-

CAD on Onshape

04/11/2017 at 23:00 • 0 commentsHi everyone, if you're following this project, just wanted to mention that we are putting our design files on Onshape to make version control easier, and so that people can access the designs on their browser if they do not have access to the same CAD tools as we use.

Designs are here:

-

It's been a while...

11/18/2016 at 21:17 • 0 commentsWe've been really busy after successfully meeting our Kickstarter goal. We've kept up our blog, but haven't made updates on our Hackaday page. Much sorrys.

If you want to follow our progress however, please check out our website www.sienci.com/blog

Thanks so much for your support!

-

In the Field: Sienci Mill One at Medella Health

09/07/2016 at 18:15 • 0 commentsWe reached out to one of the owners of the preproduction units for the Sienci Mill One to see what they have been up to with their machine. Huayi Gao, co-founder of Medella Health, showed us some cool things he’s been working on for Project Lano over the last couple of weeks.

"Medella Health is building a wearable technology solution that continuously and non-invasively monitors blood glucose levels and communicates the data with a mobile device, so patients can better manage their diabetes. (Source: Velocity)"

![]()

In this image, Huayi is testing sensors built onto wafers by probing each one using the Sienci Mill One. These sensors are designed to determine the composition of chemicals in basal tears. By programming the machine to probe them in the right sequence, Huayi can automatically test all of the sensors over an extended period of time.

Each wafer contains 44 sensors and requires extensive testing to measure a host of parameters to determine the performance of every single sensor. This implementation of the Sienci Mill One saves an enormous amount of time and money over using lab probing stations that cost thousands of dollars and require manual control.

He plans to integrate a microfluidics system and a microscope onto the Sienci Mill One for additional functionality, as well as milling wood and other materials in his spare time.

-

Assembly instructions for the Sienci Mill One now available on Instructables

09/03/2016 at 07:41 • 0 commentsWe finished writing instructions for the assembly of the Sienci Mill One. You can now learn how to assemble the Sienci Mill One here at http://www.instructables.com/id/How-to-Assemble-the-Sienci-Mill-One/

