ProtoPnP

The goal: to make a Pick and Place machine that is small on cost but big on ability

The goal: to make a Pick and Place machine that is small on cost but big on ability

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

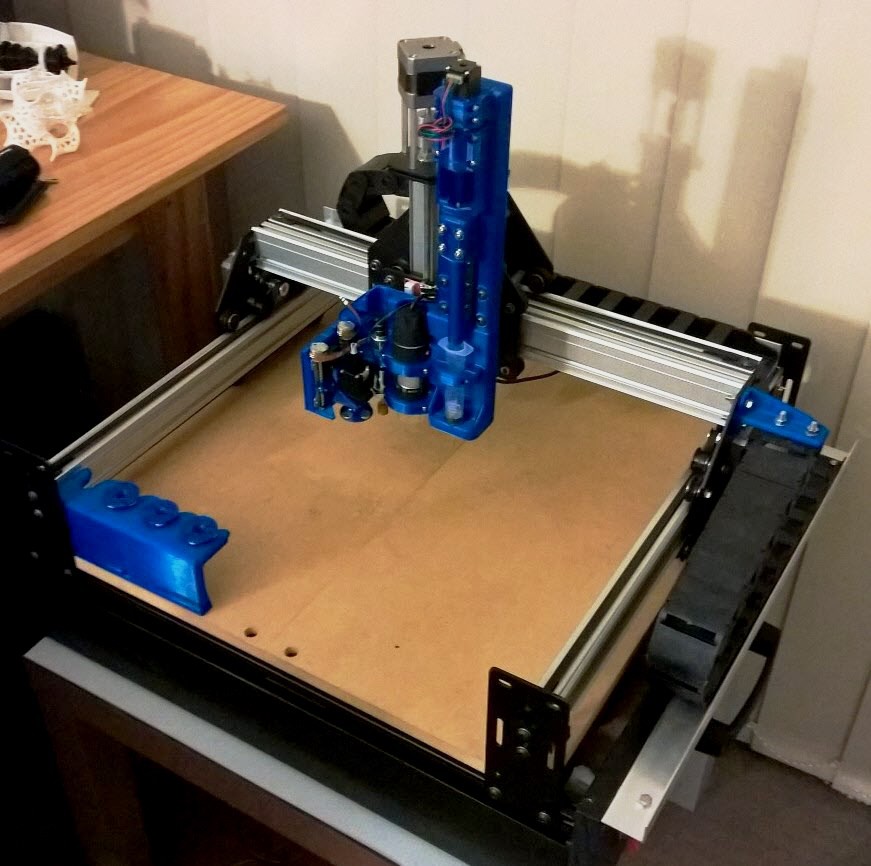

The main head has been fully assembled, and fitted to the machine! At the front of the machine, you can also see the head holder - the heads are magnetic, so they can be swapped over on the fly to manage different packages.

The cable chains have also been fitted, awaiting the cable soldering to take place.

