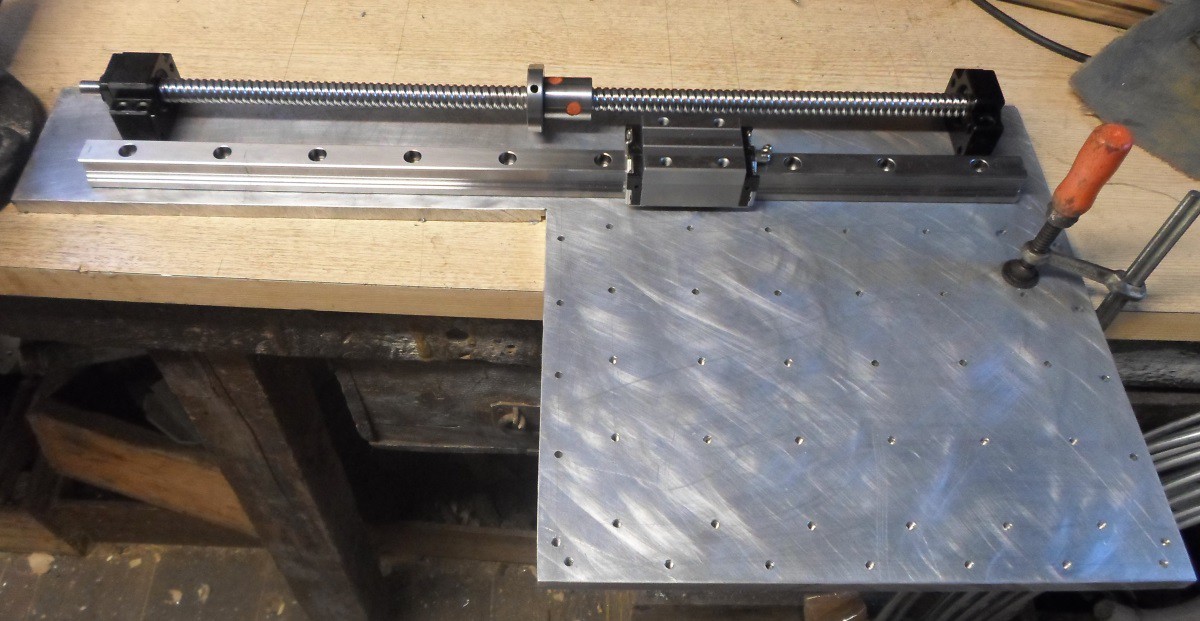

I'v been working on the base plate and some other mechanical parts of the machine. The base plate has a large number of M5 threaded holes to attach the feeders and fixtures for holding the board beeing populated. I'v finished drilling the holes, but I'v not finished tapping all yet. The Y-axis linear rail, ball screw bearings and motor mount also attaches to the base plate.

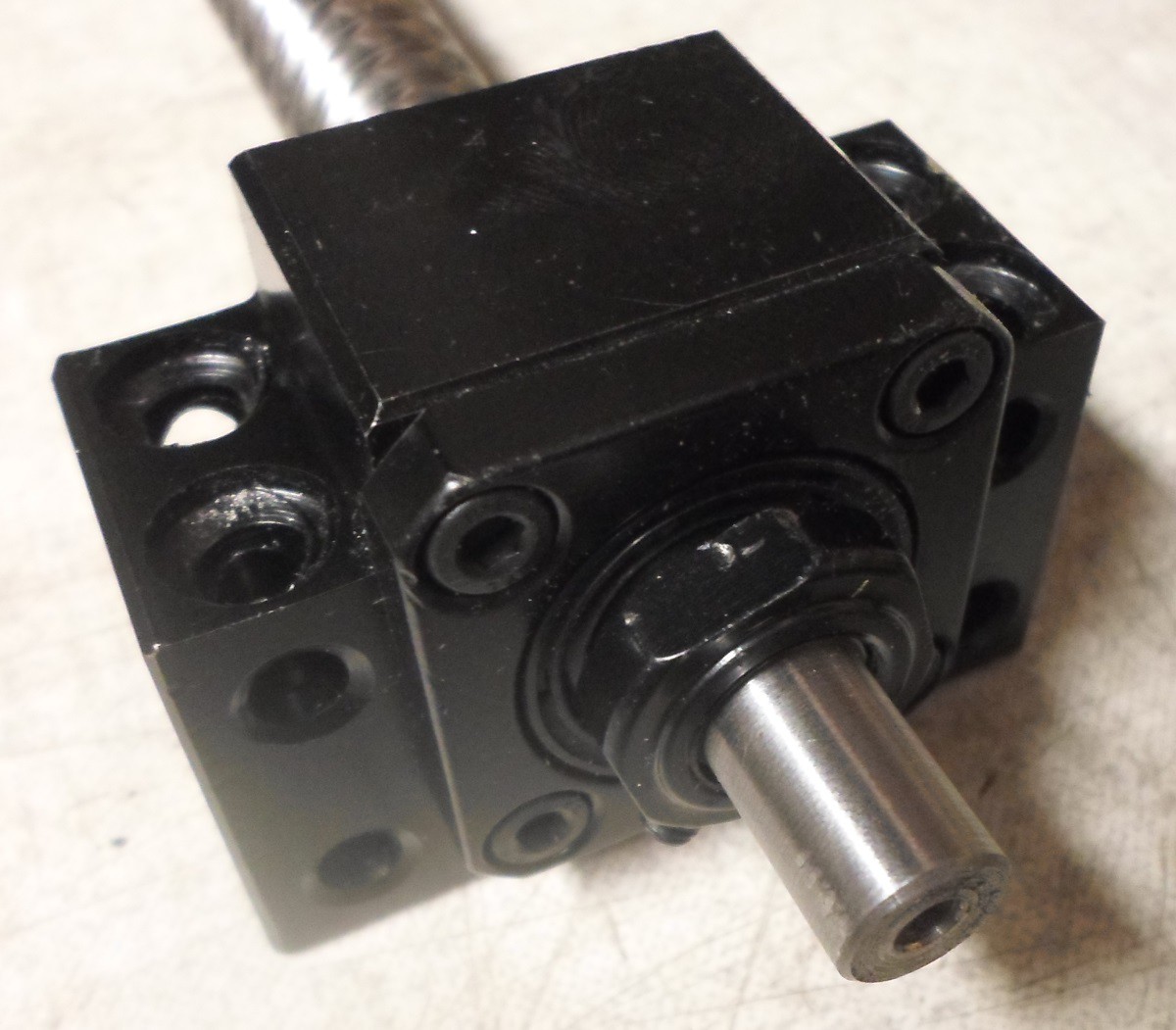

I was a bit worried about the fit of the ball screws into the bearings, but there was no problems. I left the bearings in a warm place and put the screws in the freezer. With 50 or 60C difference in temperature the bearings could be pushed on, no hammering required.

ZeptoBit

ZeptoBit

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.