This week at the DesignLab was mostly about design refinement and training for the heavy duty tools.

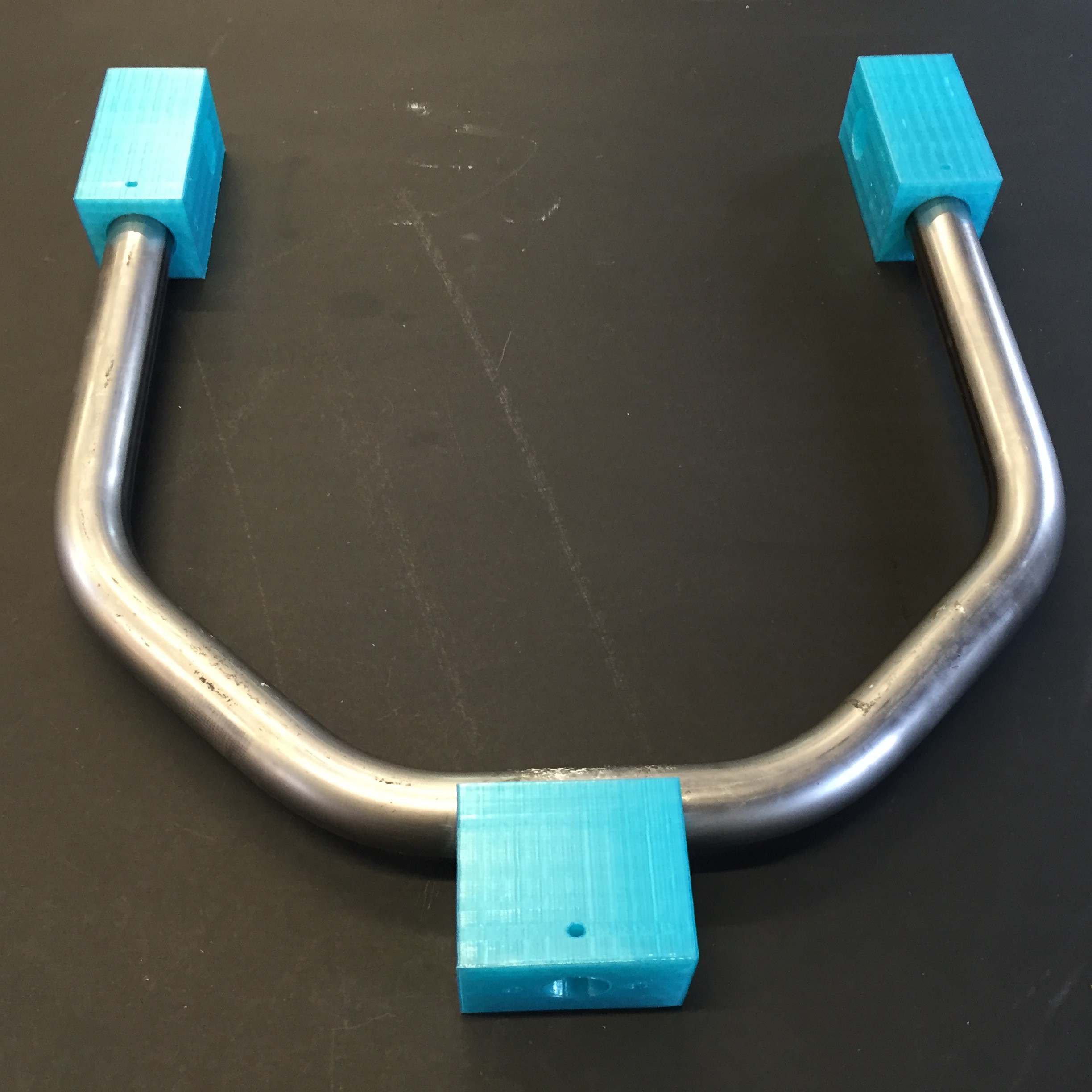

I picked up the yokes for the new Scopes from the pipe bender. It should be a much faster way to produce new units quickly and cost effectively. They seem to fit the bearing blocks I printed a while back fairly well too.