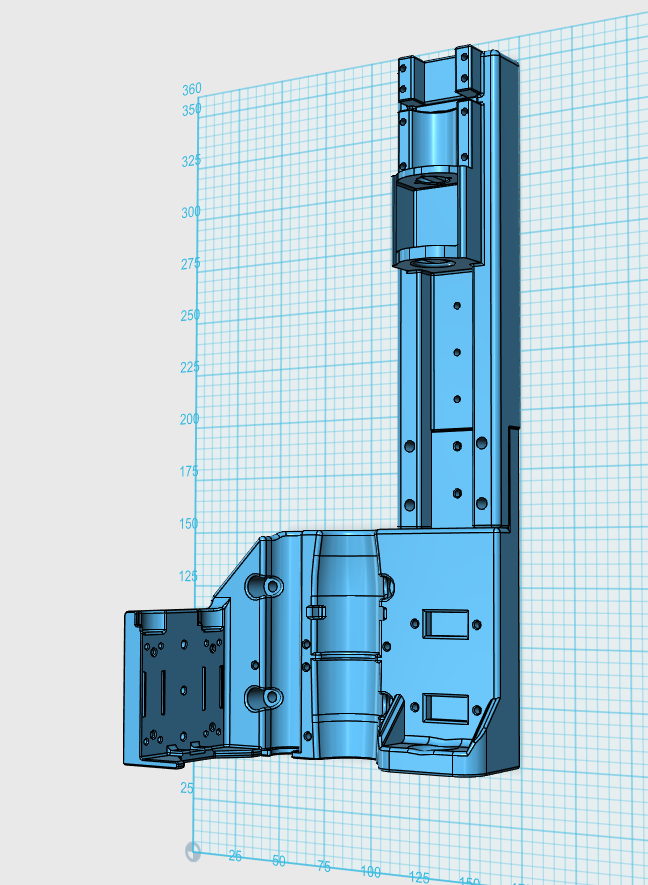

Modelling for the pick and place has been finished. The trickiest part has been the main head where the solenoid, hollow shaft stepper, webcam, and syringe extruder all need to fit. This needs to be as tight as possible - any space savings here increase the working area of the pick and place.

