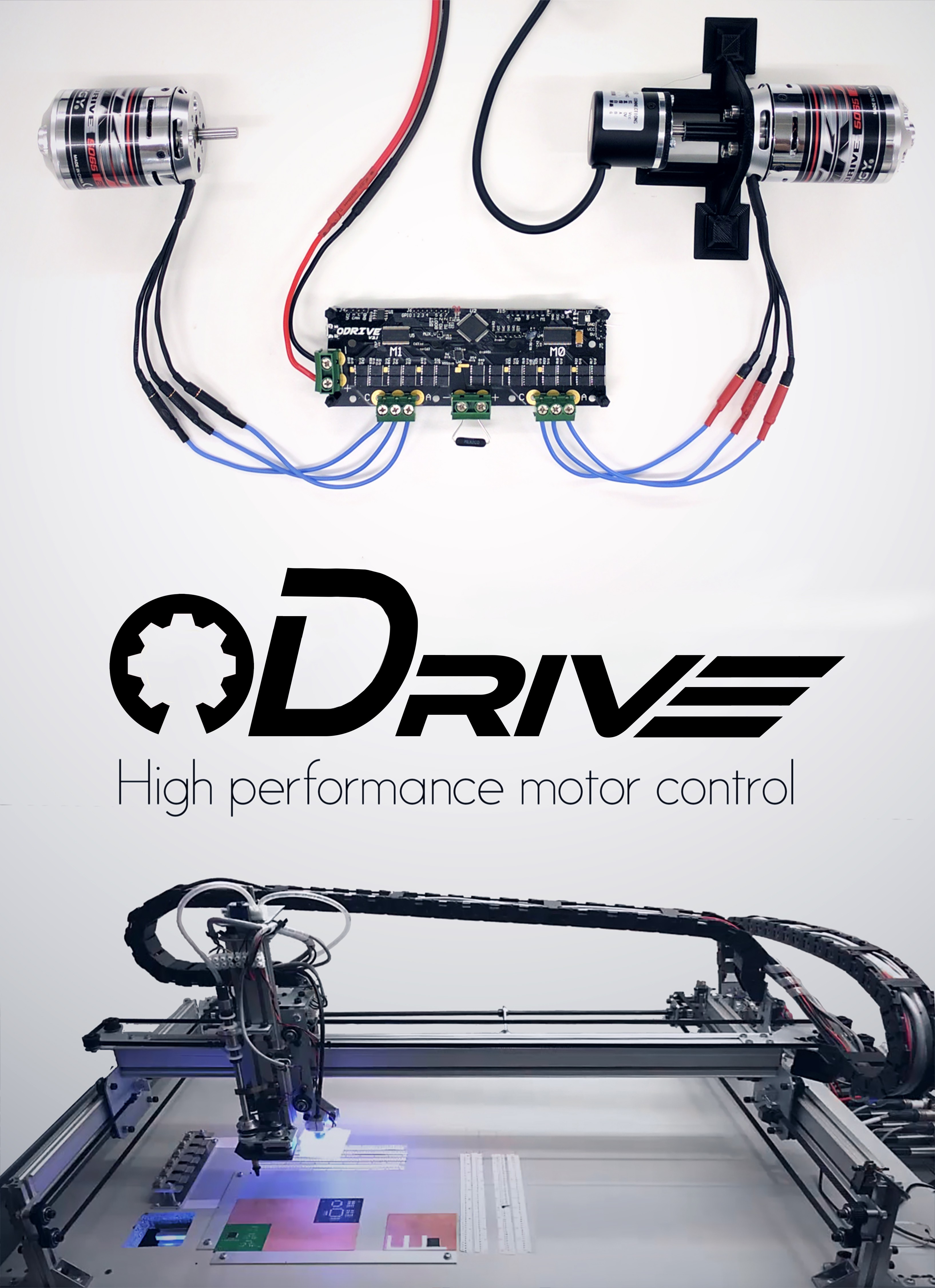

For a long time now, the main ODrive demo has been the pen plotter from more than a year ago:

This is about to change! Through a close collaboration with Juha Kuusama, the guy behind LitePlacer, I am excited to announce that there is a demo ODrive/LitePlacer demo brewing. This consists of a LitePlacer retrofitted with the vastly overpowered SK3-5065; able to put out 300N of force on the belts, and hence a theoretical acceleration of the head at 50g. This virtually unlimited power capability should be a good platform to test the actual performance of the full setup, with the ability to emulate the power capabilities of other motors by simply applying software limits.

So if you are in the area, or maybe even if you are not, please do come see the demo at the Bay Area Maker Faire on Sat/Sun the 20th/21st of May.

Oskar Weigl

Oskar Weigl

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Them escs shouldnt be on the pcb board. Theyl burn the board up specially with lipos running crazy power.

Board will burn up too.

I dont see what youve done amazing.

Arduino motor driver 1 pound and outrunner brushless motors.

Shouldve just run quadcopter set up.

PCB, PDB, 5V/12v buck, ESC with 5v for pcb, add wireless cameras ect. But I read no holding torque and you claiming crazy power.

Hype this is.

See what I mean. But your big speach I dont get.

Are you sure? yes | no

is this engineerallen?

Are you sure? yes | no

Nice but waste of time. Them motors are way epensive compared to nemas at £5 a go.

I did think this as Im from RC back ground.

Your motors will burn out and your escs as there not made to last all day long like this project requires.

Theres a reason printer motors are wo chunky ect.

What the holding torque? zero? ok you application is suitable but not many going to spend best part of a thousand bucks on a pen!

You used aluminium 2020. Why isnt your frame broken with that power?

I worked out that I cant even use nema 23 on aluminium for light milling so how you going to convince me to switch to this "which is apparently 4x stronger?"

Hmm if this was fast 3d printer I could see interest.

But from my point of view its a total waste of money. That frame youve built probably costs £200, your hole set ups say a grand. That is not cheap or a revolution.

I really dont understand what you are bragging about. who the fk it lote rara? another crap designer making false claims?

My friend. You people dont understand. Every one has google. You cant pull wool over every 1s eyes any more or lie and be deceptive. I urge you to consider that before anything as you will go no were.

Now if this was cnx in steel frame id believe you. But no way that aluminium fram is handling that power and force with out shaking to death or breaking. Wouldnt even be able to be used on 1/4 power.

Over priced waste of time.

Sorry.

Are you sure? yes | no

If you think NEMAs are accurate or fast, you clearly don't get the point of this. Sorry.

Are you sure? yes | no

Nice!!!!

Are you sure? yes | no

Nice.

Are you sure? yes | no

;D

Are you sure? yes | no