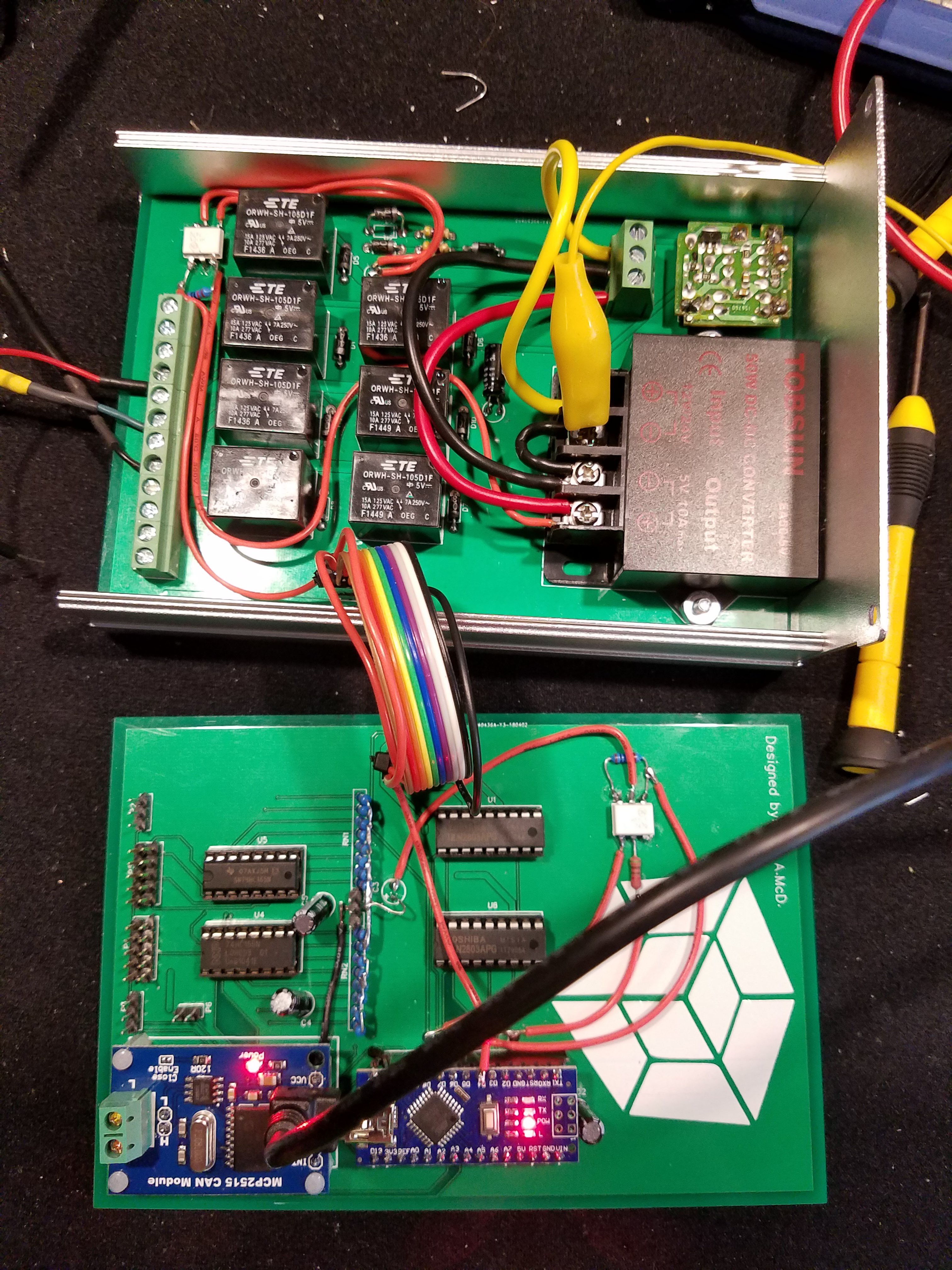

I've spent the past couple days working various parts of this project, and I have completed the controller for the climate control system.