-

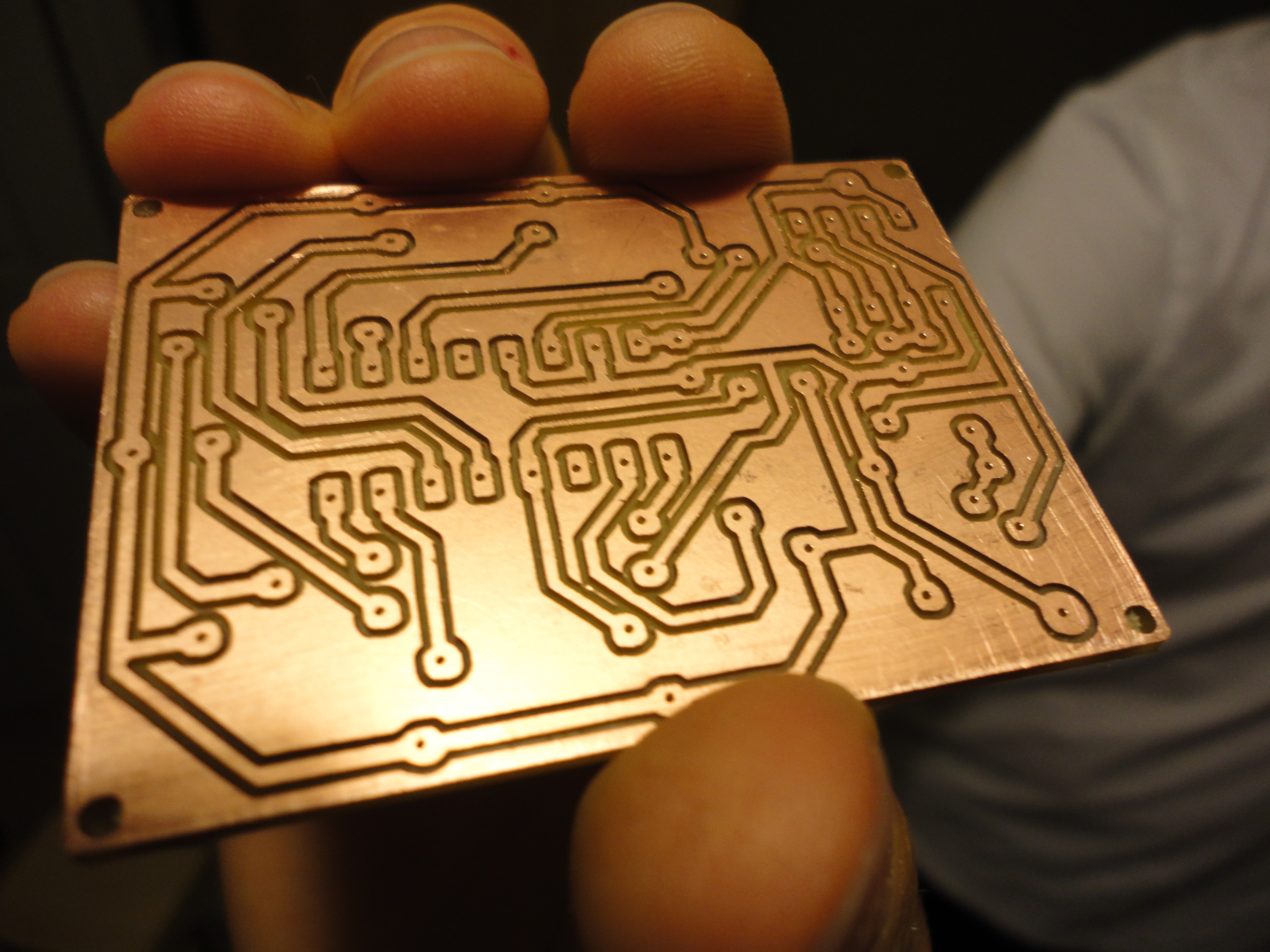

Tight nuts, better precision, nicer PCBs

08/26/2016 at 15:26 • 0 commentsPCB milling is a really useful thing to do on a CNC machine because you can build really nice, complicated electric circuits. And unlike chemical etching, which only makes the traces, a CNC machine drill holes for through hole components and cut and trim the copper clad board. Quite a few people asked about whether or not the Sienci Mill One was able to do PCB milling. So we gave it a shot.

Our first few tries were not great, since we had traces of varying sizes, even though they were all supposed to be the same. While milling large objects, a high degree of precision is not needed. But for milling PCBs with features that are fractions of a millimetre, high precision is critical.

Then we found the issue that was causing us to have sub-par boards. The nuts for the lead screws were coming loose from the gantry, and that extra bit of wiggle was causing the positioning of the machine to be off. So we tightened those screws and made sure that they wouldn’t come loose over time.

And that made a huge huge impact on the quality of our traces! Check it out:

-

$12,650CAD raised so far on Kickstarter

08/20/2016 at 17:30 • 0 commentsIt has been less than two days and we have raised $12,650 on Kickstarter!

That's awesome!

Check out the campaign: https://www.kickstarter.com/projects/sienci/sienci-mill-one-simple-and-affordable-desktop-cnc

-

Our Kickstarter Has Launched!

08/19/2016 at 00:35 • 0 commentsCheck out our Kickstarter at: https://www.kickstarter.com/projects/sienci/sienci-mill-one-simple-and-affordable-desktop-cnc/

-

The struggles of delivering your first set of kits

08/17/2016 at 02:57 • 0 commentsOver the last couple of weeks, Chris and I have been working hard on building the machines for our first set of orders. We decided to try putting together a few kits so that we would know what steps we would need to take to put them together for our Kickstarter. This also helps us figure out the lead times and what sort of quality our suppliers can provide.

