Up until now, I had been using the oven at a lower temperature, as a makeshift hot plate/convection oven to dry thin fims.

However, as I begin to use the oven for it's intended purpose (growin SiO2 and difussion) it becomes very counterproductive to use it for other things. So, a hot plate to dry the thin films was devised.

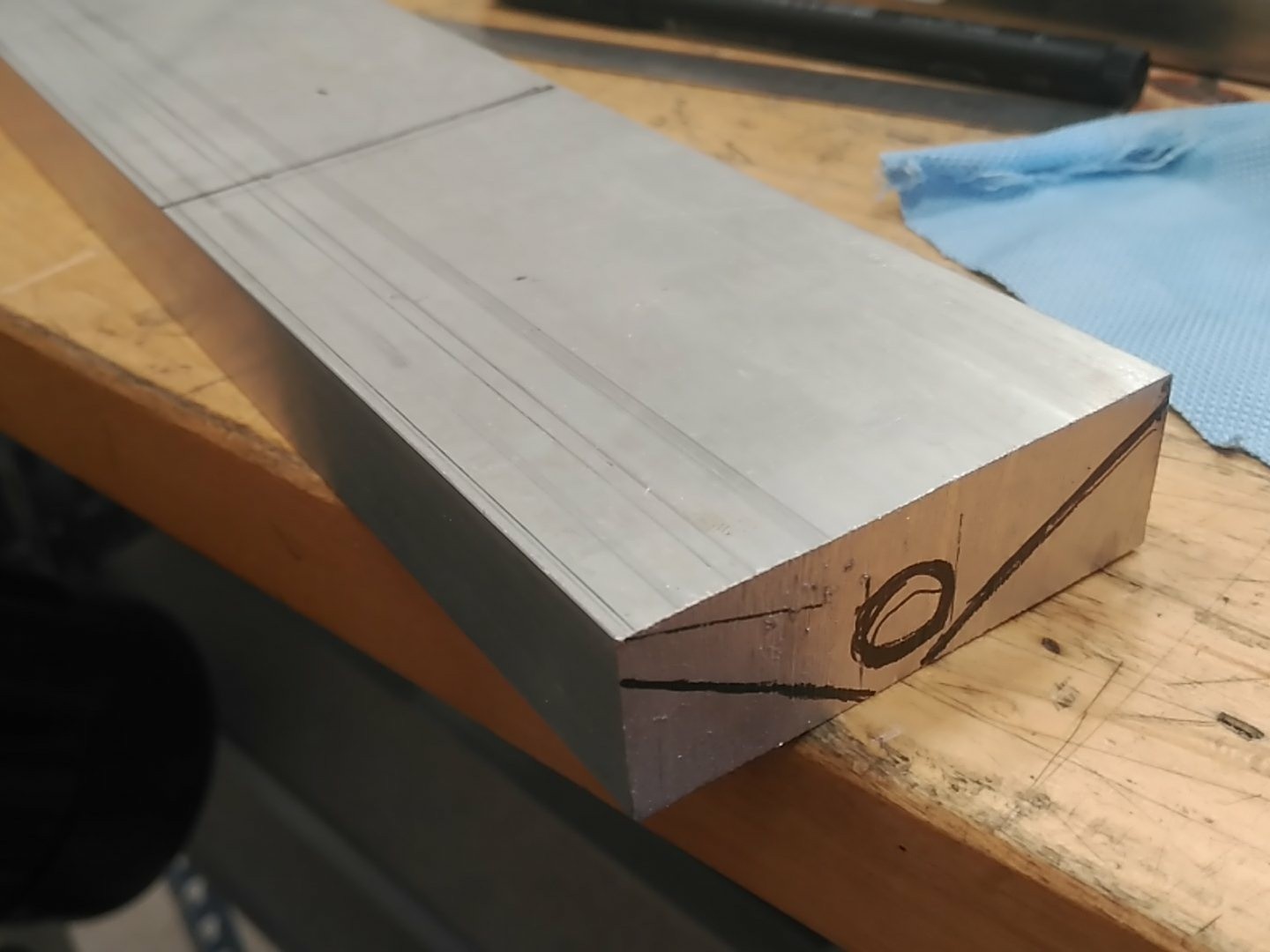

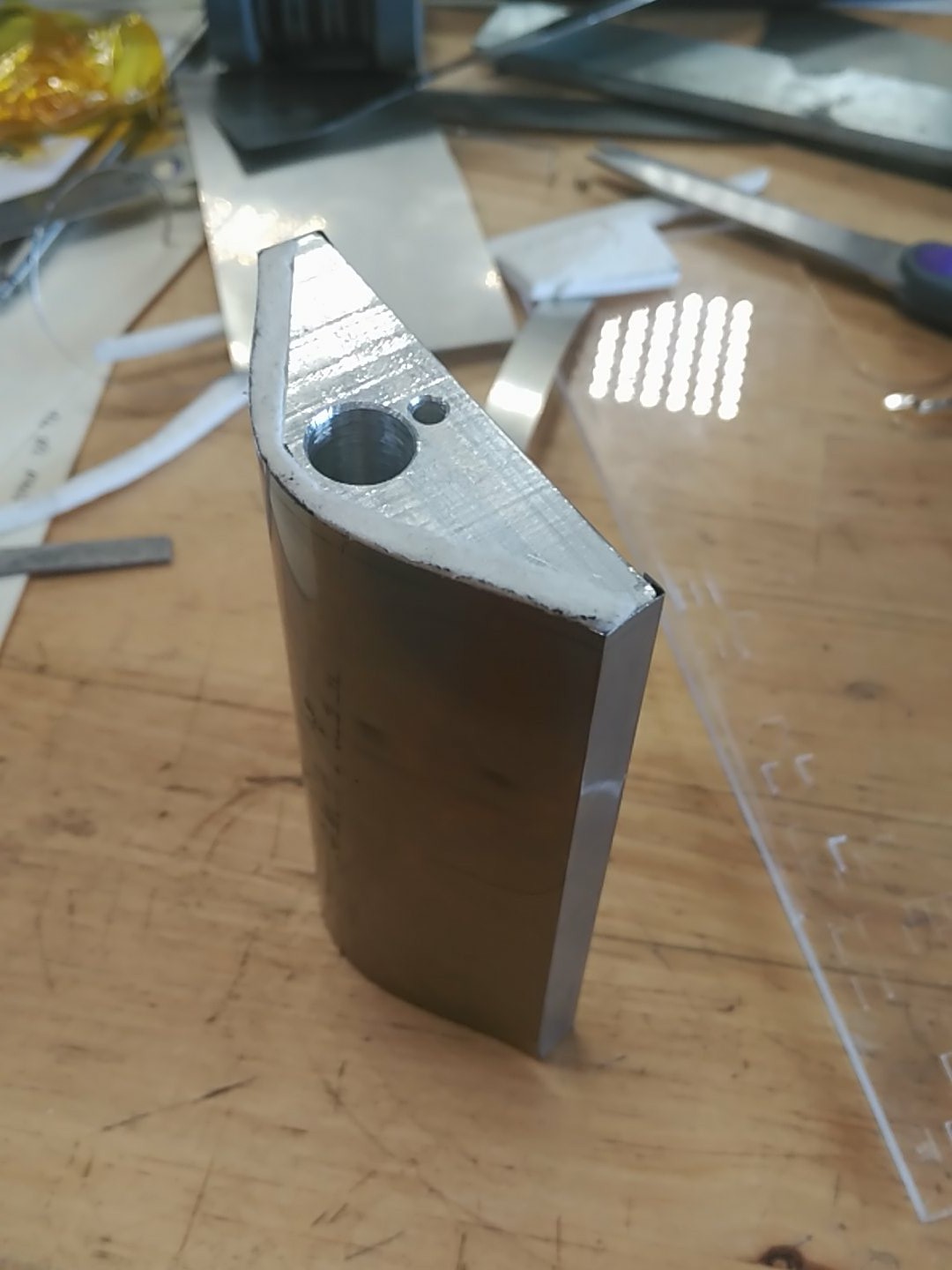

A suitable chunk of aluminium was procured from the workshop, wich offered enough space for multiple pieces and could hold in itself the heating cartridge I had around.

