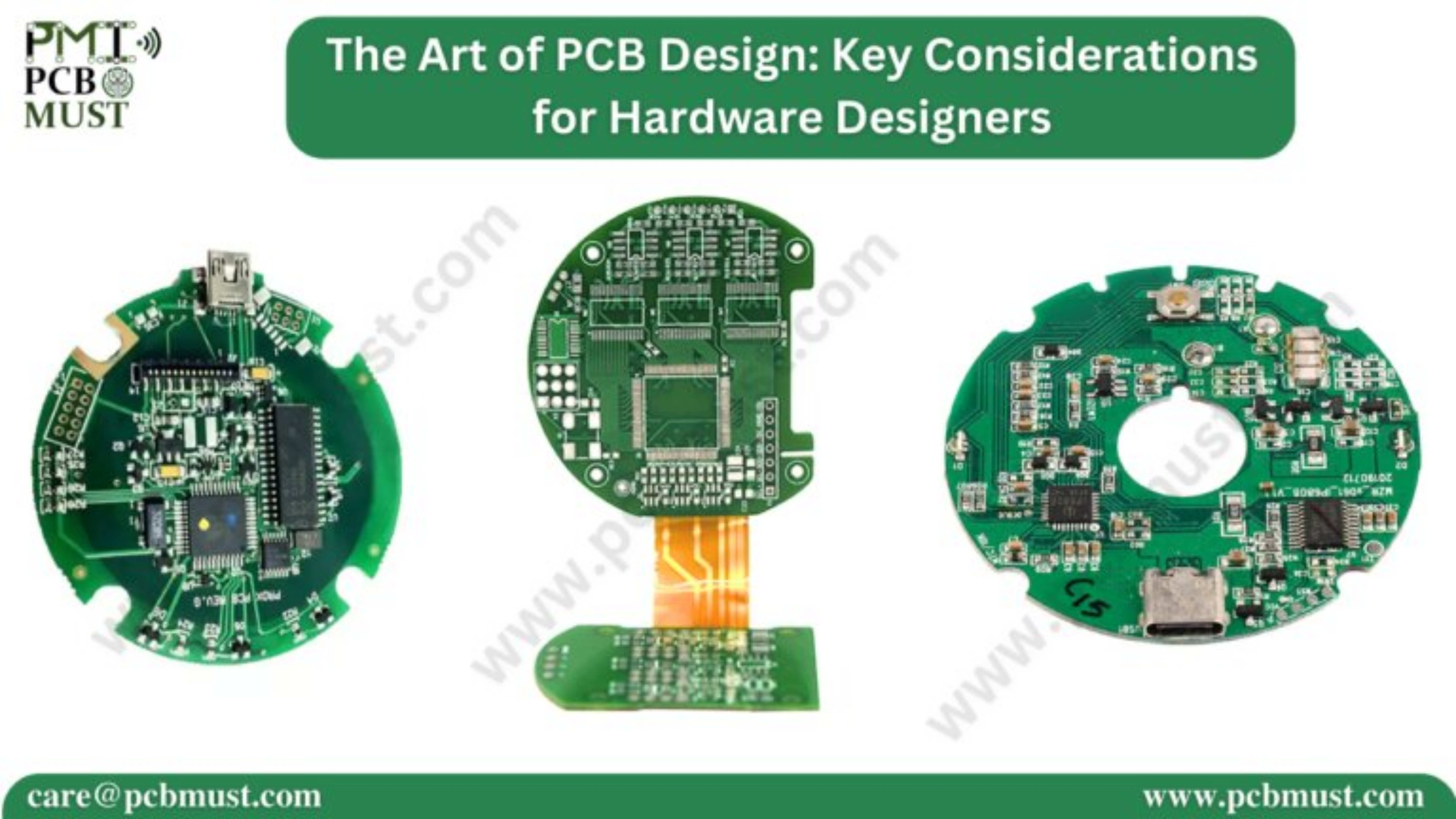

The Art of PCB Design: Key Considerations for Hardware Designers

08/18/2023 at 07:02 • 0 commentsIntroduction:

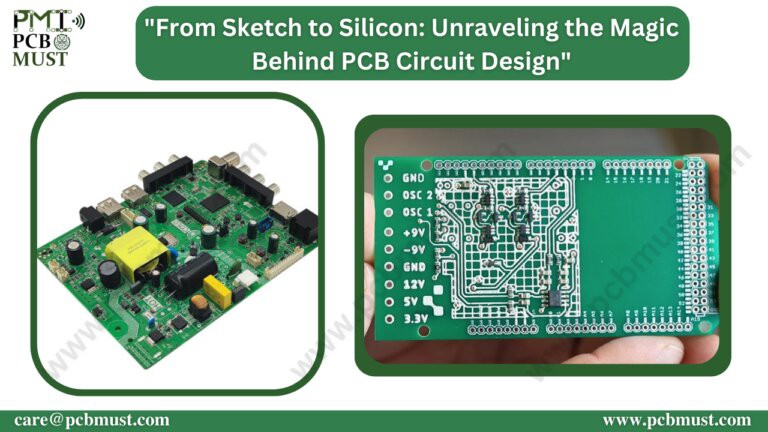

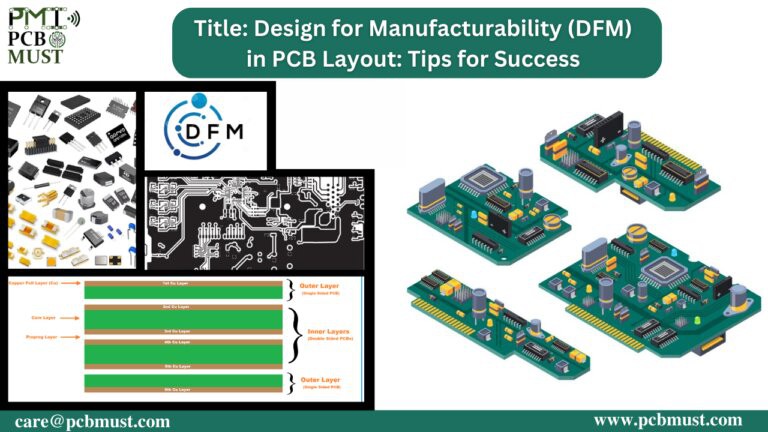

Printed Circuit Board (PCB) design is a critical aspect of hardware design that involves creating the physical layout and interconnections of electronic components. It is often referred to as the “art” of hardware design due to its intricate nature and the significant impact it has on the overall performance, reliability, and manufacturability of electronic devices. In this blog, we will explore the key considerations and best practices that hardware designers should keep in mind when approaching PCB design. From component placement and routing to signal integrity and manufacturability, mastering the art of PCB design is essential for creating successful hardware solutions.

![]()

Benefits of Effective PCB Design:

1. Signal Integrity and Performance: A well-designed PCB layout plays a crucial role in maintaining signal integrity and ensuring optimal performance of electronic circuits. Careful consideration of trace routing, signal paths, and ground planes helps minimize signal interference, crosstalk, and noise. By optimizing signal integrity, hardware designers can achieve faster data transfer rates, reduced latency, and improved overall performance of electronic devices.

2. Thermal Management: Efficient thermal management is essential for the reliable operation of electronic components. PCB design factors such as component placement, thermal vias, and copper planes influence the dissipation of heat generated during operation. By implementing proper thermal design techniques, hardware designers can prevent overheating, extend the lifespan of components, and enhance the overall reliability of the device.

3. Miniaturization and Space Optimization: With the continuous demand for smaller and more compact electronic devices, PCB design plays a critical role in achieving miniaturization and space optimization. By carefully arranging components, employing multilayer PCBs, and utilizing surface mount technology (SMT), hardware designers can maximize the utilization of available space, enabling sleek and compact devices without compromising functionality.

4. Electromagnetic Compatibility (EMC): EMC is the ability of electronic devices to operate without causing interference or being susceptible to interference from other devices. Effective PCB design helps ensure electromagnetic compatibility by employing proper grounding techniques, minimizing loop areas, and separating sensitive analog and digital components. By addressing EMC considerations during PCB design, hardware designers can minimize the risk of electromagnetic interference (EMI) and enhance the overall reliability and performance of the device.

5. Manufacturability and Cost Optimization: A well-designed PCB layout takes into account manufacturability and cost optimization. Design considerations such as component availability, ease of assembly, and efficient production processes help reduce manufacturing costs and minimize the time-to-market. Collaboration with manufacturers during the design phase facilitates the smooth transition from prototype to mass production, ensuring high-quality and cost-effective manufacturing.

Other Factors in PCB Design:

1. Component Placement and Routing: Careful component placement is crucial for optimal signal integrity, thermal management, and space optimization. Placing components in close proximity to minimize trace lengths reduces signal propagation delays and improves performance. Hardware designers must also consider factors such as power and ground plane placement, decoupling capacitors, and proper routing techniques to minimize noise and interference. Additionally, the layout should consider accessibility for assembly and repair, as well as comply with safety and clearance requirements.

2. Layer Stackup and Routing Strategy: The layer stackup and routing strategy are key considerations in PCB design. Deciding the number of layers,...

Read more -

Tinkering with Transistors: A Guide to Analog Circuit Design for Keyboards

08/17/2023 at 06:04 • 0 commentsIntroduction

In the realm of music and technology, analog circuit design has been the driving force behind the creation of timeless and expressive keyboard instruments. From the iconic sound of vintage synthesizers to the warm tones of classic electric pianos, analog circuitry has left an indelible mark on the world of music. At the heart of analog circuit design are transistors – the fundamental building blocks of countless electronic devices. In this blog, we embark on a journey of tinkering with transistors, exploring the art and science of analog circuit design for keyboards. We will uncover the benefits of transistors in shaping the sonic character of analog keyboards, understand the various factors that influence their implementation, and celebrate the magic of analog circuitry in the world of music.

![]()

Benefits of Transistors in Analog Circuit Design for Keyboards

1. Amplification and Signal Processing: Transistors serve as versatile amplifiers in analog circuit design, playing a crucial role in boosting the weak audio signals generated by keyboard instruments. As musicians press keys and create sounds, the analog circuitry relies on transistors to amplify those signals, ensuring that the resulting sounds are audible and robust. Transistors also enable various signal processing stages, allowing for creative manipulation of the sound, such as filtering, modulation, and distortion.

