"Never a failure, always a lesson". This is how I would describe the first week-end I spent on this project.

This was my first real working session on the project. I started very innocently by buying some stuff from the hardware shop down Dim Sum Lab, which is at the 14th floor of a building.

Then I went to the lab, and I spent the afternoon drilling some plastic sheets.

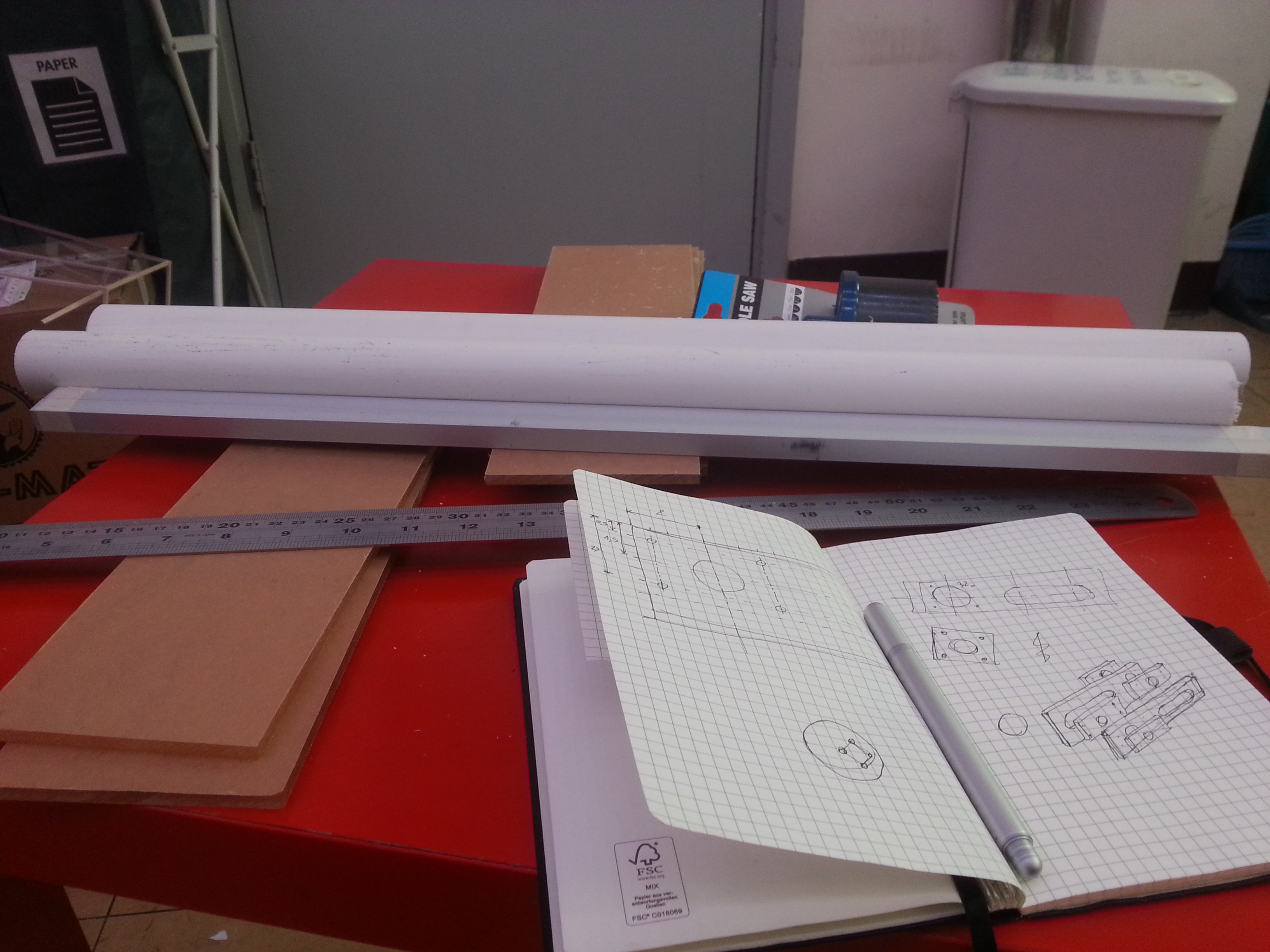

This is the stuff that I had at the beginning of the day.

