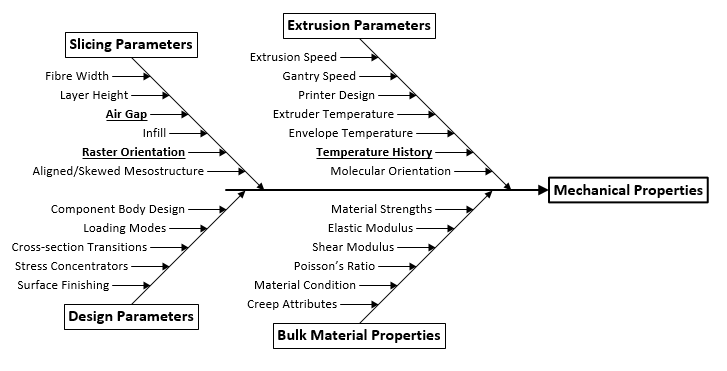

Research conducted during the project found that the material strength is a strong function of several controllable factors:

Of these, the underlined parameters were varied to determine their influence on the mechanical strength:

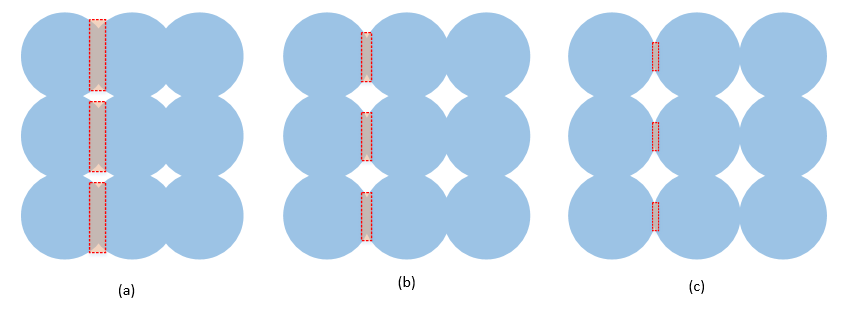

Air Gap:

Defined as the distance between adjacent extruded fibres. For example, if adjacent fibres of width 0.4 mm are deposited with 0.36 mm axis to axis distance, the air gap is -0.04 mm. Setting a negative air gap in this manner will increase the transverse and intralaminar shear strength of the print, as the air gap directly alters the bond area between adjacent fibres. Figure above shows decreasing bonding area with increasing air gap.

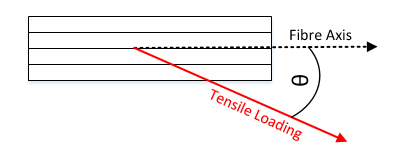

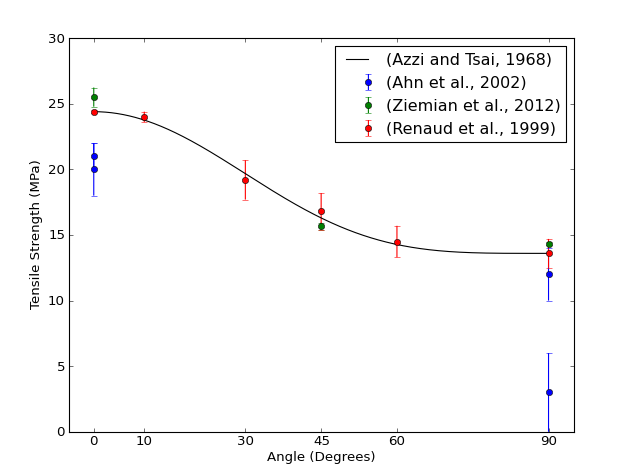

Raster Angle:

Raster angle is simply the angle between the loading direction and the fibre axis. The plot below shows a meta-analysis confirming that tensile strength is a strong function of raster angle:

Temperature History:

Early in the project, it was predicted that the interfibre bonding strength could be increased by annealing the printed tensile test coupons. The temperature histories were varied in time duration (0,30,90,120) at 125 deg C.

Basically, this doesn't work: the specimens shrink when annealed, and there wasn't any observable increase in shear strength. My (untested) hypothesis is that annealing would make the material strengths more consistent (but not greater) as the bond areas between the fibres would be more consistent - however this would likely not be worth the considerable part shrinkage.

Controlled Build Parameters

The build parameters in the table below were held constant throughout the experiment.

| Parameter | Value |

| Printer | Solidoodle 3 |

| Filament | Chi Mei Polylac PA-747 ABS Density 1.03 g/cc Melt Flow Rate 13g/10mins (load 10kg, temp 220C, ISO-1133) Yield Tensile Strength 31.0 MPa Stored with dessicant in cool dark area Natural colour (no composition-altering colourants) |

| Layer Height | 0.4 mm |

| Air Gap | -0.04 mm (10% of layer height) |

| Infill | Unidirectional Rectilinear Infill |

| Mesostructure | Aligned (ie. not skewed) |

| Extrusion Speed | 2700 mm/min |

| Extruder Temp. | 210 deg C |

| Envelope Temp. | 70 deg C |

| Test Coupon | ASTM D3039 185mm x 25mm x 2mm |

| Tensile Tester | Instron 5500R Tensile Testing Machine Single axis loading with attached extensiometer |

Sam Barrett

Sam Barrett

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.