For whatever reason I thought I'd save a few dollars and buy t-nuts for my 8020 brand aluminium extrusion from China. It turns out that the t-nuts I bought don't fit as 8020 uses a different slot profile (~5mm wide) than other 2020 extrusions (~6mm wide), so I had to either throw them out and buy proper t-nuts, or machine them down to fit. In hindsight I should've just bought the correct ones, but instead I decided it'd be a simple task.

The issue was how to hold the t-nuts while keeping the 't' area exposed so it could be machined?

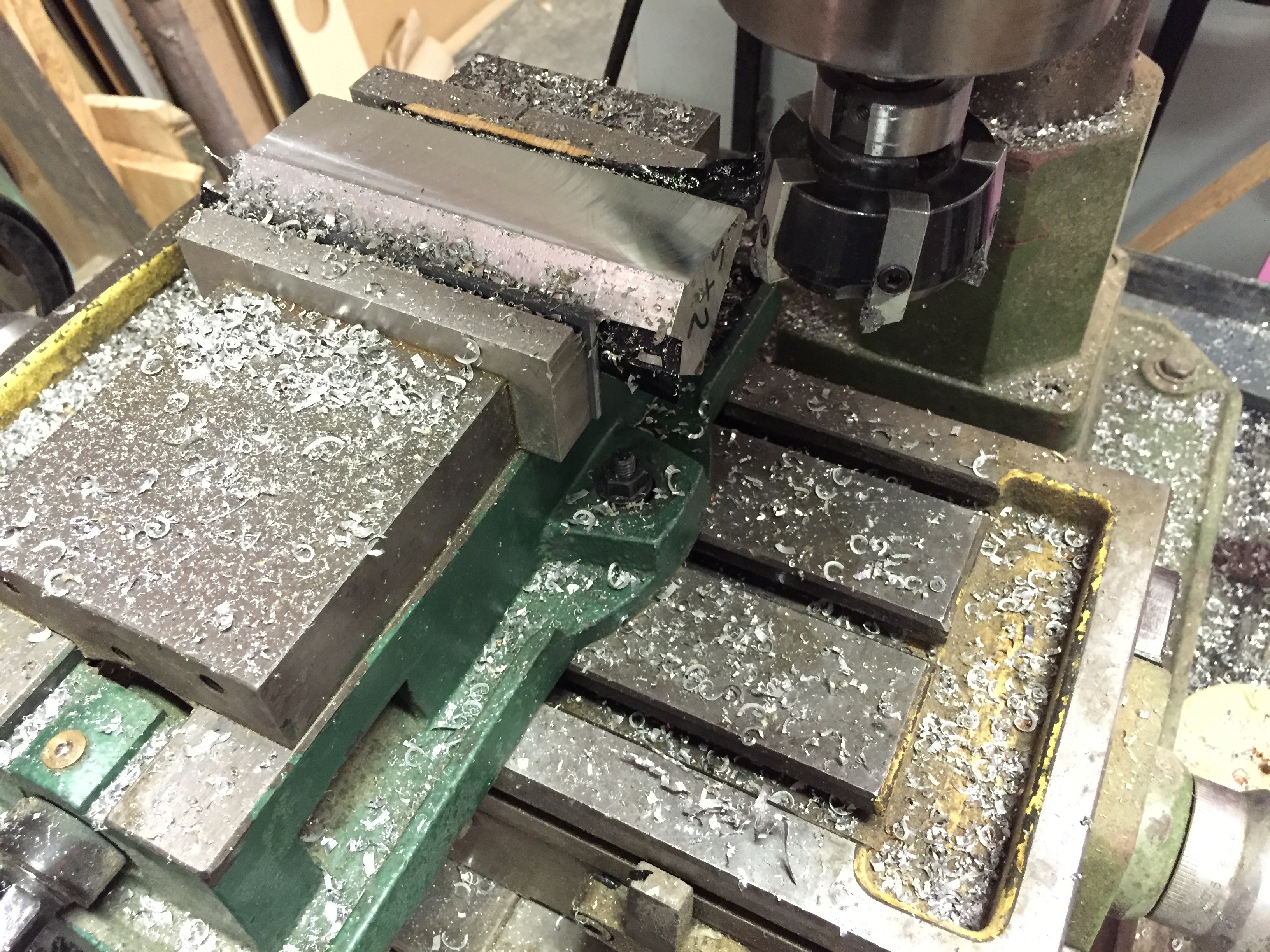

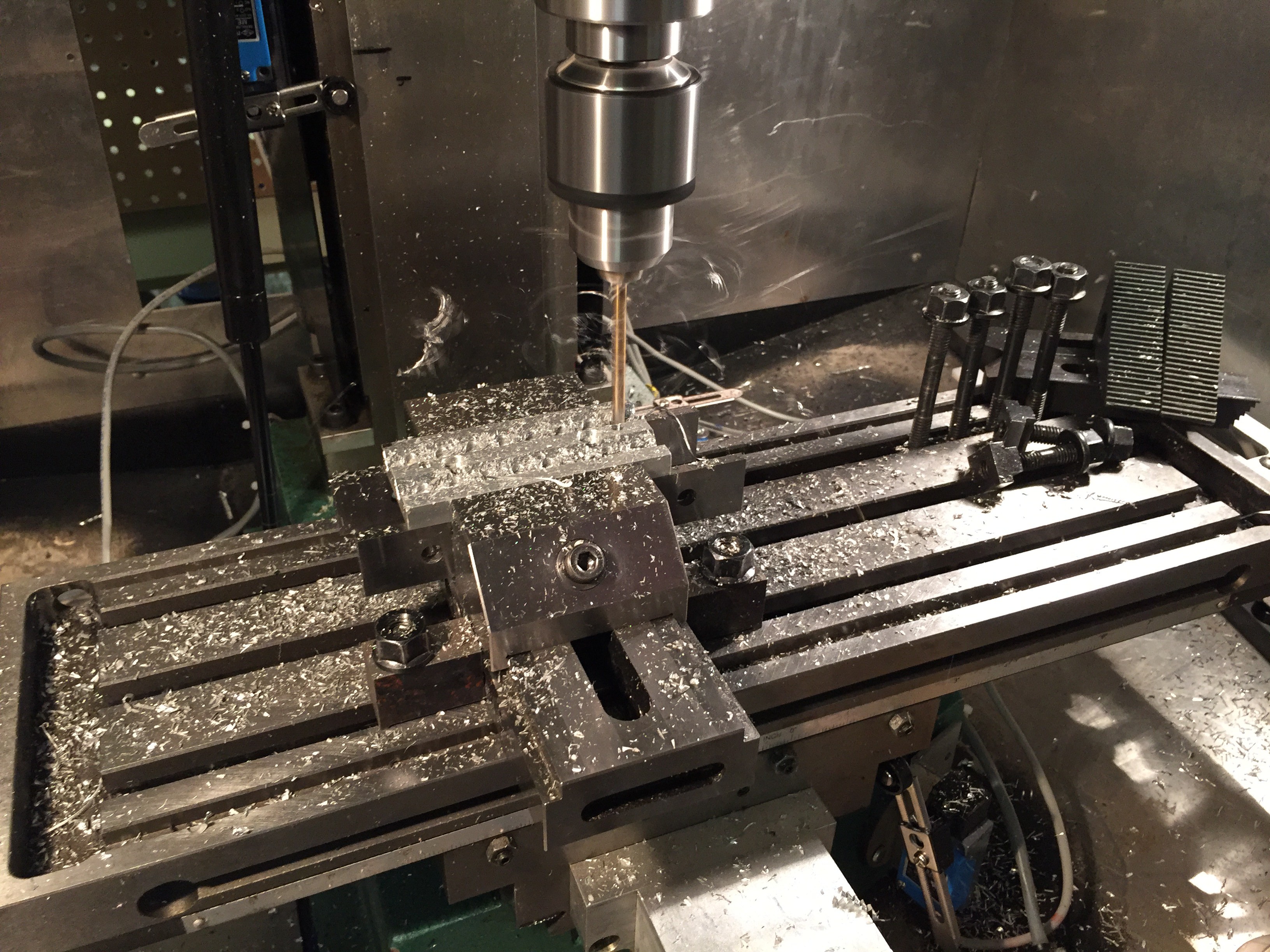

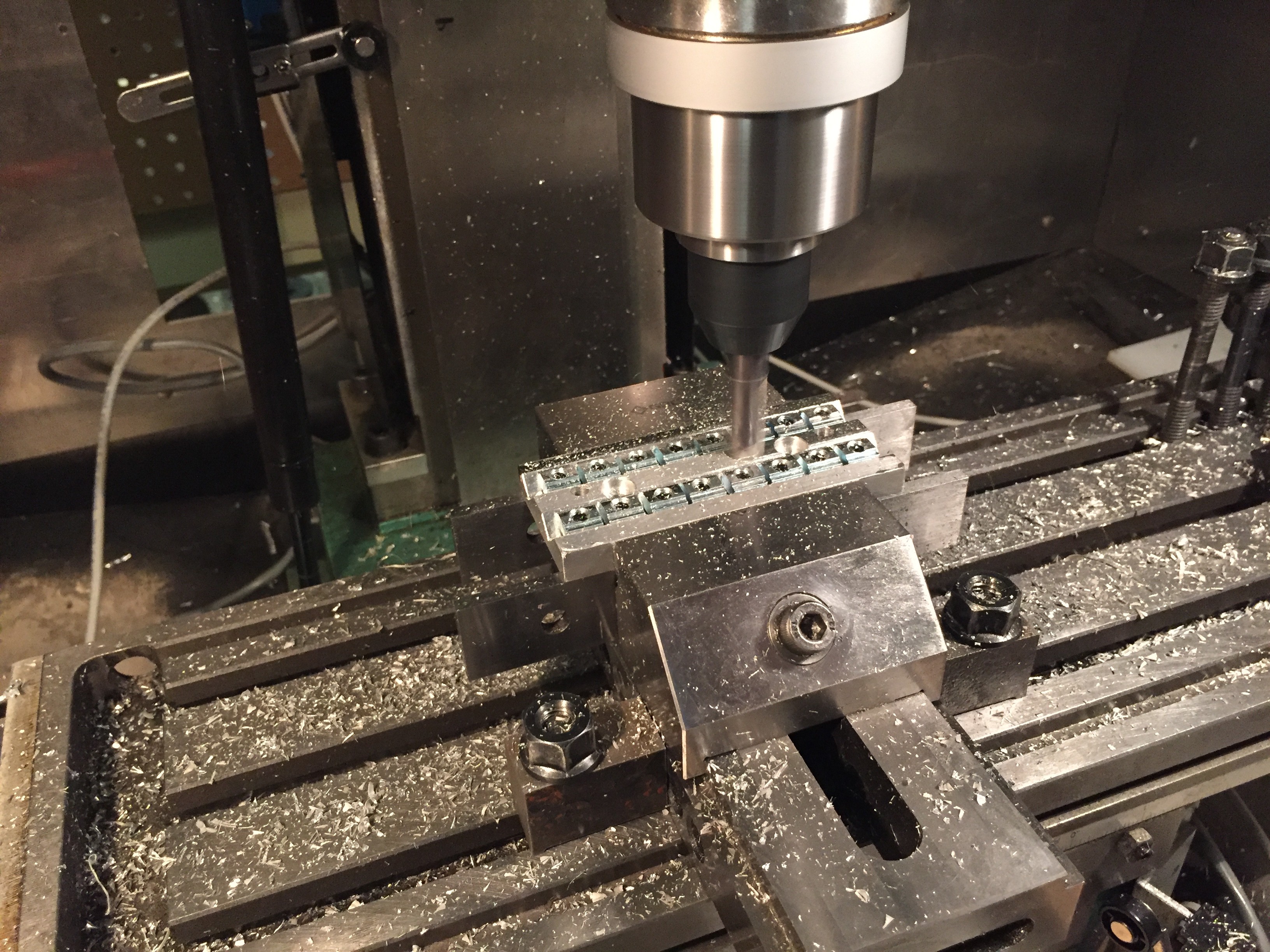

Step 1: Machine a jig...

