-

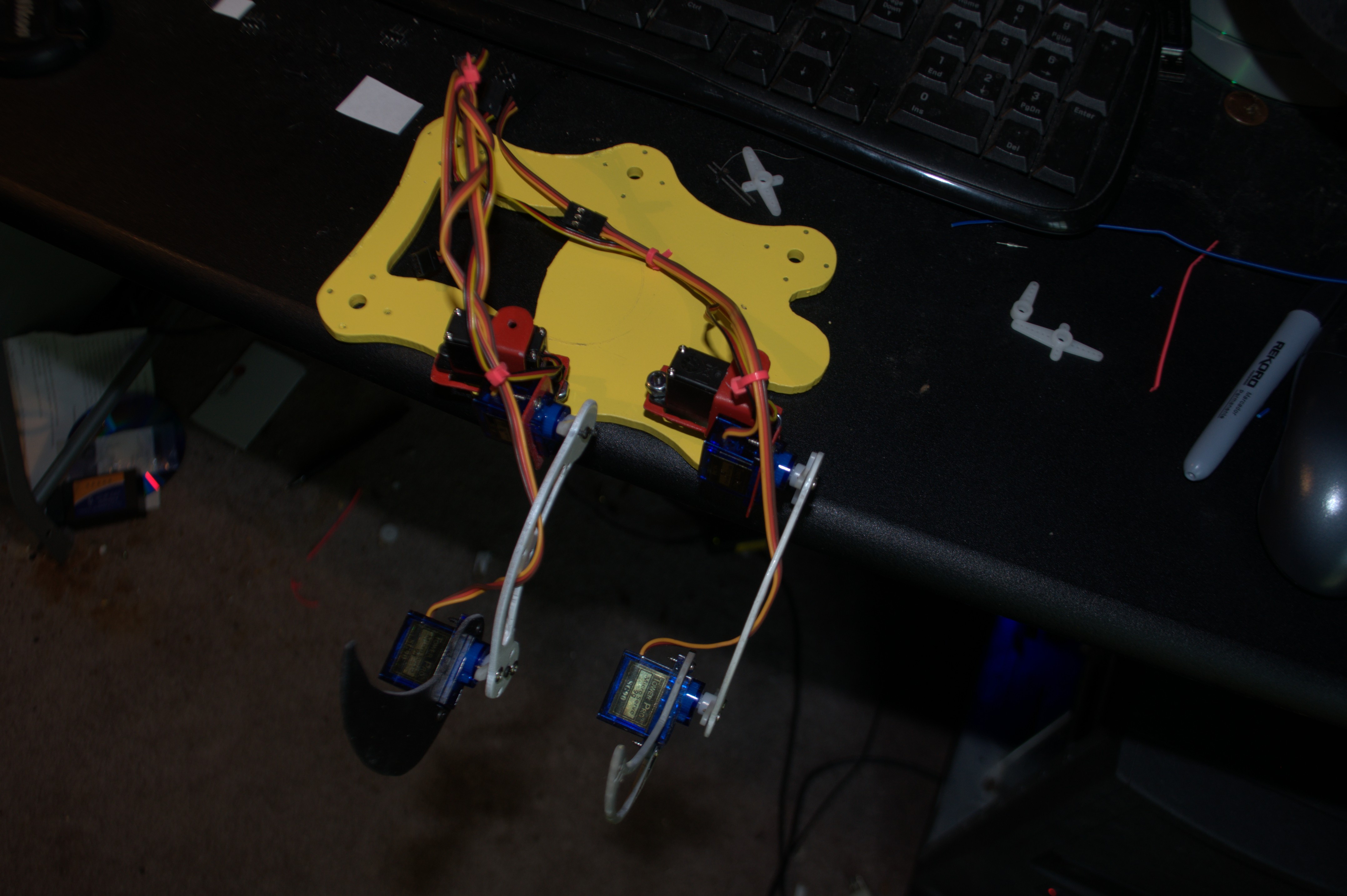

Construction photos ...

08/16/2014 at 14:45 • 0 comments...of the functional prototype of Vlad's Hexabot - the basis of the BuckyBot's spyder. Building to work out the strengths/weakenesses of the spyder design; get a single arduino to move ALL the legs: and figure out how to make a hexapod do the "hula" . The "hula" is a spyder motion in which it moves laterally in X and Y without moving the platform in Z (the vertical axis).

![]()

-

DOF = 5

07/28/2014 at 17:57 • 0 commentsExtruder has 3 DOF ... gonna make the hexabot chassis do the hula to provide lateral movement of the extruder ... 3+2 = 5 .... doesn't it? Well, anyway, 5DOF will allow BuckyBot to make simple geometric shapes from any orientation.

Will have to make an Arduino shield board to drive all the servos ... so the PCB-maker in me remains blissful ....

-

Posted crude video of ...

07/28/2014 at 17:49 • 0 comments... my arduino servo epiphany :

-

Took about 10 minutes

07/28/2014 at 14:57 • 0 commentsto program my arduino mega to run the leg servos

-

... and I thought I was being soooo clever ...

07/25/2014 at 18:52 • 0 comments... when I was actually just making it overly complicated. I can control ALL the servos with one arduino mega ... which I have in my parts box. So much for being a smart-ass engineer ... more like a dumb-ass engineer (at times) .... oh, the humanity ...

-

No more PIC microcontrollers

07/24/2014 at 20:21 • 0 commentsSigh ... I've used PIC's for years. But for this project I'm giving them up. The reason is that PIC's are just not very open-source friendly. I'm going to use Arduino Nano's from now on instead of PIC's. They're just a few dollars each, and you can't beat the user-friendly programming. Not so with using advanced PIC's under Linux... I'll waste more time coming up to speed on Linux/PIC tool chains that it would take to simply replace the microcontroller.

