Reality is a cruel taskmaster. Making a transition from tiny tubing to a planar structure like a Lab on a Chip is a perfect example.

There is a very old saying in electronics, especially where it concerns debugging something that was once working but now mysteriously is not functioning, "99% of all problems are at the interface". Nothing could more true in regards to microfluidics and Lab on a Chip. After having gone to enormous trouble preparing a substrate, laying down gold, silver and other precious metals, spending all sorts of time on artwork, generating cut files and G-Code, miking up countless batches of PDMS, preparing reagents, ordering materials, and much, much more. We finally come to the central problem.

How exactly am I to get 10 uL of this DNA into that tiny, little, thin sliver of a machine? Along with the running buffers and all the other fluids involved, there might be lots of fluid connections. Fluids here includes any gases like air needed for pneumatic valves. One common way would be to mount all the tubing interfaces in a manifold.

One simple and effective way join a tube made of vinyl, silicone, or polyamide is to slip it over the end of a glass capillary tube that is flanged. Then, one simply seals the connection with an adhesive or clamp to the substrate and the task is done.

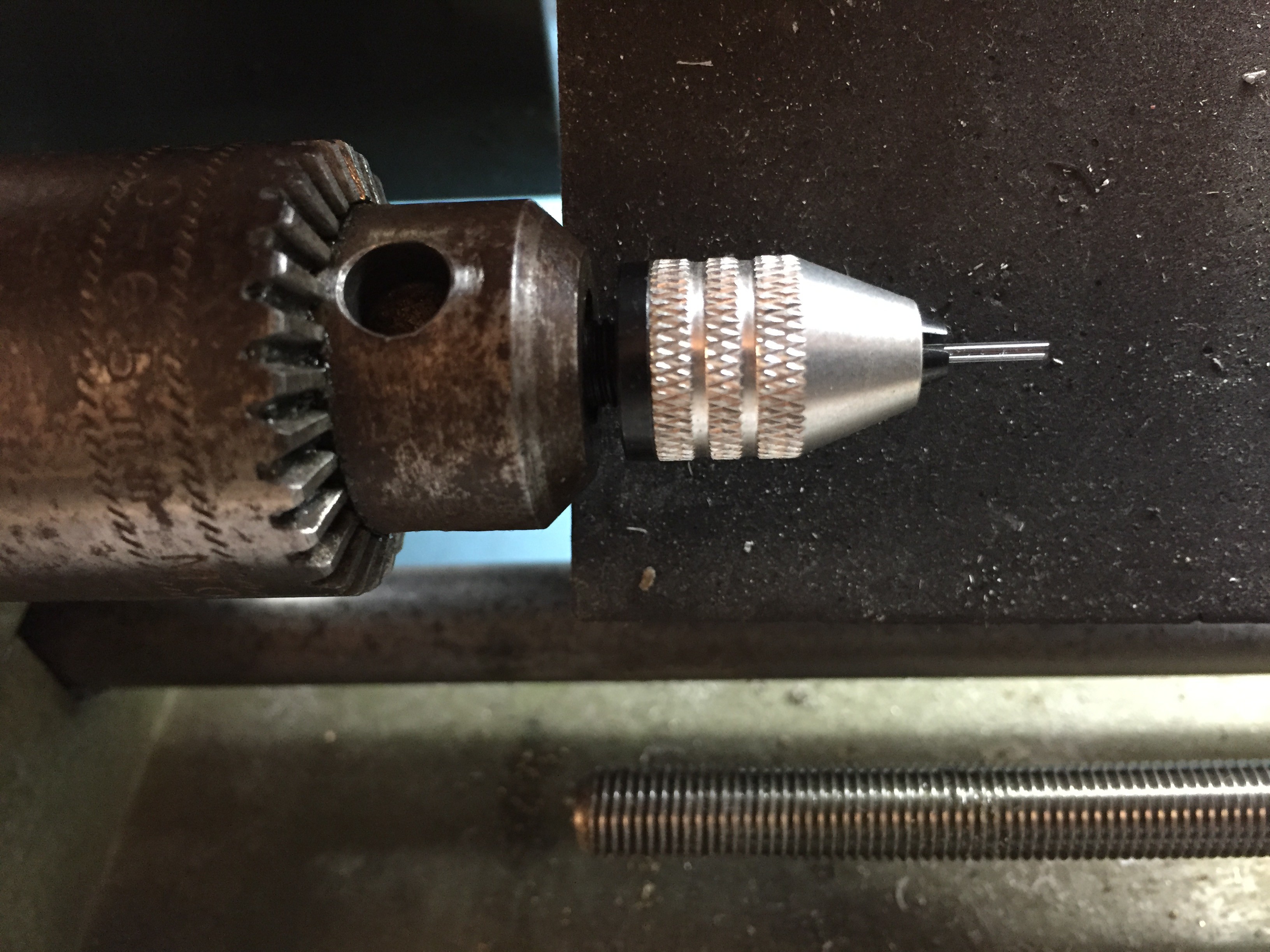

This is the equipment I used about 40 years ago when I developed the technique. I was in for a few surprises.

The basic tools are a glass lathe, capillary tubing, Oxy/Butane torch, and pin vice holding a needle.

So spin up the capillary in the lathe.

Heat the end of the capillary with a tiny hot flame while using the pin vise to keep the opening from closing, If you get the timing just right , you get a flange. You'll have to trust me on this one. It works.

As I mentioned, this glass working discovery was made quite some time ago. Between the then and now, Microflame has gone out of business. All of my spare oxygen cartridges have gone empty, and the walls of the capillary tubing that I recently purchased are too thin. Oh crap!

I promise to update this log with present day tools and materials that work! But it's going to take a few weeks while new material arrives from the other side of the world.

I even promise a nice video illustrating the technique.

Chuck Glasser

Chuck Glasser

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.