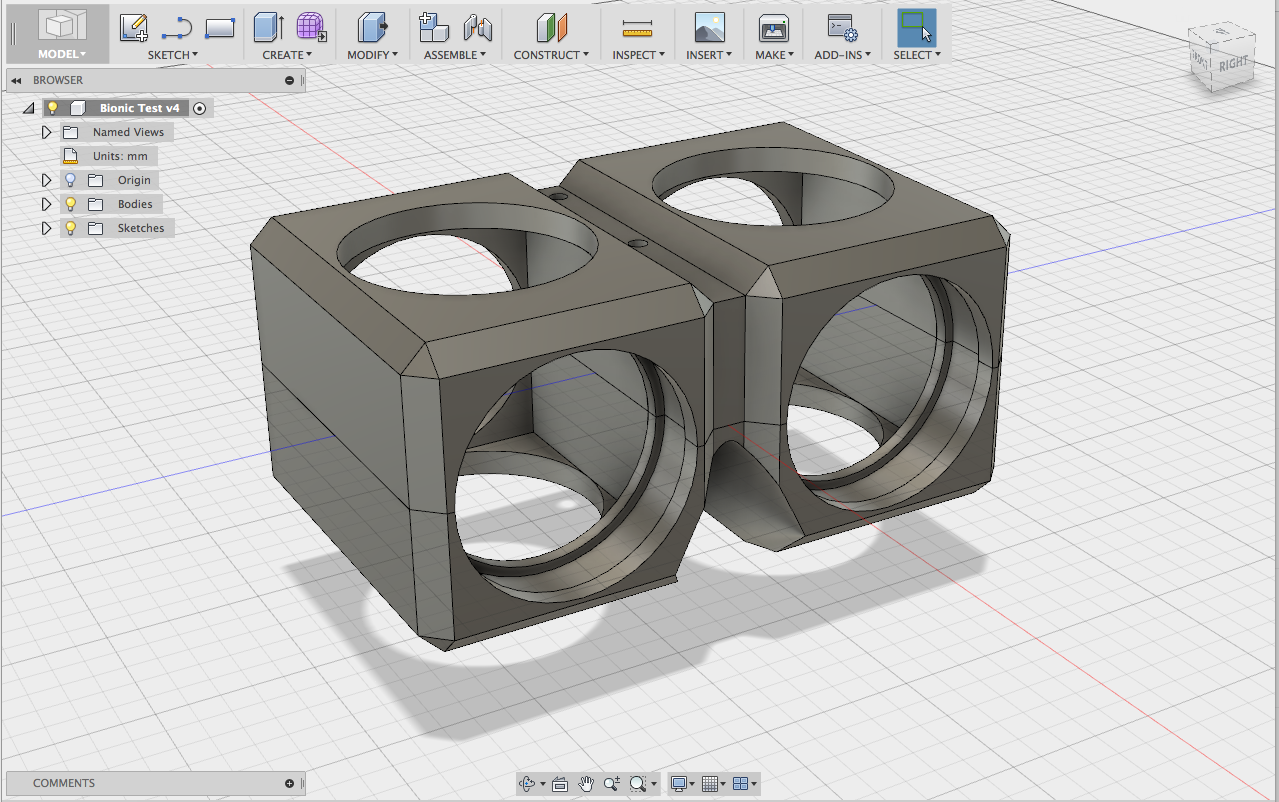

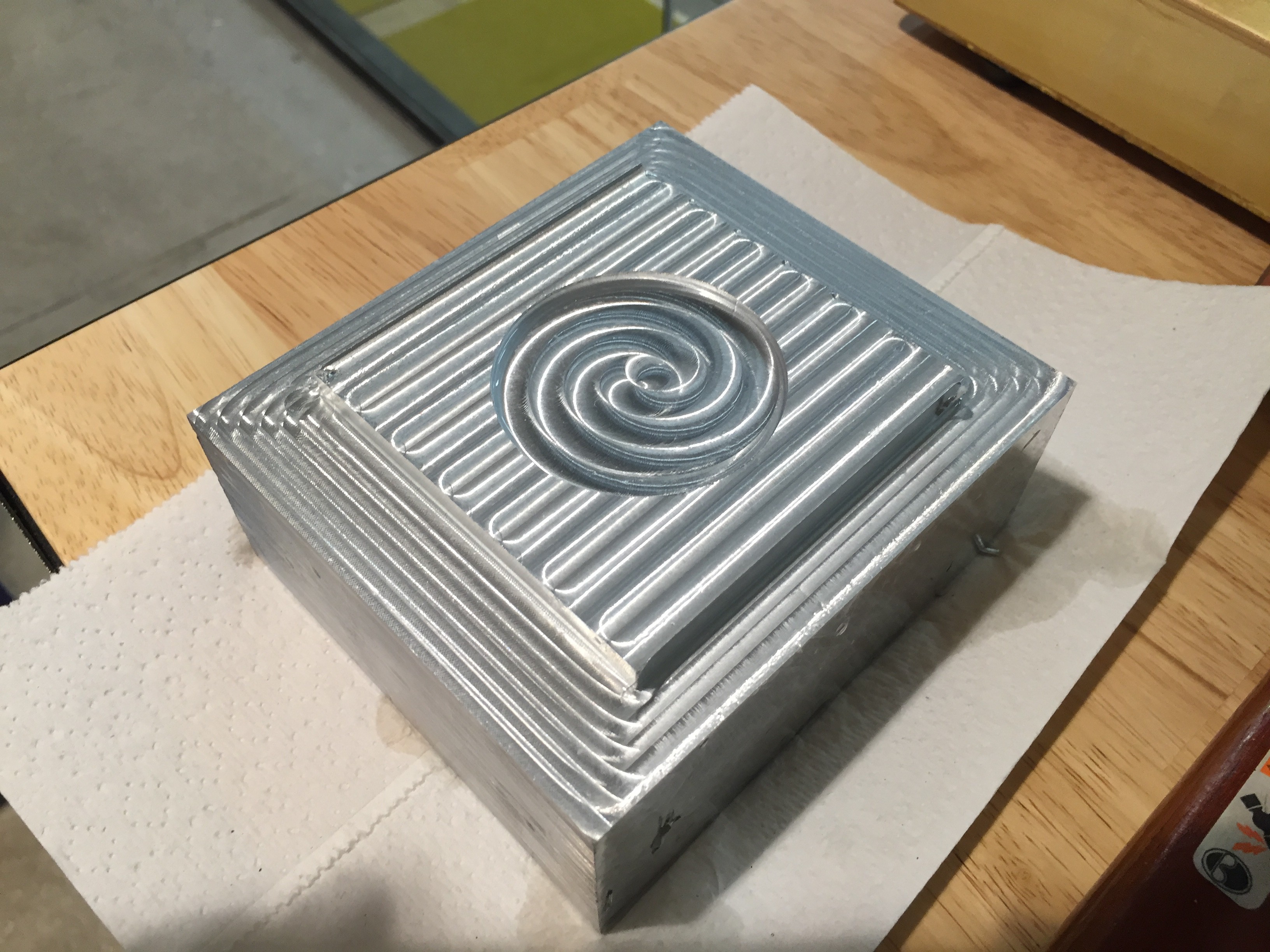

The final bearing blocks will be milled out of aluminum, so I did some training to get up to snuff on the Tormach CNC we have in house.

It's going to take a little finesse to get my bearing block design ready to be milled, but I'm excited to see what this CNC can do.

With the supply chain side of my optics fairly figured out, I've been iterating on the housing design a bit. I'm getting fairly close to having something production ready for these next few units. The question will be whether to stick to printing them or start experimenting with resin casting, injection molding, or milling them out of aluminum on the CNC.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.