Here's the 4th part in our series:

In this video, we varnish the frame and put a coat of polyurethane to protect the wood from any spillage that may happen while the bartender is mixing drinks.

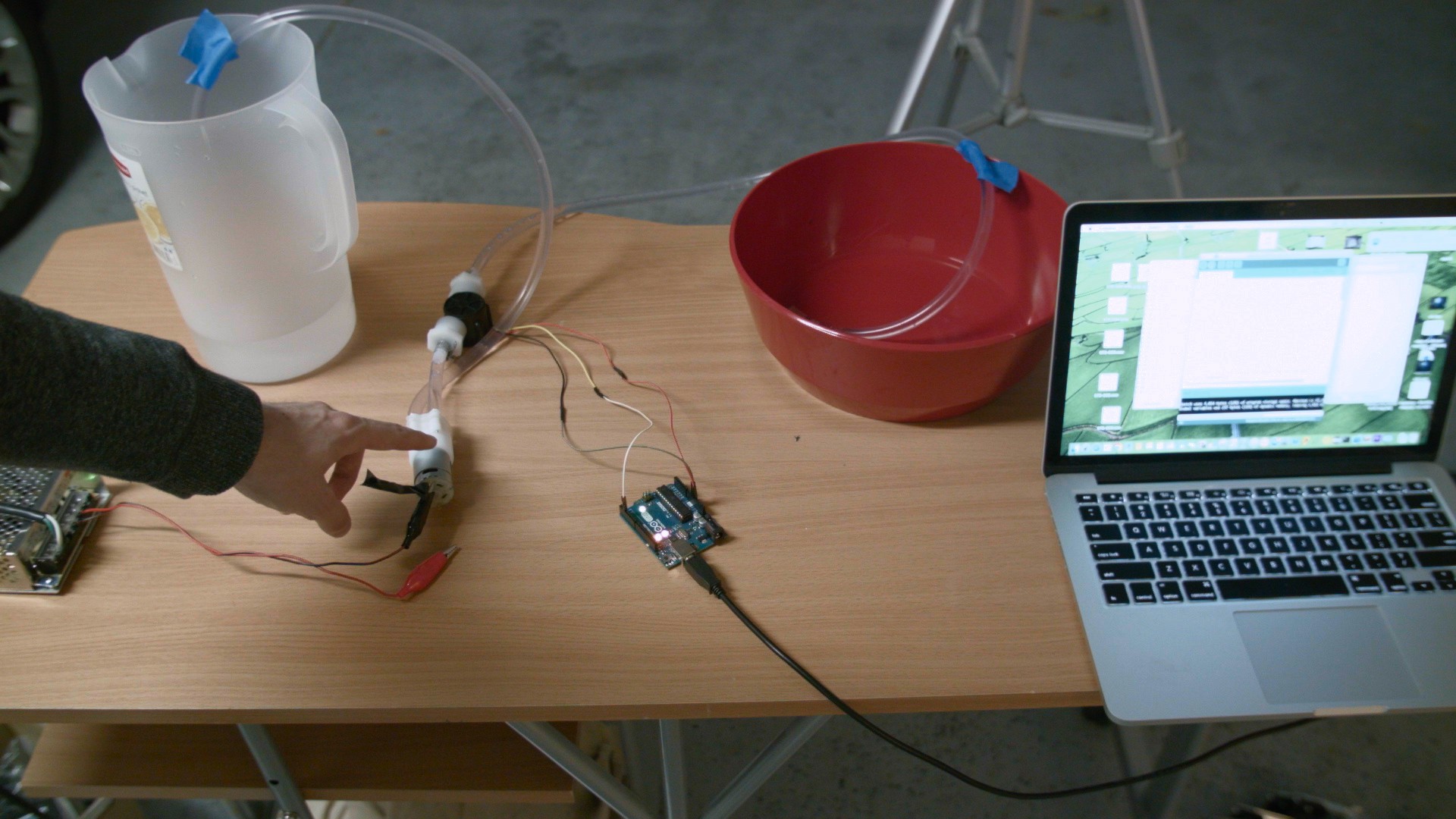

We also bought some flow meters to make our mixer output system more accurate. I setup an experiment to verify that our flow meter works as expected.