2. Low Noise and High Fidelity: In analog keyboards, where clarity and purity of sound are paramount, low noise characteristics are essential. Transistors, when properly designed, offer low noise performance, ensuring that the keyboard produces clear and pure sounds across the entire frequency spectrum. This high-fidelity audio output is one of the defining qualities of analog keyboards, capturing the subtle nuances and harmonics that contribute to their rich and organic sound.

3. Real-Time Control and Modulation: Transistors play a significant role in enabling real-time control and modulation of the sound generated by keyboard instruments. By using voltage-controlled transistors, musicians can modify various parameters, such as pitch, amplitude, and timbre, in response to their playing style and preferences. This real-time control empowers musicians to craft dynamic and expressive performances, adding a personal touch to their musical expression.

4. Modularity and Customization: Transistors facilitate the modular design of analog circuits, allowing for flexibility and customization in the construction of keyboard instruments. With modular circuitry, musicians and designers can mix and match different transistor-based modules to create unique and innovative keyboard configurations. This modularity opens up a world of creative possibilities, encouraging experimentation and pushing the boundaries of sound design.

Other Factors in Analog Circuit Design for Keyboards

1. Types of Transistors: There are several types of transistors used in analog circuit design, each with its unique characteristics and applications. The most common types are Bipolar Junction Transistors (BJTs) and Field-Effect Transistors (FETs). BJT transistors are known for their low input impedance and high gain, making them suitable for low-noise audio amplification. FET transistors, on the other hand, have low input capacitance, making them ideal for high-impedance audio circuits.

2. Power Supply and Voltage Levels: The choice of power supply and voltage levels is critical in analog circuit design for keyboards. Different circuits require specific voltage levels to function optimally, and designers must carefully manage power supply noise to ensure high-fidelity audio output. Proper power supply design is essential for preventing undesirable artifacts and interference in the sound.

3. Signal Routing and Patching: Analog keyboards often feature patch points, allowing musicians to route signals between different modules. Proper signal routing and patching...

Read more -

Troubleshooting Analog Keyboards: Common Issues and Solutions

08/15/2023 at 08:13 • 0 commentsIntroduction

Analog keyboards have an undeniable charm and appeal, known for their warm and organic sound that resonates with musicians and enthusiasts alike. However, like any electronic instrument, analog keyboards can encounter issues from time to time. Troubleshooting these issues requires a combination of technical knowledge and practical problem-solving skills. In this blog, we will explore common issues that analog keyboards may face, delve into their possible causes, and provide practical solutions to help you keep your beloved instrument in top condition. Let’s embark on the journey of troubleshooting analog keyboards, ensuring that their timeless allure continues to captivate our hearts and ears.

![]()

Benefits of Analog Keyboards and Their Maintenance

1. Warm and Organic Sound: Analog keyboards are cherished for their warm and organic sound, generated by voltage-controlled circuits and natural harmonics. Maintaining the integrity of these circuits is essential to preserve the unique sonic character of analog instruments.

2. Expressive and Dynamic Performance: Analog keyboards offer expressive and dynamic performance capabilities. Troubleshooting and resolving issues promptly ensure that musicians can maintain control over parameters like pitch, amplitude, and modulation in real-time.

3. Vintage Aesthetics and Craftsmanship: Many analog keyboards boast timeless and classic design aesthetics, showcasing exquisite craftsmanship. Proper maintenance ensures that these vintage instruments continue to look and feel as stunning as they sound.

4. Longevity and Investment: Analog keyboards, particularly vintage ones, can be valuable investments. Regular maintenance and prompt troubleshooting can extend their lifespan and preserve their value over time.

Common Issues and Troubleshooting Solutions

1. No Sound Output: One of the most common issues is no sound output. This can be due to faulty audio cables, a malfunctioning power supply, or a problem with the output jack or internal audio path. Start by checking the audio cables and connections to ensure they are secure. If that doesn’t resolve the issue, inspect the power supply for any signs of damage or malfunction. Additionally, try connecting the keyboard to a different amplifier or audio interface to rule out any external issues. If the problem persists, it might be a more complex internal issue that requires professional repair.

2. Intermittent Sound or Crackling Noises: Intermittent sound or crackling noises can result from dirty or oxidized contacts in potentiometers (knobs), switches, or jacks. To address this issue, apply contact cleaner to the affected components. Turn the knobs and toggle switches back and forth several times after applying the cleaner to remove any dirt or oxidation. Be sure to use a cleaner specifically designed for electronic components. If the problem persists, it may require deeper inspection and repair by a qualified technician.

3. Sticky or Stuck Keys: Over time, keys on analog keyboards may become sticky or stuck due to dust, debris, or worn key bushings. Carefully remove the keybed or individual keys (if possible) and clean the key contacts and key bushings with a soft cloth and isopropyl alcohol. Exercise the keys after cleaning to ensure smooth movement. If the problem persists, consult the manufacturer’s service manual or seek professional assistance.

4. Pitch Drift or Unstable Tuning: Analog keyboards with voltage-controlled oscillators (VCOs) can experience pitch drift or unstable tuning due to fluctuations in temperature or aging components. Calibrate the VCOs following the manufacturer’s instructions or consult a service manual. This process involves adjusting the VCOs to produce accurate and stable pitches. Keep in mind that periodic calibration may be necessary, especially for vintage instruments.

5. Unresponsive Modulation or Control Inputs: Unresponsive modulation or control inputs can be caused by faulty...

Read more -

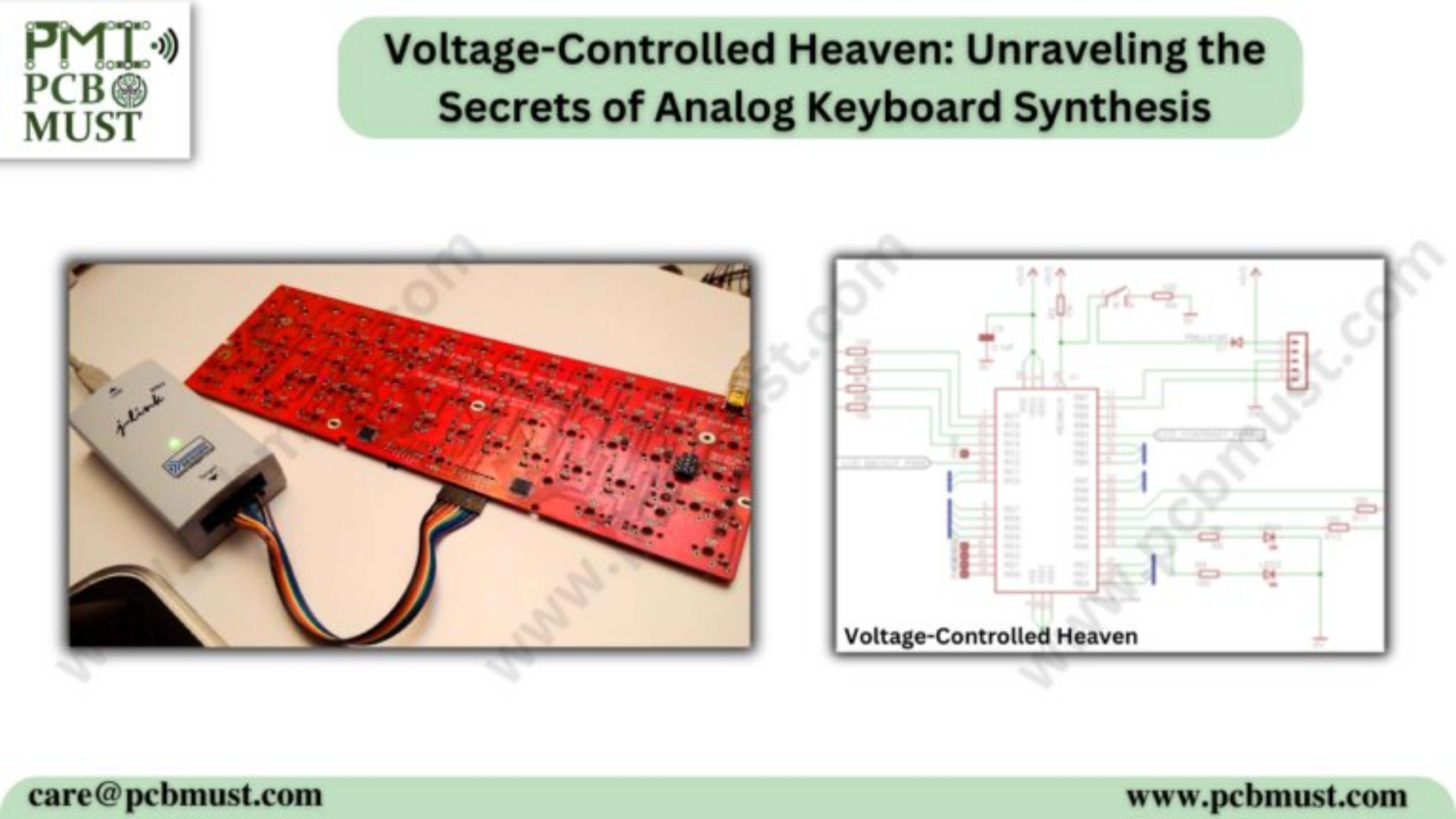

Voltage-Controlled Heaven: Unraveling the Secrets of Analog Keyboard Synthesis

08/14/2023 at 06:22 • 0 commentsIntroduction

In the world of music, the allure of analog keyboard synthesis remains timeless and captivating. These iconic instruments have shaped the sound of generations, from the mesmerizing warmth of vintage synthesizers to the expressive charm of classic electric pianos. At the heart of analog keyboard synthesis lies the magic of voltage-controlled heaven, a realm where analog circuitry weaves its sonic tapestry. In this blog, we embark on a journey of uncovering the secrets of analog keyboard synthesis, exploring the art and science of voltage-controlled circuits. We will delve into the benefits of voltage-controlled synthesis, understand the other factors that shape its unique character, and celebrate the enduring allure of analog keyboards.

