Finally got a plasma cutter so I could work sheet metal and make the fume hood to work with the nasty chemicals required.

Plasma cutting is relatively easy, however, unless you have a very good worksop, it requires some way to contain the sparks it produces, so I had to build a water bath and cut support.

A secondhand metal box was bought:

And welded shut because the ends where just spot welded.

Painted it with anti rust paint:

The cut support was made to fit inside the box and have removable blades:

As first project, I made a monitor panel for the sputtering machine.

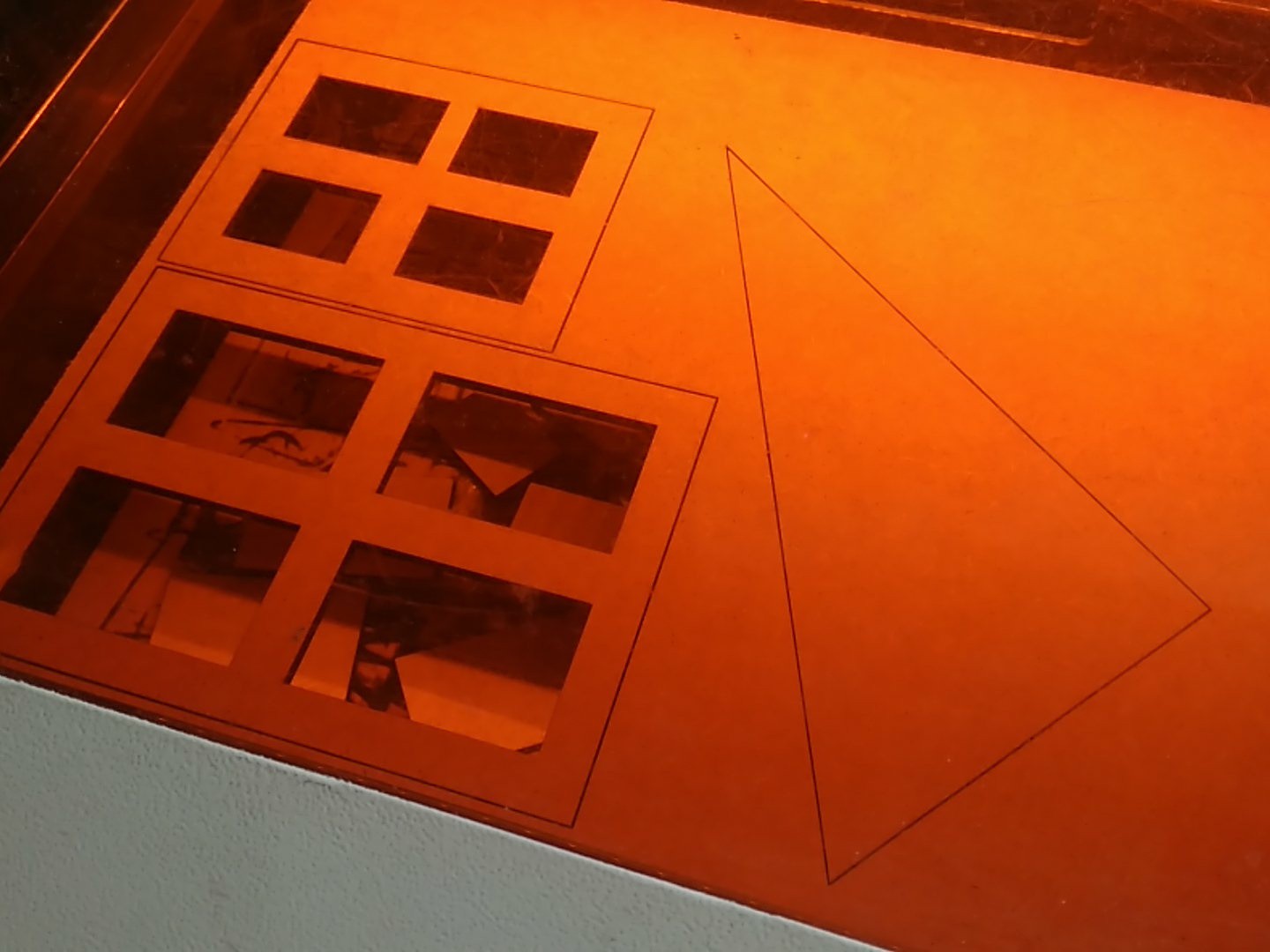

