2016 Hackaday Prize - Design your concept

This project is a single step toward a huge goal - a self-replicating machine. Others have already taken on the challenge of self-replicating the mechanical hardware of a 3D printer, I will take one small step at a time toward replicating the electronics.

How can a 3D Printer Replicate its own Electronics?

If MetalicaRap does good on its promise to build an electron beam additive manufacturing 3D printer, that printer will have a high vacuum in its main build volume. It will also have the correct optics to guide a beam of electrons onto a tiny spot. If it can do that, it can also guide a beam of ions onto a small spot. By placing a blank silicon die in the build area of MetalicaRap, the focused ion beam can selectively n- or p-dope silicon and create the fundamental building blocks of integrated circuits - transistors, diodes, capacitors, resistors, and more. Metallization layers can similarly be deposited in the vacuum chamber.

Then why does a semiconductor fab cost so much money?

Because it uses photolithography to manufacture a lot of chips fast and simultaneously. Photolithography is an extremely delicate and high-initial cost process. Modern semiconductor fabs also try to make transistors on the smallest possible scales to pack as much into a chip as possible, which greatly increases costs and engineering requirements.

Can you really make semiconductors at home?

Jeri Ellsworth already did it (despite everyone telling her it was impossible), and I replicated her results a few years ago. She made her masks by hand and used diffusion doping, which means that her transistors were too big and inconsistent to make an integrated circuit. With ion implantation, there problems are reduced.

So what exactly are you making?

The specific goal of this project is to demonstrate ion implantation using standard scientific equipment, and then going backward and seeing if there is any way to simply or improvise some of the equipment so that it can be printed using electron beam additive manufacturing, and so that the process can take place at higher pressures. In the future, my design can be incorporated into MetalicaRap so that it can replicate its own circuits.

Another challenge that I will explore is how much can 3D printer microcircuitry be simplified so that it can be printed at larger (and therefore more reliable) scales.

Why did you wait so long to do this?

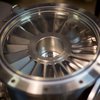

What enabled this project to go forward was acquiring a QSTAR XL tandem mass spectrometer, which has many of the parts needed for an ion implantation design.

Any news?