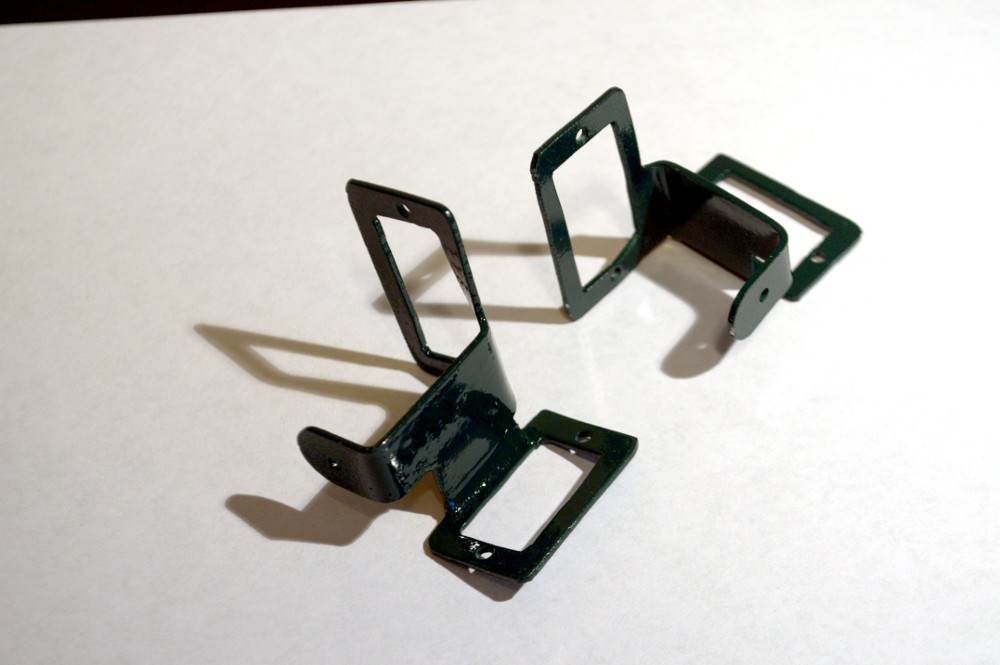

Switched to 0.050" aluminum and the woes go away. 3 brackets usable out of 3 tries... widened the metal surrounding the servo holes and got a small sheet of of 18 ga from OnlineMetals. The scroll saw sill cuts it, and you can bend it up without breaking it. Now I can finish the spyder and get to the extruder...

Ranarchy

Ranarchy

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.