Let's build it! I decided to build it on perfboard, since I don't have a PCB mill.

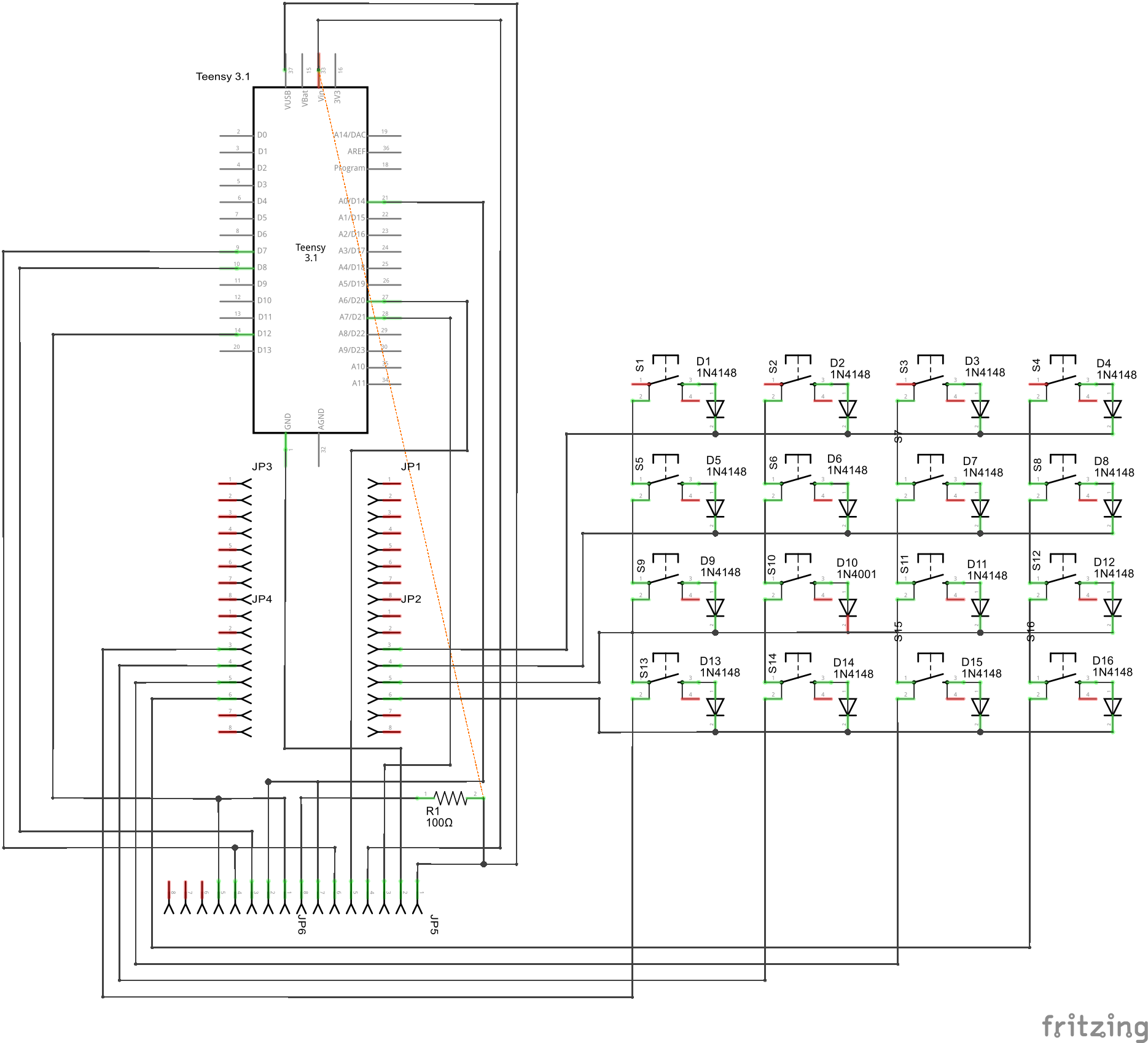

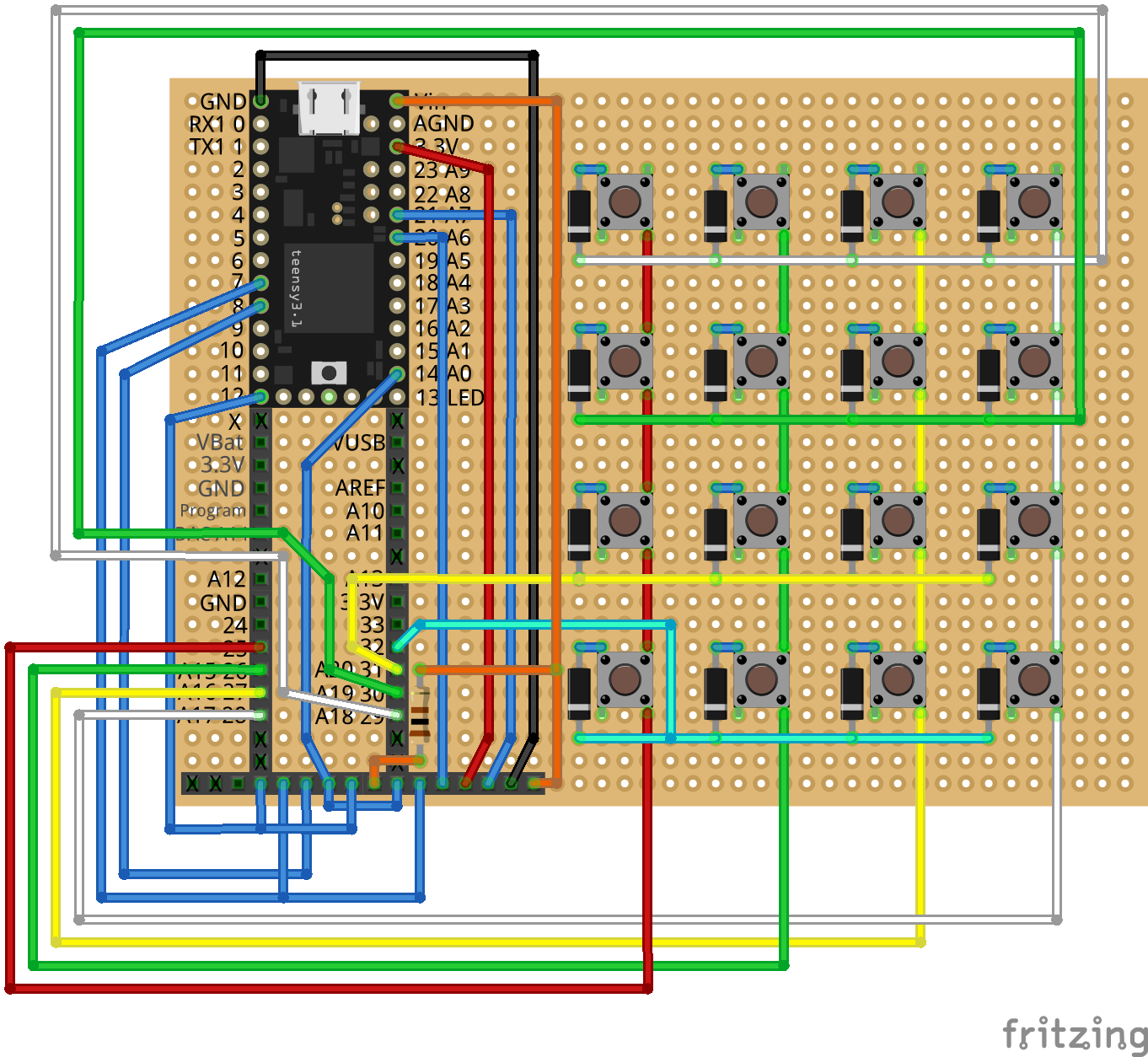

First, I laid the whole thing out in Fritzing so that I could see how best to use my perfboard to handle a Teensy (with Megsy expansion) and the screen and keyboard.