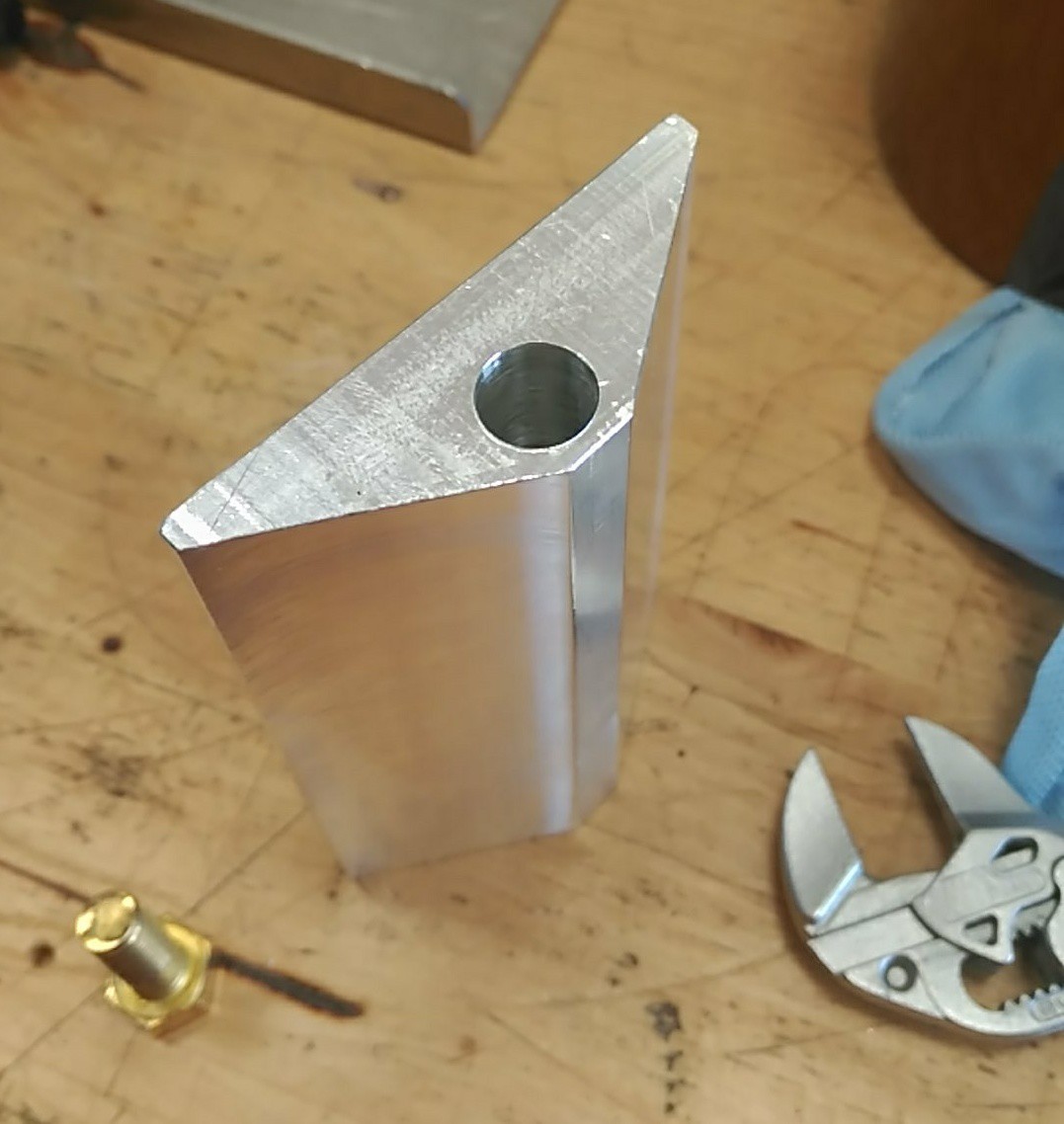