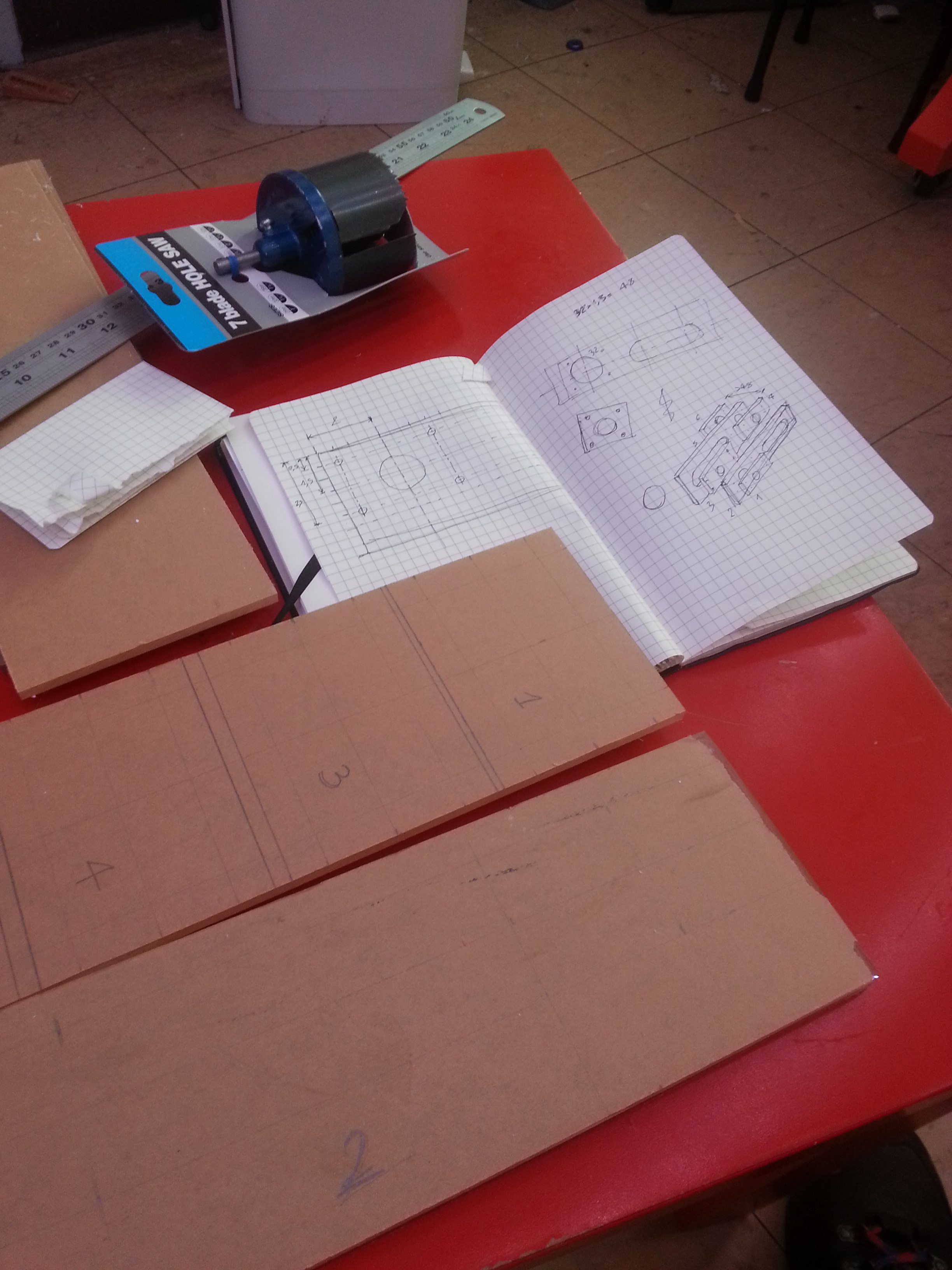

This is how everything was planned to be:

Everything looks nice on those pictures, right?

Everything looks nice on those pictures, right?