Parts from Shenzhen:

We received our parts from Shenzhen through a supplier that manufactures 3D printer and CNC parts. We ordered a small number stepper motors, eccentric nuts, and Delrin V wheels through this supplier, and they were kind enough to take our small order and ship it to us through Express Shipping. Even with a 3 day delay after Typhoon Nida slamming the area and people unable to go to work, we got our shipment on time for our first set of deliveries.

![shenzen nema 17]()

Assembly:

Since last week I have brought the kits to two companies in Ontario. There were a couple of hitches but after ironing them out, things went fairly smoothly.

At the first session I found that the M3 screws that hold the NEMA 17 motors to the angle mounts were slightly too long… 2mm too long in fact. This was causing the screws at the other end of the motor to start turning out, and I had to go find the proper screws for the machine. I also discovered that we would need to tolerance the through holes wider to make assembly easier. We didn’t get to complete the assembly of the machine that day, but since then I’ve found the correct screws and will be going back this week to finish up the build.

-update- We have finished assembling and testing the machine and it is working great.

![medella health assembly]()

At the second session with another company, I found that the second issue was that the the front shield of the machine offered too snug of a fit. Luckily I had a shield that was slightly thinner, and was able to replace and complete the assembly. After I left, the customer discovered that without the bed being completely level, the machine had issues cutting out materials from a blank stock. Under typical use, this small discrepancy would not make a difference, but in applications like PCB milling or cutting very thin materials, even cuts can be critical. I am working on this with the customer to provide the documentation needed to level the bed, or issue a refund if things cannot be resolved.

Final thoughts:

I can’t say these past experiences were completely smooth sailing, but with what I learned from these assembly sessions, we know what to watch out for when start mass manufacturing these machines. As Paul Graham states in his essay “Do Things That Don’t Scale”, this initial step of getting out and putting our machine in an uncontrolled environment is a important step for us to learn what it will be like when we do scale.

-

Our Kickstarter Video is Live!

08/11/2016 at 03:38 • 0 commentsWe've finally created our Kickstarter video! Our Kickstarter will go like on the 18th!

-

Workshop at Communitech: Turning your designs into an object you can hold in your hands

07/29/2016 at 21:22 • 0 commentsGoing from a drawing on your computer to a real object in your hand can be a difficult process. While tools like laser cutters and 3D printers have come down in price and have gone up in ease of use, CNC milling has been one of the more challenging machines to put on a desktop.

While the fact that you can get production quality parts from virtually any material may be an awesome feature to have for engineering firms and small businesses, the need for incredibly robust mechanics and complicated set-up and programming procedures has made desktop CNCing a late bloomer in the low cost rapid prototyping industry. With the emergence of low cost machines like the Shapeoko and the X Carve, Nomad and Carvey, as well as the newly developed Sienci Mill One, it’s easier than ever to put a CNC machine on your desktop.

Our team at Sienci Labs brought the Sienci Mill One to Communitech to run a workshop with one our our clients, Medella Health, to show how their hardware engineers could take their designs and ideas and produce them using the machine. Medella Health develops next generation biosensors and electronics, to monitor our health and change the way we take care of ourselves.

With programs like Onshape and Kiri:Moto, we were able to create teflon flow cell sensors that retail for thousand dollars each, and create prototypes that would take weeks to fabricate and cost thousands of dollars through out-of-house firms. With deskop CNC machines like the Sienci Mil One, companies like Medella Health can create a wide number of things at a fraction of the cost and time. Not only that, Onshape’s easy to use interface makes learning the software simple for both seasoned CAD warriors and brand new users, so that companies can get their engineers onto the platform painlessly.

We’re excited to be on the forefront of changing the way we turn digital designs into real physical objects, and technologies like browser based CAD and CAM, as well as low cost rapid prototyping tools will change the way we create.

![workshop picture]() Hardware engineers from Medella

Hardware engineers from Medella![onshape demo medella]() Trying out Onshape

Trying out Onshape

Sienci Mill One: Simplifying Desktop CNC Milling

CNC desktop machines are expensive and complicated. This machine changes all that.

Andy Lee

Andy Lee

Hardware engineers from Medella

Hardware engineers from Medella Trying out Onshape

Trying out Onshape