Heating regulation system include features:

- Starting procedure

- Stop heating

- Shutdown

- Overheating (emergency)

- UPS cooperation for emergency stop

- WiFi LAN connection for remote command line

There will be Stage two to use practical experience from system application

.

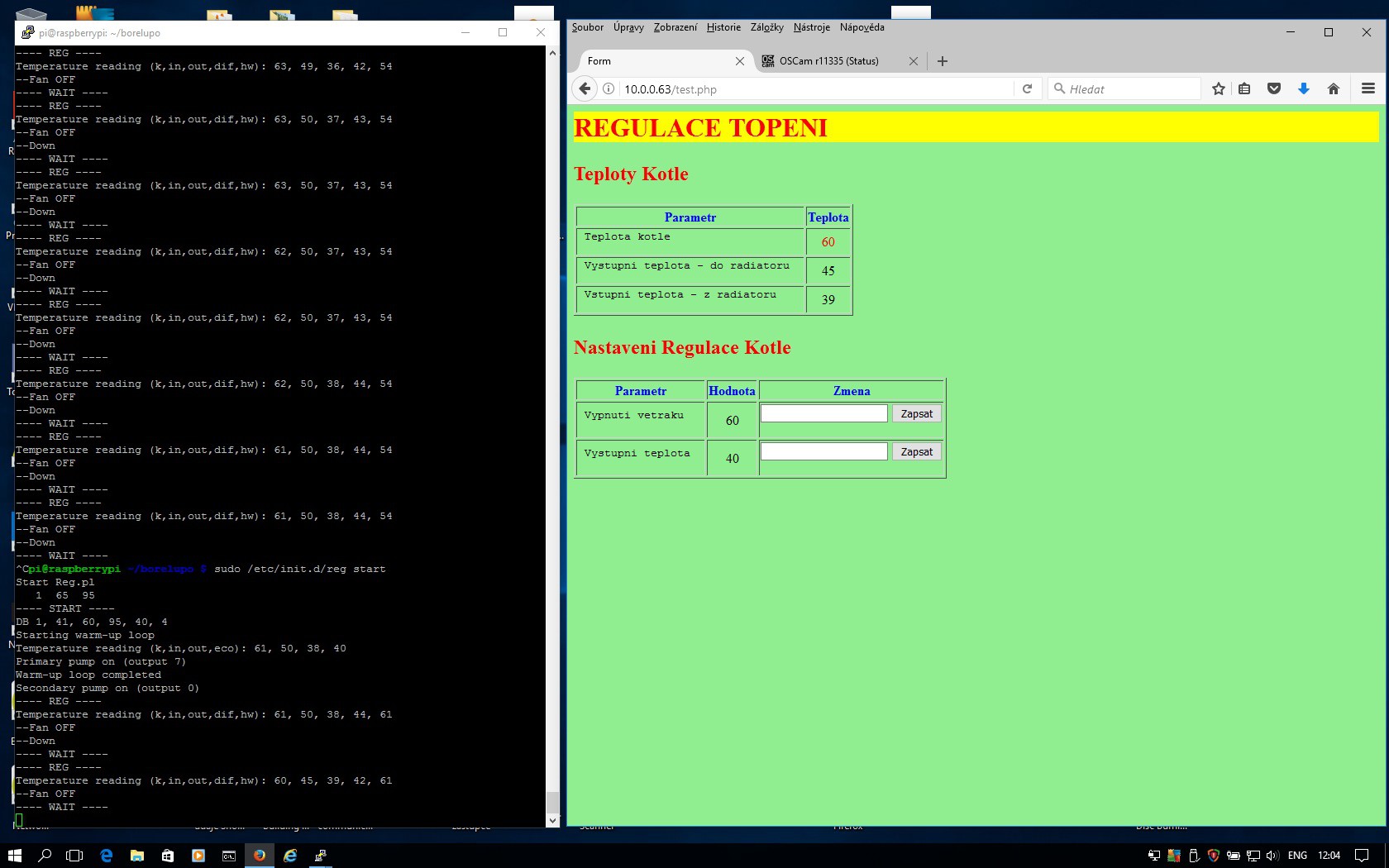

STAGE 2 on the way - Web interface and MySQL is working!