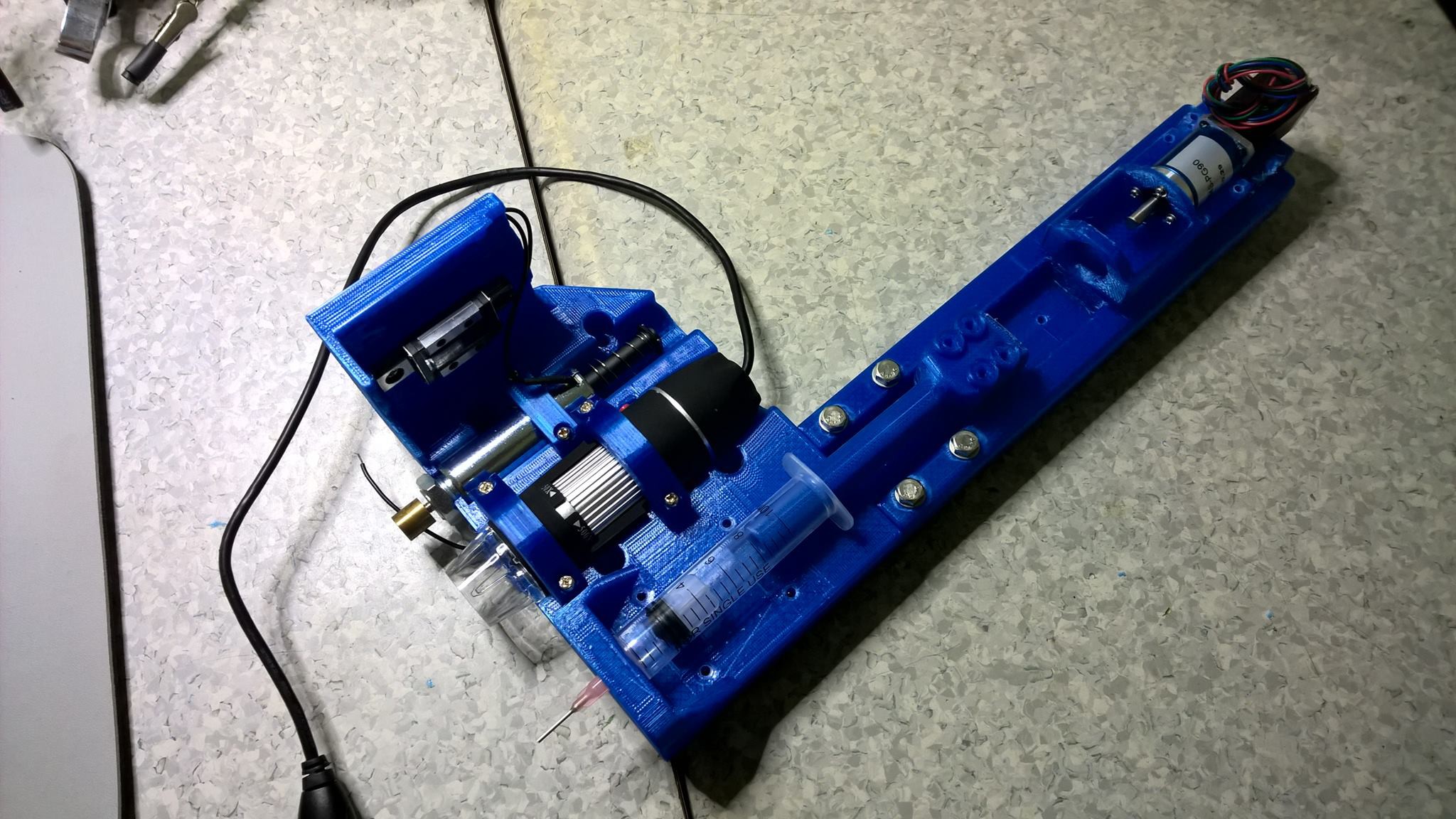

All of the parts have also been printed, with some reprints now in progress, and the assembly of the main head has begun. While it has been tough to fit everything together, it is slowly getting there.

There has been a long time between posts, and with good reason: I've been moving house. This means little project progress, but also means that there is now a proper workspace for this project:

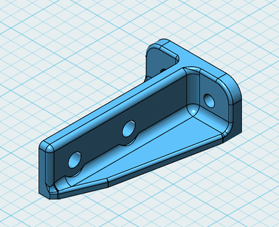

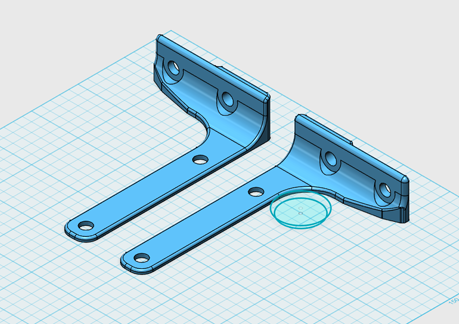

Now that my 3D printer and soldering station have a home, I've begun modelling the 3D printed brackets for the cable chain that will hold all of the wiring. This will make it easier for wiring looms to be repeatably made, in addition to the standardised wooden box that makes the base.

Most of the parts have arrived, and there are a variety of bolts, needles, pneumatic connectors and stepper motors:

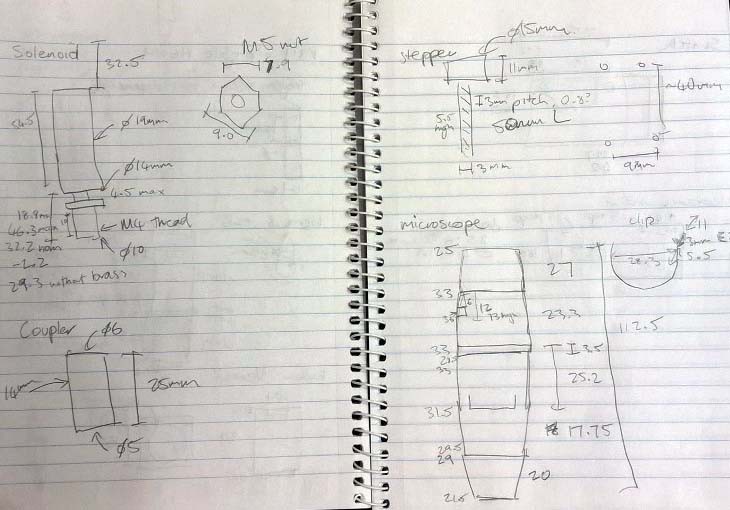

The basic layout of the main head for the ProtoPnP has been finished, and all of the main parts for this build have been measured in preparation for modelling the head. The hardest part has been the USB microscope, which has some interesting geometries:

Unfortunately, being caught in the middle of a house move, most of my tools are packed up and out of service. This has been delaying the printing of parts and the electrical wiring of the machine.