In real life, I had 28 pin sockets available, for Teensy/Megsy, but only 8 pin sockets, so the two extra pins displayed on the screen socket were indeed a problem.

Also, note that I used the far right side of the socket for the screen. That was a bad decision that would bite me later...

In order to clear the buttons, I needed to drill a few more holes, so I just went at it with a screwdriver.

So I wired it up! I didn't have headers with the right number of pins for the screen, so I used two smaller ones. Unfortunately, I chose the wrong side to wire it up to, the screen overlaps the buttons a bit... GAH!

You can see on the back where the keypad is wired up, and you can see the Teensy and Teensy 3.1 wired up on the back side of the board. I actually used my Megsy project for the Teensy here, giving myself access to even the tiny pads on the bottom of the board.

Does it work? You betcha!

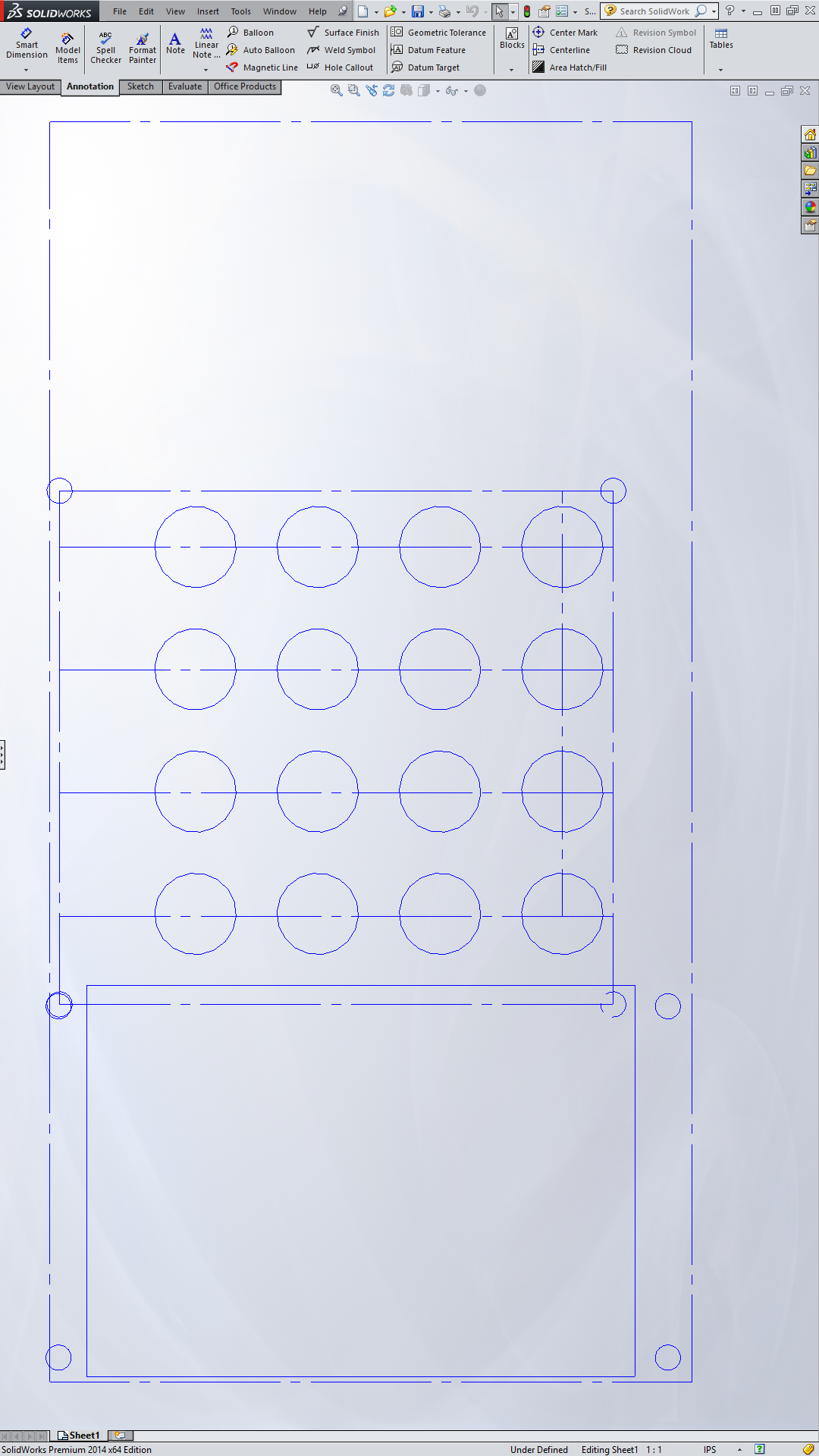

I took some scrap that we had salvaged from the bend tests for Twister to build our case in. But it needed some holes for buttons and screen and mounting, so I designed a template in Solidworks. This was done extremely quickly... show is the next day!

Then, I used the laser cutter at MAG Lab in Pomona to cut it.

After cutting, it came out like this. (Actually, this is the 2nd one cut from the same bit of bent acrylic. We had to cut it in half.)

We also need some holes for the audio jack and USB port, so I drilled those in the side with a drill press and a step drill. I learned my lesson from earlier times... the step drill is the only way to drill acrylic.

So we put it all together...

Looks good, but looks can be deceiving...

The switch PCB is riding up on the edge of the screen PCB... both have to be mounted flush with the panel, and I didn't account for the added width of the screen from the bottom PCB. D'oh!

I'm running out of time and material to make changes, but I've got one more bent piece of acrylic with me, maybe try that?

I want to be really careful to line it up right. I know, I'll use some scrap cardboard on a low power setting to determine where the beam will be...After a couple of tries, I think I have it lined up right... lets give it a go!

Looks nice, but...

It seems like I had even more trouble despite my efforts. The holes were too close to the edge of the case for decent mounting...

Looking at it now, that isn't as terrible as I thought. So I went back to the first draft and determined to make it work...