Stage Two include:

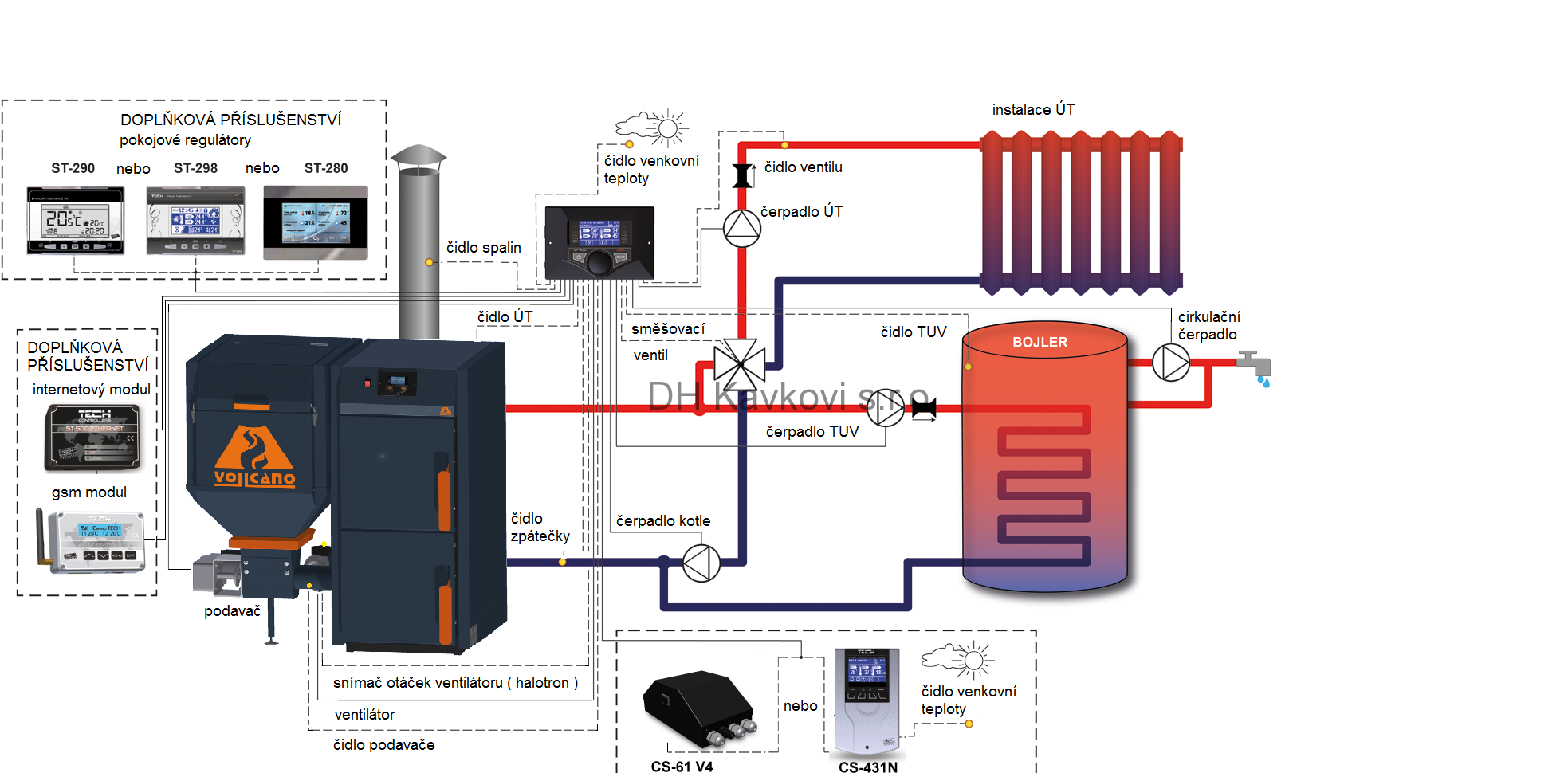

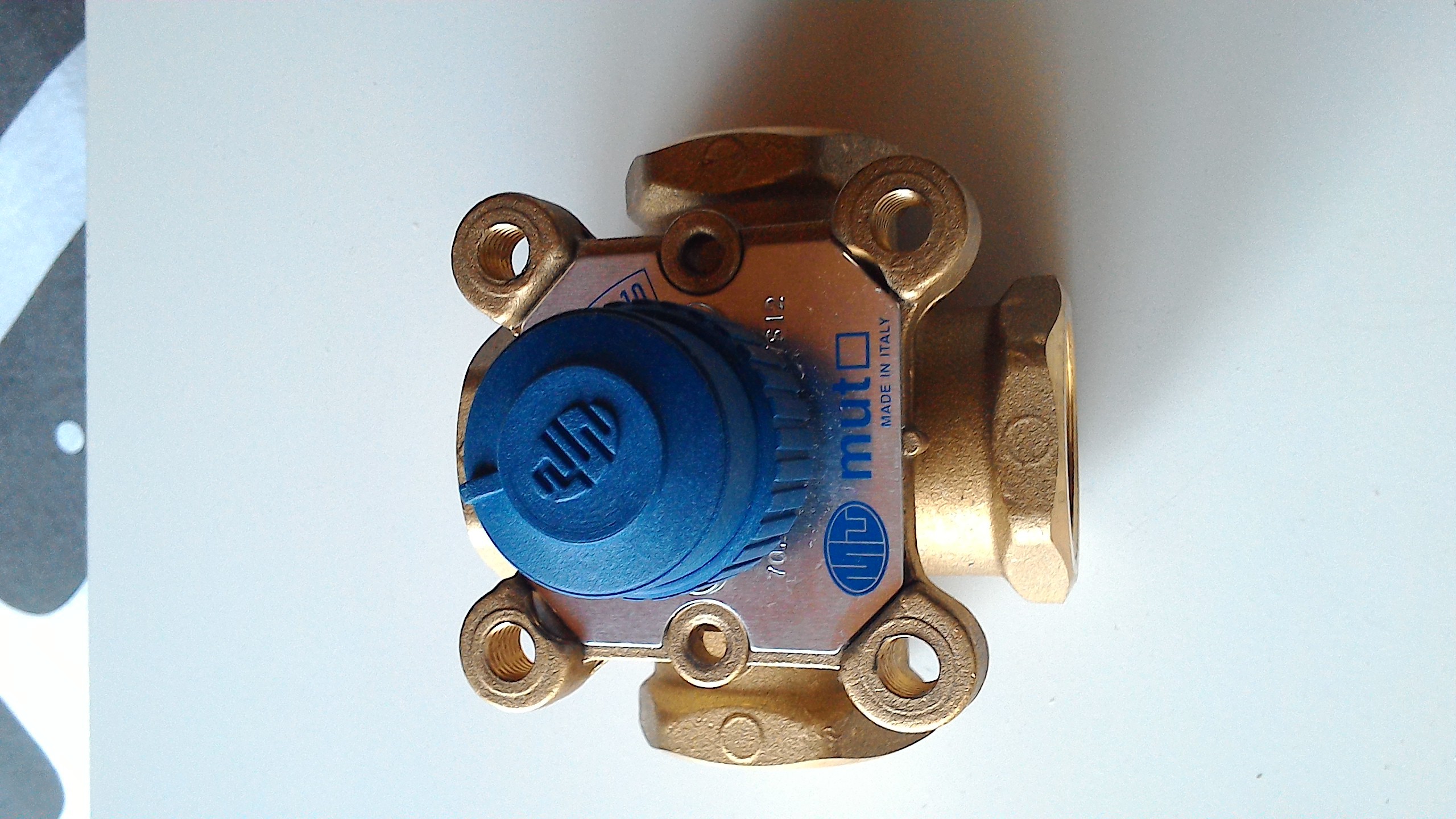

- Change regulation valve from threeway to fourway

- Remote Low boiler temperature alarm

- MySQL for statistic and settings

- Web interface

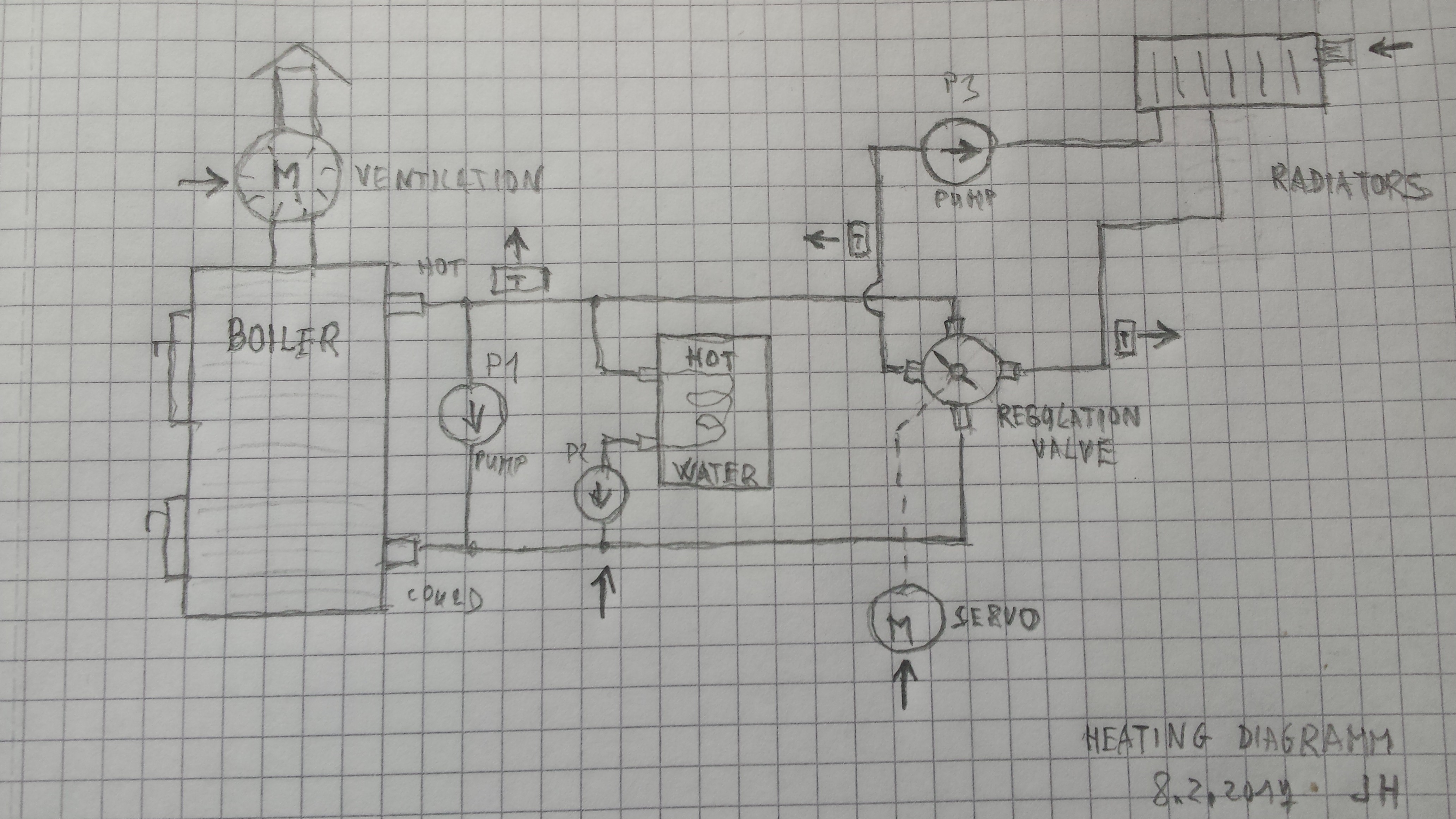

Stage two required main change of Pi SW becouse regulation valve change. Current first boiler loop with thermostatic element (like car cooling thermostat) end threeway valve for radiators loop will be change for fourway valve only. Reason for the change is that thermostat is non linear element which make regulation loop unstable and complicate SW regulation.

Now I am waiting for end of heating season and changes should be ended untill November 2016 as deadline.

Code is writen in Perl. Could be possible to use any Raspberry Pi model.

.

Second (Main Idea)

Regulation valve servo use analog input from 2 V to 10 V. I am lazy to work with 10 bits outputs from D18B20 and D/A converter. It is why I used four bits outputs from PiFace interface as:

Down

Fast Down

Up

Fast UP

(No change)

There is long time RC constant and PiFace outputs changes guide charge or discharge of one big capacitor. Capacitor voltage is output for the servo.

Other outputs:

- First water loop pumpe switch

- Second loop pumpe switch

- Flue exauster switch (regulate boiler itself temperature)

- Red LED for not in operation mode.

STAGE THREE IDEAS

- New web page with boiler status and informations from various sensors. (Current web page is mainly for system check and developing.)

- Connect controller to ZigBee network to collect other sensors data.

- Try to predict from boiler data time to boiler refuel necessity?

- ZigBee boiler status indicator. (Green, Yelow, Red, sound alarm)

- Use D/A converter instead analog stuff.

JanoHak

JanoHak