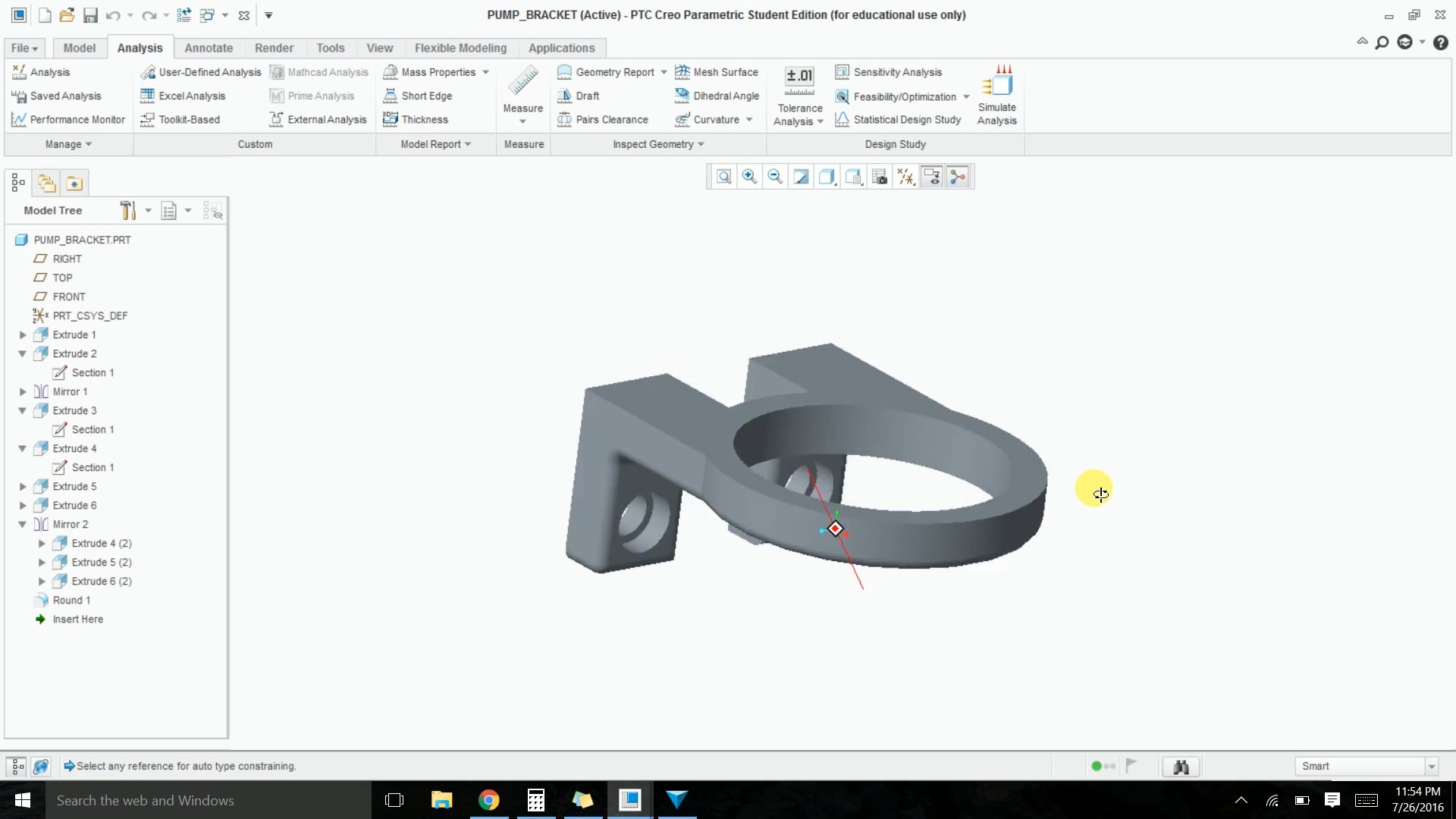

Davis starts using a new modeling software called Creo PTC. This program can speed up modeling because subcomponents are built on a parameter tree. A change to a parameter in the tree can effect everything dependent on it . In 123d, it is much more difficult to make changes once a part is built.

Using this software, he created some mounting brackets for the mixer pumps. Davis also assembled 4 of the 6 dispenser mechanisms with a few parts that we printed since the last video.

Hacker House

Hacker House

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.