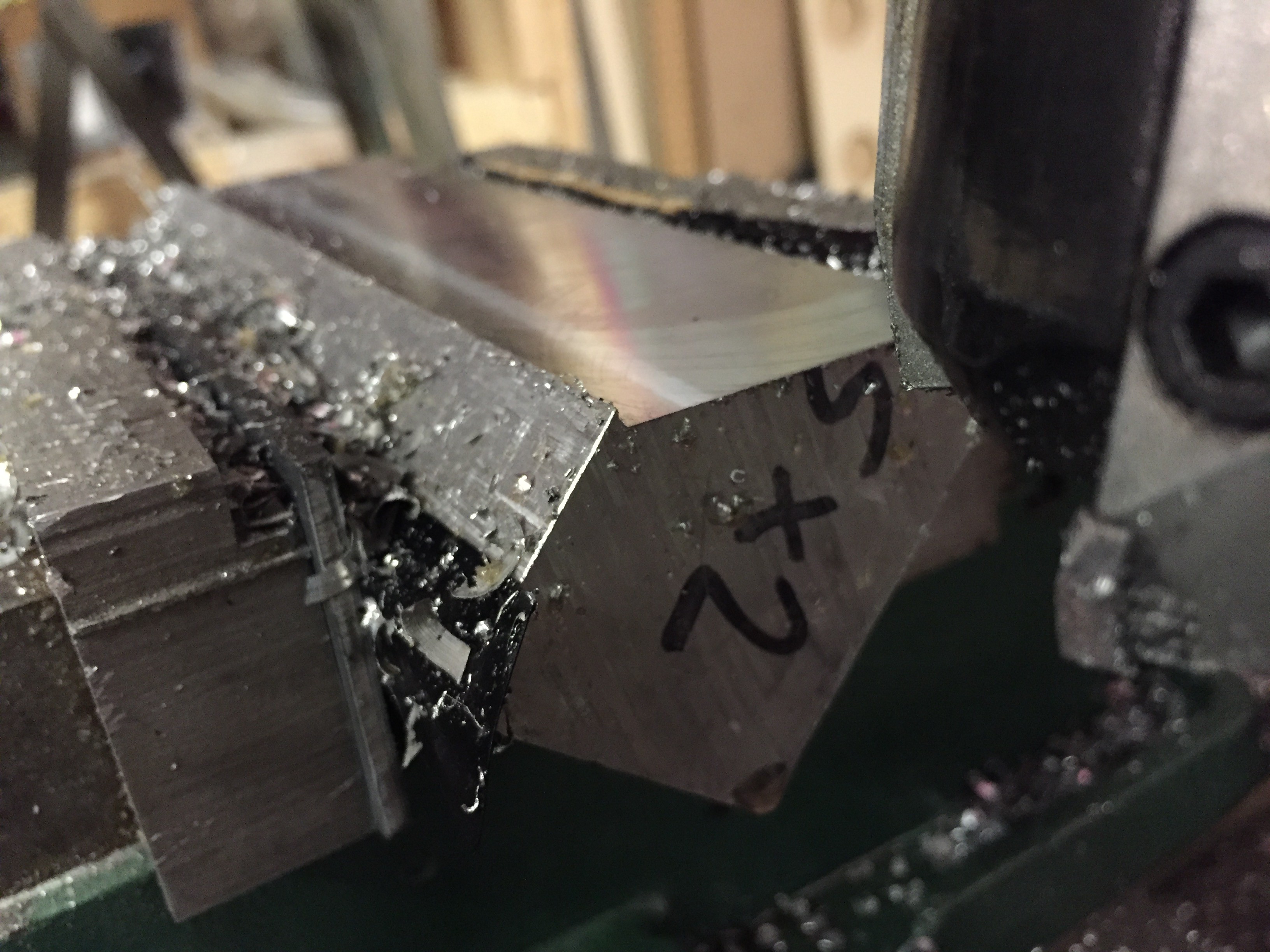

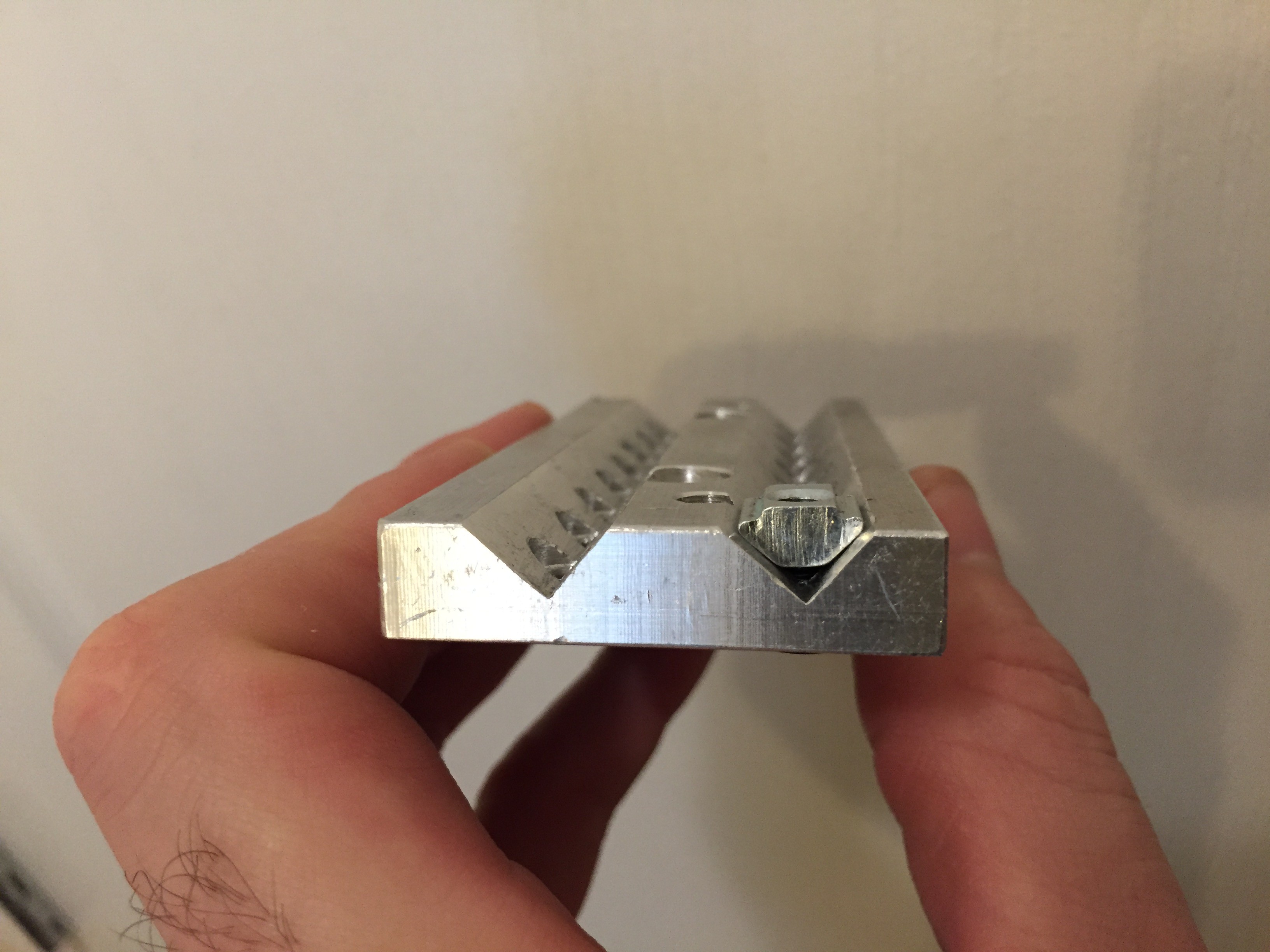

