I really don't want to have to use custom CNC machining to make the motor, so I'm searching for what I can use for making the motor.

rack with no pinion

Benefits:

+ precision

+ flat-topped teeth. like in steppers.

Drawbacks:

- wrong material

- eddy currents

- no idea, where to get one

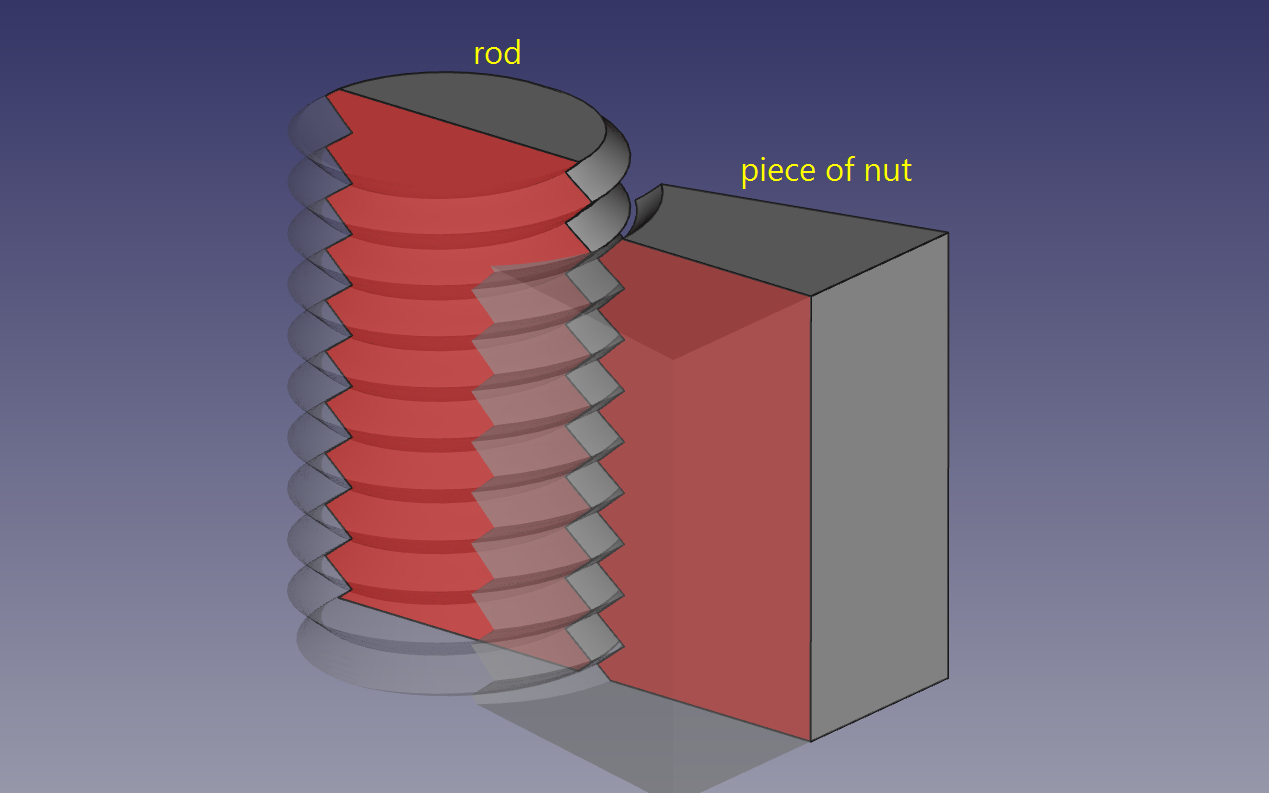

Threaded rod and nuts

Benefits:

+ precision

+ easy to obtain, cheap

Drawbacks:

- wrong material

- eddy currents

- spiky ridges. Can be smoothed out, but it's not easy to do precisely.

Saws

Benefits:

+ easy to obtain, cheap

+ thin, so can be stacked to get rid of eddy currents

Drawbacks:

- wrong material

- spiky ridges. Can be smoothed out, easier than with threaded rods.

- not made to be precise, generally.

Ferromagnetic 3d-print (PLA with iron)

(thanks to @Lupus Mechanicus for steering me to this!)

example: http://www.amazon.com/Ferromagnetic-grams-3D-Printing-Filament/dp/B019J1E7GI

benefits: AWESOME!

+ precision

+ flexibility. Motor can be tailored to fit the printer.

+ no eddy currents

drawbacks:

- bad temperature stability, might require active cooling

DeepSOIC

DeepSOIC

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.