With the excellent result achieved with the improvised spin coater, it becamse sacrilegous to leave it at that, dangling wires and crappy mounting.

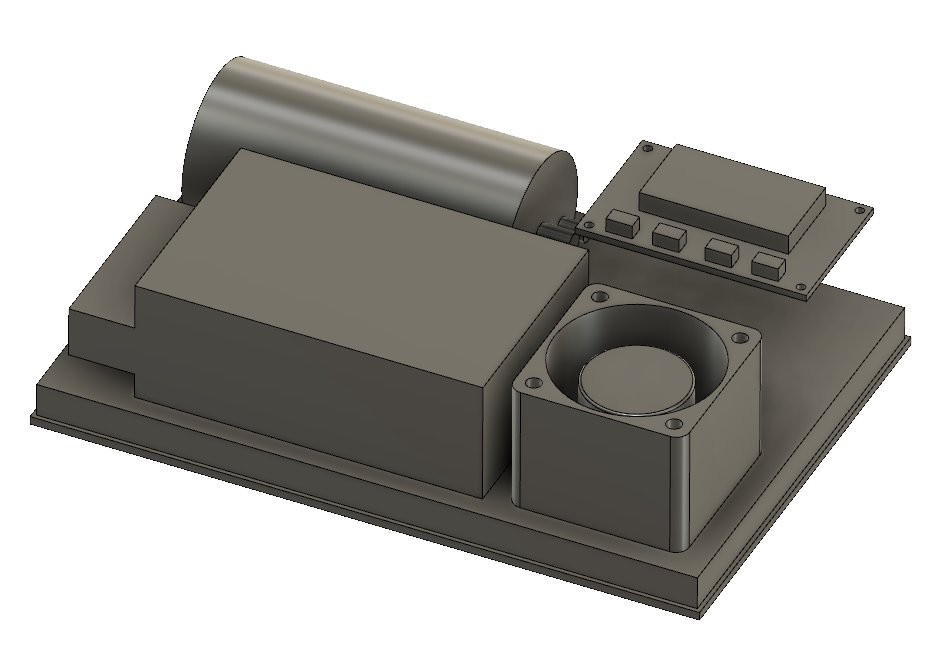

Thus, I set myself on the task of building a nice enclosure. First I quickly modelled everything in Fusion:

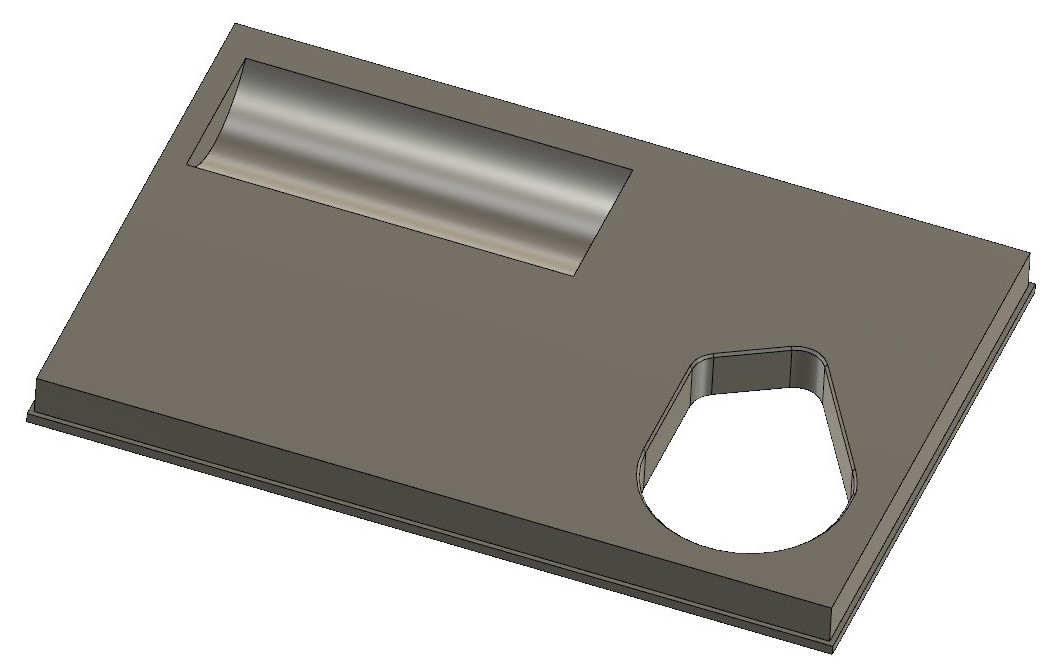

A thick base was added, so it's weight could act as vibration dampening. It would have a recess for the vacuum pump, as it was 8mm thicker than the power supply, and also a hole for the vacuum adapter for the motor to fit in. Resuming, I wanted the thinnest possible unit.

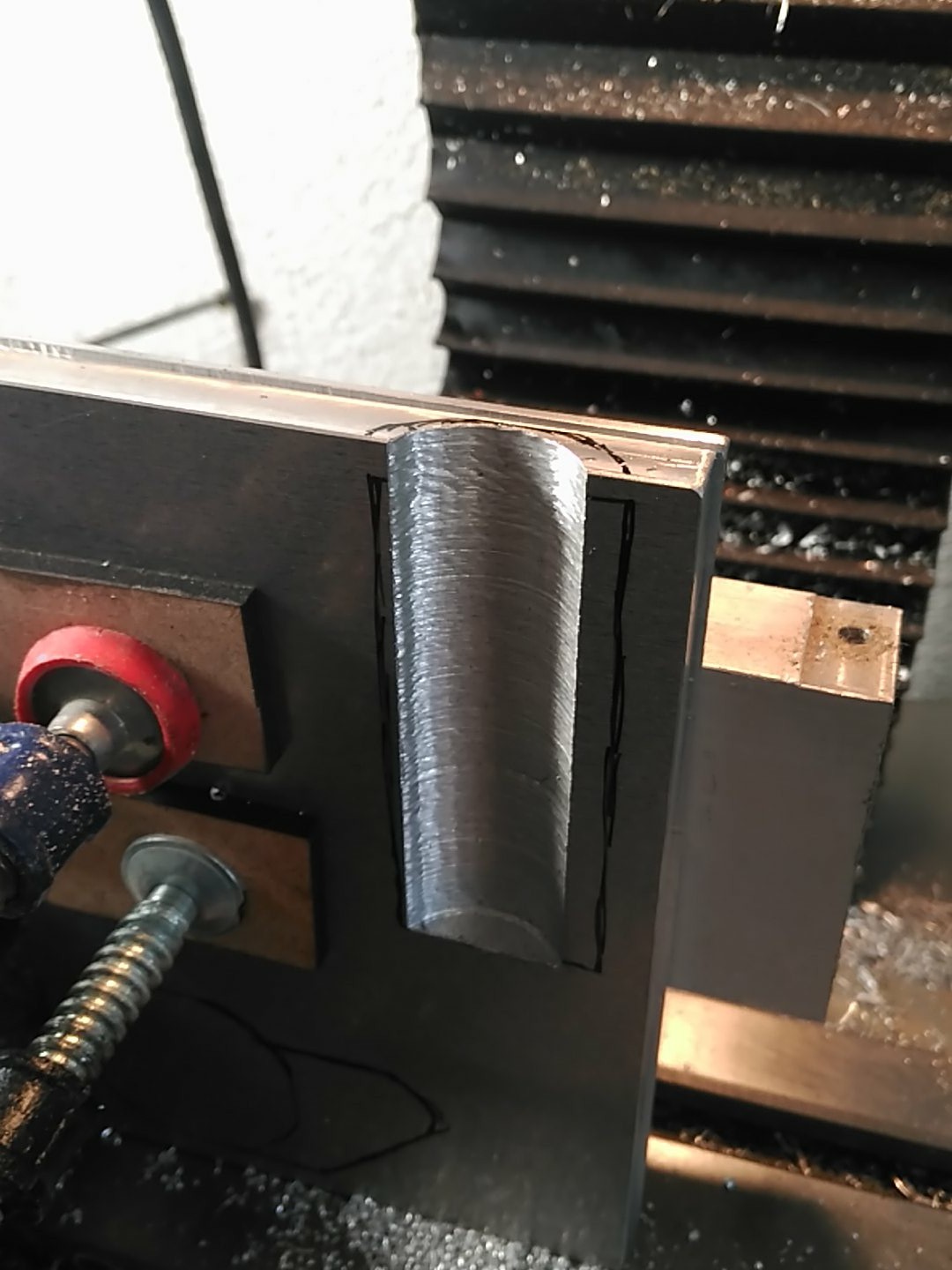

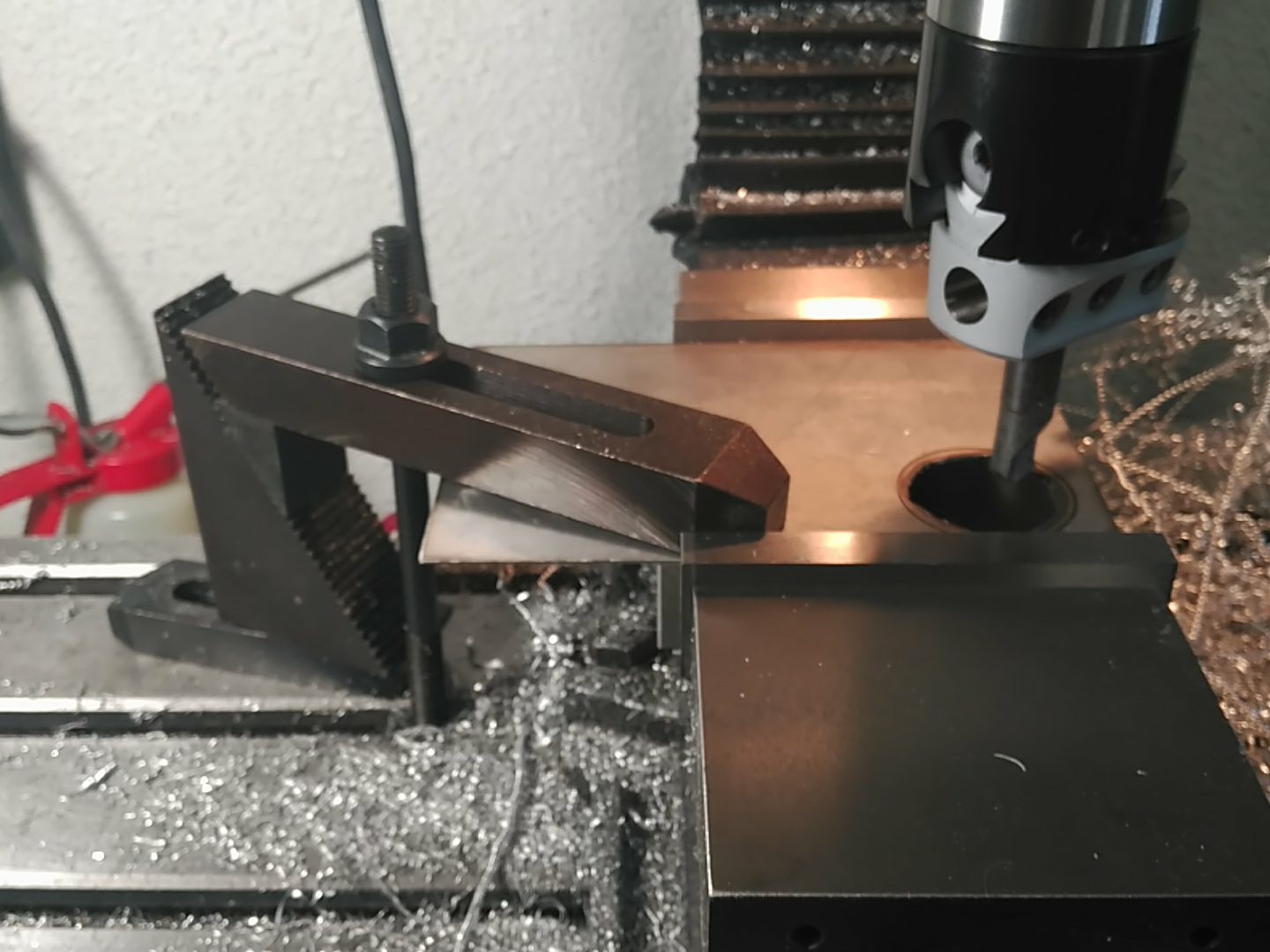

With that, I set up workshop to machine, cut and weld everything.

First, pump recess machining:

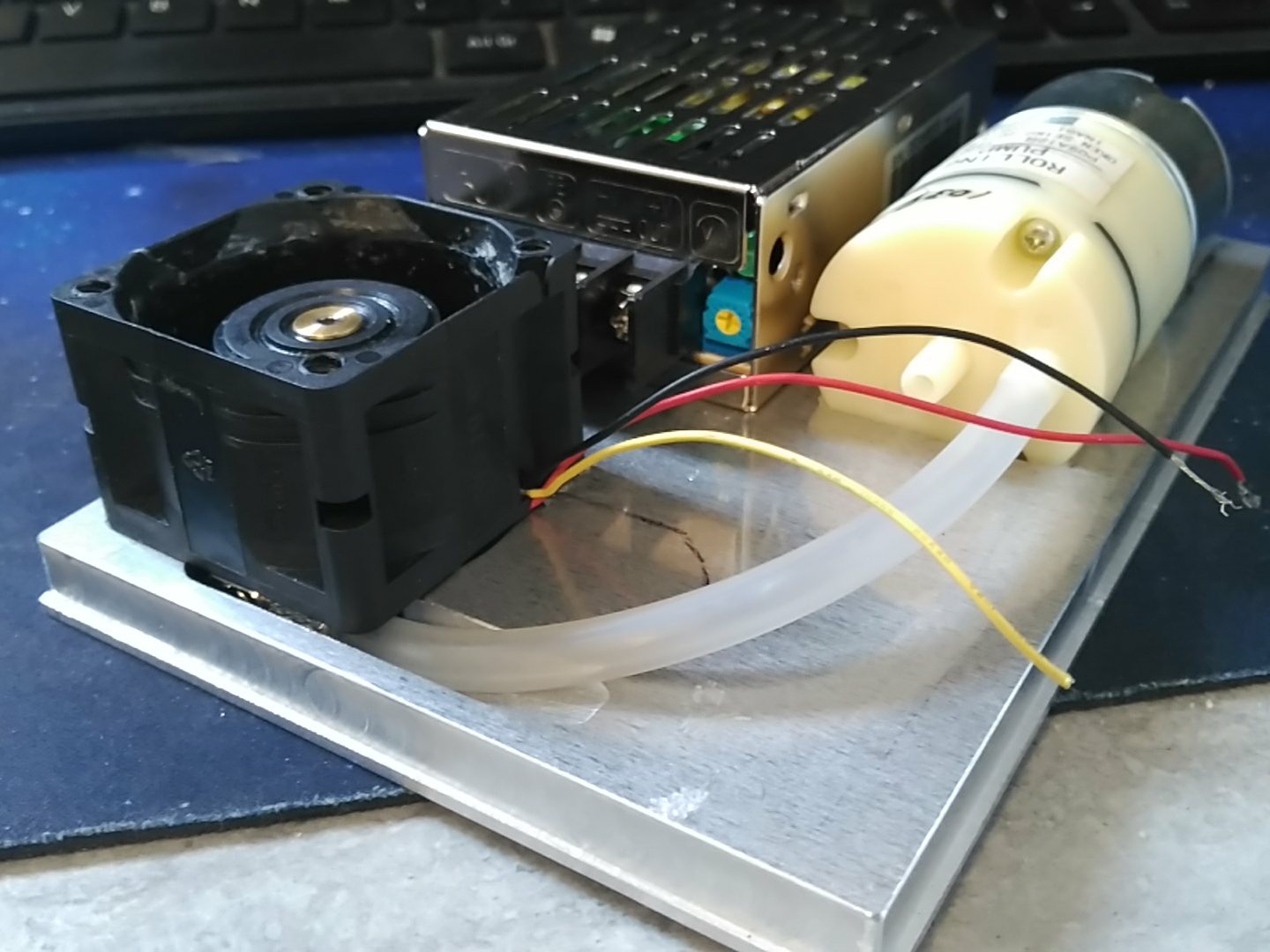

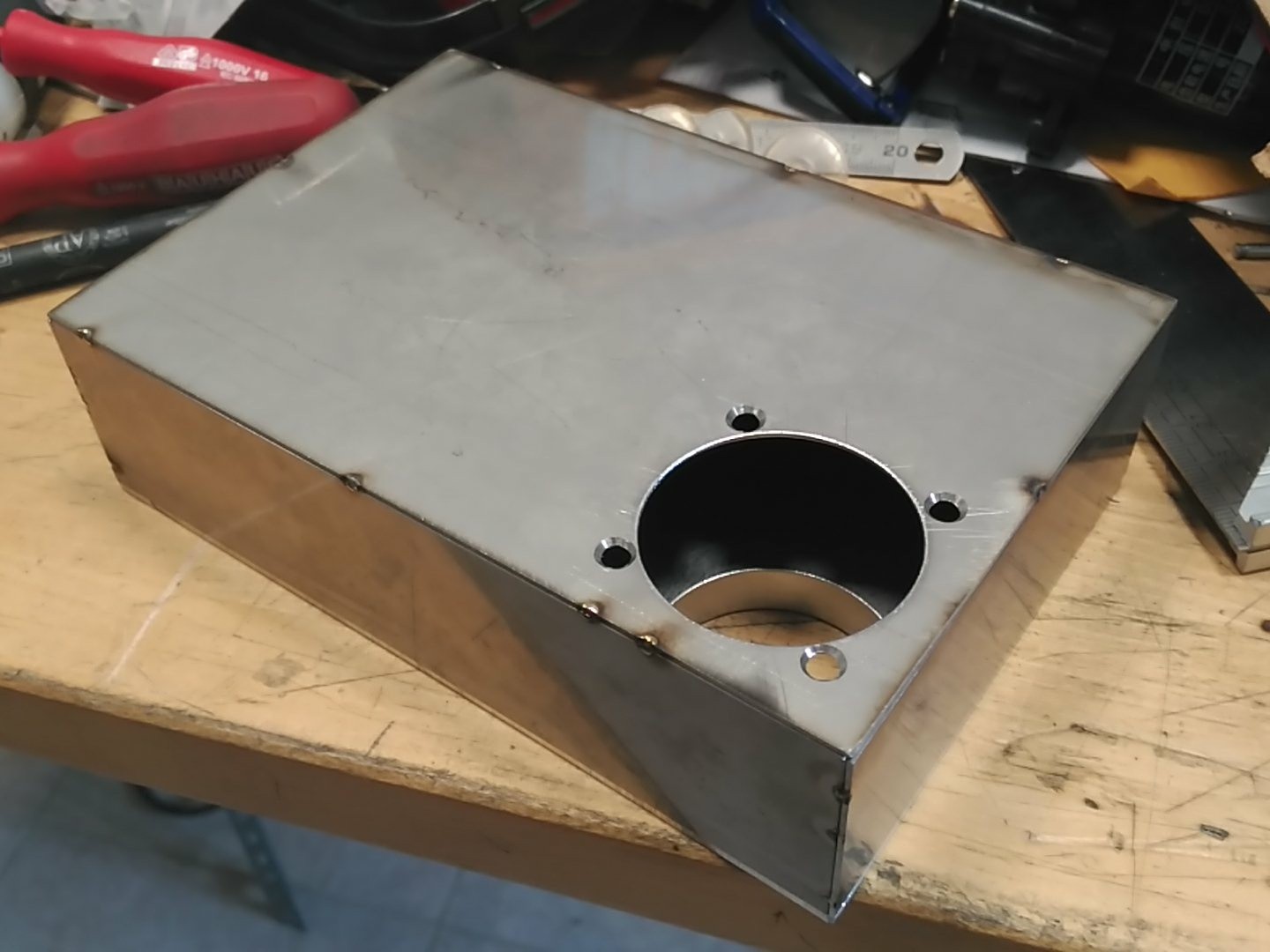

Halfway there:

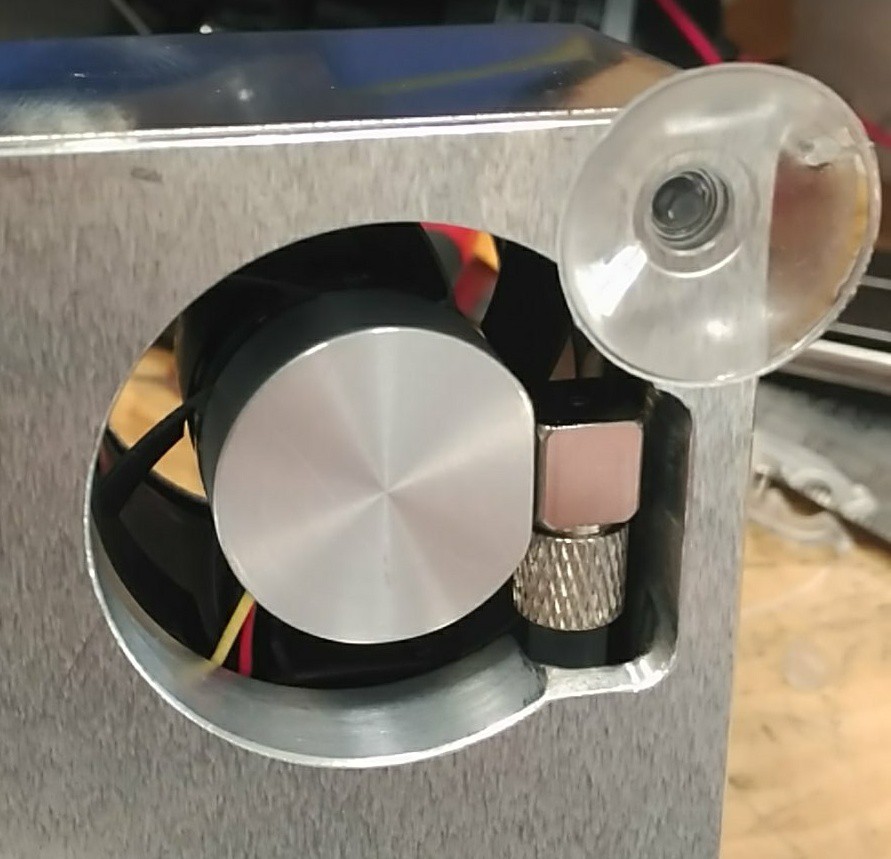

The acuum adapter connector was changed to a slimmer one, and thus, the shape of it's recess was also changed on the fly:

Top side:

Pump clearance with the power supply:

I also added suction cups.

With that done, a stainless case began to take shape:

Spot welded:

Fully welded and blended:

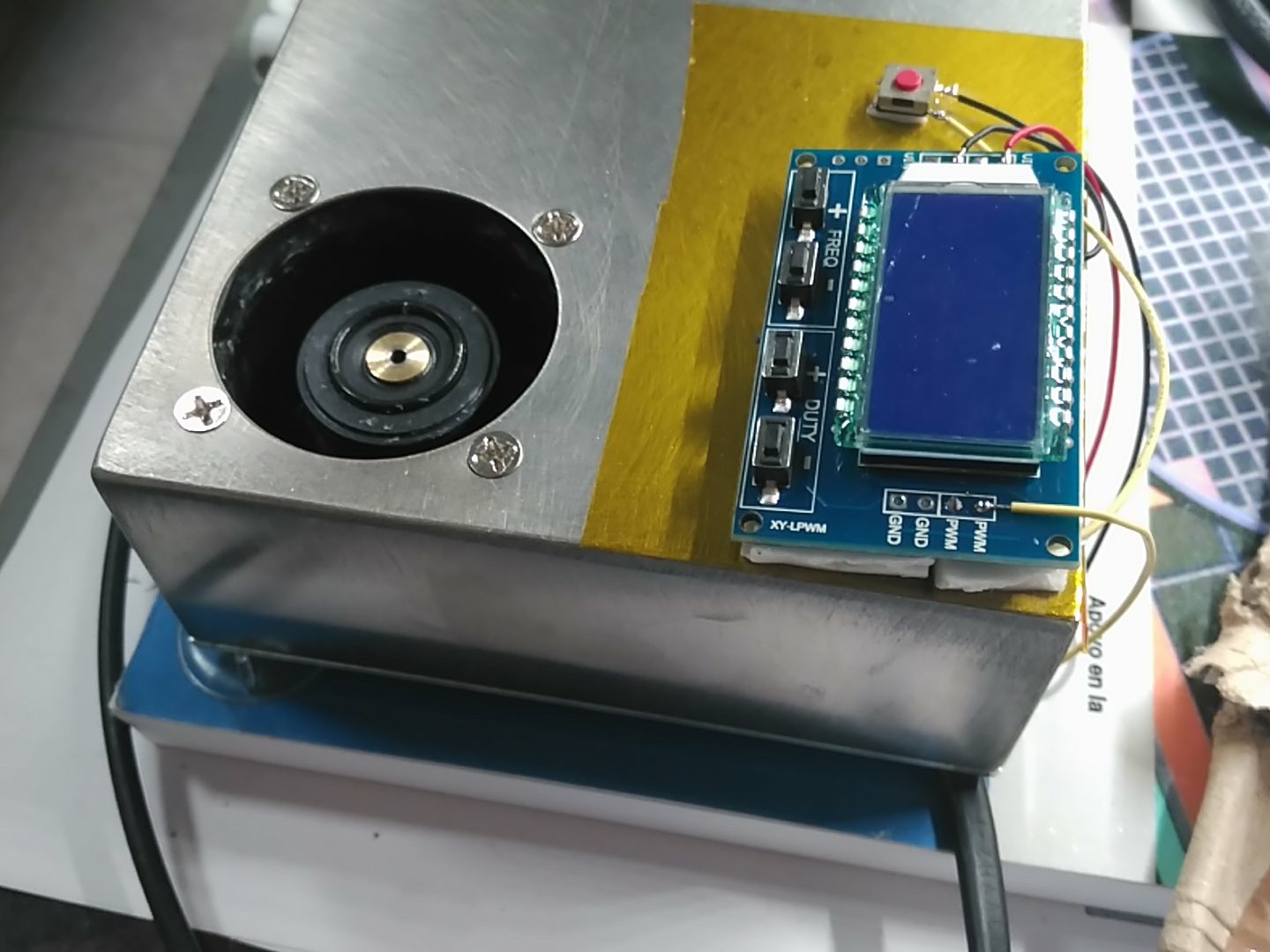

At this point, since I didn't had neither AC connectors nor panel mount buttons, I decided to leave the case like that, and just attach the controller to the outside with double sided tape (over kapton for easy removal) and wait the components.

working placement:

There!

There!I hope the rest of the pieces arrive soon. ^^

Nixie

Nixie

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.