Relays for controlling the fan, 5V DC-DC switched power supply, timer circuit from the original rear-window-defrost, CAN-bus controller, and an Arduino. The headers on the left of the bottom board are for the servos and encoders that interface with the OEM push-pull cable system.

Here's the code for the Arduino:

#include <Servo.h>

#include <mcp_can.h>

#include <SPI.h>

#include <EEPROM.h>

#define CAN_INT 2

#define AC_STATUS 5

#define SERVO_2 6

#define SERVO_1 7

#define LOAD_DATA 8

#define CLK_INH 9

#define CAL_BTN 3

#define FAN_SET1 A0

#define FAN_SET2 A1

#define FAN_SET3 A2

#define FAN_SET4 A3

#define DEF_TOG A4

#define AC_EN A5

#define RECIRC_EN A6

#define AC_STATUS_ANALOG A7

#define DEF_STATUS 4

MCP_CAN CAN0(10);

bool CANgood = false, def_toggle = false, AC_enable = false, recirc_enable = false;

long unsigned int rxId;

unsigned char len = 0;

unsigned char rxBuf[4], txBuf[4];

Servo servo1, servo2;

unsigned int encoders1 = 0, encoders2 = 0;

int numberOfPositions_1 = 0, numberOfPositions_2 = 0;

byte fans = 0, temp_1 = 0, destination = 0;

unsigned long time = 0,time2=0;

void setup() {

Serial.begin(115200);

pinMode(CAN_INT, INPUT);

pinMode(AC_STATUS, INPUT);

pinMode(DEF_STATUS, INPUT);

pinMode(SERVO_2, OUTPUT);

pinMode(SERVO_1, OUTPUT);

pinMode(LOAD_DATA, OUTPUT);

pinMode(CLK_INH, OUTPUT);

pinMode(CAL_BTN, INPUT_PULLUP);

pinMode(FAN_SET1, OUTPUT);

pinMode(FAN_SET2, OUTPUT);

pinMode(FAN_SET3, OUTPUT);

pinMode(FAN_SET4, OUTPUT);

pinMode(DEF_TOG, OUTPUT);

pinMode(AC_EN, OUTPUT);

pinMode(RECIRC_EN, OUTPUT);

digitalWrite(FAN_SET1, LOW);

digitalWrite(FAN_SET2, LOW);

digitalWrite(FAN_SET3, LOW);

digitalWrite(FAN_SET4, LOW);

digitalWrite(RECIRC_EN, LOW);

digitalWrite(AC_EN, LOW);

digitalWrite(DEF_TOG, LOW);

digitalWrite(CLK_INH, HIGH);

digitalWrite(LOAD_DATA, HIGH);

//digitalWrite(CAL_BTN, HIGH);

servo1.attach(SERVO_1);

servo2.attach(SERVO_2);

if (CAN0.begin(CAN_1000KBPS) == CAN_OK) {

CAN0.init_Mask(0, 0, 0x7Ff);

CAN0.init_Mask(1, 0, 0x7ff);

CAN0.init_Filt(0, 0, 0x00e); // climate control data

CAN0.init_Filt(2, 0, 0x00e);

CAN0.init_Filt(3, 0, 0x00e);

CAN0.init_Filt(4, 0, 0x00e);

CAN0.init_Filt(5, 0, 0x00e);

Serial.print("can init ok!!\r\n");

CANgood = true;

}

else {

Serial.println("not ok");

//while (true) {}

Serial.println("continuing");

}

if (!digitalRead(CAL_BTN)) {

Serial.println("calibration");

calibrateEncoders();

}

for (int i = 0; i < 4; i++) {

txBuf[i] = 0;

