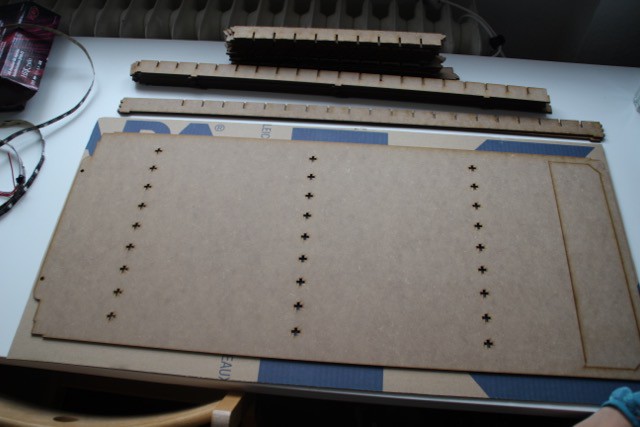

Matrix construction was done in DesignSpark Mechanical (Free CAD tool from RS, win only :-( )

I used the Lasercutting service offered by Formulor.

10 LED-stripes with 20 LEDs of each (WS2812, 30 LED/m) were placed on the backplane before putting all the pieces together.

First test after assembling:

In the lower section, all the electronic is placed but still can be removed from the back side even after placing the veneer.

Finished matrix with veneer surface:

makeTVee

makeTVee

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.