Note: Experimental design is discussed at length in the research notebook.

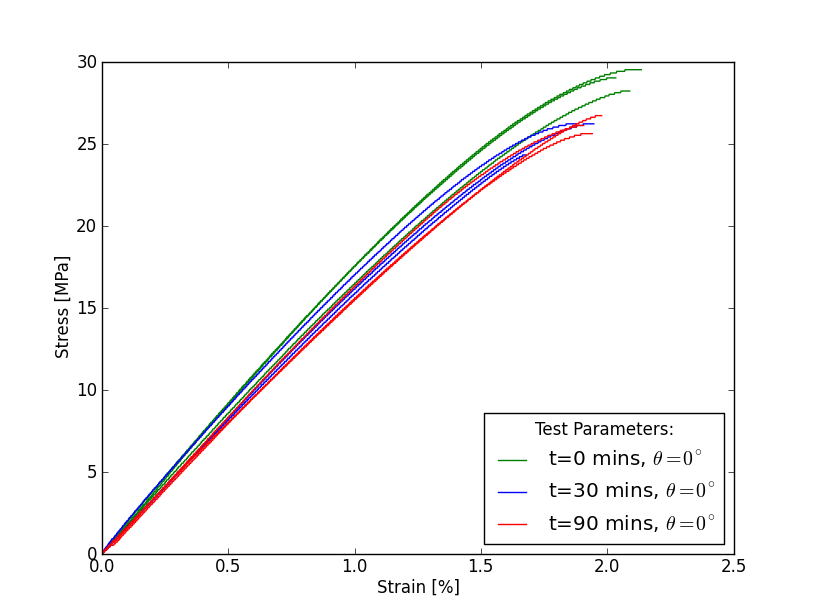

Tensile testing of the produced test coupons showed that the material properties between printed specimens were remarkably similar when loading was along the fibre:

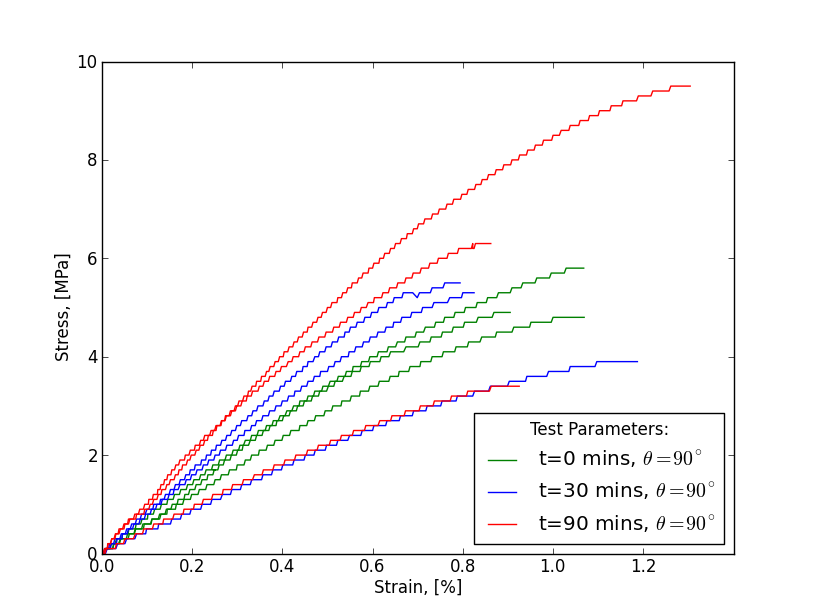

The transverse strengths, however, were not nearly as consistent:

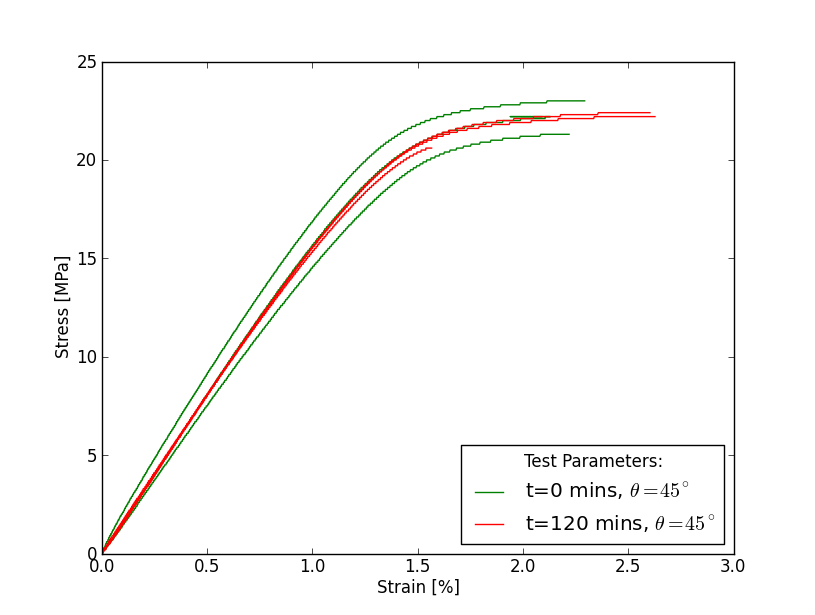

The 45 degree orientation test interestingly showed ductility near the failure region:

Some interesting properties of the FDM material can be observed from the above plots:

- Low strength - transverse strengths above are on the order of 1% of the strength of steel.

