According to the engine data I have found (distibutor 040 905 205.32) the vaccum advance starts to add up to the base+centrifugal advance at manifold pressures above 60mmHG. After that an additional advance is added to the distributor up to 11~15° at 270mmHg. This is performed mechanically by a capsule with a flexible membrane attached to the distributor.

In new vehicles the manifold pressure is measured by using a sensor, usually a piezoresistive sensor, powered by 5Volts and providing a linear output voltage within a givem pressure range. Such sensors are specified in KPa therefore to find a sensor that fits the VW air cooled carburetor system it is necessary to convert the MAP values to KPA.

60mmHG = 8KPa

270mmHG = 36KPa

Unfortunately most of the MAP sensors available in the market are in the range of 200-400Kpa. The most suitable sensor I was able to find was one of the models used in the early fuel injection systems.

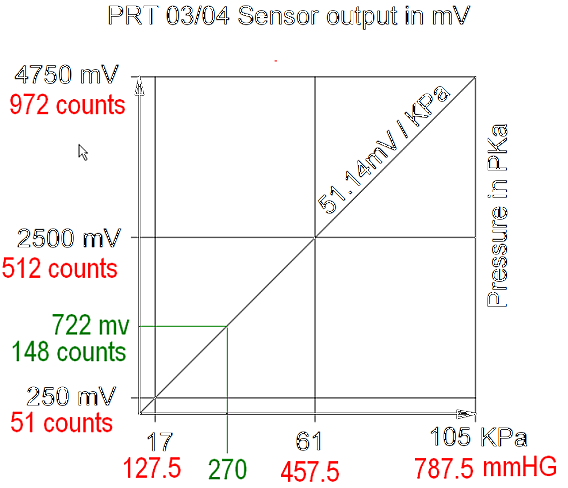

Such sensor, modelPRT 03/04 is manufactured by Magnetti Marelli has a ful with a full scale of 100KPa. The bad is that the measuring range for this sensor begins at 17KPa (127.5 mmHg) and this will will cause some loss in the beginning of the pressure scale we need to cover.

Another issue to consider is the voltage range for the expected pressure range the sensor will work on. It will vary from 250mV to 722mV. Initially the AVR ADC will be measuring this value directly and this will result in ADC output values in the range of 51 to 148 counts which is less than 100 values. That may be a good size for a lookup table but it might be necessary to add an amplifier. This will be addressed in the test results.

danjovic

danjovic

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.