If you are interested in Microfluidics the Princeton Microfluidics Laboratory is a great place to start. No matter where your reading may take you you will find numerous reference to the use of SU-8 as a way of making master molds for the casting of PDMS, the preferred material for making microfluidic devices. While, I'm sure the use of SU-8 is a fantastic method, it's to my way of thinking, too much technology for a simple problem, especially in consideration of the resources required to implement the technique.

Briefly, microchannel paths are drawn using a calligraphy pen using molten agarose as the ink and PDMS is cast and cured directly over the drawing producing a microfluidic channel.

The purpose of the Space Grade experiments and machine development in support of the effort are to explore what is possible using a ceramic as a substrate for projects in Molecular Biology and Neuro Interposers and Neuro Cybernetic devices. While Molecular Biology as a term needs no explanation the term Neural Interposer does. An interposer is a electrical device for routing one connection to another. For a prosthetic device a neural interposer forms a bridge between what may be measured electrically in terms of muscle and nerve activity at the stump to the prosthetic device designed replace some or all of the missing function. Although based upon entirely different principles than are found in a prosthetic limb, a "Brain Computer Interface" is also a neural interposer.

The devices all slightly larger than a poker chip have a hexagonal shape and are called tokens. On one side of the the token may be found electrodes that are designed to interface to fluids. On the other side the electronics that generate or process the signals at the electrodes.

For tokens to be successful they must respond to the problems of interfacing with fluids as the duck takes to water. Similarly, the electronics located within the very same device must be immune to both water and the corrosive salts that will always be present. Interesting problem!

This test concerned itself with the immiscibility of agarose and PDMS.

