A fairly detailed list of parts, sources and augmentations is maintained in the Delta Flyer project's readme on github, here.

Delta Flyer

A Kossel Mini type 3D Printer

Implementation

A Kossel Mini type 3D Printer

Implementation

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

A fairly detailed list of parts, sources and augmentations is maintained in the Delta Flyer project's readme on github, here.

I got raw CT data of my nephew, derived a great 3D model from the data and printed a bunch of them. This is one of the reasons why I actually built the Flyer, for printing skulls and bones..

I use ATX power supplies on my printers. I do so because they're readily available and have gone through a relatively large amount of safety scrutiny for home-use (especially considering I only buy high-quality PSUs). Also I really like having a high-quality 5V source around as I use for things.

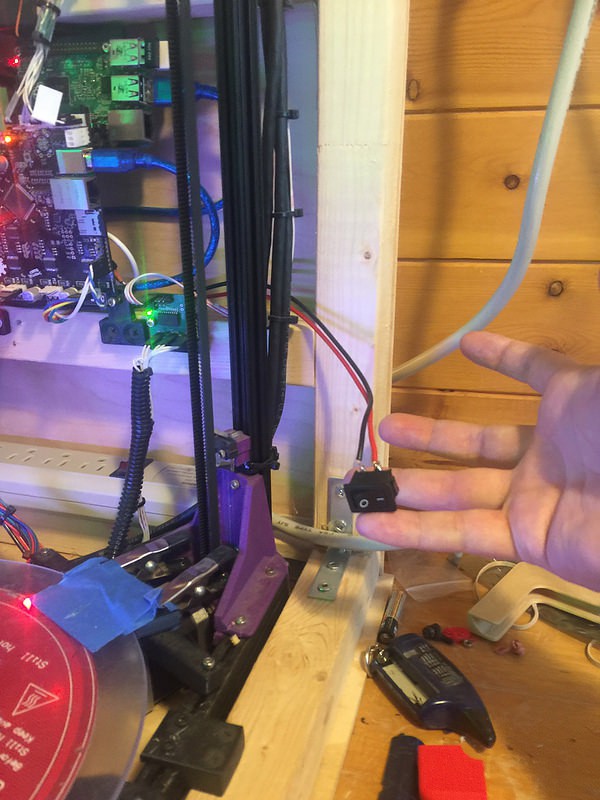

The rocker switch I use for the Delta Flyer has just hung aimlessly until now. Today I CADed-up a model for a casing for it and installed it. It looks absolutely excellent.

Illuminatrix is my favourite lighting system for 3D printers.

To refit the DeltaFlyer with Illuminatrix, I added a vertical tower to mount the LED bar upon. I wired-up an Arduino Mini to my Raspberry Pi to control the Illuminatrix firmware with the Illuminatrix Octoprint plugin.

My Flickr Album for this is here.

I quickly started wanting to take the DeltaFlyer on voyages. A Kossel-type machine on its own is disturbingly exposed so I decided a case was necessary. Also, I had nothing housing any of my electronics, which is not ideal.

I made the case a bit multi-function, here's what it does for me:

Click on the photo below to see my TARDIS build photos on Flickr.

For the Delta Flyer's maiden voyage, I opted to go cheap and use Prime Line rollers (referenced in an earlier log). They're fairly inexpensive and I didn't have much grief finding them at a couple different local stores. They definitely have slop in them, so they're not really a good choice and probably go from rough to terrible as print speed is increased. Episode II here is to illustrate how well these actually work.

I found that I could get passable motion. I ultimately replaced the Prime Line rollers with Delrin rollers. I was stunned to find the first prints out of the Delrin's looked exactly the same as the Prime Line wheels. This led to eventually find my main source of error was my print bed could move during the print. Therefore, I'm not really sure what the quality limit on the Prime Line rollers really is. My guess is you could get pretty damn good but if you tried to print fast, the slop in the bearings would become intolerable.

Last weekend I managed to get the Delta Flyer running. Most of the parts I've sourced came from very inexpensive (relatively) suppliers in China and I didn't pay extra for shipping, meaning shipping has taken a very long time.

I've also been a bit worried that calibrating a Delta would be really brutal and have been kind of dreading the potential pitfalls.

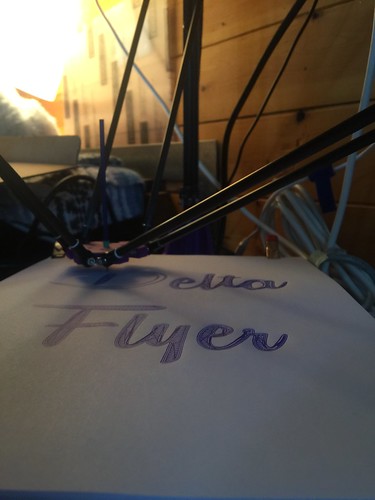

For a first run, I decided to use very cheap rollers (Prime Line shower door rollers as discussed in my previous entry). Once I got the moving parts assembled, I decided NOT to install the hotend and just get er calibrated well enough to operate a Bic Pen. I took some careful measurements, entered them in to my Smoothieware config file and surprisingly things have worked out quite well. Check it out! And here's a video rendition. I'll add that I print throught Octoprint (using OctoPi), it's wonderful and Cupcake155 (my first printer) has used it for a long time. I, of course, go through Wifi too.

And here's a video rendition. I'll add that I print throught Octoprint (using OctoPi), it's wonderful and Cupcake155 (my first printer) has used it for a long time. I, of course, go through Wifi too.

I've posted various photos up to this point in my Album for Delta Flyer's initial life on Flickr here.

I think it was a great idea to calibrate the motion through a pen before going 3D. Had I skipped that, I probably wouldn't have suffered a lot, but in the event of a measurement error, I think it probably saved me a lot of grief.

I've hesitated to commit myself to V-rollers as they just seem comically expensive. I eventually found this, which has given me hope. Typically hacks like that aren't that helpful to me as I live outside of the States (in awesome Canada). Thankfully I found these at Home Depot for about $1.80/wheel. I don't expect them to be a long-long term solution, but I suspect they'll get me pretty far considering.

Create an account to leave a comment. Already have an account? Log In.

:)

I wanted a name to reflect that it's a delta printer. I had started a different delta build before this that got my first 'good' name for a delta; Polar Bear. I love Star Trek, so Delta Flyer naturally came next, for my deranged mind.

I'd say the choice was perfect.

But, at some point, you have to use your Delta Flyer to print a model of THE Delta Flyer. You know that, right? :D

@Starhawk Most definitely.. It was the DeltaFlyer's ~3rd print, but I can't find the pic to prove it - maybe I'll have to print another, for the Christmas tree.

Become a member to follow this project and never miss any updates

By using our website and services, you expressly agree to the placement of our performance, functionality, and advertising cookies. Learn More

I like the name of this project.

I also like Star Trek.

I'm not sure there's a coincidence there...