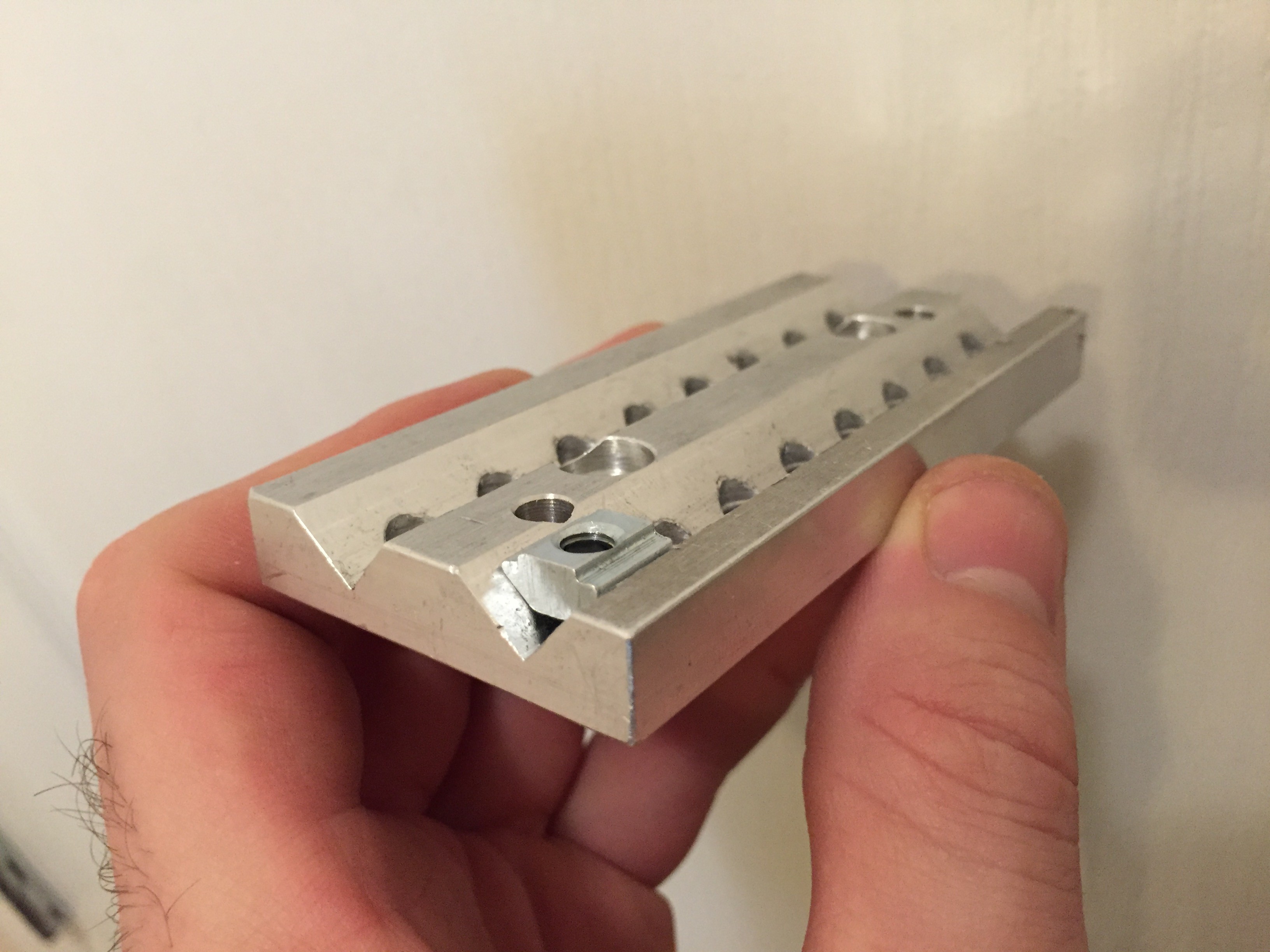

Step 2: For the jig...