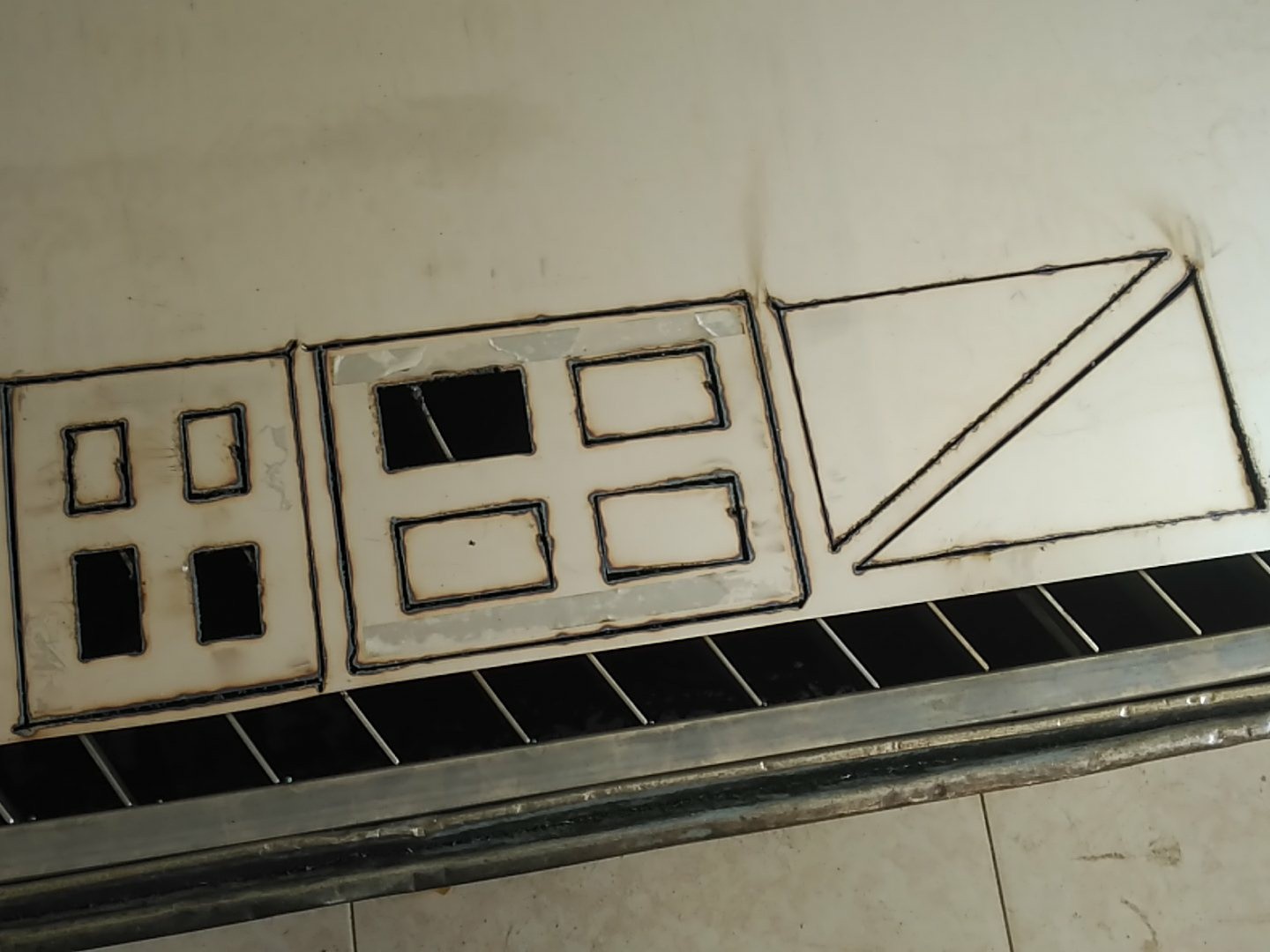

Good thing about plasma cutting, is that you can make wood templates, and so I lasercut some:

You must remember to adjust for the kerf and nozzle width (for my cutter it's 3.375mm/r (1mm kerf)

I have much to learn on plasma cutting, so this was not perfect, but should work.

Since this uses high voltage and I didn't want to have weird feedback loops between the instruments, I installed separate battery holders for each one. They are 9V flip-ups from guitar equipment.

Nixie

Nixie

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.