![]()

Benefits of Voltage-Controlled Synthesis in Analog Keyboards

1. Expressive Sound Modulation: One of the key benefits of voltage-controlled synthesis is its ability to modulate various parameters in real-time, allowing musicians to shape and sculpt the sound with expressiveness and nuance. By applying voltage to different components like oscillators, filters, and amplifiers, musicians can create dynamic and evolving soundscapes. This real-time control empowers artists to infuse their performances with emotion and creativity, making each rendition a deeply personal and expressive journey.

2. Hands-On Sound Design: Voltage-controlled synthesis offers a hands-on and tactile approach to sound design. Musicians interact with the instrument directly, manipulating knobs, sliders, and patch cables to sculpt the sonic landscape. This intimate connection between musician and instrument fosters a deeper understanding of sound synthesis and nurtures a sense of exploration and experimentation. By tinkering with the circuits, musicians become artisans, shaping sound with their hands and hearts.

3. Rich and Harmonically Complex Tones: Analog keyboards, with their voltage-controlled circuits, generate rich and harmonically complex tones that resonate with listeners. Unlike their digital counterparts, analog circuits produce natural harmonics and overtones, contributing to the warm and organic sound of these instruments. The subtle imperfections of analog synthesis add character and depth to the music, making each performance unique and evocative.

4. Endless Sonic Possibilities: Voltage-controlled synthesis offers endless sonic possibilities due to its modular and patchable nature. Musicians can connect various modules and components in different ways, creating custom signal paths and exploring new sonic territories. This flexibility allows for an infinite range of sound design options, making analog keyboards a playground for creative expression and sonic exploration.

Other Factors in Analog Keyboard Synthesis

1. Oscillators: Oscillators are the primary sound generators in analog keyboards. Voltage-controlled oscillators (VCOs) produce various waveforms such as sine, sawtooth, square, and triangle waves. By manipulating the voltage that controls the oscillators’ frequency, musicians can create different pitches and timbres. VCOs play a central role in shaping the fundamental character of the sound.

2. Filters: Filters play a significant role in shaping the timbre of the sound. Voltage-controlled filters (VCFs) allow specific frequencies to pass through while attenuating others. By adjusting the voltage controlling the filter cutoff, musicians can control the brightness and character of the sound. VCFs introduce a dynamic and expressive dimension to the sound design, allowing for evolving textures and tonal changes.

3. Amplifiers: Amplifiers control the volume and dynamics of the sound. Voltage-controlled amplifiers (VCAs) determine how the amplitude of the audio signal responds to changes in voltage. This voltage control allows for dynamic and expressive variations in volume, contributing to the musical performance. VCAs enable musicians to shape the articulation and emotional impact...

Read more -

Building Blocks of Analog Keyboards: Understanding Oscillators and Filters

08/12/2023 at 06:47 • 0 commentsIntroduction

In the world of music, analog keyboards have a timeless appeal, captivating musicians with their warm and rich sounds. These instruments rely on the magic of analog circuitry, which forms the foundation of their unique and expressive sonic character. At the heart of this circuitry are two essential building blocks: oscillators and filters. Oscillators generate the raw sound waveforms, while filters shape and sculpt the sound, allowing musicians to create a diverse range of tones. In this blog, we will delve into the fundamental elements of analog keyboards, exploring the benefits of oscillators and filters, understanding their role in sound synthesis, and uncovering the factors that influence their design.

![]()

Benefits of Oscillators and Filters in Analog Keyboards

1. Versatile Sound Generation: Oscillators are the workhorses of sound generation in analog keyboards. They produce various basic waveforms, such as sine, sawtooth, square, and triangle waves, forming the foundation of a wide range of sounds. Filters, on the other hand, allow musicians to sculpt these waveforms, adding richness and complexity to the sound. The combination of oscillators and filters enables musicians to create versatile and expressive timbres that span from smooth and ethereal to gritty and aggressive.

2. Warm and Organic Tones: One of the most cherished qualities of analog keyboards is their warm and organic tones. The continuous and smooth signal produced by oscillators and the natural resonance of filters contribute to this desirable sonic character. Unlike digital synthesizers, analog keyboards produce harmonically rich and naturally evolving sounds, creating a connection with musicians and listeners alike.

3. Real-time Sound Shaping: Oscillators and filters in analog keyboards offer real-time sound shaping capabilities. Musicians can adjust various parameters, such as frequency, resonance, and modulation depth, in real-time, allowing for immediate and intuitive control over the sound. This hands-on approach to sound sculpting empowers musicians to shape their performances with a deeply personal touch.

4. Dynamic and Expressive Performance: The interplay of oscillators and filters adds a dynamic and expressive dimension to performances. Modulating filter parameters with envelope generators or LFOs (Low-Frequency Oscillators) enables musicians to create evolving and animated sounds. This expressive potential enhances musical storytelling and emotional communication through the instrument.

Other Factors in Understanding Oscillators and Filters in Analog Keyboards

1. Types of Oscillators: Analog keyboards can employ different types of oscillators, each with its unique characteristics. Voltage-Controlled Oscillators (VCOs) are common in many analog synthesizers and offer precise tuning control. Digital Waveform Generators (DWGs) use digital techniques to generate waveforms and can provide a broader range of sound possibilities. The choice of oscillator type influences the tonal palette and capabilities of the instrument.

2. Waveform Mixing: Oscillators often include waveform mixing options, allowing musicians to combine multiple waveforms to create complex and layered sounds. Waveform mixing adds depth and texture to the sound, making it an essential feature in sound design.

3. Filter Types: Analog keyboards feature various filter types, such as low-pass, high-pass, and band-pass filters. Each filter type shapes the sound in distinct ways, emphasizing or attenuating certain frequency ranges. The choice of filter type greatly impacts the tonal character and versatility of the instrument.

4. Filter Resonance: The resonance parameter in filters enhances specific frequencies, creating a resonant peak around the cutoff frequency. At higher resonance levels, filters can produce a distinct “self-oscillation” effect, where the filter itself generates a pitched sound. This creative use of resonance expands the sonic possibilities...

Read more -

Mastering the Basics: An Introduction to Analog Circuit Design for Keyboards

08/11/2023 at 10:18 • 0 commentsIntroduction

In the fast-paced world of technology, keyboards have become an integral part of our daily lives. From traditional desktop keyboards to cutting-edge mechanical gaming keyboards, these input devices have evolved to cater to diverse needs and preferences. Amidst the digital revolution, analog circuit design remains a fundamental aspect of keyboard technology. Understanding the basics of analog circuit design is essential for keyboard enthusiasts, makers, and engineers seeking to create exceptional typing experiences. In this blog, we will delve into the fundamentals of analog circuit design for keyboards, exploring its benefits, key factors, and the significance of mastering these basics in the realm of modern keyboard

![]()

Benefits of Analog Circuit Design for Keyboards

1. Higher Fidelity and Sensitivity: Analog circuitry allows keyboards to achieve higher fidelity and sensitivity in detecting key presses. Unlike digital signals that offer discrete values, analog signals provide continuous variations in voltage, enabling precise and accurate measurement of keypress data. This heightened sensitivity results in a more responsive and tactile typing experience, enhancing user satisfaction and comfort during prolonged typing sessions.

2. Reduced Latency: Latency, the time between a keypress and the corresponding action on the screen, is a critical factor in keyboard performance. Analog circuits facilitate low-latency communication between the key switches and the computer, ensuring near-instantaneous feedback to users. This reduction in latency is particularly crucial for gamers and professionals who demand rapid and precise responses from their keyboards.

3. Customization and Flexibility: Analog circuit design offers greater flexibility and customization options for keyboard designers. They can fine-tune various parameters, such as actuation points, key travel distance, and tactile feedback, to create a personalized typing experience for different users. This adaptability empowers designers to cater to diverse preferences and typing styles, ultimately enhancing user comfort and productivity.

4. Energy Efficiency: Analog circuits contribute to improved energy efficiency in keyboards, particularly in wireless devices. Unlike digital circuits that consume power continuously for polling and processing, analog circuits draw power only when a key is pressed. As a result, energy consumption is minimized, prolonging battery life and reducing the environmental impact of keyboards.

Other Factors in Analog Circuit Design for Keyboards

1. Switch Types: The foundation of analog circuit design in keyboards lies in the switches themselves. Various types of switches, such as membrane, scissor, mechanical, or capacitive switches, offer distinct tactile feedback and actuation mechanisms. Each switch type contributes to the overall feel and performance of the keyboard, and designers must carefully choose the appropriate switch type based on the intended usage and user preferences.

2. Key Matrix Design: To minimize the complexity of wiring and reduce the number of connections, keyboards use a matrix layout for their keys. However, this design can introduce challenges like ghosting and crosstalk. Ghosting occurs when a keypress triggers unintended inputs, while crosstalk refers to interference between adjacent keys. Designers must optimize the key matrix layout to mitigate these issues and ensure accurate and reliable typing performance.

3. Debounce Circuitry: Mechanical switches can generate multiple signals due to bouncing contacts when a key is pressed or released. Debounce circuits are crucial in keyboard design to filter out these extraneous signals, preventing false inputs and ensuring smooth and accurate typing. Proper debounce circuitry guarantees a seamless typing experience without unintended keystrokes.

4. Analog-to-Digital Conversion (ADC): In modern keyboards, analog signals from the key switches must be converted...

Read more -

Creating Unique Tones: Analog Modulation Techniques for Keyboards

08/10/2023 at 06:35 • 0 commentsIntroduction

In the realm of music, keyboards have long been cherished for their ability to produce a diverse range of tones, from lush pads to soaring leads and everything in between. Behind the magic of these unique sounds lies the art of analog modulation, a technique that breathes life into the music. Analog modulation offers a wealth of creative possibilities, allowing musicians to shape and evolve their tones in real-time. In this blog, we will delve into the world of analog modulation techniques for keyboards, exploring the art and science of creating unique tones. We will uncover the benefits of analog modulation, understand the various modulation techniques available, and celebrate the endless potential of these expressive and versatile methods.

