If you haven't seen it already, over at #CD/DVD mechanisms and cartesian thinggie[s?] @johnowhitaker came up with a technique to laser-melt toner directly onto materials such as copper-clad board!

(That description and link will likely become a bit redundant, as this project-page progresses!)

Here's a log of my (@esot.eric) attempts. Result: VERY PROMISING.

See More about my experiments... Click below!

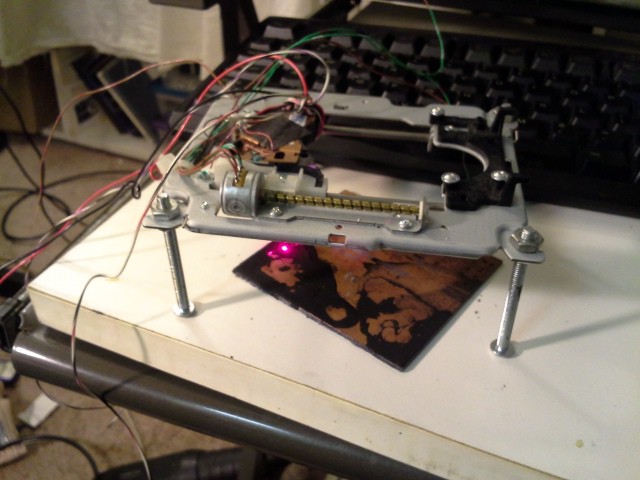

This is from a 20x DVD-RW drive. The focusing-lens has been removed and this lens hotglued on. This lens is from an old camera, but its focal-length is about the same as a magnifying-glass. In fact, I used a magnifying-glass for my earlier experiments and only decided to use this one because its size lends itself well to mounting. (In other words, if you've got a magnifying-glass, go ahead and use it!). The result is that the focal-point is an inch or so away from the laser (rather than the original focusing-lens's 1-2mm) making it much easier to focus on the material (in fact, it seems to work fine without adjustment for materials as thin as tissue-paper to as thick as a PCB).

This particular laser I've been running at 250mA reliably. I haven't attempted to go higher. (And, for the above photo, I accidentally wired it backwards. Thank Goodness it didn't blow! My supplies've run out and my graveyard is large!)

-----------------

These attempts are all moved by hand... Now that I've got these VERY PROMISING results, I'm going to rig up an X-Y system soon.

-----------------

Here's an early (failed) experiment.

Note that the laser's path is clearly visible (nice!).Note also: Do Not Shake the mixture! Stir it carefully so as not to introduce air-bubbles!

@johnowhitaker's formula is: Rubbing Alcohol and Toner. It took a few tries to get the right thickness (and, actually, I'd almost given up before finding it).

I used the butt-end of a pen cap, with a white/clear housing, to stir the mixture. First I poured toner into a margarine tub, then I added a little alcohol while the tub was tilted. The toner didn't mix in entirely, so I kept scooping more in until the thickness was *just enough* to coat the pen-cap (no more!) and still drain off slowly, revealing the color of the pen-cap.

At that point, pour it onto the PCB and drain it off...

Here's another from the first failed attempt(s):

I drew a "2" (sideways, near the bottom).The idea is to use a cotton-swab to remove the un-melted toner surrounding the lasered-portion. If the mixture is too thick, it seems to dry like thick paint, and the amount of rubbing necessary to remove it is enough to damage your traces. This one *seemed* to work, but wasn't quite right, and by the time I got it all cleaned up the traces were damaged... here's the lasered-portion for comparison:

Note how there was no lasered "cross-piece"... Frustration with trying to remove that and surrounding material ruined the traces.

Note: Don't rub vigorously with the cotton-swab, friction creates heat, heat melts toner.

(For size-comparison, the row of pads on the right are for a compact-flash connector, using the old toner-transfer-paper method, long ago).

Note also: Don't try using alcohol to clean up (until later)... it just rips the traces right up.

Now for the VERY PROMISING results:

This, again, was with it *just* thick enough to coat the pen-cap while still draining off slowly:

This is a little bit confusing, I didn't clean the board first, so there's a patch of permanent-marker near the corner interfering with the toner and traces... This was a handy unintentional experiment, too... I'll talk about that later.

I also added a square later-on... Here they are rubbed off with a cotton-swab (note the ugly permanent marker still under the first squiggles).

The traces actually have a bit of heft, almost like... the results of a layer from a 3D "cornstarch-printer" (whoa! hmmmm).

Now here's where that patch of permanent-marker gets interesting... Notice how clean the square turned out, with just some rubbing with a cotton-swab... Cool! It was pretty resilient this time. Awesome. Then I got a bit cocky and decided to try alcohol cleaning, and that square wiped right off.

After that I heated the "squiggled" area with a heat-gun to "set" the traces. Worked well... And then, I tried alcohol again... this time to clean up that permanent marker... and... NO PROBLEM.

Those traces are measuring about 17mils, which is a bit larger than I expected, but perty good for home-made early experiments, no?

I'm certain the laser could be better-focussed, also maybe the toner was still too thick, and flowed a bit when I heated it... I certainly wouldn't put the resolution cap at 17mil with this first experiment.

So, some observations... This turned out much better than I expected, especially after those initial failed attempts. I hesitated to rub too hard to clear out the unmelted material between corners and in tight spaces, but I think I could've been more vigorous (or at least more patient) and gotten even better results. Maybe a thinner mixture would work even better. And, one could design boards around these constraints, as well. (or might not even have to). I was thinking to try to avoid things like sharp corners, thinking about paths for material-removal... but then again, where there are sharp corners, there's probably not going to be *another* (unconnected) trace nearby, so even if the excess material isn't removed, it probably wouldn't matter.

And, besides, look again at that detail (WTF? My camera was set to 640x480?!)

Even in the sharp corners it cleaned up pretty good.Now, as far as resilience for PCB-etching, I think it's pretty much a sure thing. Awesome.

(I'll wait 'till I can actually etch a usable board before trying).

As far as using this method for e.g. creating labels on metal instrument-panels... I'm not sure yet. It can be scratched off, but I didn't try heating it more (and from the bottom?). Clear-coat over the top might be a good idea. Or maybe even a clear pre-treatment under the toner to make it grab better?

AGAIN:Keep following this project-page for updates and more-detailed instructions/experimental-results. Also, check out @johnowhitaker's original log-entry for step-by-step instructions and his #Mini Laser Cutter.

Eric Hertz

Eric Hertz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.