-

Everything figured out!

07/24/2014 at 18:23 • 0 commentsOh crap ... this might actually work. Have figured out how to do everything required for the BuckyBot ... mechanically and electronically, that is. Still have the tethering problem, but will work that out during the prototype phase.

Extruder turned out to be the key ... but I have that integrated with the hexapod now... Last post was just the start of the integration. It all fits. While I am fabricating parts and constructing the prototype I will endeavor to document everything...

The extruder only needs 3 degrees of freedom IF I USE THE HEXAPOD TO PROVIDE TWO OTHERS!

... and I think I figured out the signal processing to allow it to do just that. It requires positional feedback, though....

-

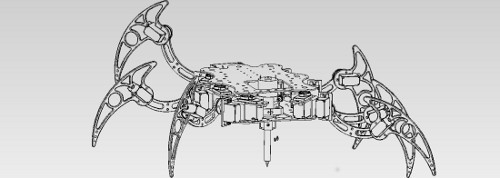

Integrating Extruder Design with HexaBot Spyder

07/20/2014 at 13:02 • 0 commentsThis is how it fits generally with the spyder. The extruder itself will have 2 DOF (pitch and roll ... yaw not required). A third DOF will be vertical translation of the extruder. Examining the geometric transform requirements to print using only these extruder DOF's. I can use the Spyder motion to provide translation in X,Y, and Z, if and when necessary. Higher res image and pdf file will be up on ranarchy.org soon.

![]()

-

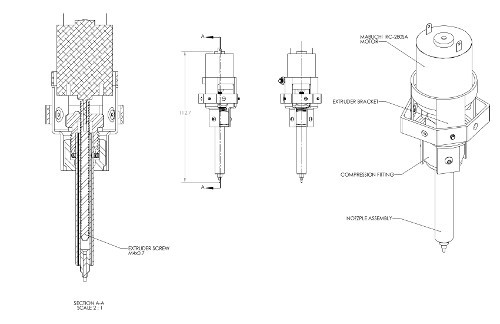

Extruder design almost complete

07/20/2014 at 12:49 • 0 commentsI think the motor is a little overkill, but it also fits the spyder design... for full resolution and/or pdf file, I will add this to ranarchy.org, along with drawing of how it fits into the Spyder/Hexapod portion of the BuckyBot...

![]()

-

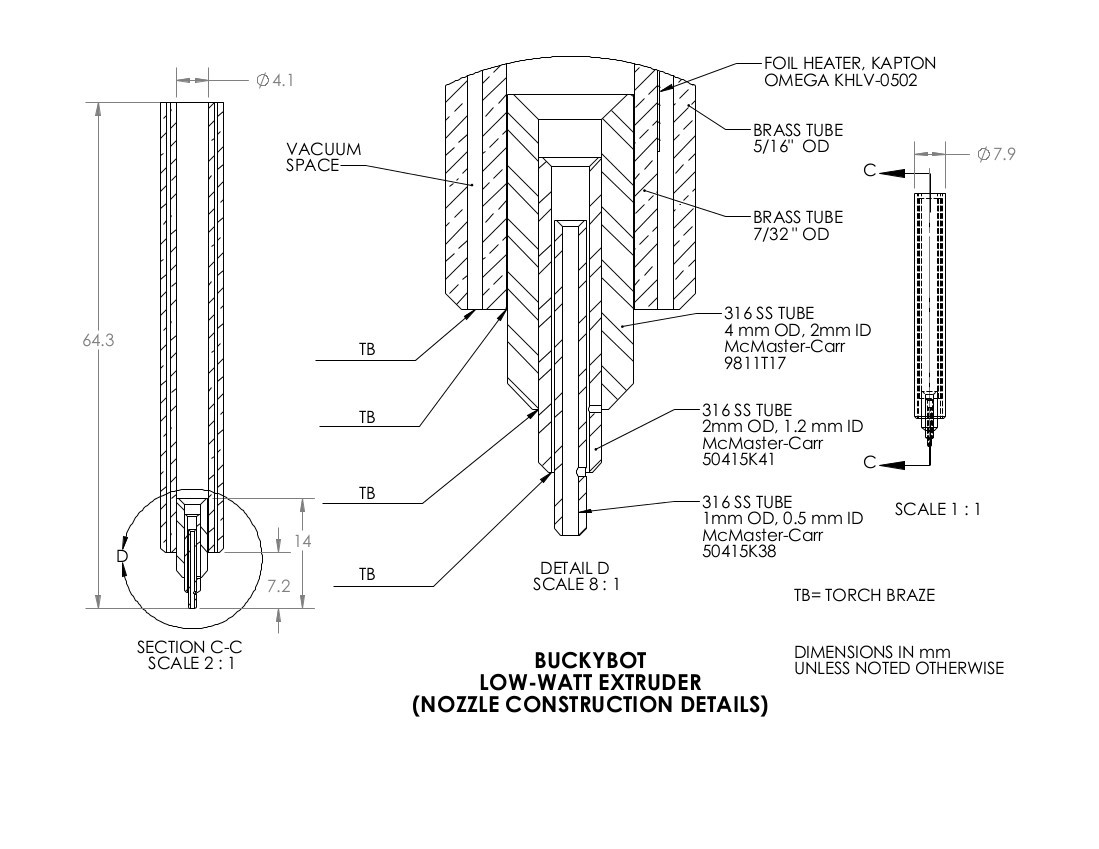

Extruder Design begun

07/15/2014 at 18:56 • 0 comments

Ranarchy

Ranarchy