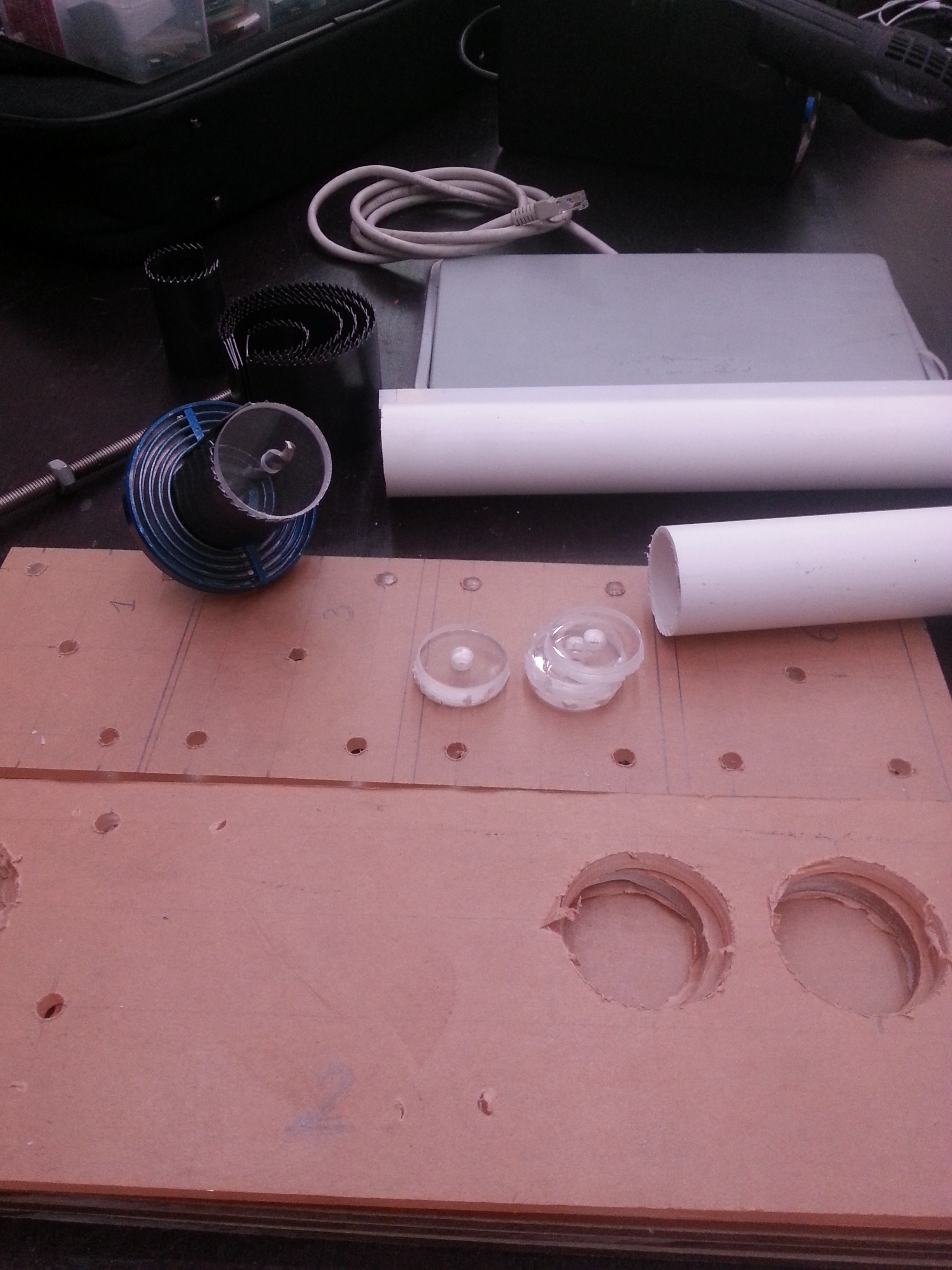

However, at the end of the day, I realized that the holes did not match the tubes that I bought and that were supposed to go into it. One of a few mismatch that I discovered that day.

Below is the picture of what was done that day. The tubes, the discs, and the holes don't match.

I tried to go back to the shop but it was closing, and it would stay closed for the rest of the week-end. So, I just had to go back home and meditate on the lessons of that weekend.

So here they are.

The first one, is on the way I work on this project. I can't go and try and see if it works at the end of the day. Because this is never going to work at the end of the day. I will now apply a much more rational approach to this project, as engineers do. This month is dedicated to exploring the landscape of this project. If I want usefull answers, I need to ask the right questions. First and foremost, I need to think about this questions.

Luckily, this week-end already answered some questions.

It showed that I could absolutely realize this project at Dim Sum Labs.

Also, I learned that using plastic tubing and plastic sheet is relevant for prototyping because it is really to work on.

At last, it gave me confidence that I can really make this project.

That was all for that week-end, not so much achievements but a lot of usefull feedback that will hopefully speed-up the next work sessions!

Alain Sanguinetti

Alain Sanguinetti

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.