Goals:

- Free (or at least really cheap)

- Easy

- Available

- Open source

- Automate: the instruments used have QR code which is scanned when used and reported to the printer queue, so a replacement can be printed and keep stock stable

- Usable (with real application)

Steps:

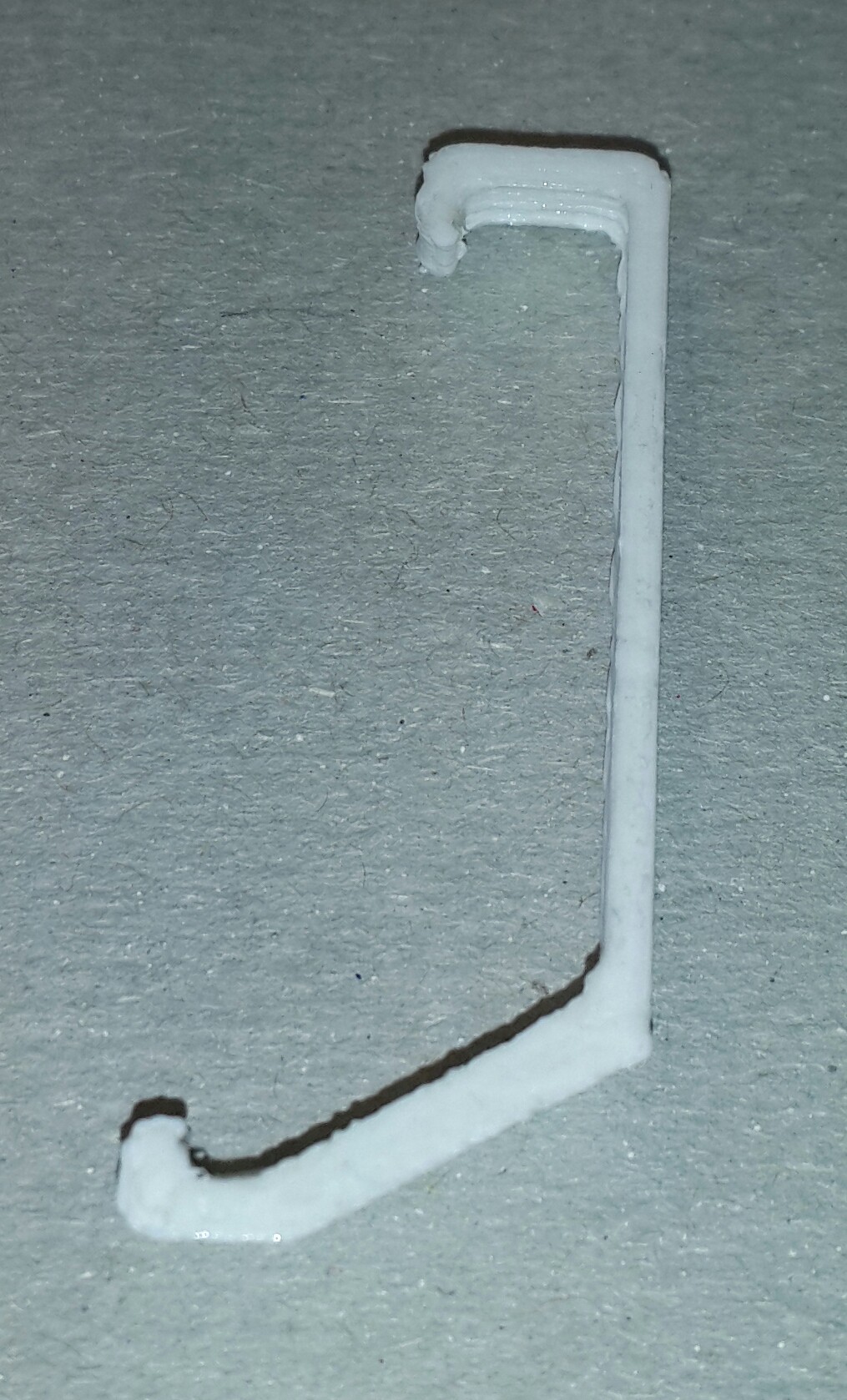

- design the instrument with 3d software

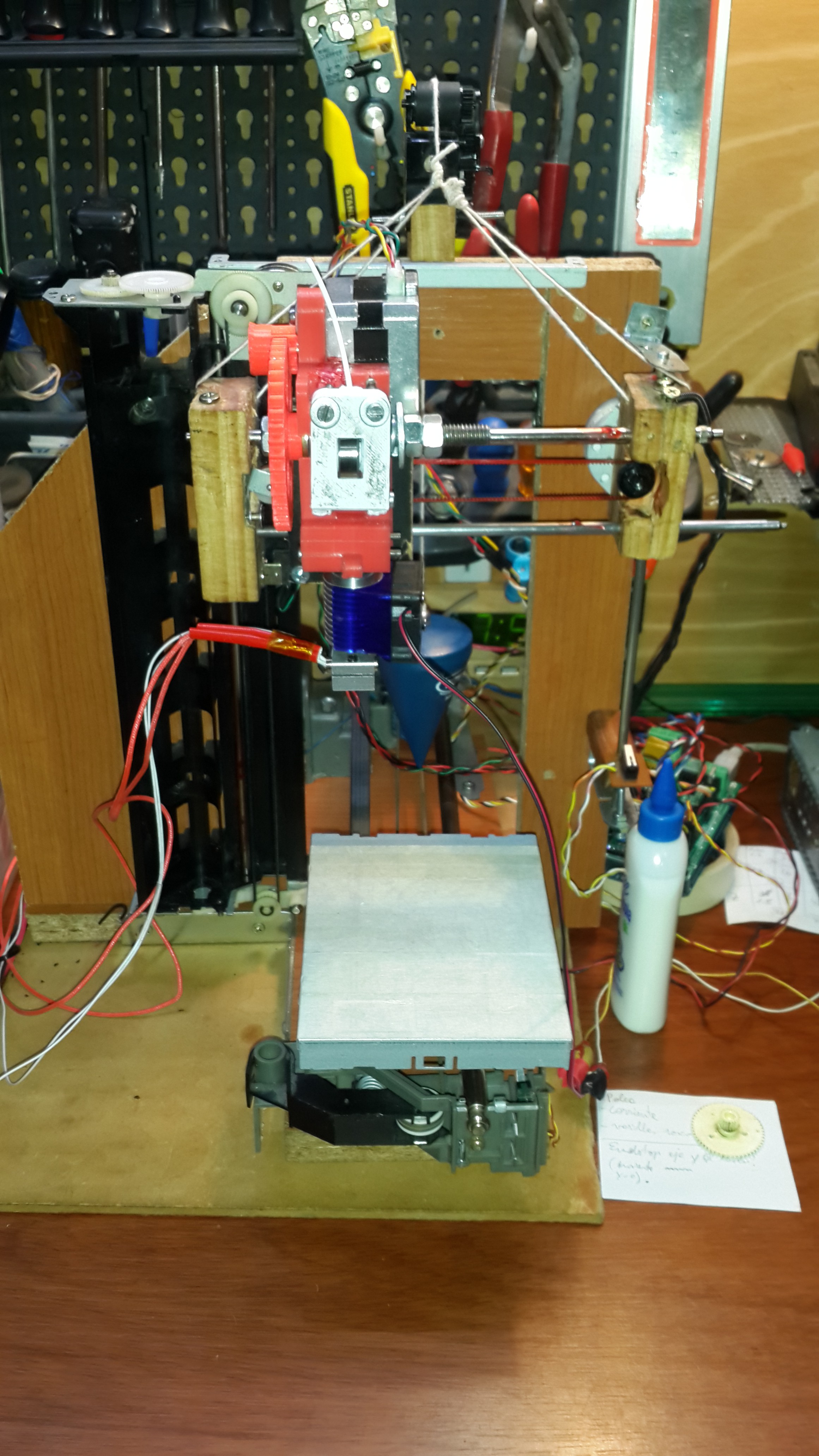

- build 3d printer with scrap parts (i think i can build it only buying the hot end. I already have a semiworking machine that i will be testing as plotter soon, if it works i'll start adding the hot end, extruder, hot bed and all the 3d print related elements).

- print an actual instrument like a retractor

- test it in real life application (i.e. surgery)

- enjoy Nobel prize =P

leandro

leandro

This is an exciting concept. Dentistry uses plastic instruments and devices for specific applications.