- Inconsistent tranverse strength - this is almost certainly due to the inconsistent transverse bonding area causing a 'weakest link' phenomenon.

- Remarkably linear-elastic behaviour until close to the failure point.

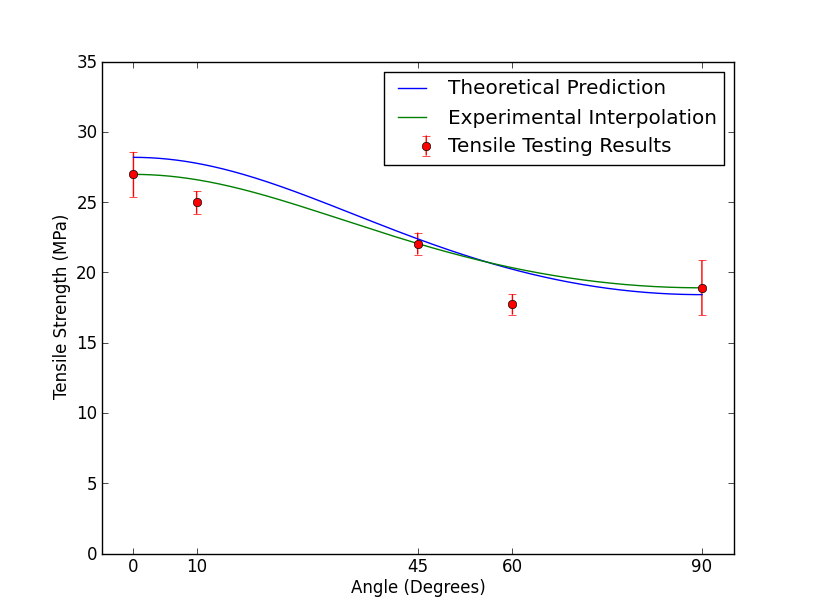

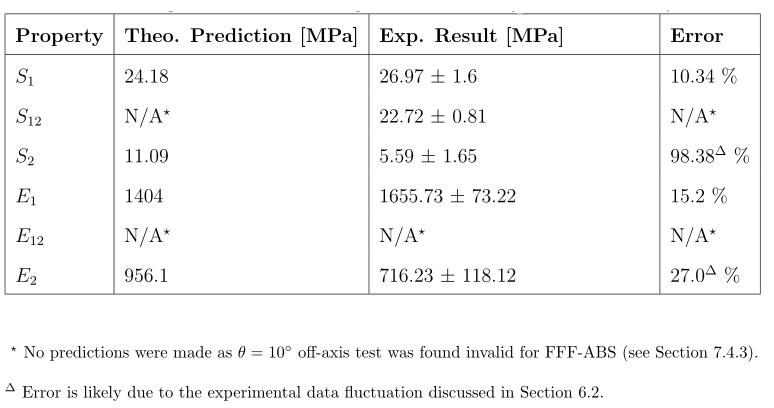

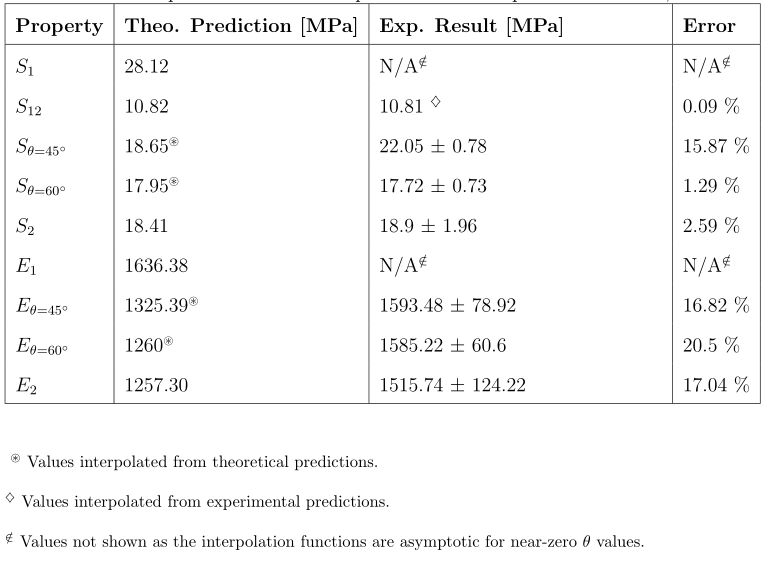

Two tensile test sessions gave experimental data for the material tensile/transverse/intralaminar strengths, which were compared to the predictions as below:

Graphing the predicted strength against the experimental data shows reasonable accuracy of the estimation method:

The errors between the prediction and experiment were actually quite small, given that strength prediction of the FDM material has never been done before! This is promising for future work into characterising the properties of FDM material - or perhaps it's simply useful on it's own. Based on the research conducted here, stronger prints can be made by having a more negative air-gap, as interfibre bonding increases.

We can also make rough predictions about the strengths of the printed material - it seems reasonable to assume about 25 MPa tensile strength, 10 MPa intralaminar shear strength and 15 MPa transverse tensile strength for ABS under the same conditions - though definitely conduct your own testing before using these values.

Sam Barrett

Sam Barrett

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.