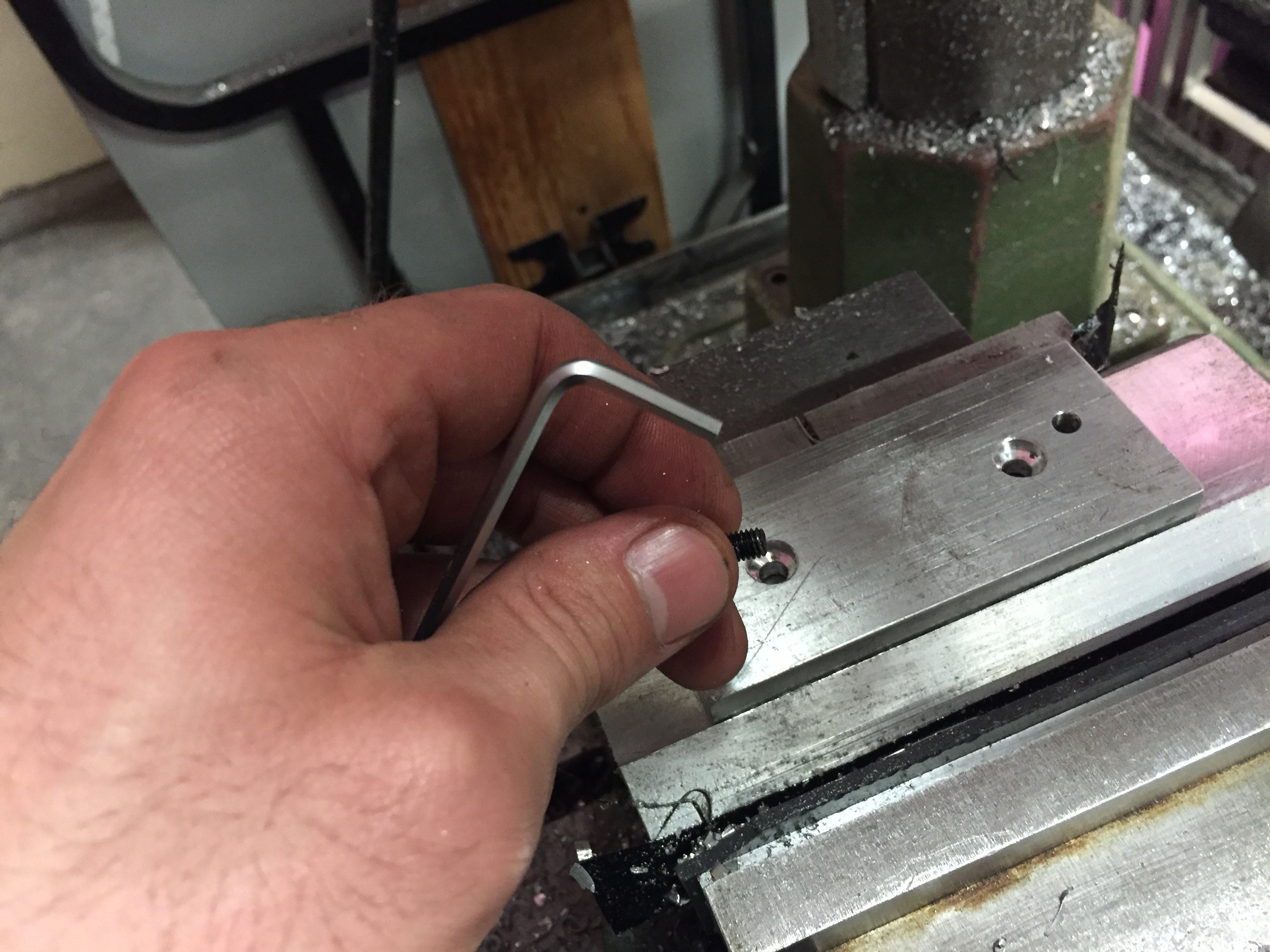