![]()

Benefits of Analog Modulation Techniques for Keyboards

1. Expressive and Dynamic Performances: Analog modulation techniques infuse performances with expressiveness and dynamism. By modulating various parameters such as pitch, amplitude, and timbre in real-time, musicians can add nuance and emotion to their playing. This expressiveness empowers artists to create captivating performances that resonate with listeners on a deep emotional level.

2. Versatility in Sound Design: Analog modulation opens up a world of versatility in sound design. Musicians can use modulation techniques to create a wide range of textures, from subtle and gentle movements to wild and unpredictable sonic landscapes. This versatility allows for experimentation and the exploration of new sonic territories.

3. Organic and Harmonically Rich Tones: Analog modulation imparts an organic and natural quality to the tones produced by keyboards. The continuous and smooth changes in parameters give rise to harmonically rich and evolving sounds, reminiscent of acoustic instruments. This organic quality adds warmth and depth to the music, captivating the ears and hearts of the audience.

4. Real-Time Control and Interaction: Analog modulation offers real-time control and interaction between different parameters. Musicians can manipulate the modulation sources, such as LFOs (Low-Frequency Oscillators), envelopes, and other voltage-controlled circuits, during performance. This real-time control allows for spontaneity and adaptability, making each rendition a unique musical experience.

Other Factors in Analog Modulation Techniques for Keyboards

1. Low-Frequency Oscillators (LFOs): LFOs are a fundamental modulation source in analog keyboards. They generate periodic waveforms at low frequencies, typically below the audible range. Musicians use LFOs to modulate various parameters, creating cyclic and rhythmic variations in the sound. Common LFO waveforms include sine, triangle, square, and sawtooth.

2. Envelope Generators: Envelope generators shape the evolution of sound over time. They produce voltage signals that control parameters like amplitude, filter cutoff, and pitch. ADSR (Attack, Decay, Sustain, Release) envelope generators are particularly popular, as they allow for precise control over the envelope’s shape.

3. Ring Modulation: Ring modulation is a technique where two audio signals are multiplied together, producing sum and difference frequencies. This process generates new harmonic content, resulting in metallic and bell-like tones. Ring modulation is often used to create unusual and otherworldly sounds in electronic music.

4. Frequency Modulation (FM): Frequency modulation involves modulating the frequency of one oscillator (the carrier) with the output of another oscillator (the modulator). FM synthesis produces complex and evolving timbres, allowing musicians to achieve bell-like, metallic, or even chaotic sounds.

5. Amplitude Modulation (AM): Amplitude modulation is the process of varying the amplitude of an audio signal using the output of another signal. AM synthesis can produce effects like tremolo or add harmonics to the original sound, enriching the overall timbre.

6. Sample...

Read more -

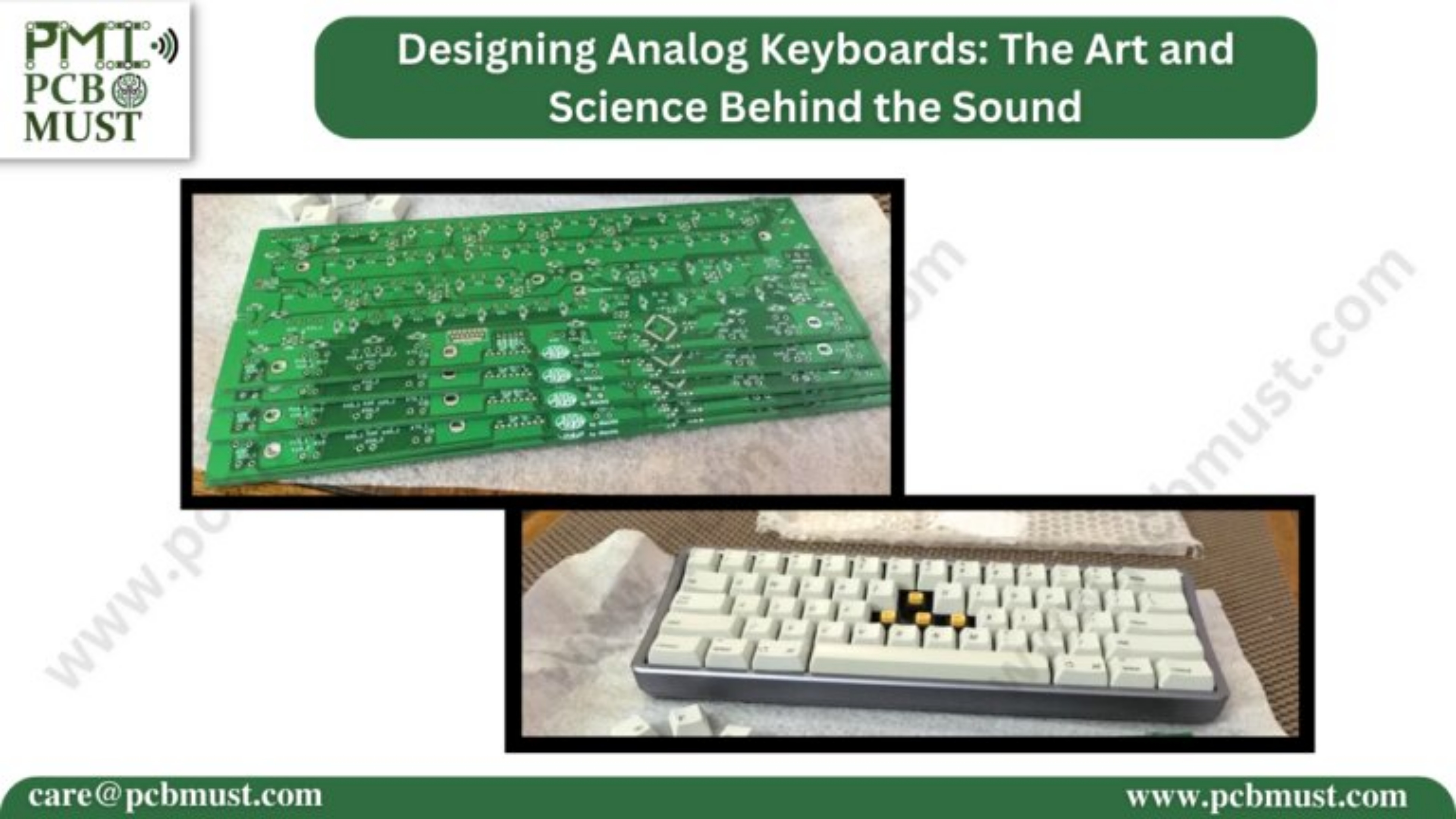

Designing Analog Keyboards: The Art and Science Behind the Sound

08/08/2023 at 09:07 • 0 commentsIntroduction

In a world dominated by digital technology, there exists a subculture of keyboard enthusiasts who revel in the charm of analog keyboards. These mechanical wonders, characterized by their distinct sound and tactile feedback, evoke nostalgia and a sense of connection to the past. Designing analog keyboards is a delicate fusion of art and science, where the choice of materials, switch types, and form factors all play a role in crafting the perfect typing experience. In this blog, we will delve into the art and science behind designing analog keyboards, exploring the benefits they offer, the various factors influencing their design, and the magic that makes them a beloved choice for typists and gamers alike.

![]()

Benefits of Analog Keyboards

1. Immersive Typing Experience: One of the primary attractions of analog keyboards is the immersive typing experience they provide. Unlike their membrane counterparts, every keypress on an analog keyboard elicits a tangible response. The tactile feedback and distinct sound of each keystroke offer typists a unique sense of connection to the keyboard. This immersive experience can turn the mundane task of typing into a delightful and enjoyable endeavor.

2. Precision and Responsiveness: Analog keyboards are renowned for their precision and responsiveness. The analog switches enable variable actuation points, meaning that the force required to register a keypress can be adjusted according to user preferences. This customization allows for a keyboard that adapts to the user’s typing style, resulting in enhanced typing speed and accuracy.

3. Durability and Longevity: The mechanical design of analog keyboards contributes to their exceptional durability. The key switches have a longer lifespan compared to membrane-based keyboards, often lasting for millions of keypresses without losing their performance. This longevity ensures that the keyboard remains a reliable companion for years to come, making it a worthy investment for keyboard enthusiasts.

4. Unique Sound Profile: One of the defining features of analog keyboards is their distinct sound profile. The clicky and tactile sound created by the switches adds an auditory dimension to the typing experience, giving typists an audible reassurance of their keystrokes. This satisfying sound profile has earned analog keyboards a dedicated following among users who appreciate the aesthetics of sound.

Other Factors in Designing Analog Keyboards

1. Switch Types: Switch selection is a critical factor in designing analog keyboards. Various switch types, such as Cherry MX, Gateron, or Topre, offer different tactile feedback and sound profiles. For instance, “clicky” switches produce an audible click sound upon actuation, while “linear” switches offer a smooth keystroke without an audible click. The choice of switch can significantly influence the overall typing experience, making it a vital consideration for keyboard designers.

2. Actuation Force and Distance: Actuation force refers to the amount of force required to register a keypress, while actuation distance is the distance the key must travel to activate the switch. Keyboard designers must carefully balance these factors to meet user preferences. Some typists prefer a lighter actuation force for faster typing, while others may prefer a heavier actuation force for increased typing precision. Likewise, the actuation distance can impact typing speed and fatigue, making it an essential consideration in the design process.

3. Keycap Material and Profile: Keycaps are another critical aspect of analog keyboard design. Different keycap materials, such as ABS or PBT plastic, can affect the sound and feel of keystrokes. Additionally, the keycap profile, such as spherical or cylindrical, can impact ergonomic comfort and typing accuracy. The combination of keycap material and profile contributes to the overall aesthetic and tactile experience of the keyboard.

4....

Read more -

Power Play: Optimizing Energy Efficiency in Electronics Design

08/07/2023 at 11:30 • 0 commentsIntroduction:

In an era where sustainability and energy efficiency are paramount, optimizing energy consumption in electronics design has become a critical focus. With the rapid advancement of technology and the increasing demand for portable devices, reducing power consumption has become essential to extend battery life, reduce environmental impact, and enhance user experience. In this blog post, we will explore the benefits of optimizing energy efficiency in electronics design, discuss important factors to consider, delve into other key considerations, and conclude with the significance of power optimization in the design process.

