After much hard cad work V2 is finished! Well it was finished a few weeks ago. I'm a bit late with the progress update. It ended up being slightly harder than expected but fusion was far easier to use than creo parametric. I'm gladt I made the switch to fusion 360.

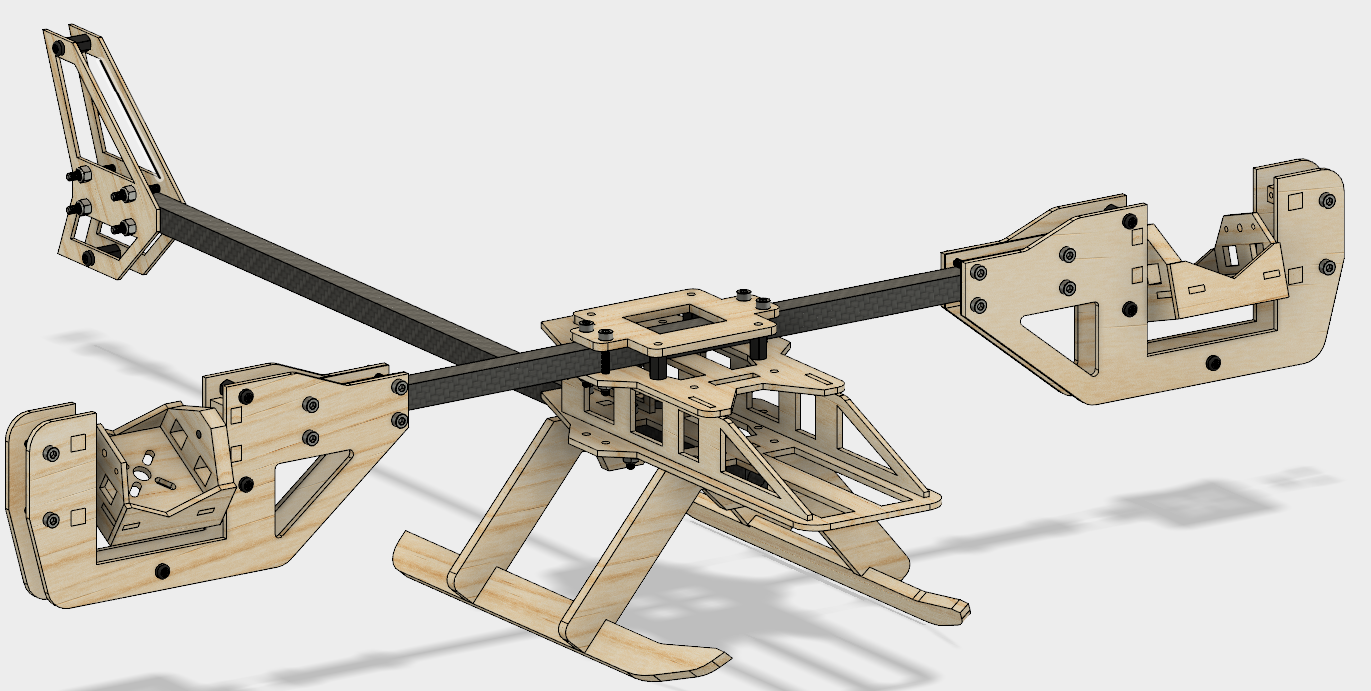

So here he is, V2 in all it's glory.

The nice thing about fusion is I can input material density and get a weight estimate. This frame comes in at around 285 grams. Not bad, I could probably do better with carbon fiber or fiberglass but that stuff is a royal pain to work with. The plan is to laser cut the plywood then bolt/glue the frame together. I tried to keep the glue to a minimum. The less glue the simpler to repair and Bi-copters crash A LOT. There not too practical but still fun. The black spars are 10mm carbon fiber spars from Hobbyking. Cheap and light while being strong enough. 10mm is likely over kill for a craft of this size anyways.

The nice thing about fusion is I can input material density and get a weight estimate. This frame comes in at around 285 grams. Not bad, I could probably do better with carbon fiber or fiberglass but that stuff is a royal pain to work with. The plan is to laser cut the plywood then bolt/glue the frame together. I tried to keep the glue to a minimum. The less glue the simpler to repair and Bi-copters crash A LOT. There not too practical but still fun. The black spars are 10mm carbon fiber spars from Hobbyking. Cheap and light while being strong enough. 10mm is likely over kill for a craft of this size anyways.

I submitted this design for the design for auto desk challenge and won 250$ for my troubles. Very generous of autodesk. I submitted a second design as well but I have yet to receive any info on it's status. Now I just need to export the parts to the laser cutter and cut the thing.

Here is the link to the Fusion 360 gallery for the project. I'll also place the model into the downloads on this project page to if any one wants it.

Spencer

Spencer

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.