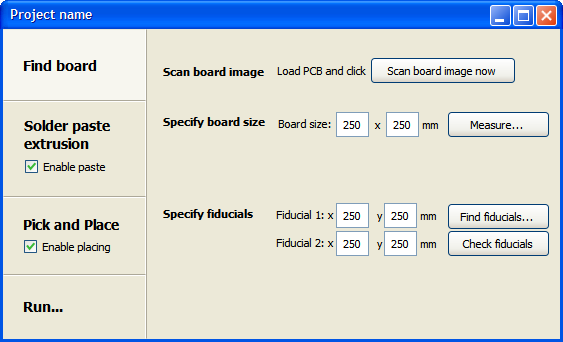

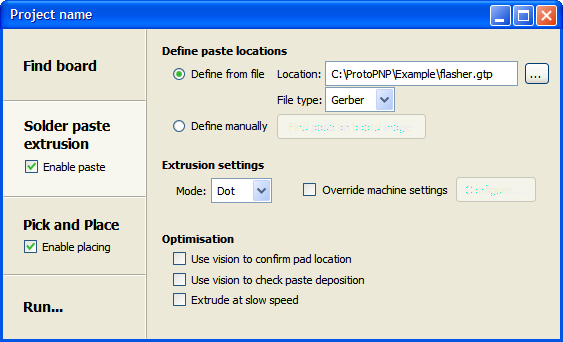

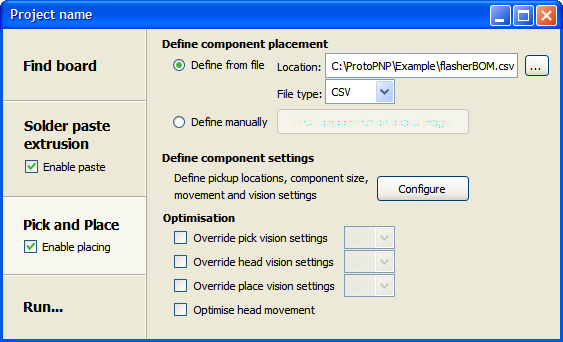

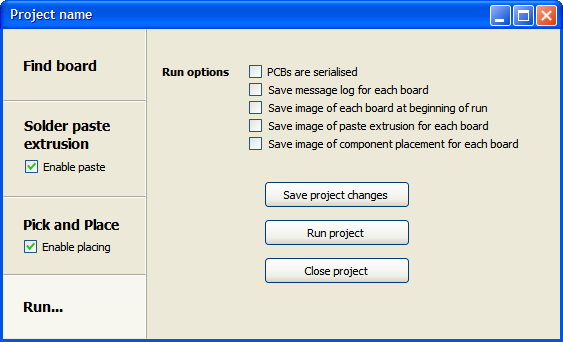

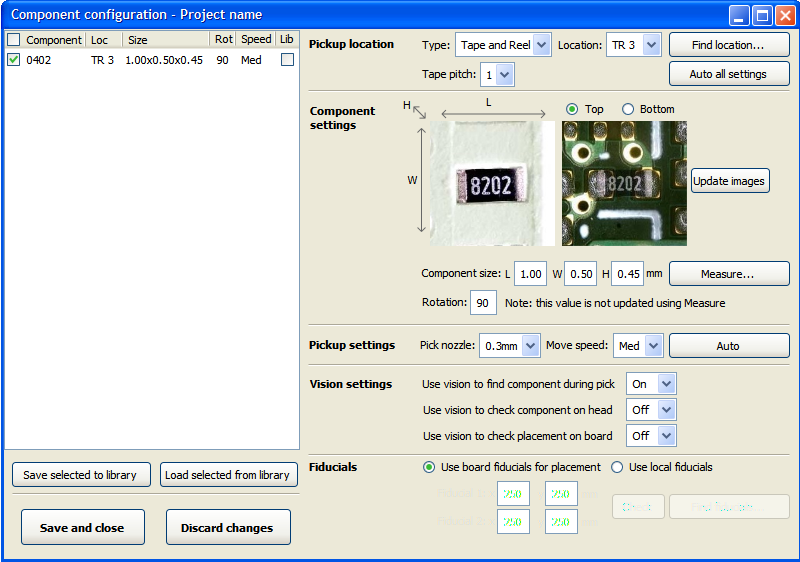

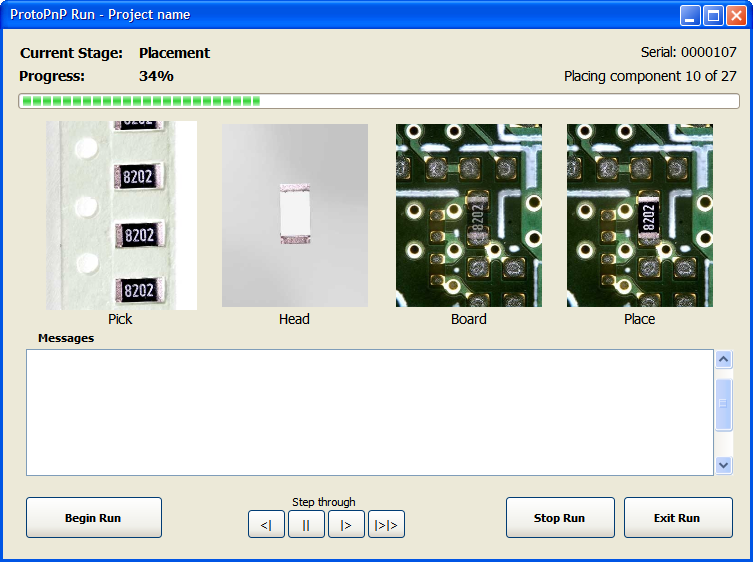

The last few days have been spent working on the design of the user interface, and the draft is now complete. The emphasis in the design has been to try and streamline the workflow, automate as many parts of the setup as possible, and make use of vision assistance to improve setup where the tasks cannot be fully automated.

There are four parts to the initial menu: Board Location, Paste, Placement, and Run:

Hidden in the Placement menu, under Configure, is the below menu, which controls all of the settings relating to each component, including feeder location, rotation, and movement settings.

Finally, the Run portion of the software provides a summary of all current visual inputs, messages fed through the software, and the ability to step through the operation to trial the created program.

This is an initial log to record the progress so far on this project. Currently:

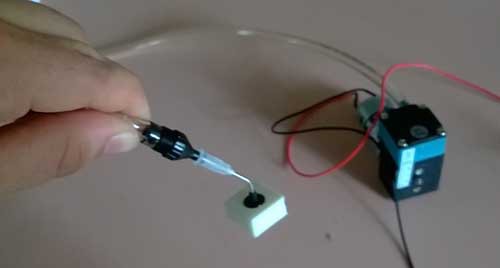

The pump selected for this project has been tested, and can successfully pick up a 20mm calibration cube:

Once all of the parts have arrived, the wiring of the ShapeOko2 frame and building of the tool head can begin.

Initial designs for the tool head have been completed; the current concept is to use the Nema 8 hollow shaft stepper motor for component placement and the 90:1 Nema 8 stepper motor for solder paste extrusion, with the micro stepper being used to raise and lower components during fast travels, and the solenoid used to actuate the tape feeders. The design of the feeders will be loosely based on industry-standard feeders, optimised for lower actuation force and lower tolerance parts.