![]()

Benefits of Optimizing Energy Efficiency:

1. Extended Battery Life: One of the primary benefits of optimizing energy efficiency is the extension of battery life. By reducing power consumption, electronic devices can operate for longer durations without requiring frequent recharging. This enhances the user experience and convenience, especially for portable devices such as smartphones, tablets, and wearables.

2. Environmental Sustainability: Energy-Efficient Electronics Design contributes to environmental sustainability by reducing the overall energy consumption. Lower power requirements translate into decreased carbon emissions, conserving resources and minimizing the ecological impact associated with energy generation. By designing with energy efficiency in mind, designers can actively contribute to a greener future.

3. Cost Savings: Optimizing energy efficiency in electronics design can lead to cost savings. By reducing power consumption, companies and individuals can lower their energy bills and operational expenses. Additionally, energy-efficient designs often require smaller batteries or power supplies, resulting in reduced manufacturing and component costs.

4. Enhanced Performance: Energy optimization not only reduces power consumption but also enhances overall performance. By focusing on efficient power usage, designers can allocate resources effectively, minimize energy wastage, and optimize the performance of electronic devices. This ensures that the device operates smoothly and efficiently, providing a better user experience.

5. Competitive Advantage: In today’s market, energy efficiency has become a significant factor influencing consumers’ purchasing decisions. Designing energy-efficient products can give companies a competitive edge by meeting the growing demand for sustainable and eco-friendly solutions. It can also help build brand reputation as a responsible and environmentally conscious organization.

Important Factors in Optimizing Energy Efficiency:

1. System-Level Approach: Optimizing energy efficiency requires a system-level approach. Designers should consider the entire electronic system, including the hardware, firmware, and software components. By analyzing the power requirements and usage patterns at each level, designers can identify opportunities for optimization and implement energy-saving techniques.

2. Low-Power Components: Selecting low-power components is crucial in achieving energy efficiency. Choose components such as microcontrollers, sensors, and displays that are designed specifically for low-power operation. These components often incorporate power-saving features, such as sleep modes, dynamic voltage scaling, and power gating, which significantly reduce power consumption.

3. Power Management Techniques: Implementing effective power management techniques is essential for optimizing energy efficiency. Techniques such as dynamic power scaling, clock gating, and power gating allow designers to dynamically adjust power consumption based on the device’s operational requirements. By activating or deactivating specific components or reducing clock frequencies when not in use, power consumption can be significantly reduced.

4. Energy-Aware Design: Designing with energy efficiency in mind involves considering the...

Read more -

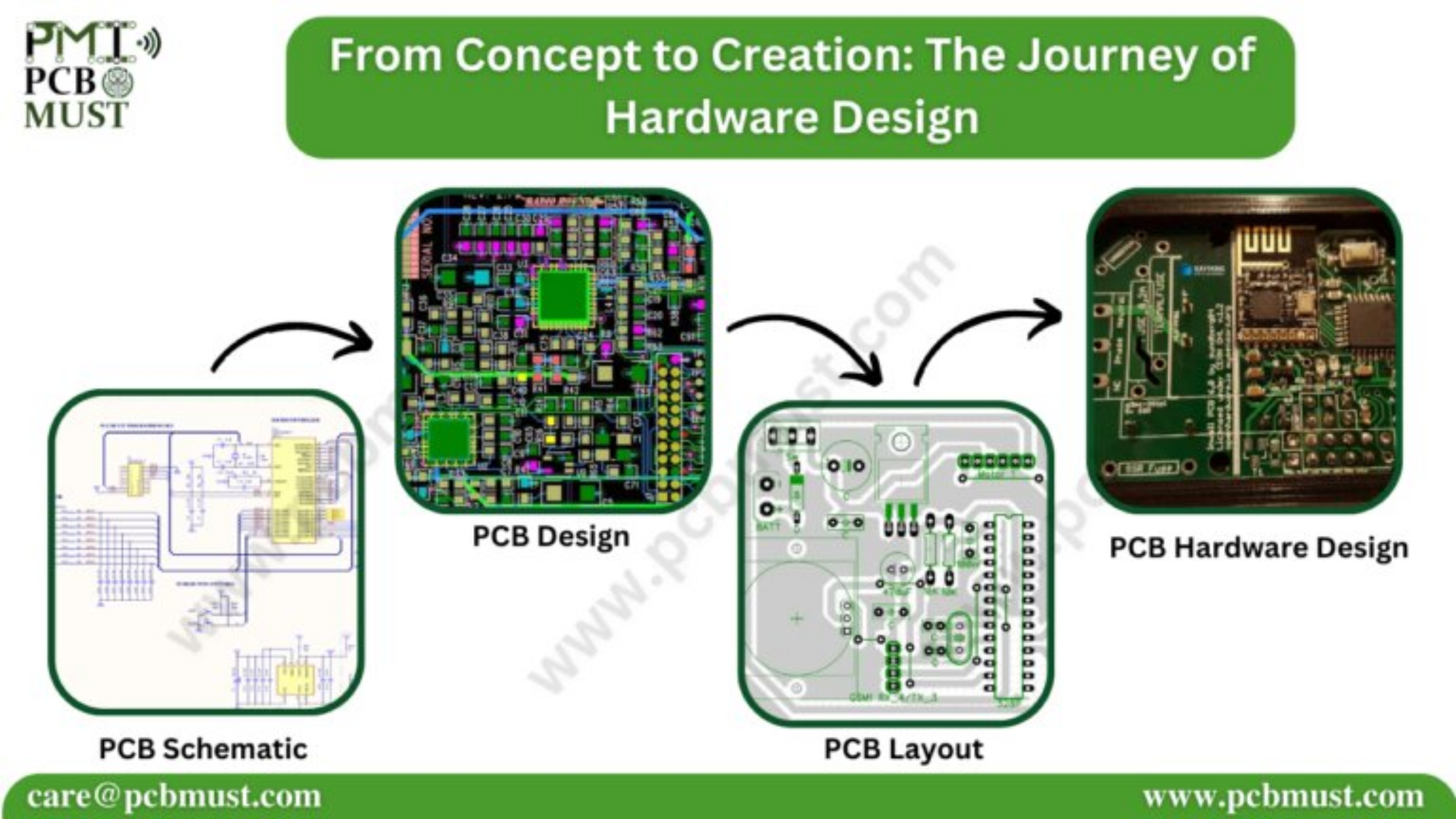

From Concept to Creation: The Journey of Hardware Design

08/04/2023 at 10:32 • 0 commentsIntroduction:

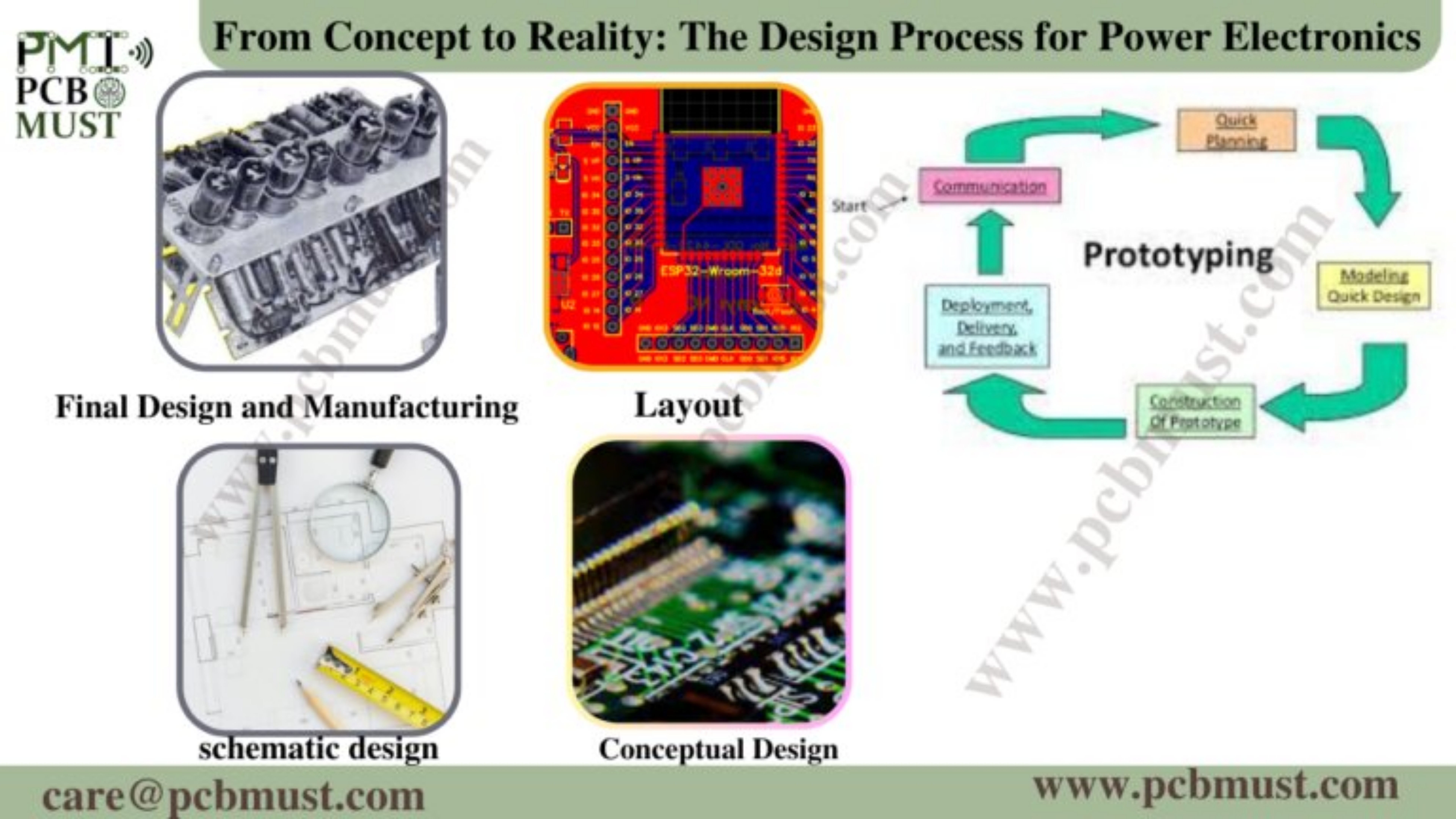

In the ever-evolving world of technology, hardware design stands as a fundamental pillar in bringing innovative and groundbreaking products to life. It encompasses the entire process of transforming an abstract concept into a tangible, functional device. From the initial spark of an idea to the final product hitting the market, hardware design involves a myriad of stages and factors that contribute to the success of a device. In this blog, we will explore the fascinating journey of hardware design, delving into its benefits and other important factors that shape this intricate process.

