I mentioned in a Previous post that before we can start manufacture, we need to have some basic functionality tests to preform QA testing. For a couple of months I was unable to work on this project, but now I am back to being able to spend most of my weekends again. So I have been able to make some progress.

Currently the following is ready:

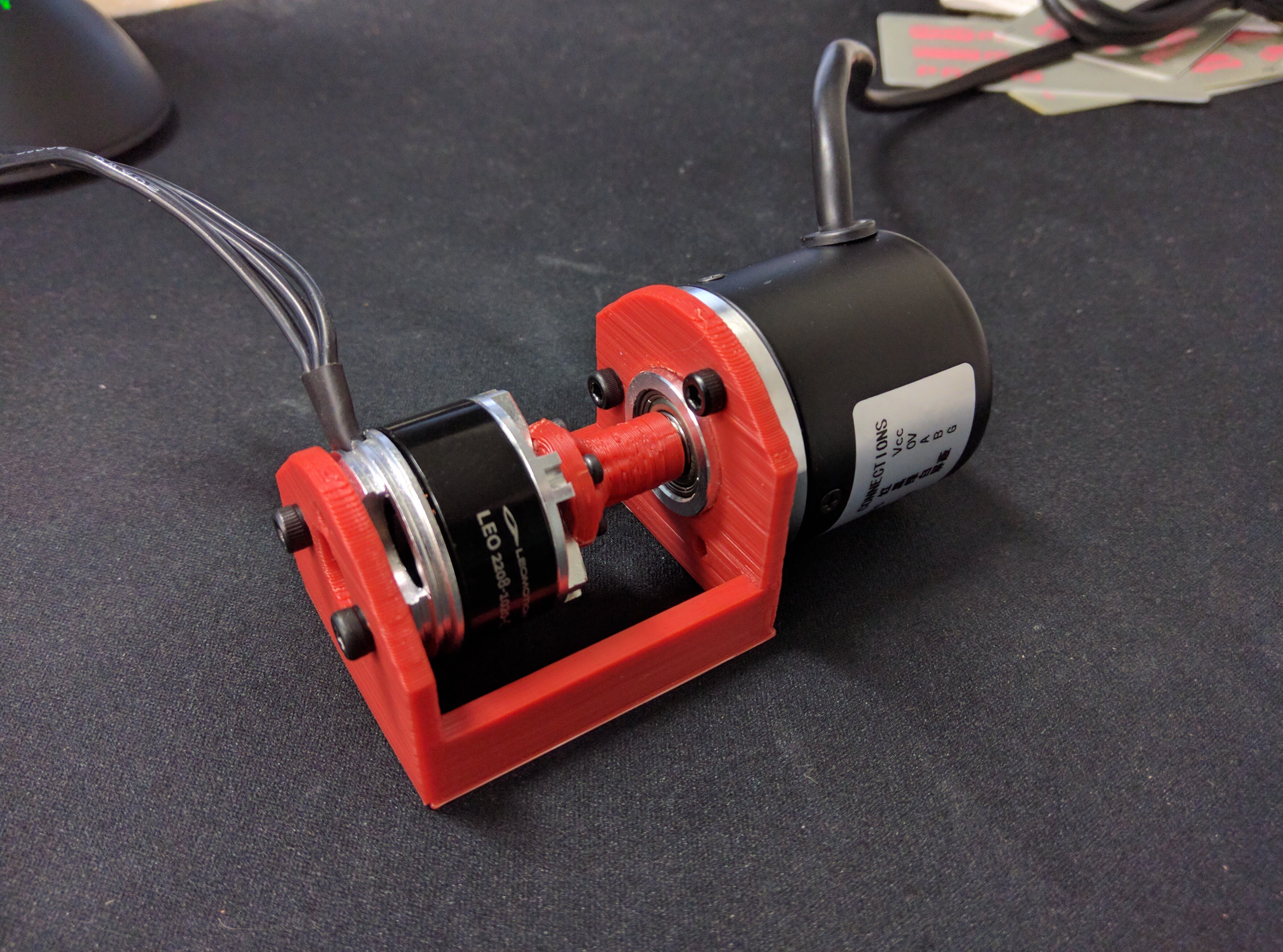

- Testing rig with a motor and encoder

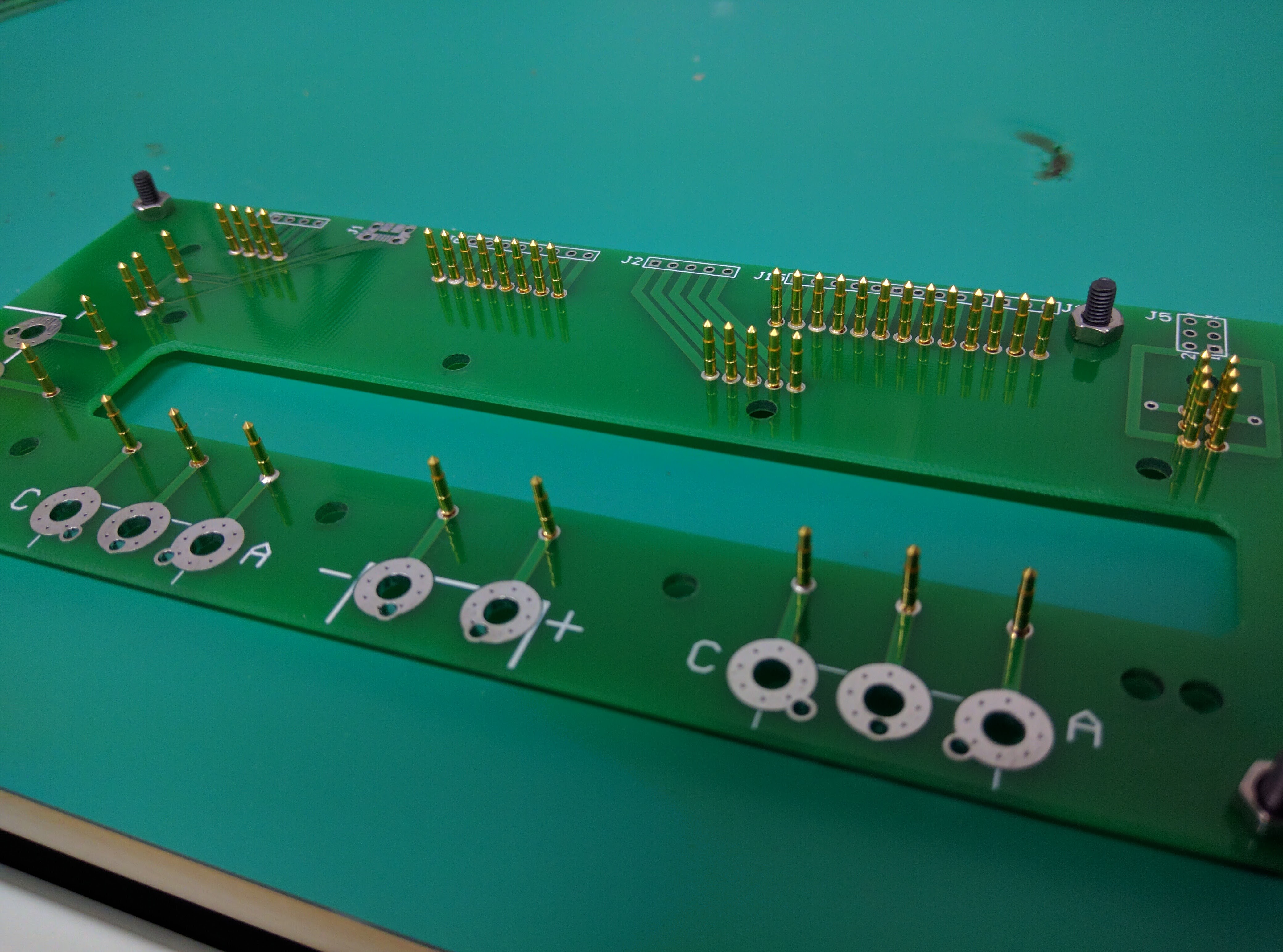

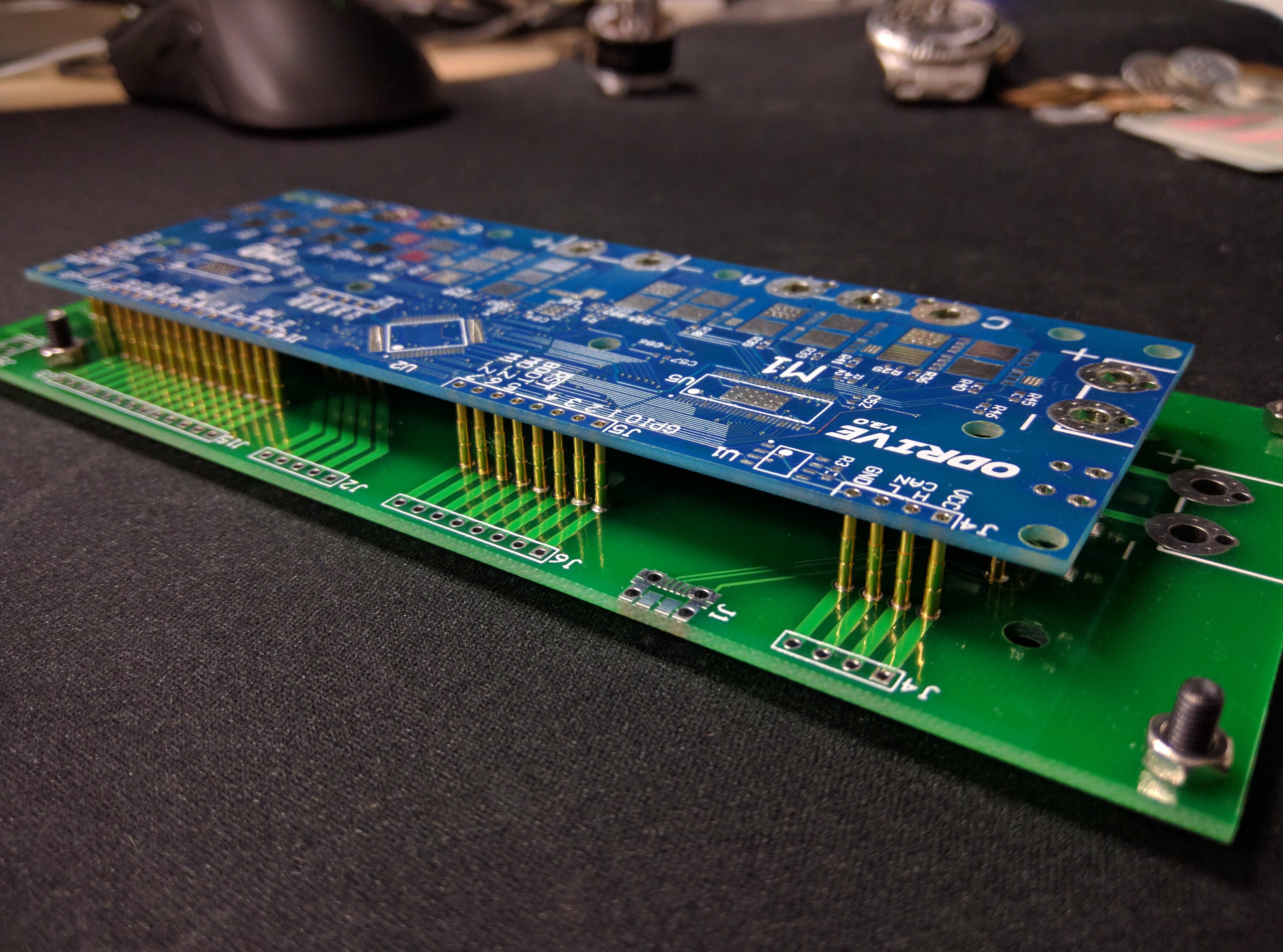

- Testing PCB with pogo pins to make quick connections during testing

- Low level code to trigger current sensing and motor control from the 3-phase PWM pheriperal

- Online current sensor calibration

- Lock-in, open-loop voltage vector motor spinning

- Automatic motor resistance measurement

The following is still left to be done before manufacturing can commence:

- Test that the bed-of-nails board makes good electrical contact

- Check that the transient response of the current sensing is good

- Low level code to allow hand-over of the ADCs between the two motor channels

- Write the encoder drivers

- Finish up the test routines to be able to detect faults

Pictures and video!

Below is a motor-encoder pair doing lock-in, open-loop voltage vector motor spinning.

New motor test cradle. The design is openly available, Link.

Some pictures of the bed-of-nails. The design is openly available, Link.

Oskar Weigl

Oskar Weigl

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Hmmmmm, sexy bed of nails, I hope it works out.

Are you sure? yes | no