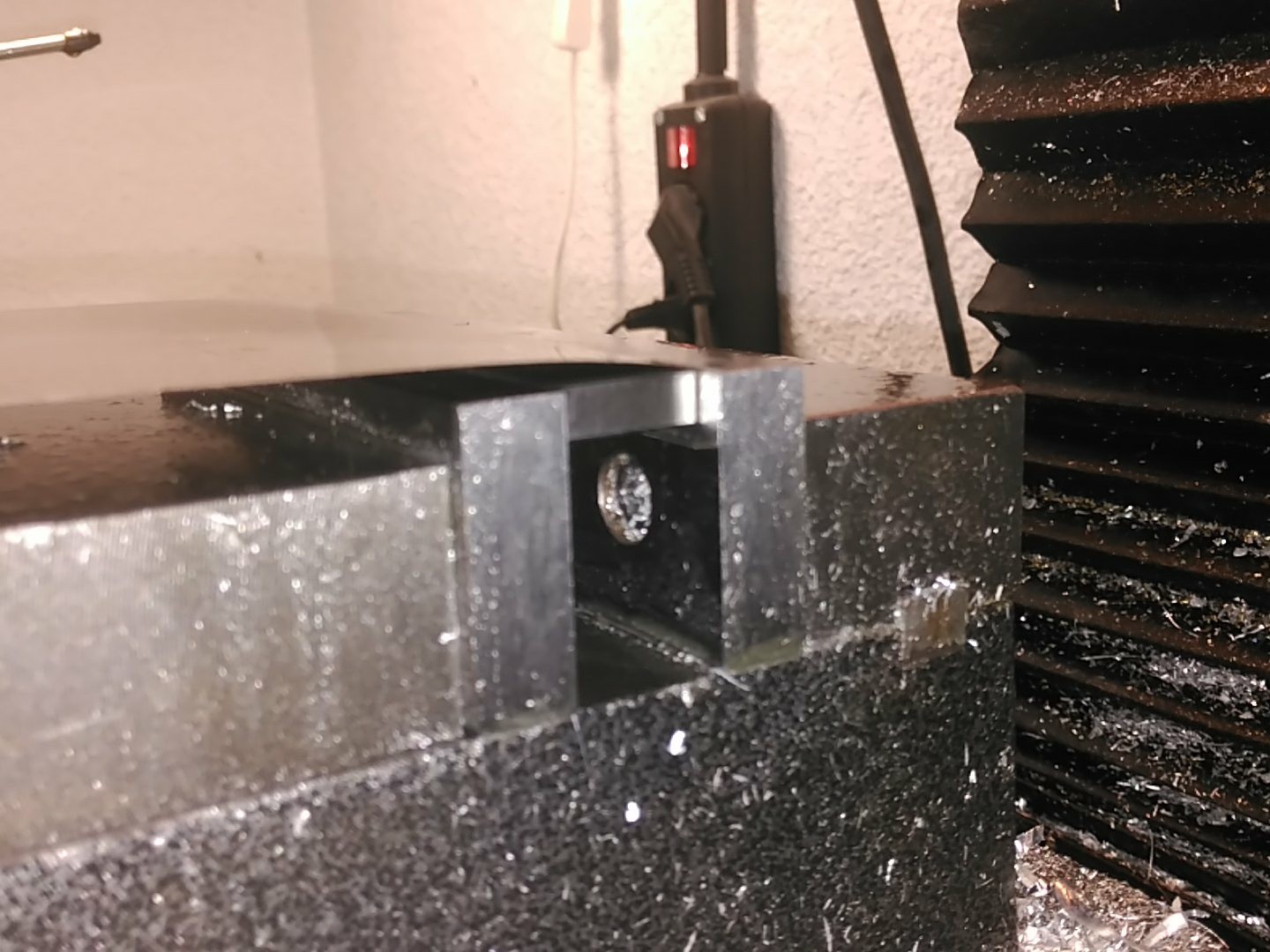

Drilled and milled:

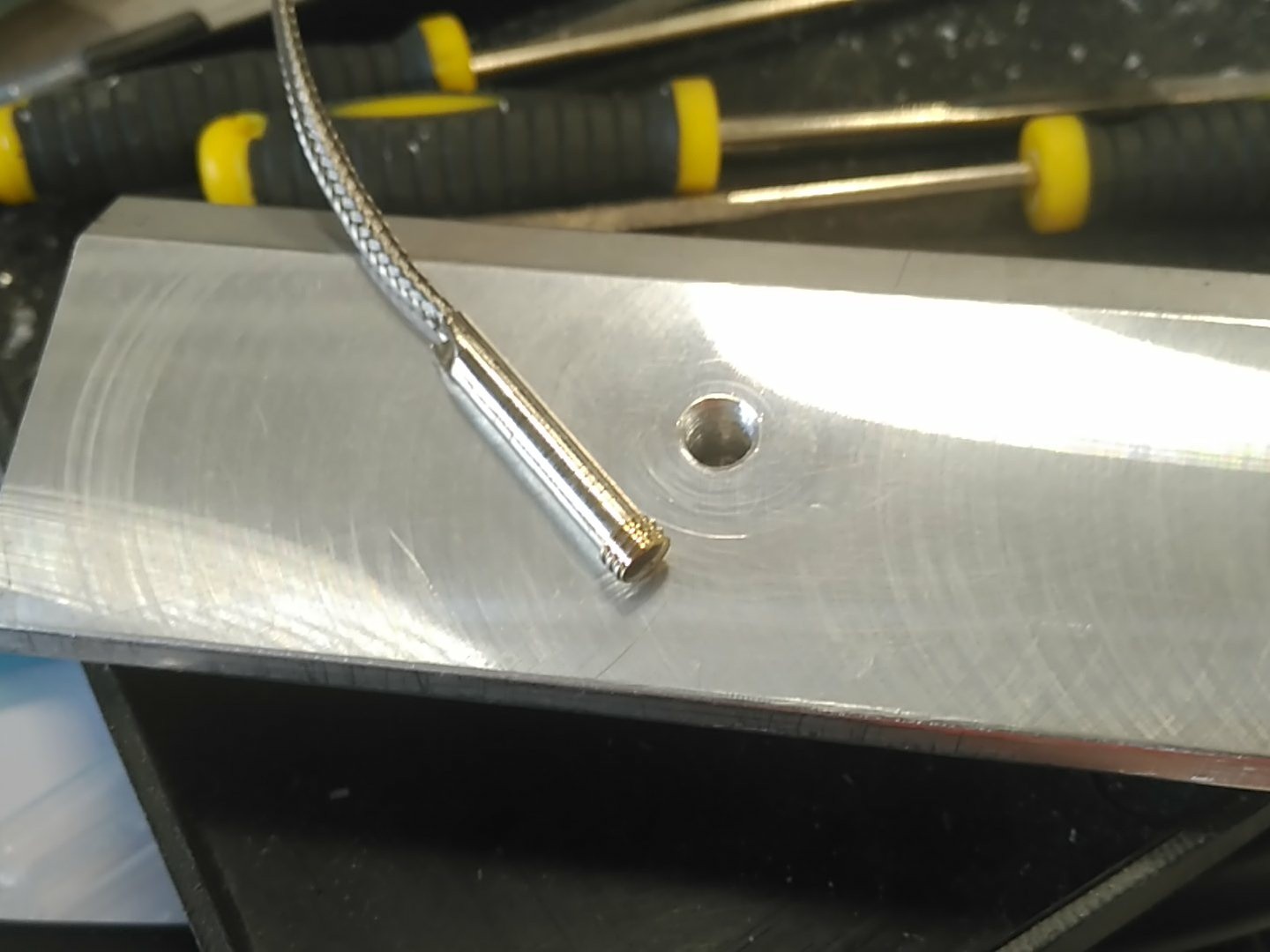

For the K probe, the retention screw had a weird thread I didn't had a matching tap for, so I ended threading the probe itself to M5 and screwing that into the aluminium block. Having it's head sitting just 3mm below the surface of the plate. Plenty of thermal compound was employed.