![]()

Benefits of Hardware Design:

1. Innovation and Creativity: At the heart of hardware design lies the ability to innovate and unleash creativity. It provides engineers and designers with a platform to explore new solutions to real-world problems. By pushing the boundaries of what is possible, hardware design leads to the development of cutting-edge products that revolutionize industries and improve people’s lives. Through hardware design, novel features and functionalities can be incorporated into devices, providing unique user experiences and setting new industry standards.

2. Customization and Optimization: Hardware design allows for customization and optimization of devices to meet specific requirements. Designers can tailor the hardware components, circuitry, and architecture to achieve desired performance, power efficiency, and form factor. This flexibility enables the creation of devices that cater to diverse user needs, whether it’s a compact wearable device or a high-performance server. By optimizing hardware design, engineers can enhance functionality, reduce power consumption, and optimize space utilization.

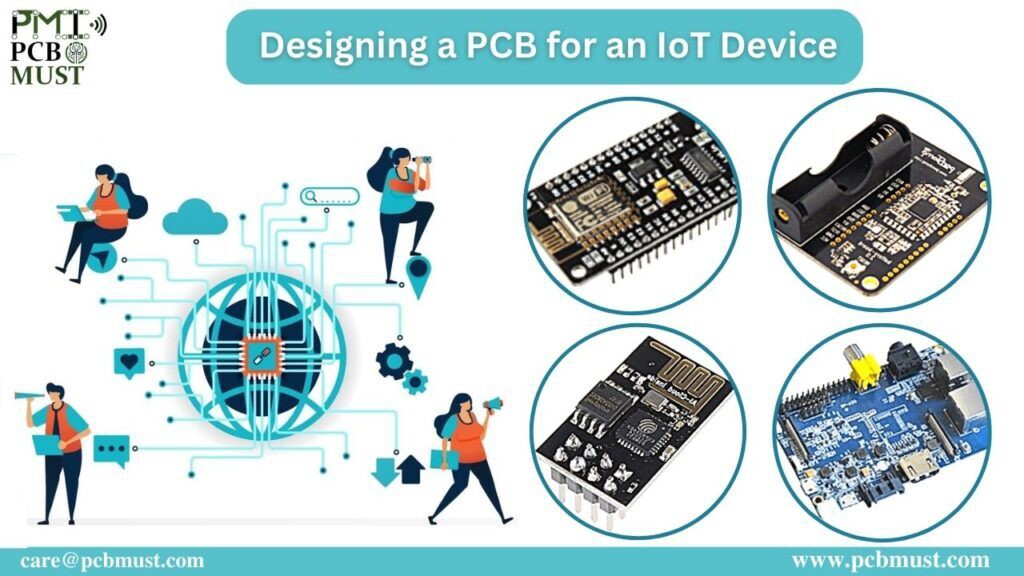

3. Integration and Connectivity: In our increasingly interconnected world, hardware design plays a crucial role in enabling seamless integration and connectivity among various devices. Designers need to consider the compatibility of hardware components, protocols, and interfaces to ensure smooth communication between different systems. Well-designed hardware facilitates the integration of sensors, actuators, wireless modules, and other technologies, enabling devices to interact with each other and the surrounding environment effectively. This connectivity opens up endless possibilities for automation, IoT applications, and smart ecosystems.

4. Reliability and Robustness: Hardware design focuses on creating devices that are reliable and robust in various operating conditions. Designers carefully select and test components to ensure their durability, stability, and resilience to external factors such as temperature, humidity, and vibration. Through meticulous design and testing, hardware engineers can create products that withstand the challenges of real-world usage. Robust hardware design enhances user satisfaction and trust in the brand, while also reducing product failures and warranty claims.

5. Cost Optimization: Hardware design plays a crucial role in optimizing manufacturing costs. By carefully selecting components, simplifying circuitry, and optimizing production processes, designers can reduce material costs and improve manufacturing efficiency. Additionally, thoughtful design choices can lead to easier assembly, maintenance, and repair processes, resulting in cost savings throughout the product’s lifecycle. Cost optimization enables companies to offer competitive pricing while maintaining profitability.

Other Factors in Hardware Design:

1. Prototyping and Testing: Prototyping is an integral part of the hardware design process. It involves building a physical model or a small batch of devices to evaluate the design’s feasibility, functionality, and performance. Prototyping helps identify design flaws and allows for iterative improvements before mass production. Rigorous testing, including functionality tests, stress tests, and compatibility tests, ensures that the final...

Read more -

Emerging Trends in Power Electronics: From Wide-Bandgap Devices to Internet of Things

08/03/2023 at 09:34 • 0 commentsIntroduction:

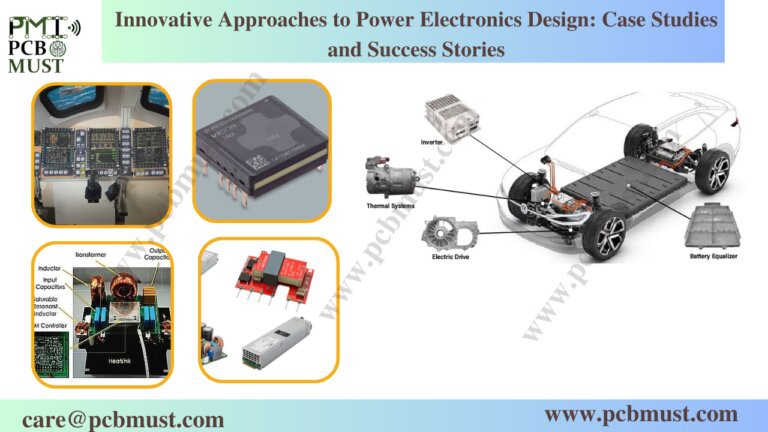

Power electronics technology has been evolving rapidly, driven by the need for higher efficiency, increased power density, and improved system performance in various industries. Emerging trends in power electronics are shaping the future of energy conversion and management. From the adoption of wide-bandgap semiconductor devices to the integration of power electronics with the Internet of Things (IoT), these advancements are revolutionizing power systems across sectors. In this blog, we will explore the emerging trends in power electronics, their benefits, and other factors contributing to their adoption and impact.

![]()

Benefits of Emerging Trends in Power Electronics:

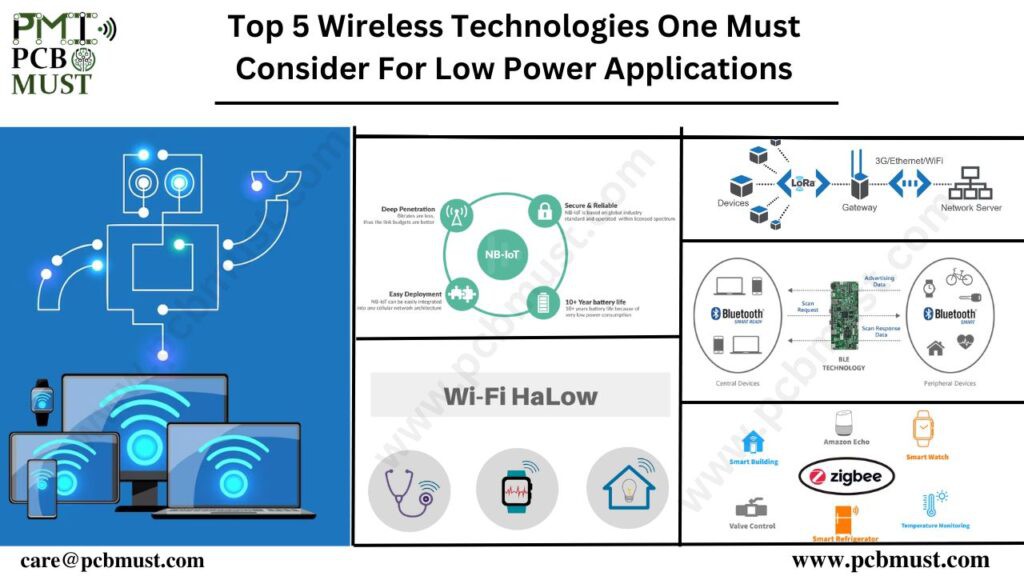

1. Wide-Bandgap Semiconductor Devices: One of the most significant trends in power electronics is the adoption of wide-bandgap semiconductor materials, such as silicon carbide (SiC) and gallium nitride (GaN). These materials offer superior characteristics compared to traditional silicon-based devices, including higher breakdown voltage, faster switching speed, lower switching losses, and higher operating temperatures. The use of wide-bandgap devices in power electronics results in increased efficiency, reduced system size and weight, improved thermal management, and enhanced overall system performance.

2. Higher Power Density and Miniaturization: Emerging trends in power electronics aim to achieve higher power density and miniaturization, enabling more compact and lightweight systems. The use of advanced semiconductor devices, improved packaging techniques, and optimized thermal management contribute to higher power density and reduced system volume. Higher power density translates into smaller and more efficient power electronics systems, making them suitable for applications with limited space requirements, such as electric vehicles, portable electronics, and aerospace systems.

3. Energy Efficiency and Sustainability: Emerging trends in power electronics emphasize energy efficiency and sustainability. Wide-bandgap semiconductor devices offer lower conduction and switching losses, resulting in improved overall system efficiency. Enhanced efficiency reduces energy consumption, lowers carbon emissions, and contributes to a greener and more sustainable future. Energy-efficient power electronics systems are critical for applications like renewable energy integration, electric transportation, and smart grids, where optimizing energy utilization is paramount.

