The time is ripe for another frame change! After making some test cuts, I made some observations, notably:

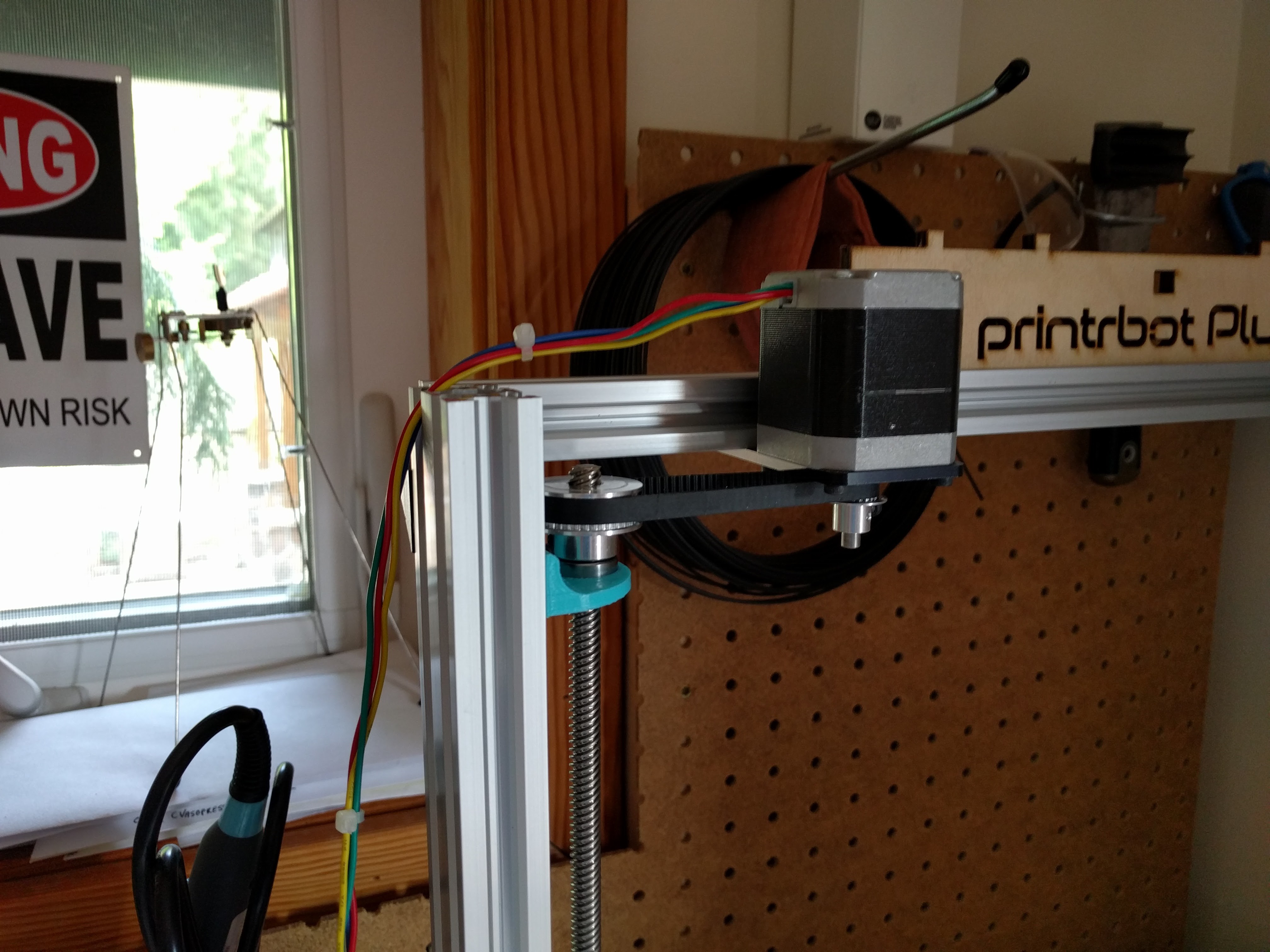

- I was a serious amount of walkout due to the dremel I am using. This will be solved my using a legit metal mount and a more powerful tool (the Makita I mentioned in the previous build log).

