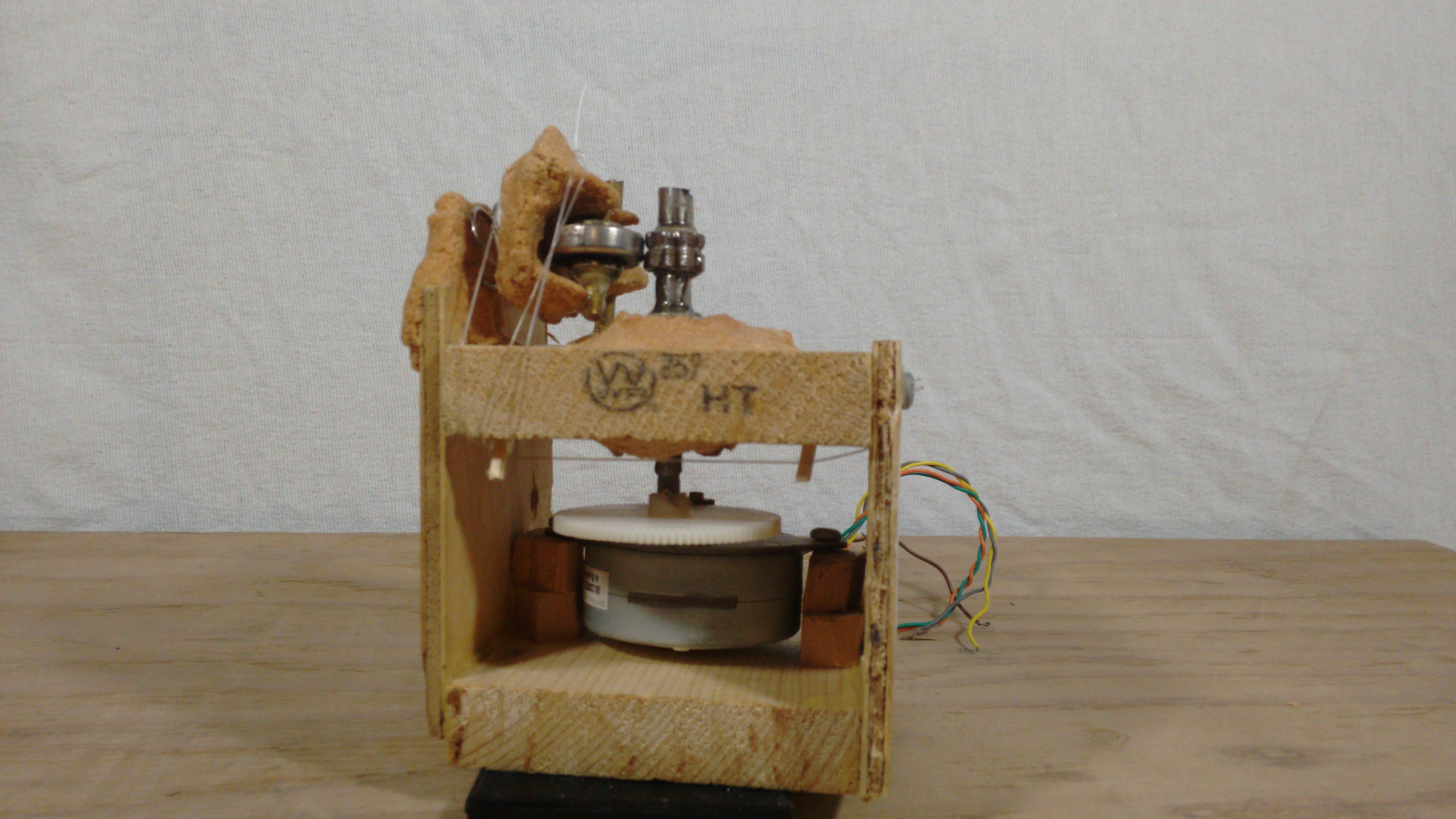

Print Arm 3d uses a Bowden extruder to reduce the weight the print head has to move around. The mechanical end of this extruder was made from old electronics, some basic parts, wood, and glue. It was constructed using basic hand tools. It uses a knurled “bolt” that bites into the filament and pushes it past an aligned ball bearing. The ball bearing is positioned and tensioned using both the spring and some nylon twine. It is designed to be hand made.

The “bolt” in the system is actually ahex nut epoxied to a piece of smooth rod which has grooves to hold a gear on one end. The shaft is epoxied to two ball bearings which are held in place by being epoxied to a custom wooden form. The shaft is driven by a stepper motor screwed to the piece of wood.All of the custom parts you see were hand sculpted from a mixture ofwood glue and sawdust. The rest is either plywood, 1*4, brass rod, or a spring from the OWI robot arm battery holder. To align the bearing with the knurled nut I loop a piece of nylon cord over it, and

around an anchor point to adjust it’s exact tension and position.

The next step is to mount the bowden tube near it and test it. The bowden tube is an 1/8" ID Teflon tube.

The next step is to mount the bowden tube near it and test it. The bowden tube is an 1/8" ID Teflon tube.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.