After all the swarf machining the Y-axis motor mounts, I decided to hook up the flood coolant system for the CNC mill as the next part I was going to machine was the X-axis motor mount, and that would involve a huge amount of material removal, so chip evacuation was a big concern.

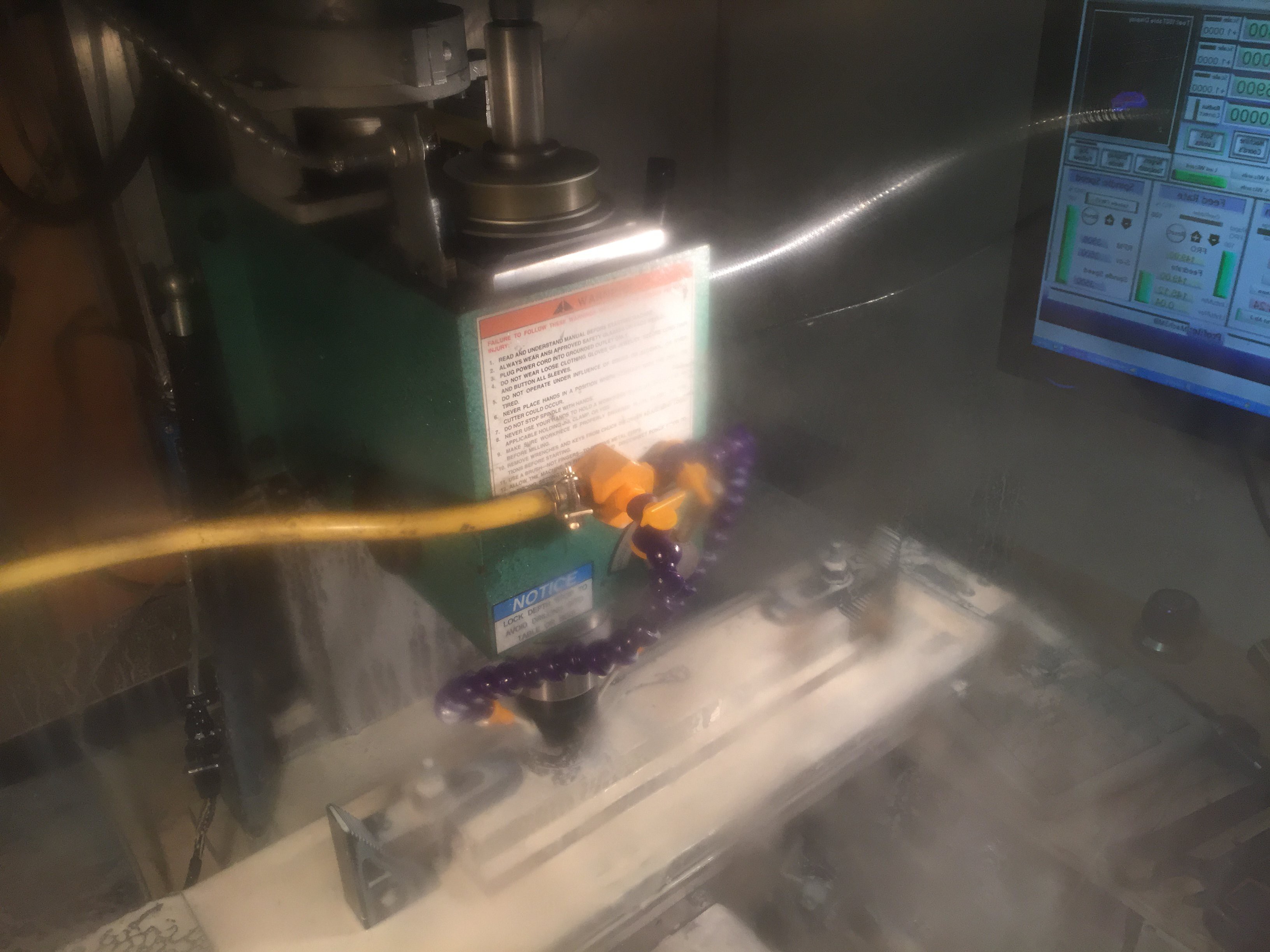

Thankfully this huge mess was expected, and the CNC is fully enclosed! Don't worry, that's just a reflection of the computer's monitor; it's not actually in the enclosure. :)

Oh hey, look - I found an angle where I can kinda see the work piece even.