4. Integration with the Internet of Things (IoT): The integration of power electronics with the Internet of Things (IoT) is an emerging trend that holds significant potential for transforming various industries. By connecting power electronics systems to IoT platforms, real-time monitoring, control, and data analytics become possible. IoT integration allows for remote monitoring and diagnostics, predictive maintenance, energy optimization, and demand response capabilities. Power electronics systems can adapt and respond intelligently to changing operating conditions, resulting in improved performance, reliability, and operational cost savings.

5. Digitalization and Advanced Control Techniques: Emerging trends in power electronics encompass digitalization and advanced control techniques. Digital control enables precise and adaptive control algorithms that optimize power flow, minimize losses, and improve system response. Furthermore, digitalization facilitates the implementation of advanced control techniques such as model predictive control (MPC), adaptive control, and machine learning algorithms. These techniques enhance system performance, fault detection, and the ability to handle dynamic load variations.

Other Factors in Emerging Trends of Power Electronics:

1. Thermal Management: As power electronics systems become more compact and power-dense, effective thermal management becomes increasingly crucial. Efficient cooling techniques, such as advanced...

Read more -

Breaking New Ground: Exploring Cutting-Edge Techniques in Hardware Design

08/02/2023 at 07:34 • 0 commentsIntroduction:

In the dynamic landscape of technology, hardware design is constantly evolving to meet the demands of the digital age. From smartphones and smart appliances to autonomous vehicles and artificial intelligence systems, hardware designers are continuously pushing boundaries and exploring cutting-edge techniques. These innovative approaches in hardware design not only improve performance and functionality but also open up new possibilities for industries and users alike. In this blog, we will delve into the world of cutting-edge techniques in hardware design, exploring their benefits and other factors that contribute to their success.

![]()

Benefits of Cutting-Edge Techniques in Hardware Design:

1. Enhanced Performance: One of the primary benefits of cutting-edge techniques in hardware design is the significant enhancement in performance. Advanced techniques, such as parallel processing, hardware acceleration, and specialized co-processors, enable devices to execute complex computations and tasks at lightning-fast speeds. By leveraging the latest hardware advancements, designers can create devices that deliver superior performance, improved responsiveness, and seamless user experiences. Enhanced performance opens doors for innovative applications and empowers industries to achieve new levels of efficiency and productivity.

2. Power Efficiency: Cutting-edge techniques in hardware design also focus on optimizing power efficiency. With the increasing demand for energy-efficient devices, designers employ techniques like voltage scaling, clock gating, and low-power component selection to minimize power consumption. Additionally, advancements in power management systems, such as dynamic voltage and frequency scaling (DVFS), allow devices to adjust their power consumption based on workload demands. Power-efficient hardware design not only extends battery life but also reduces energy costs and contributes to a greener and more sustainable future.

3. Integration and Miniaturization: Cutting-edge hardware design techniques enable seamless integration and miniaturization of devices. Advancements in system-on-chip (SoC) design, 3D integration, and advanced packaging technologies allow for more functionalities and increased performance in smaller form factors. The ability to pack powerful components into compact devices opens up possibilities for wearable technology, Internet of Things (IoT) devices, and mobile computing. Integration and miniaturization offer convenience, portability, and a wide range of applications across industries.

4. Design Flexibility: With cutting-edge techniques, hardware designers gain increased flexibility in design. Field-programmable gate arrays (FPGAs), for example, allow for the reconfiguration of hardware circuits on the fly, enabling rapid prototyping and design iterations. This flexibility enables designers to explore innovative ideas and adapt to changing requirements without the need for significant hardware modifications. By leveraging flexible design techniques, designers can optimize performance, address evolving user needs, and reduce time-to-market.

5. Security and Privacy: As technology becomes more interconnected, ensuring security and privacy in hardware design is paramount. Cutting-edge techniques integrate robust security features into hardware devices, such as secure enclaves, hardware-based encryption, and tamper-resistant designs. Hardware security modules (HSMs) provide secure key storage and cryptographic operations, protecting sensitive data from unauthorized access. By incorporating advanced security measures into hardware design, designers bolster user trust, protect valuable assets, and mitigate potential cybersecurity risks.

Other Factors in Cutting-Edge Hardware Design:

1. Advanced Materials: Cutting-edge hardware design often involves the use of advanced materials with unique properties. Graphene, for example,...

Read more -

Power Electronics in Consumer Electronics: Innovations for Energy-Efficient Devices

08/01/2023 at 06:19 • 0 commentsIntroduction:

Consumer electronics have become an integral part of our daily lives, encompassing a wide range of devices such as smartphones, laptops, televisions, and home appliances. Power electronics technology plays a significant role in improving energy efficiency, enhancing performance, and enabling advanced features in consumer electronics. In this blog, we will explore the importance of power electronics in consumer electronics, the benefits it brings, and other factors that contribute to the development of energy-efficient devices.

![]()

Benefits of Power Electronics in Consumer Electronics:

1. Energy Efficiency: One of the primary benefits of power electronics in consumer electronics is improved energy efficiency. Power electronic converters, such as switch-mode power supplies (SMPS), help regulate and convert electrical energy with minimal losses. These converters operate at high efficiency levels, ensuring that consumer electronic devices consume less power during operation. Energy-efficient power electronics contribute to reduced electricity bills, extended battery life in portable devices, and a lower environmental impact by reducing overall energy consumption.

2. Size and Weight Reduction: Power electronics technology enables size and weight reduction in consumer electronic devices. The use of high-frequency switching power supplies allows for the miniaturization of power conversion circuits. Switch-mode power supplies are smaller and lighter compared to traditional linear power supplies, making them ideal for compact devices like smartphones, tablets, and wearable devices. Power electronics advancements enable consumer electronics manufacturers to create sleek, lightweight, and portable devices that are highly convenient for everyday use.

3. Enhanced Battery Life: Consumer electronics often rely on battery power for their operation, and power electronics plays a crucial role in extending battery life. Power management integrated circuits (PMICs) optimize power flow, regulate voltage levels, and manage battery charging and discharging processes. These power management systems ensure that devices operate efficiently, consuming minimal power from the battery when idle and delivering power on demand for optimal performance. By maximizing battery efficiency, power electronics technology improves the overall battery life of consumer electronic devices.

4. Fast Charging Capabilities: Power electronics innovations have led to the development of fast charging technologies in consumer electronics. High-power charging adapters, combined with power management systems, deliver higher charging currents to recharge batteries quickly. Fast charging technologies, such as Qualcomm’s Quick Charge and USB Power Delivery (USB PD), have become prevalent, allowing users to rapidly charge their smartphones, tablets, and laptops. Power electronics advancements enable faster and more convenient charging experiences for consumers.

5. Advanced Features and Functionality: Power electronics enables advanced features and functionality in consumer electronics devices. Devices like smartphones and smart TVs incorporate power electronics-based touch screens, OLED displays, and LED backlighting, offering improved visual quality and interactivity. Additionally, power electronics technology enables intelligent power management, allowing devices to optimize performance, automatically adjust power consumption based on usage patterns, and integrate features like gesture control, voice recognition, and artificial intelligence.

Other Factors in Power Electronics for Consumer Electronics:

1. Power Conversion Efficiency: Power conversion efficiency is a critical factor in power electronics for consumer electronics. Efficient power conversion ensures that energy is effectively utilized within the device and minimizes energy losses during the conversion process. Power electronics components, such as power transistors...

Read more -

Introduction to Power Electronics: Understanding the Basics of Electrical Energy Conversion

07/31/2023 at 07:33 • 0 commentsIntroduction:

Power electronics is a dynamic field that revolves around the efficient conversion and control of electrical power. It deals with the study and application of solid-state devices and circuits for transforming, regulating, and conditioning electric power. Power electronics play a critical role in various industries, including renewable energy, electric vehicles, industrial automation, consumer electronics, and more. In this blog, we will explore the fundamentals of power electronics, its benefits, and other essential factors that contribute to its significance in today’s world.

![]()

Benefits of Power Electronics:

1. Enhanced Energy Efficiency: One of the key advantages of power electronics lies in its ability to significantly improve energy efficiency. Through the use of power electronic devices and advanced control techniques, electrical energy can be converted and regulated with minimal losses. These losses typically manifest as heat dissipation during the conversion process. By reducing energy losses, power electronics help lower energy consumption, resulting in reduced operating costs and a more sustainable approach to power utilization.

2. Flexibility and Adaptability: Power electronics offer tremendous flexibility and adaptability in power conversion and control. Semiconductor devices such as diodes, transistors, thyristors, and integrated circuits enable precise control and transformation of electrical power to meet specific requirements. This versatility allows power electronics to cater to a wide range of applications, including motor control, renewable energy integration, electric vehicle drivetrains, power supplies, and more.

3. Integration of Renewable Energy: Power electronics plays a crucial role in integrating renewable energy sources, such as solar and wind power, into the existing power grid. Renewable energy systems generate power in different voltage and frequency ranges, which need to be converted and synchronized with the grid’s parameters. Power electronic converters facilitate this integration by efficiently converting and regulating the power output from renewable sources to match the grid requirements. This enables a smoother and more reliable integration of renewable energy into the overall power system.

4. Improved Power Quality: Power electronics has a significant impact on improving power quality, which refers to the stability and reliability of the electrical power supply. Power electronic devices and control techniques allow for precise regulation of voltage, frequency, and waveform characteristics, ensuring a consistent and high-quality power supply. By mitigating issues such as voltage sags, swells, harmonics, and transients, power electronics contributes to stable and efficient operation of sensitive equipment and systems, including industrial machinery, data centers, healthcare facilities, and more.

5. Enhanced Motor Control: Power electronics finds extensive application in motor control systems. By employing variable frequency drives (VFDs) and power electronic converters, the speed and torque of electric motors can be accurately controlled. This results in energy savings, improved motor performance, reduced mechanical stress on the system, and enhanced overall system efficiency. Motor control plays a crucial role in various industries, including manufacturing, transportation, and robotics, where precise control over motor operation is essential.