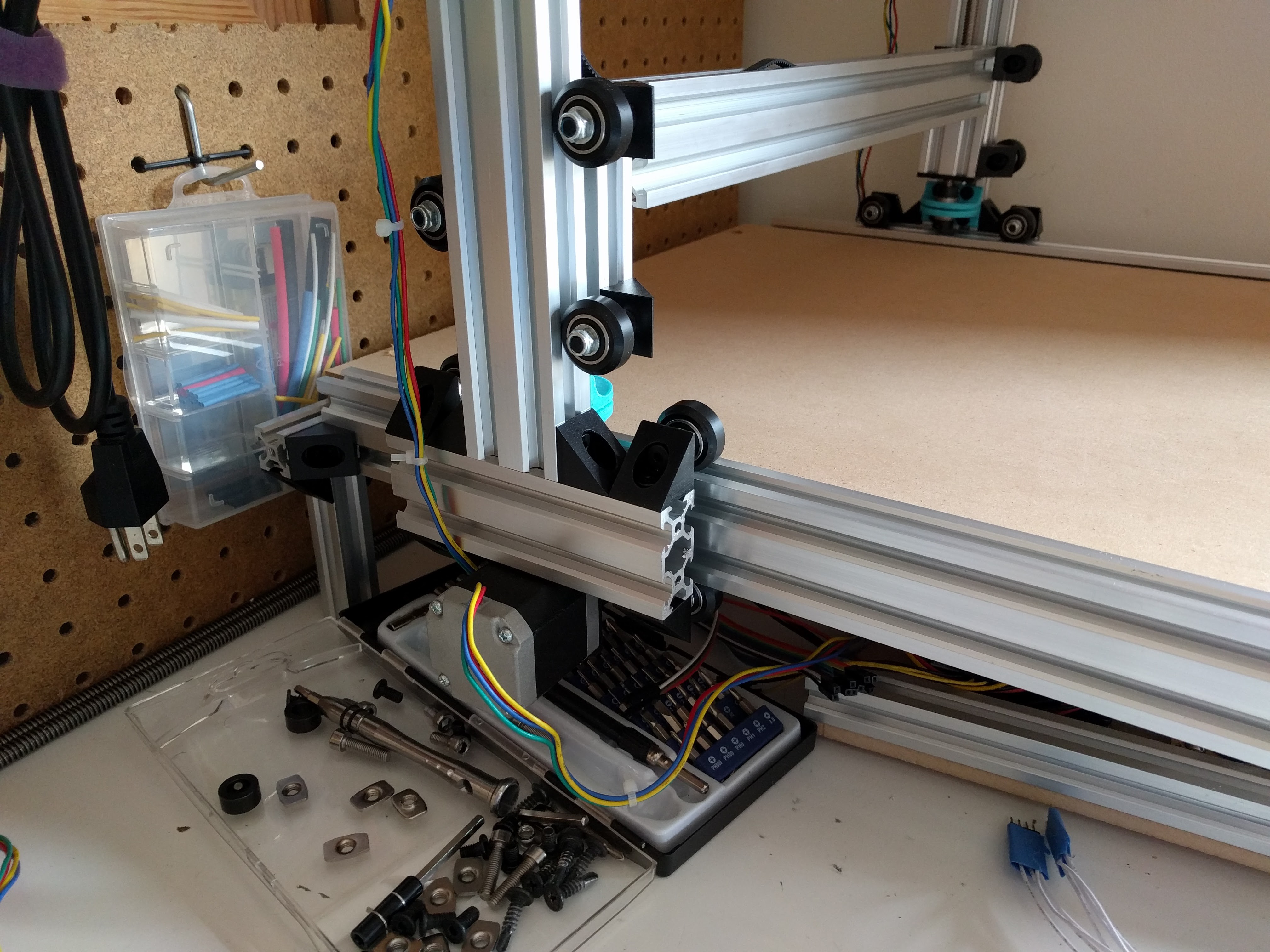

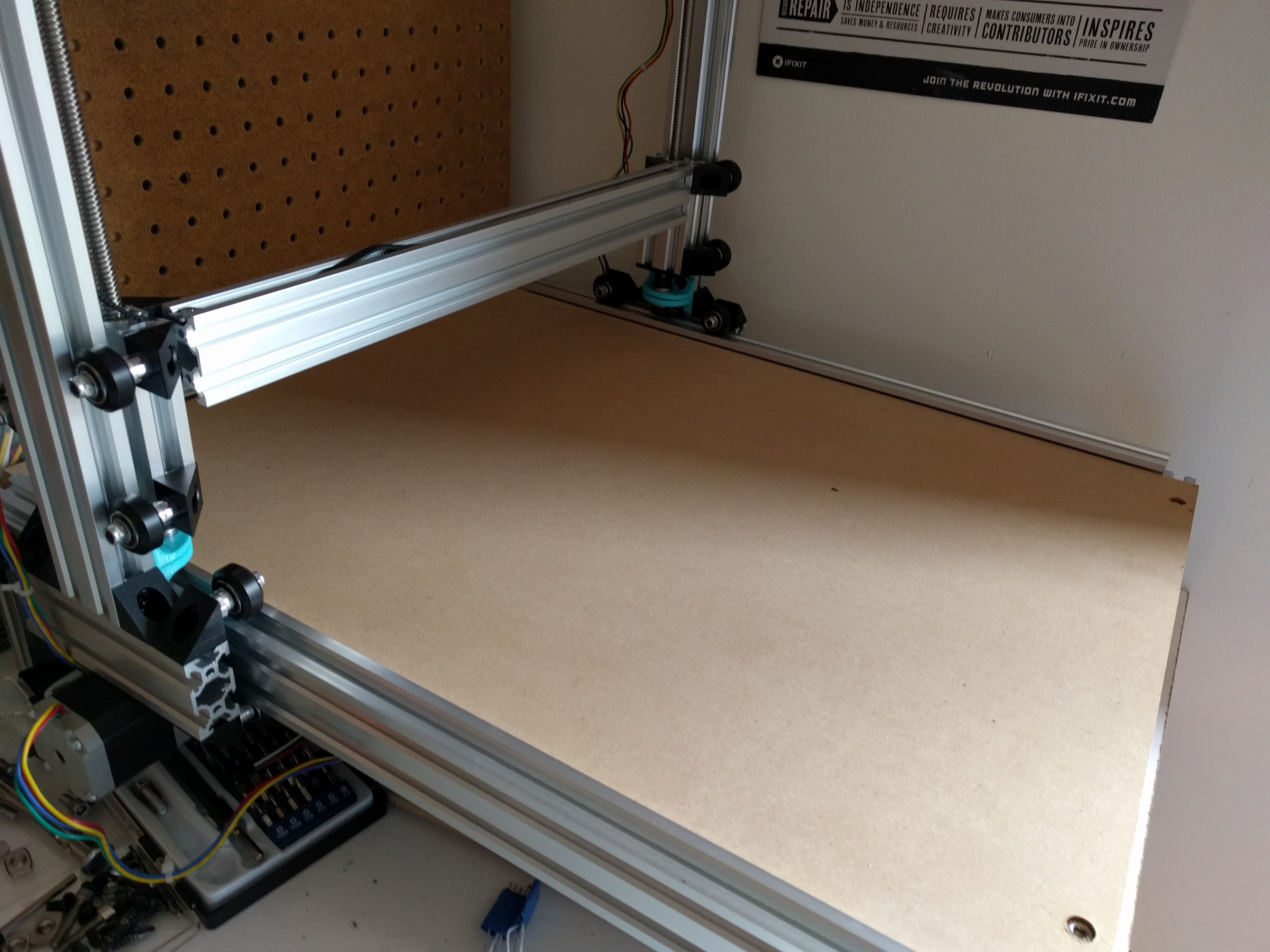

- The bed would flex due to only three points, very close together. His caused cuts to be at an angle which is now resolved with the fixed bed design.