So I put the PCB in the grinder in my shop and made it fit.

Looks good... but you know there is a giant *but* coming...

What are all those spots on the left of the screen?

Oh, that is just the touch sensitivity going bonkers at this crazy pressure on the right side... I have code in to let you draw on the screen to test the touch stuff...

Well, the touch screen isn't necessary for the show, so I guess it will have to do.

So I give the box to Tina and she goes off to do the show, and amazingly it behaves fine. Mission accomplished!

But I still have "unfinished business" with it....

Today, I want to fix up the touch before I take it out to 23b, so I disassemble the thing to grind the board again.

I had attached the buttons on one side with some double-backed foam tape, so I had to use some Goo Gone to get the residue off.

Then I took it back to the grinder. I think I was a bit overzealous, tho.

Do ya think 3/4 of a diode will still work ok?Actually, it seems fine, although I do need to resolder the lead that attached the keyboard to the Teensy board there...

How about that screen?

Hmmm. This is still problematic... let's try the spare screen and see if it is any better?

Ok, so this one works, at least. I gotta say, the touch signal from these screens is TERRIBLE! Seriously, this is even with averaging 4 samples and using a stylus and the signal cannot even draw a straight line.

Well, let's button it up...So, I completed the 3 day build of the sample player in time for the show, and after the event managed to solve a few more problems with it.

Still remaining to do:

- Finish wiring the other 8 keypad buttons.

- Add functionality to the LCD touch screen to select samples, adjust levels, add effects, etc.

- Add MIDI ports. With those it can also run NanoEgg software and give me a more rugged platform for carrying that around.

- Add a port for the SD card that doesn't require futzing inside the case.

- Add a volume knob. The audio board has a connection for it.

- Add an audio input to record samples.

- Maybe add some other adjustment pots.

- Make a case that is not open on 3 sides.

But this works and is good enough to handle shows. So far, only one song requires samples, but maybe in future here will be others. Now that we have that capability, the sky is the limit!

T. B. Trzepacz

T. B. Trzepacz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.