}

}

void loop() {

// every 500 ms, send an update to the main controller

if ((millis() - time) > 500) {

time = millis();

txBuf[0] = txBuf[0] | fans;

txBuf[0] = txBuf[0] | (def_toggle << 4);

txBuf[0] = txBuf[0] | (AC_enable << 5);

txBuf[0] = txBuf[0] | (recirc_enable << 6);

txBuf[1] = temp_1;

txBuf[2] = destination;

txBuf[3] = analogRead(AC_STATUS_ANALOG)>300?1:0 | (digitalRead(DEF_STATUS) << 1);

CAN0.sendMsgBuf(0x7ff, 0, 4, txBuf);

Serial.print("AC status: ");

Serial.println(digitalRead(AC_STATUS));

Serial.print("Defroster Status: ");

Serial.println(digitalRead(DEF_STATUS));

Serial.println("");

}

// This is here for testing purposes

/*if((millis()-time2)>5000){

time2=millis();

//def_toggle = true;

recirc_enable = !recirc_enable;

AC_enable = !AC_enable;

if(fans==16){

fans=0;

}else if(fans==0){

fans=1;

}else{

fans = fans << 1;

}

}*/

// If the CAN bus has new data for this controller, read it an do stuff with the data

if (!digitalRead(CAN_INT) && CANgood) {

CAN0.readMsgBuf(&len, rxBuf);

rxId = CAN0.getCanId();

if ((rxId == 0x00e) && (len >= 3)) {

fans = rxBuf[0] & B00001111;

def_toggle = rxBuf[0] & B00010000;

AC_enable = rxBuf[0] & B00100000;

recirc_enable = rxBuf[0] & B01000000;

temp_1 = rxBuf[1];

destination = rxBuf[2];

}

}

// we only want to turn on one of the fan signals at a time, so check to make sure that only one bit is set high or all are low

if (countSetBits(fans) <= 1) {

digitalWrite(FAN_SET1, fans & B00000001);

digitalWrite(FAN_SET2, fans & B00000010);

digitalWrite(FAN_SET3, fans & B00000100);

digitalWrite(FAN_SET4, fans & B00001000);

}

// send a pulse to the defrost timer

if (def_toggle) {

digitalWrite(DEF_TOG, HIGH);

delay(200);

digitalWrite(DEF_TOG, LOW);

def_toggle = false;

}

digitalWrite(AC_EN, AC_enable);

digitalWrite(RECIRC_EN, recirc_enable);

updateServos(temp_1 , destination );

}

bool updateServos(byte servo_1_pos, byte servo_2_pos)

{

// A lot goes on in the next few lines of code

// starting with new position variables and working outwards:

// these two variables are in the range of 0 to 255 so lets map it to a new range.

// the new range is from 0 to whatever the caliration set as the max position.

// the calibration set the max position in EEPROM in the last two addresses.

// once the mapping is complete, we read the current encoder data and use that as the address

// to look up what the current position is.

// to make sure we are working with good values, lets contrain this position values that are

// between 0 and the max position as read from the last two addresses in EEPROM.

// subtract our mapped int from the current position to get our offset.

// multiply this offset by 10 so that the servo speed will be quick.

// constrain maximum servo speed to +/-30.

// add 90 because that is the "stop" speed.

// write to the servo.

byte len = EEPROM[EEPROM.length() - 1] - 2; // stay 2 positions away from edge

byte currentPos = EEPROM[highByte(read74HC165())];

if (currentPos != 255) { // check for out of bounds value (255) prior to updating servo

servo1.write(

constrain(

(

currentPos

- map(

servo_1_pos, 0, 255, 2, len // stay 2 positions away from edge

)

) * 10 , -30, 30

) + 90

);

} else {

return false; // hit out of bounds

}

len = EEPROM[EEPROM.length() - 2] - 2;

currentPos = EEPROM[lowByte(read74HC165())];

if (currentPos != 255) {

servo2.write(

constrain(

(

currentPos

- map(

servo_2_pos, 0, 255, 2, len

)

) * 10 , -30, 30

) + 90

);

} else {

return false;

}

return true;