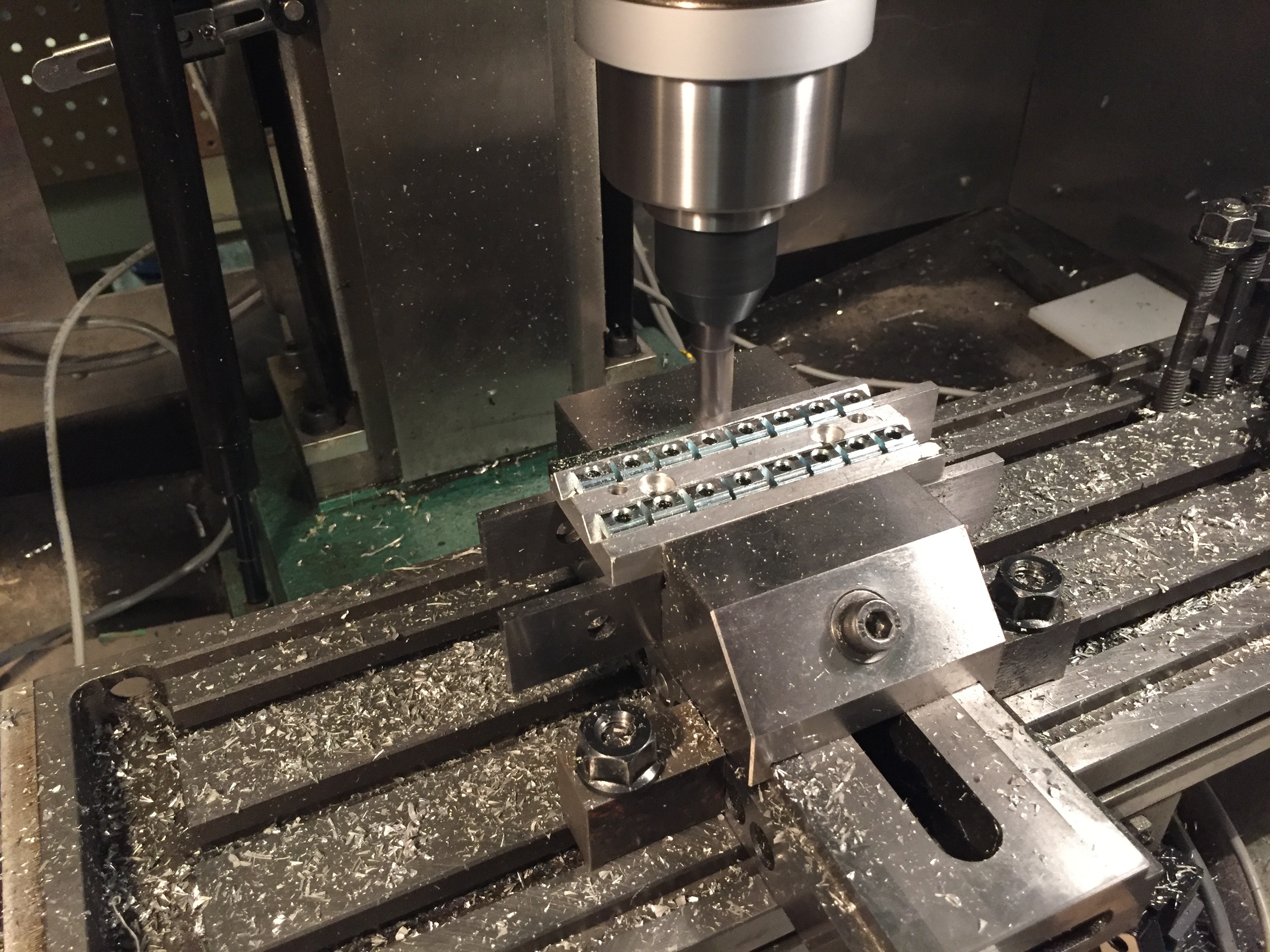

Step 3: To hold the t-nuts...

