This is just a design concept at the moment. Here are the problems I'm facing with my current stations:

1. Two irons are still not enough. I would use at least three. Yes, I just have two hands, but waiting for the iron to cool down, is not what I want. I'm actively using three type of head (one for SMD discrete components, one for the SMD drag soldering and one for trough hole)

2. The WD-2 always heat up both of the irons, even it isn't needed, what is waste of energy

3. I'm forgetful. Time to time I left the soldering station switched on, on my bench. This isn't just dangerous, but also waste of energy.

4. Call me an idiot, but I want to measure/log the consumed energy - even integrate the energy measurement into my home automation system.

So my plan is the following:

Build a soldering station mainly around an ESP8266 module, using Arduino. for the control and display use some 2.8-3.5 TFT touch screen. Make the iron connector sockets modular, to be able accommodate the Weller WS-80/WSP-80 and a few type of Hakkos.

Use optical sensors for the irons to detect if it is fitted into the holders. If it is there switch the iron off after certain period of time.

Use switching power supply instead of the heavy and pricey transformer if it is possible (looks like all of the irons I was looking for need 24V, means I can handle the whole thing with a 24V/200-300W PSU)

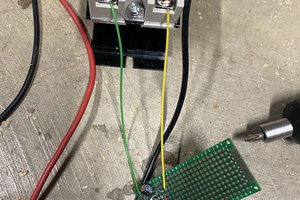

The power consumption can be measured by an ACS712 hall sensor, and can be logged via MQTT client on the ESP8266.

SUF

SUF

pastcompute

pastcompute

ProgressTH

ProgressTH

Will Stone

Will Stone

k

k