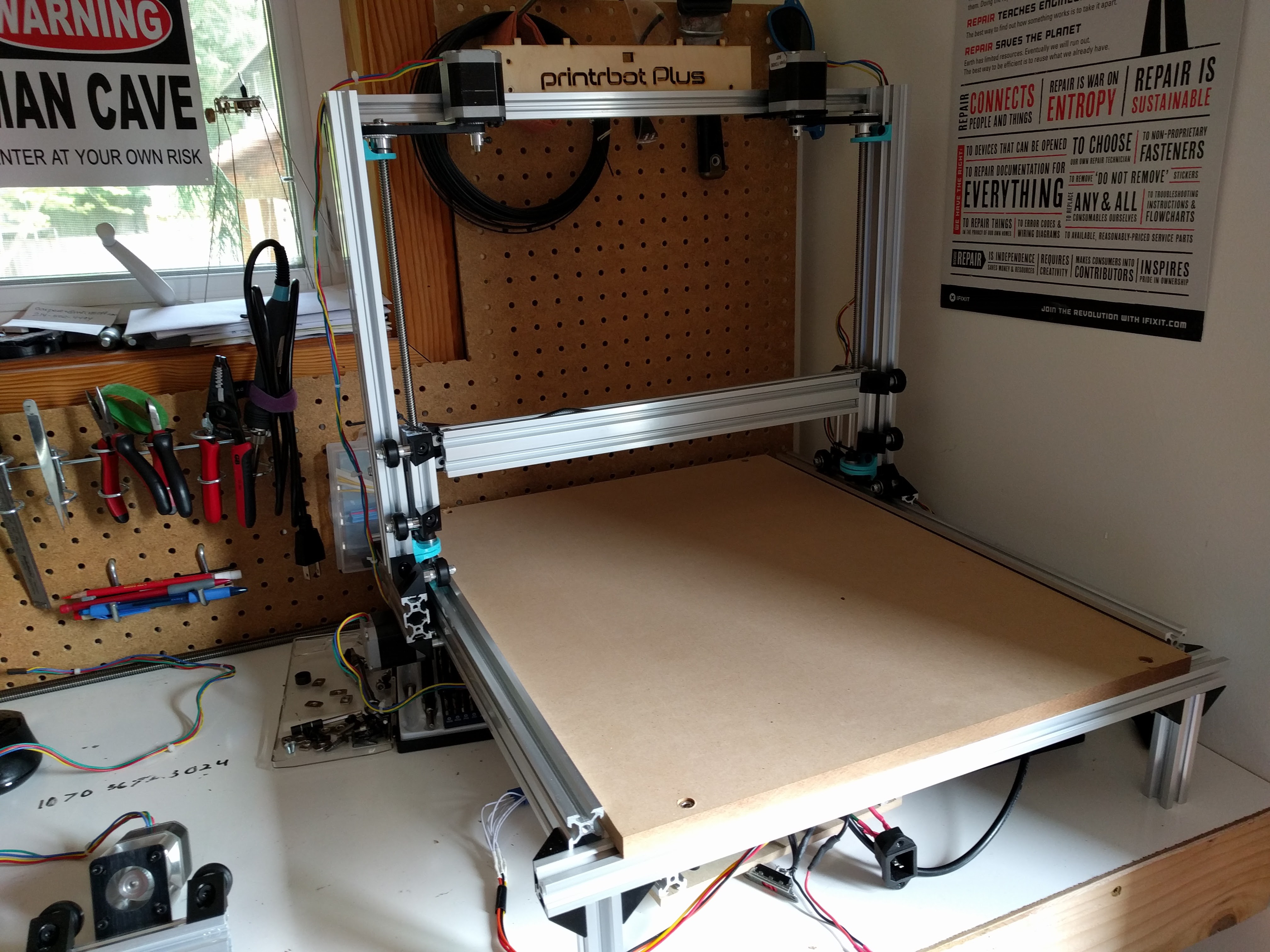

- Also, even with 3D printing in mind, The z was higher than I needed. Shortening it would allow me to change to a moving gantry and fixed bed system.