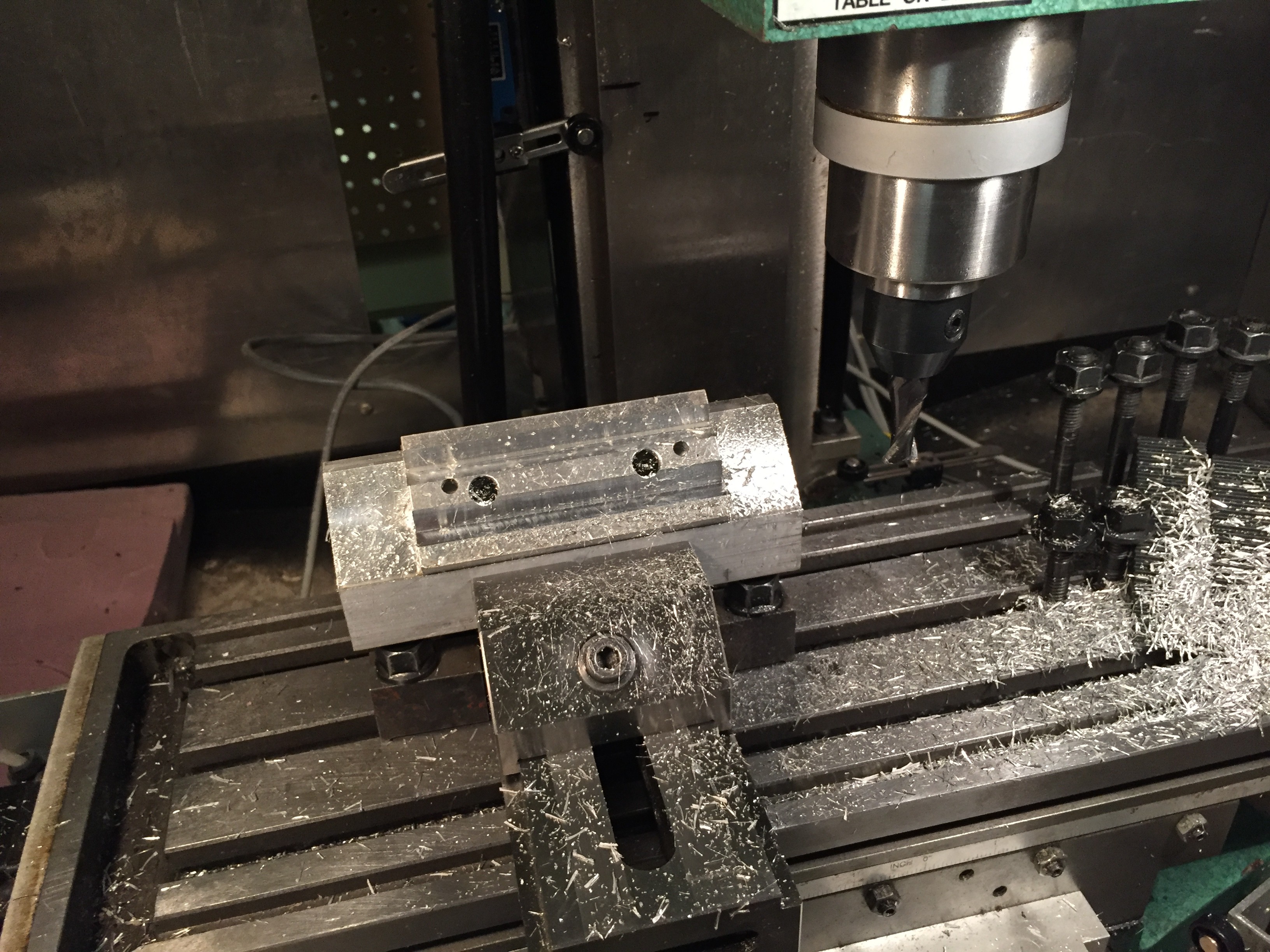

Step 4: So they can finally be machined. All 200 of them.

Lesson learnt. That yak has never been so clean cut in its life.

Richard Sim

Richard Sim

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.