The intent for the design of parts in this project is to allow them to either be 3D printed or CNC milled, so that a single machine can be purchased, the parts made, and then the machine modified to make a pick and place.

Create an account to leave a comment. Already have an account? Log In.

As a current PnP user (LitePlacer), I can say with utmost certainty: Use Machined Luer lock needles, not the cheap plastic ones; use shielded USB microscope cameras; use as flat and square a table surface as possible, with mounting holes (single sided, dual.sided PCBs); adjustable LED brightness via software is essential; tape feeders are indispensable.

It's not the first PnP projet on Hackaday, but I'm curious to see how you will do it.

For which OS do you plan to have the software? Linux? I've seen many project using Windows and .NET... so something OpenSource that would work on Linux would be nice :-)

It's not the first, but my focus is to make it easy to use and fast to set up. Hence, a lot of time is being spent on developing a slick workflow, with a lot of vision-assistance and automation for functions (e.g. auto-aligning parts by matching components to their footprint).

I'm going to be using LabVIEW and OpenCV on Windows for the initial development, with the aim to transition to Python once the interface and functionality is locked down. I know LabVIEW might not be the best OpenSource approach, but it ticks a number of boxes for me: it's good for GUIs, easier to understand for non-programmers, has good community support, is relatively cheap, and it's a language I know relatively well.

Become a member to follow this project and never miss any updates

...drop the solder paste dispenser. Most everyone just buys a cheap stencil from OSHStencils and gets solder paste on to PCBs much quicker.