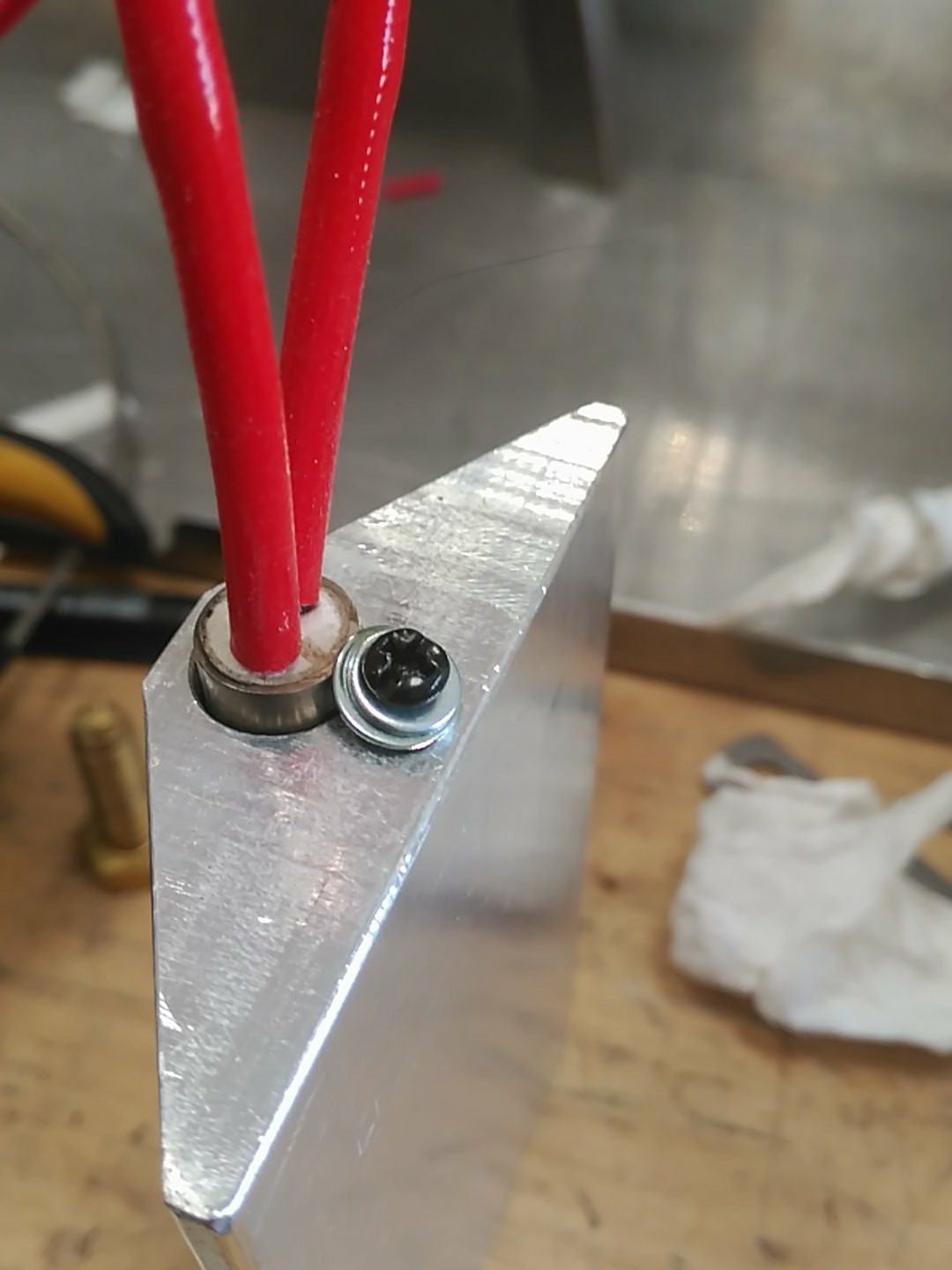

The heating cartridge was retained with a screw and plenty of thermal compound too.

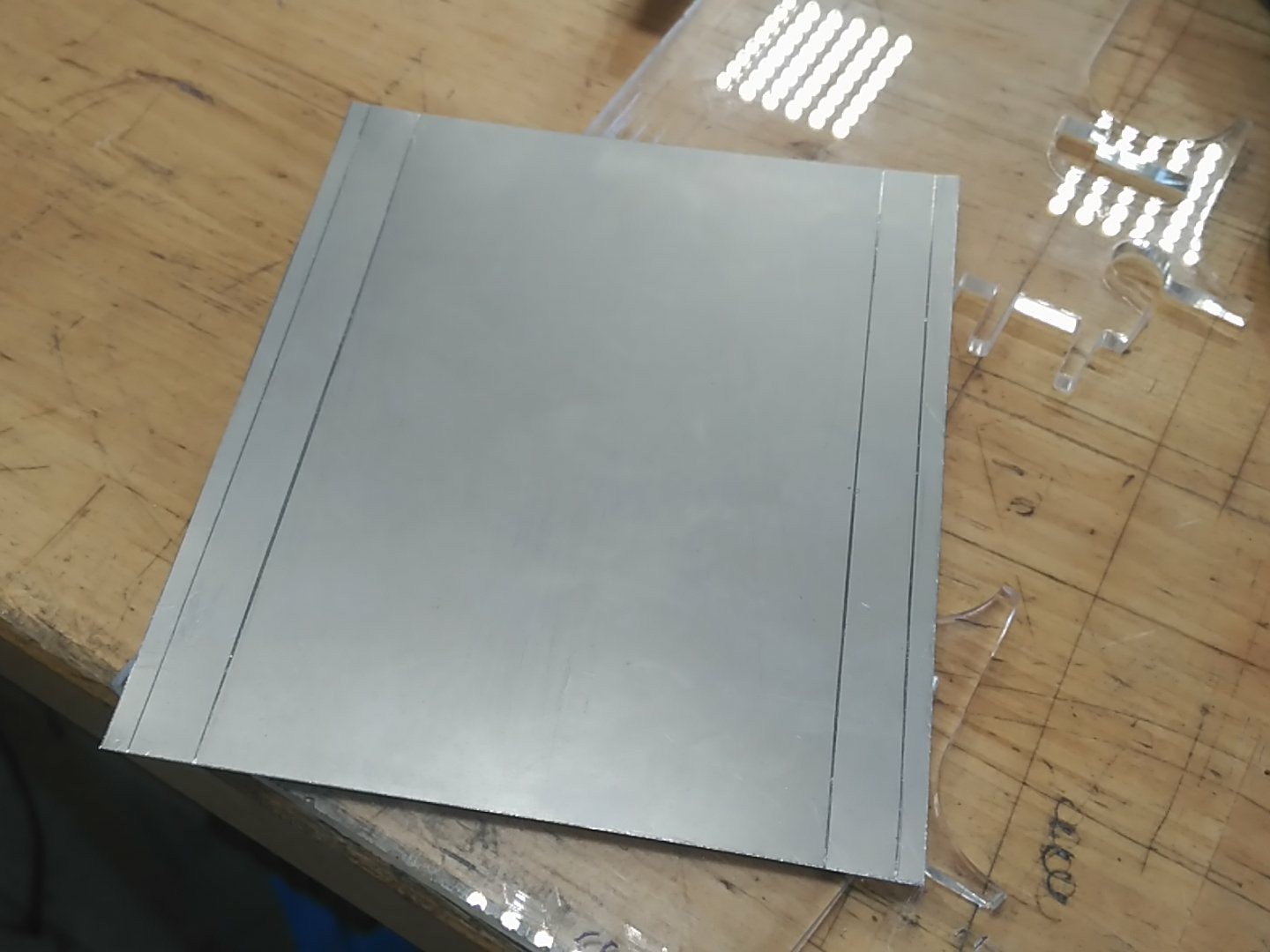

Finally, I wanted to add some termic isolation to the bottom, so the assembly could be made compact. Ceramic matt tends to be fragile, so mechanical subjection is not recomendable. Instead, I scissor cut a piece of solder paste stencil and marked it with a cutter.

Clamping it into a vice, it was first hand bent and then shaped with a nylon mallet:

The inside corners where bent using a spacer:

With that and careful measurement, a super nice bracket for the ceramic matt was done:

To further isolate the electronics from the plate, sheet metal legs where spot welded to the plate:

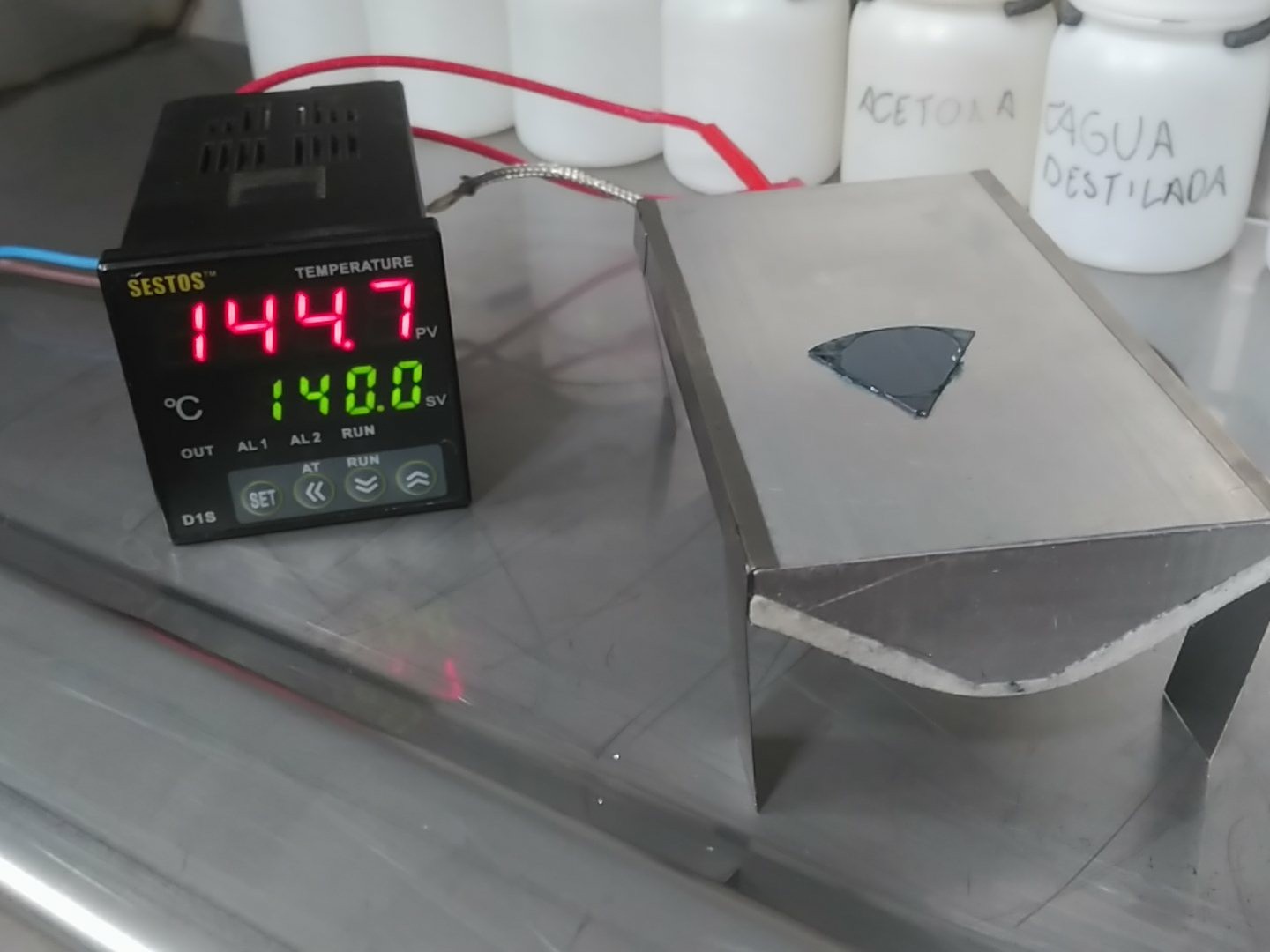

With that, but pending a different temperature controller with SSR capabilities, I connected it to an old controller I had around, and for now, I have a sketchy, but working hot plate!

Once I get the definitive controller, everything will be made much compact, with the plate on top of the controller + SSR, a nice case and some form of heat shield so you can't accidentally touch the hotplate sides.

Nixie

Nixie

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.