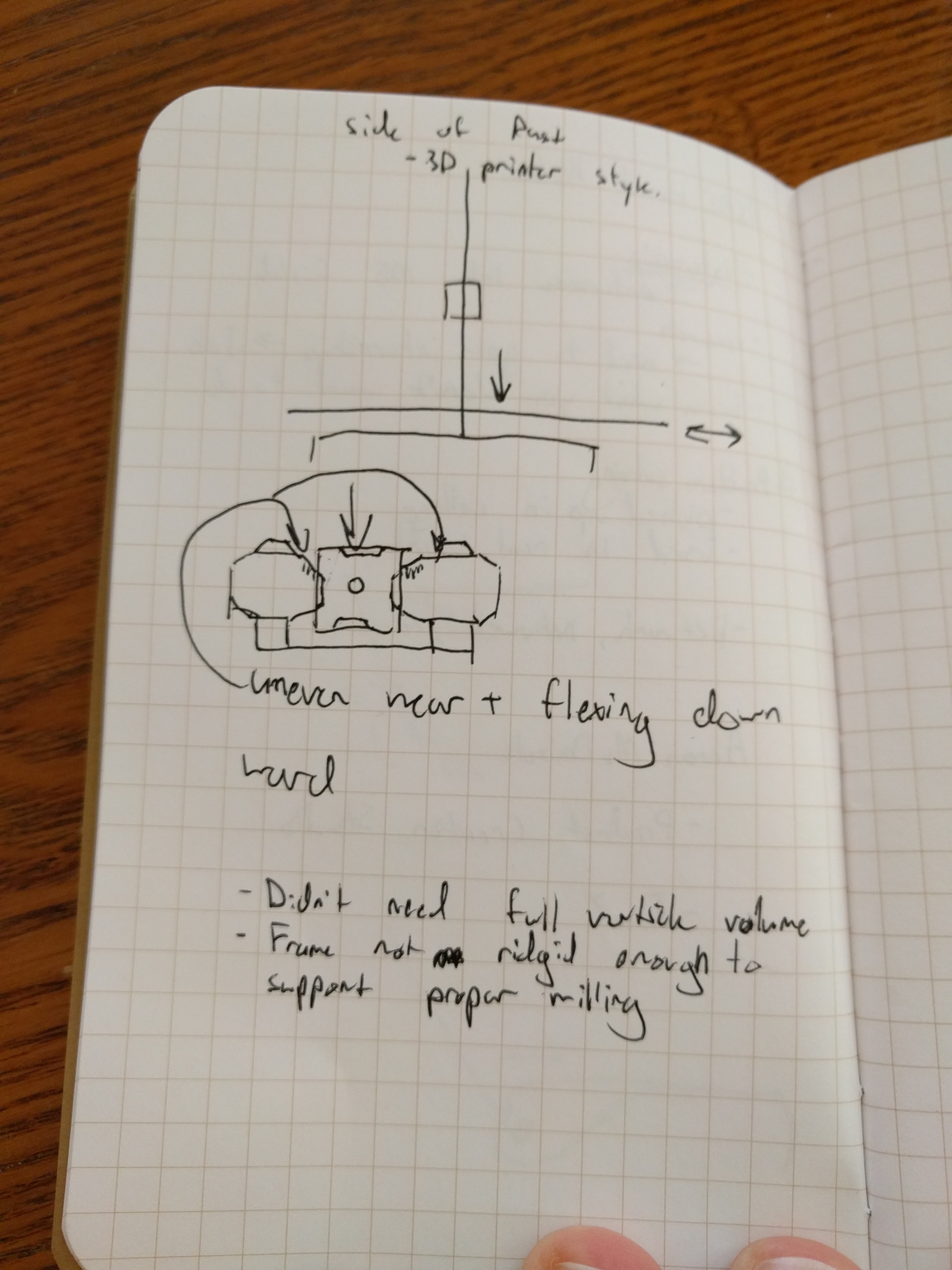

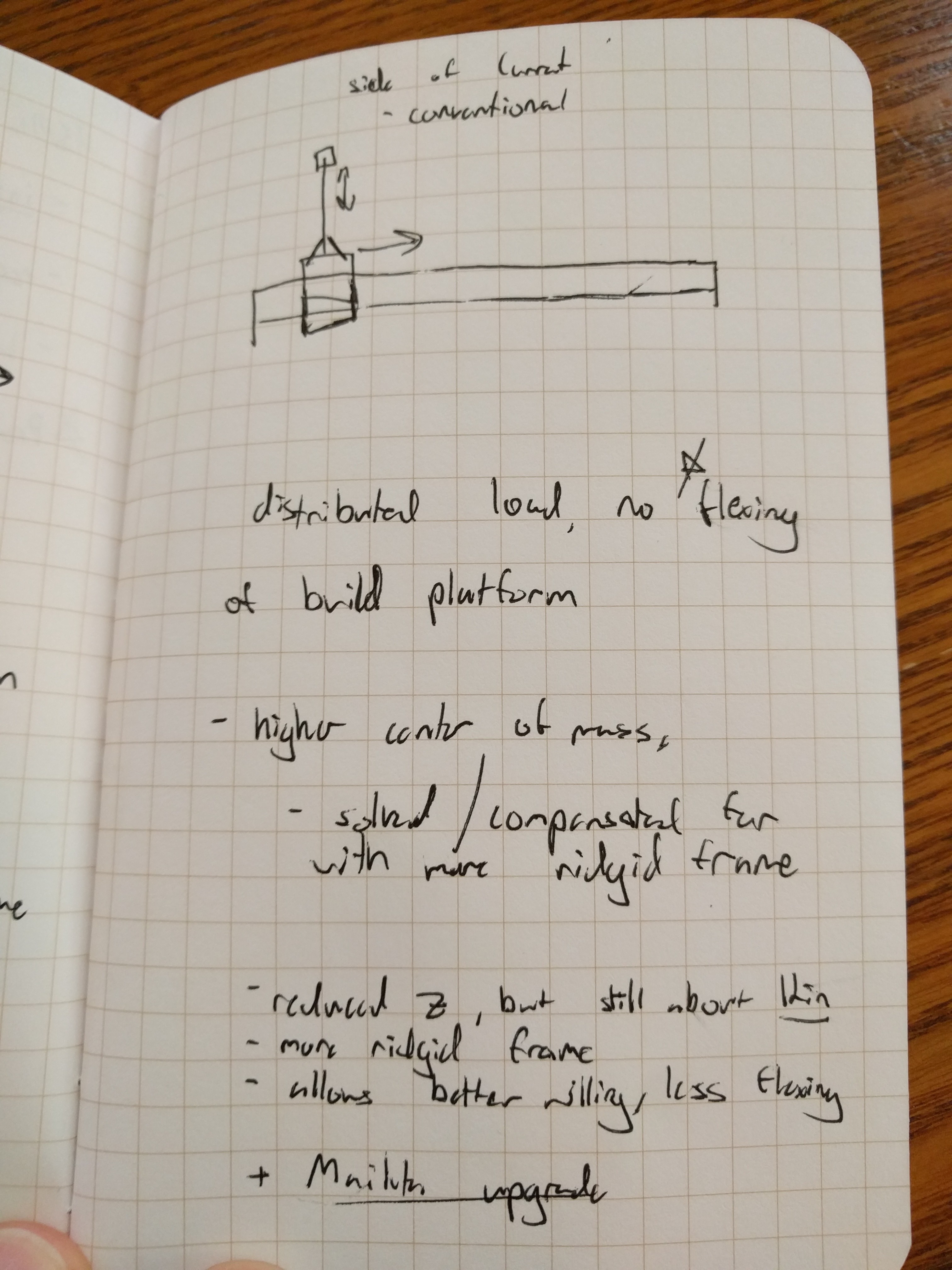

- Here are a few notes in my notebook:

The solution is to change the design from a more 3D printer inspired design to a more conventional milling setup. This keeps the bed in place and lets the gantry move in both the x and y direction. This new setup allows for a more ridged frame to allow for less walkout/better milling as well as supporting a heavier, more powerful spindle.

Alex Anderson

Alex Anderson

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.