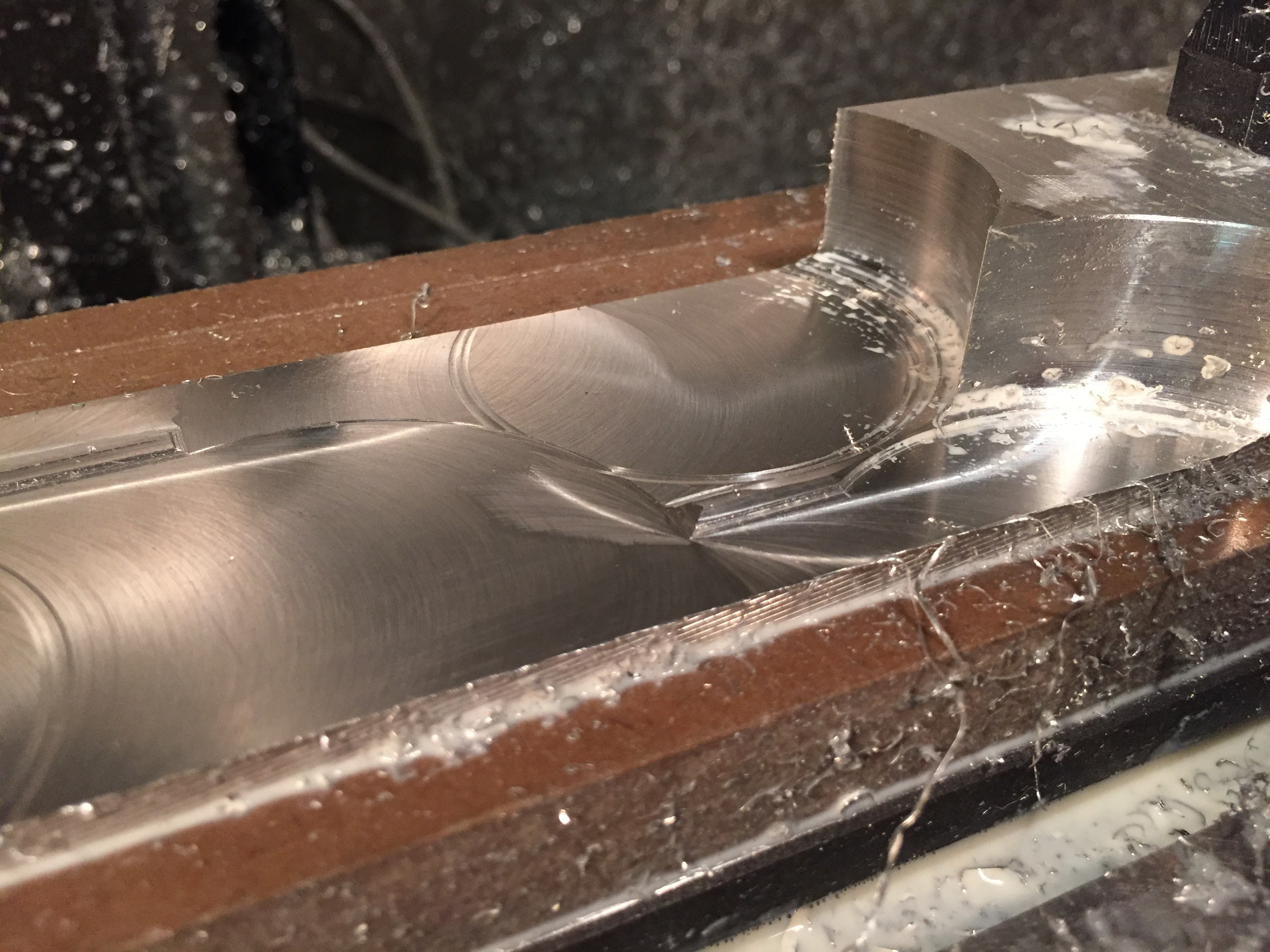

The aftermath of a several hour machining operation was pretty messy.

Unfortunately the part was a failure due to me entering the incorrect tool diameter into the CAM for the toolpath, causing all the features on the part to be removed. Oops. Another lesson learnt.

Richard Sim

Richard Sim

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.