}

//======================================================================

// Reads two bytes from the 74HC165 registers

unsigned int read74HC165()

{

digitalWrite (LOAD_DATA, LOW); //load the push button state into the 74HC165

asm("nop\n nop\n"); //some delay

digitalWrite (LOAD_DATA, HIGH);

digitalWrite (CLK_INH, LOW); //enable 74HC165 clock

asm("nop\n nop\n"); //some delay

unsigned int Switches = SPI.transfer16(0); //get the position

digitalWrite (CLK_INH, HIGH); //disable 74HC165 clock

return Switches; //switches will have the value read by then 74HC165

}

// END of read74HC165()

//======================================================================

void calibrateEncoders() {

for (int i = 0 ; i < EEPROM.length() ; i++) {

EEPROM.write(i, 255);

}

while (!digitalRead(CAL_BTN)) {}

Serial.println("Starting Clibration of number 1.");

Serial.println("Press button when reaching start point.");

delay(2000);

servo1.write(100);

while (digitalRead(CAL_BTN)) {}

servo1.write(90);

Serial.println("end position noted");

byte encoder_1 = highByte(read74HC165());

byte encoder_2 = encoder_1;

int pos = 0;

delay(2000);

Serial.println("Other direction");

delay(1000);

servo1.write(80);

while (digitalRead(CAL_BTN)) {

int tester = countSetBits(encoder_1 ^ encoder_2);

if (tester > 1) {

Serial.println(tester);

}

if ((tester == 1) && (EEPROM[encoder_1] != EEPROM[encoder_2])) {

//Serial.println(encoder_1, BIN);

//Serial.println(pos);

servo1.write(90);

delay(5);

EEPROM[ encoder_1 ] = pos;

encoder_2 = encoder_1;

pos++;

delay(5);

servo1.write(80);

}

encoder_1 = highByte(read74HC165());

}

servo1.write(90);

EEPROM[ EEPROM.length() - 1 ] = --pos;

while (!digitalRead(CAL_BTN)) {}

Serial.println("Starting Clibration of number 2.");

Serial.println("Press button when reaching start point.");

delay(2000);

servo2.write(100);

while (digitalRead(CAL_BTN)) {}

servo2.write(90);

Serial.println("end position noted");

encoder_1 = lowByte(read74HC165());

encoder_2 = encoder_1;

pos = 0;

delay(2000);

Serial.println("Other direction");

delay(1000);

servo2.write(80);

while (digitalRead(CAL_BTN)) {

int tester = countSetBits(encoder_1 ^ encoder_2);

if (tester > 1) {

Serial.println(tester);

}

if ((tester == 1) && (EEPROM[encoder_1 + 512] != EEPROM[encoder_2 + 512])) {

//Serial.println(encoder_1, BIN);

//Serial.println(pos);

servo2.write(90);

delay(5);

EEPROM[ encoder_1 + 512 ] = pos;

encoder_2 = encoder_1;

pos++;

delay(5);

servo2.write(80);

}

encoder_1 = lowByte(read74HC165());

}

servo2.write(90);

EEPROM[ EEPROM.length() - 2 ] = --pos;

Serial.println("test");

time = millis();

while ((millis() - time) < 10000) {

updateServos(1, 1);

}

Serial.println("test1");

time = millis();

while ((millis() - time) < 10000) {

updateServos(254, 254);

}

Serial.println("test2");

delay(1000);

}

unsigned int countSetBits(int n)

{

unsigned int count = 0;

while (n)

{

n &= (n - 1) ;

count++;

}

return count;

}Schematics for this little gizmo can be found here :

https://easyeda.com/andrewmcdan/encoder-servo-controller (This board has the Arduino on it.)

https://easyeda.com/andrewmcdan/Encoder-Breakout

https://easyeda.com/andrewmcdan/encoder-servo-controller-2 (This board has the relays on it.)

More updates to come!

AndrewMcDan

AndrewMcDan

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.