Other Factors in Power Electronics:

1. Semiconductor Devices: Power Electronic Circuits rely heavily on various semiconductor devices, including diodes, transistors, insulated-gate bipolar transistors (IGBTs), silicon-controlled rectifiers (SCRs), and emerging technologies such as silicon carbide (SiC) and gallium nitride (GaN) devices. Understanding the characteristics, limitations, and applications of these devices is crucial for designing and implementing efficient power electronic systems.

... Read more -

Power Electronics Applications in Renewable Energy Systems: Harnessing Sustainable Power Sources

07/29/2023 at 09:24 • 0 commentsIntroduction:

Renewable energy sources, such as solar and wind power, have gained significant attention in recent years due to their potential to address the challenges of climate change and reduce dependence on fossil fuels. Power electronics plays a crucial role in the integration and utilization of renewable energy systems. By effectively converting, regulating, and managing the electrical power generated from renewable sources, power electronics enables the seamless integration of sustainable power sources into the existing electrical grid. In this blog, we will explore the applications, benefits, and other factors of power electronics in renewable energy systems.

![]()

Benefits of Power Electronics in Renewable Energy Systems:

1. Efficient Power Conversion: One of the primary benefits of power electronics in renewable energy systems is efficient power conversion. Solar panels and wind turbines generate electricity in forms that may not match the grid requirements. Power electronic converters, such as inverters, are used to convert the direct current (DC) output from solar panels or wind turbines into alternating current (AC) suitable for grid integration. These converters ensure maximum power extraction from renewable sources while maintaining high efficiency during the conversion process.

2. Voltage and Frequency Regulation: Power electronic converters allow for precise voltage and frequency regulation, ensuring that the power generated from renewable sources matches the grid requirements. Grid-connected inverters provide active control over the voltage and frequency, enabling stable and synchronized power injection into the grid. This regulation is crucial for maintaining the stability and reliability of the electrical grid while incorporating variable and intermittent renewable energy sources.

3. Maximum Power Point Tracking (MPPT): Solar panels and wind turbines have varying operating characteristics based on environmental conditions. Power electronics employ maximum power point tracking (MPPT) algorithms to optimize the power output from renewable sources. MPPT techniques continuously adjust the operating parameters of the renewable energy systems, such as the voltage and current, to ensure the extraction of the maximum available power. By maximizing the energy harvested from solar and wind resources, power electronics increase the overall system efficiency.

4. Grid Integration and Power Quality: Power electronics facilitates the seamless integration of renewable energy systems into the electrical grid. Grid-connected inverters synchronize the renewable energy generation with the grid parameters, enabling a smooth injection of power. Power electronics also play a crucial role in ensuring power quality by regulating voltage, frequency, and waveform characteristics. Advanced control algorithms and filtering techniques are employed to minimize grid disturbances, harmonics, and voltage fluctuations caused by the intermittent nature of renewable energy sources.

5. Energy Storage Integration: Power electronics enable the integration of energy storage systems, such as batteries, with renewable energy systems. Energy storage systems play a vital role in mitigating the intermittent nature of renewable energy sources and ensuring a consistent power supply. Power electronic converters control the charging and discharging processes of the batteries, efficiently managing the energy flow between the renewable energy system, the storage system, and the electrical grid. This integration enhances grid stability, load balancing, and the utilization of renewable energy resources.

Other Factors in Power Electronics for Renewable Energy Systems:

1. Advanced Semiconductor Devices: Power electronics systems rely on advanced semiconductor devices for efficient energy conversion and control. Silicon-based devices, such as insulated-gate bipolar transistors (IGBTs), are commonly used in power electronic converters....

Read more -

Exploring Power Electronics in Industrial Automation: Optimizing Energy Usage and Control

07/27/2023 at 06:43 • 0 commentsIntroduction:

Industrial automation is revolutionizing the manufacturing sector, bringing greater efficiency, precision, and control to production processes. Power electronics plays a crucial role in industrial automation by providing the necessary tools for efficient energy usage, power conversion, and precise motor control. From variable speed drives to power supplies and robotics, power electronics enables automation systems to operate with enhanced energy efficiency and optimized control. In this blog, we will explore the importance of power electronics in industrial automation, its benefits, and other factors that contribute to the optimization of energy usage and control in manufacturing processes.

![]()

Benefits of Power Electronics in Industrial Automation:

1. Energy Efficiency: Power electronics is instrumental in optimizing energy usage in industrial automation systems. Variable speed drives (VSDs), also known as adjustable speed drives, enable the control of motor speed according to the required load. By adjusting the motor speed to match the process demands, power electronics ensure that energy is used efficiently, reducing energy wastage during low-demand periods. This energy-saving capability not only contributes to cost reduction but also aligns with sustainability goals, reducing the environmental impact of industrial operations.

2. Precise Motor Control: Power electronics systems offer precise control over motors, resulting in improved motor performance and overall system efficiency. By employing power electronic converters, such as inverters and motor drives, motor speed and torque can be accurately regulated to match specific process requirements. This level of control allows for better synchronization, reduced mechanical stress, and enhanced energy efficiency in industrial automation systems. Precise motor control is especially crucial in applications where precise positioning, speed control, or torque regulation is necessary.

3. Power Quality and Stability: Power electronics helps maintain power quality and stability in industrial automation systems. Power conditioning devices, such as active power filters and voltage regulators, mitigate issues like voltage sags, harmonics, and transients, ensuring a stable power supply. By improving power quality, power electronics minimizes the risk of equipment failures, production disruptions, and data corruption. The ability to maintain a stable and reliable power supply is essential for sensitive equipment, control systems, and critical industrial processes.

4. Power Conversion and Distribution: Power electronics is responsible for converting and distributing electrical power in industrial automation systems. Power supplies and converters transform the incoming power to the required voltage and frequency levels for different components and systems. These devices ensure efficient power conversion, optimal distribution, and isolation between different parts of the automation system. Power electronics also facilitate the integration of renewable energy sources, such as solar panels or wind turbines, by efficiently converting and regulating the power output to match the automation system’s requirements.

5. Harmonic Reduction and Power Factor Correction: Power electronics devices, such as active power filters and power factor correction units, address power quality issues related to harmonics and poor power factor. Harmonics are undesirable voltage and current distortions that can negatively impact equipment performance and efficiency. Power electronics-based filters and correction units mitigate harmonics and improve the power factor, reducing energy losses and ensuring compliance with utility standards. By achieving better power quality and power factor, power electronics contributes to efficient and reliable operation of industrial automation systems.

Other Factors in Power Electronics for Industrial Automation:

1. Motor Drive Technology: Motor...

Read more -

Advancements in Power Semiconductor Devices: Enhancing Efficiency and Performance

07/26/2023 at 10:50 • 0 commentsIntroduction:

Power semiconductor devices are the building blocks of power electronics systems. They play a critical role in the efficient conversion, control, and management of electrical power. Over the years, significant advancements have been made in power semiconductor technology, leading to improved efficiency, higher power density, and enhanced performance of power electronic systems. In this blog, we will explore the advancements in power semiconductor devices, their benefits, and other factors that contribute to their importance in achieving efficient power conversion and control.

![]()

Benefits of Advancements in Power Semiconductor Devices:

1. Higher Efficiency: One of the key benefits of advancements in power semiconductor devices is the improved efficiency of power electronic systems. Newer devices have lower conduction and switching losses, enabling more efficient power conversion. Reduced losses result in higher overall system efficiency, leading to lower energy consumption, reduced operating costs, and a greener approach to power utilization. This is particularly important in applications where energy efficiency is crucial, such as renewable energy systems, electric vehicles, and industrial automation.

2. Increased Power Density: Advancements in power semiconductor devices have enabled higher power density in power electronic systems. Power density refers to the amount of power that can be handled within a given volume or space. Higher power density allows for more compact and lightweight power electronic systems, making them suitable for applications with limited space requirements. The increased power density not only saves physical space but also improves system integration and reduces overall system costs.

3. Improved Switching Speed: Modern power semiconductor devices exhibit improved switching characteristics, such as faster turn-on and turn-off times. This faster switching speed allows for higher operating frequencies, leading to reduced component sizes, improved system response times, and increased power throughput. Faster switching also reduces power losses during the switching transitions, enhancing overall system efficiency. The improved switching speed enables the design of power electronic systems with faster dynamic response and improved control capabilities.

4. Higher Voltage and Current Ratings: Advancements in power semiconductor technology have led to devices with higher voltage and current ratings. Higher voltage ratings allow for the handling of high-power applications, such as grid-connected systems and high-voltage motor drives. Similarly, higher current ratings enable the efficient control of large electric motors, industrial machinery, and high-power distribution systems. These advancements in voltage and current ratings provide greater flexibility and expand the range of applications where power electronic systems can be deployed.

5. Wide-Bandgap Semiconductor Materials: One significant advancement in power semiconductor devices is the adoption of wide-bandgap semiconductor materials, such as silicon carbide (SiC) and gallium nitride (GaN). These materials offer superior properties compared to traditional silicon-based devices. Wide-bandgap devices exhibit higher breakdown voltages, lower conduction losses, and higher thermal conductivity. This enables power electronic systems to operate at higher voltages and temperatures, resulting in improved efficiency, reduced cooling requirements, and higher power handling capabilities.

Other Factors in Advancements of Power Semiconductor Devices:

1. Packaging and Thermal Management: Advancements in power semiconductor devices are closely linked to advancements in packaging and thermal management techniques. The packaging of power semiconductor devices plays a crucial role in ensuring proper heat dissipation, electrical isolation, and mechanical support. Innovative packaging technologies, such as direct bonded copper...

Read more -

Security Matters: Safeguarding Hardware Systems from Cyber Threats

07/25/2023 at 06:43 • 0 commentsIntroduction: In today’s interconnected world, the security of hardware systems is of paramount importance. From personal devices like smartphones and laptops to critical infrastructure systems and industrial control systems, hardware security plays a crucial role in protecting sensitive data, ensuring system integrity, and safeguarding user privacy. Cyber threats continue to evolve, making it imperative for hardware designers to implement robust security measures. In this blog, we will explore the importance of securing hardware systems, the benefits it brings, and the key factors to consider in safeguarding these systems from cyber threats.

![]()

Benefits of Securing Hardware Systems: