I've been distracted by another project, but I'm making progress. I tried to build a mold to attach to the heating tube, but my welder decided against it. I figured out what was broken and I'm waiting for a part to arrive so I can fix it. Then the real fabrication can finally get under way. Anyway, here's the idea.

Let's automate everything!

In the spirit of the automation round, here are some grand dreams of automating this whole machine.

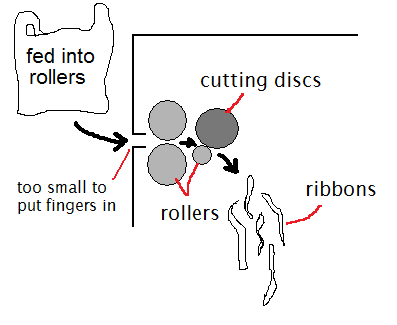

Automatic bag feeding - The bag is fed into simple rollers that pull the bag into the machine. Directly after the rollers the bag passes through a series of very sharp circular cutters that slice the bag into thin ribbons. The ribbons go into the heating tube... automatically. That's a tricky part.

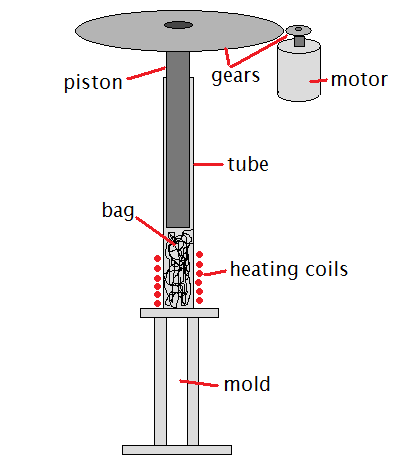

Automatic heating and injecting - The tube is heated inductively up to 180C and is held there for about three minutes to melt the plastic. The piston requires a lot of pressure which could be provided by a substantially geared down motor turning a thick threaded rod.

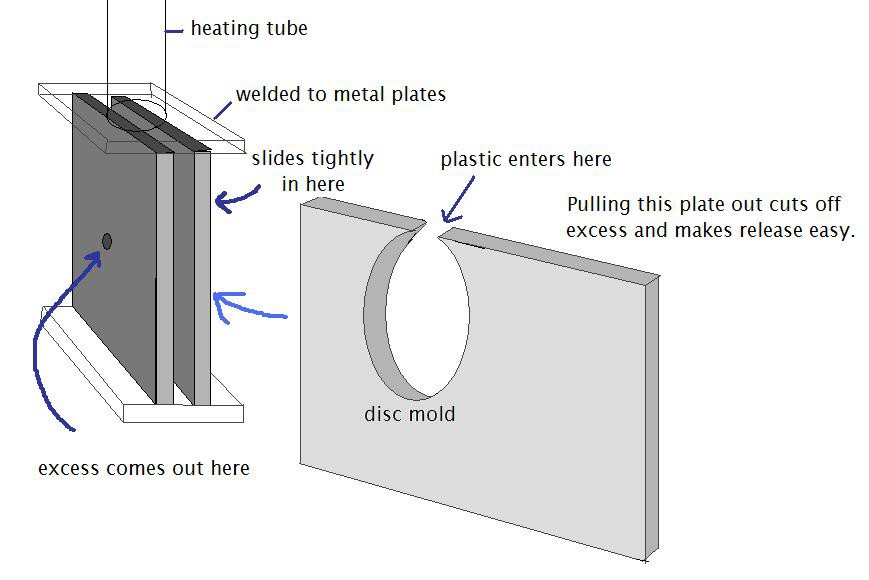

Automatic disc ejection and entertainment - After injecting the disc and cooling for a moment, the mold plate is pulled out of the sandwich(see figure at top). This cuts off any extra bits and allows the disc to be easily popped out. To pull the plate out another heavily geared down motor could drive a lever connected to the plate. When the plate slides out, it causes a rod to knock the disc from the mold. The disc falls down into the entertaining apparatus.

To be honest, there will not be that much automation in the final product. I like the idea of having the user pull levers and get involved in the process. It is more fun that way.

shlonkin

shlonkin

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.