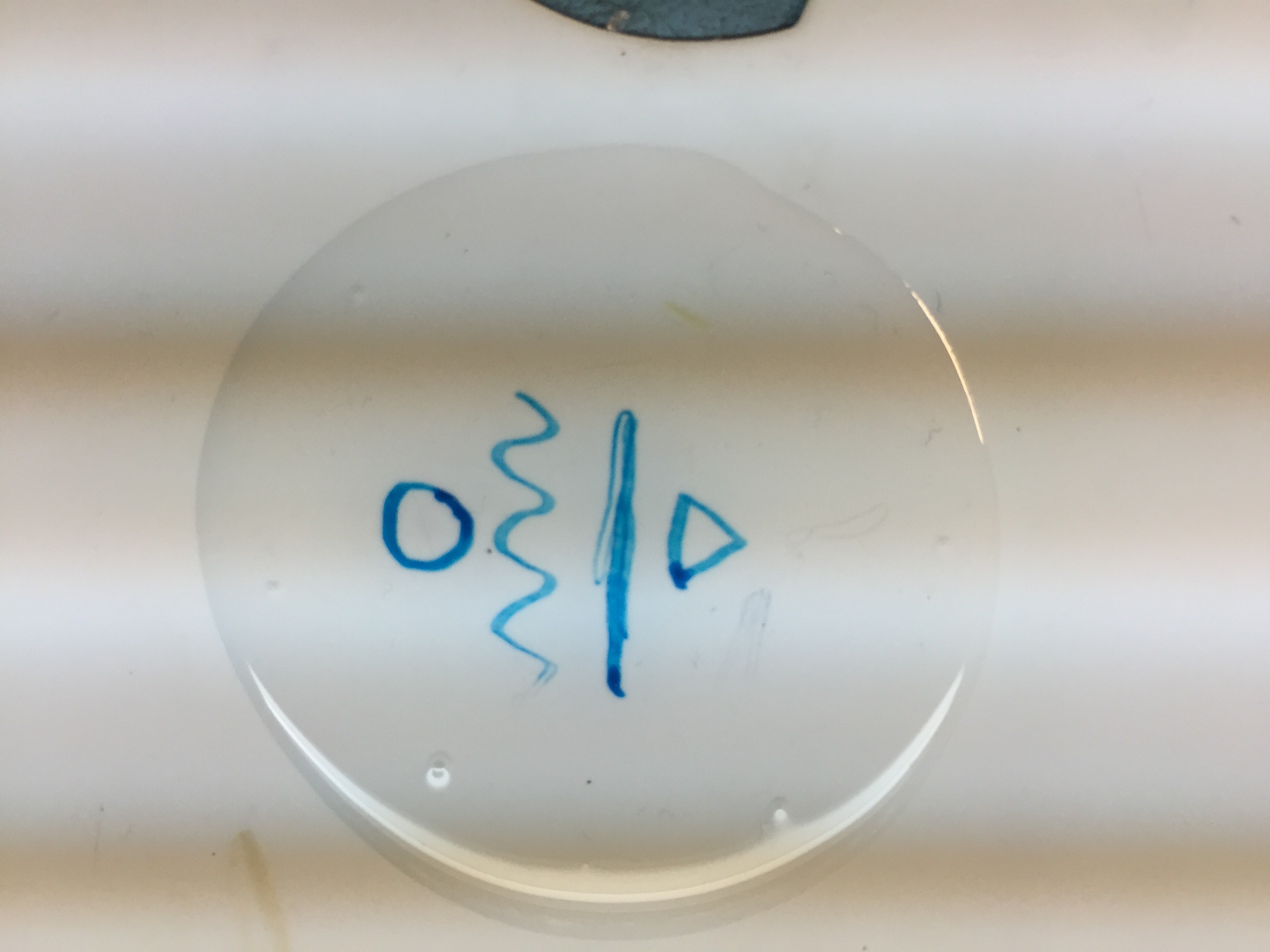

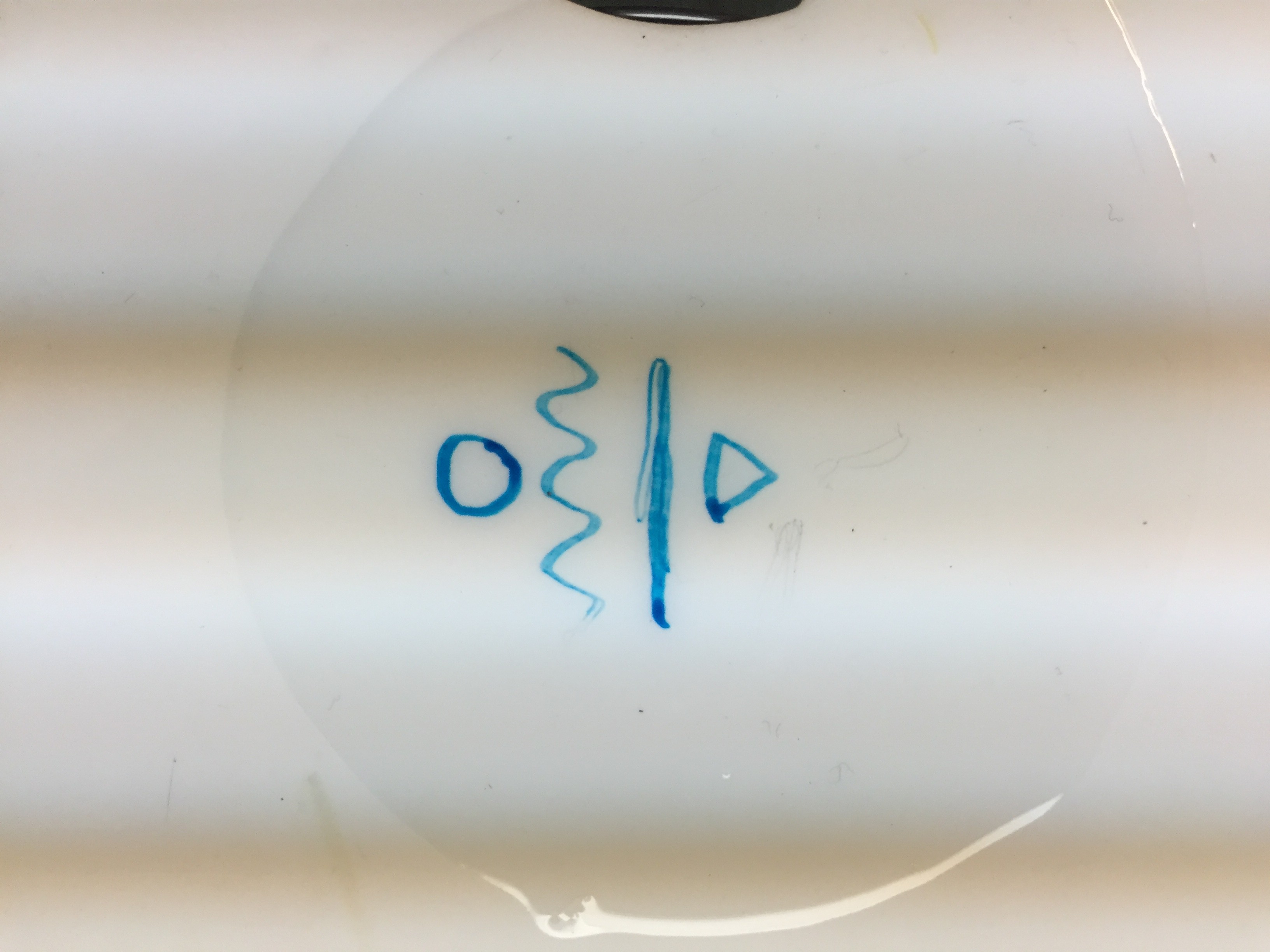

50 uL of Cyan inkjet ink was mixed with 50 uL of 0.8% agarose and using a calligraphy nib drawn onto an alumina substrate. The fluid was kept warm in a water bath to keep the agarose from gelling on the pin. There is no significance to the choice of symbols.

5.5 mL of Sylgard 184 PDMS was then mixed and poured directly on top of the agarose ink and cured in a lab oven at 80 degrees C for one hour.

under the heat of the curing process the PDMS continued to spread across the surface of the substrate. Note that there is absolutely no evidence of smearing or diffusion of the ink into the PDMS 50 mil thick. This observation strongly suggest that the two reagents are indeed imiscible.

What this means is that, in this case, microcapillaries may be drawn directly on a ceramic substrate and that the PDMS may be cast directly over the agarose channels, without effect.

This alone however will not be sufficient. DNA is known to have a extremely high affinity for glass. The same should be expected for alumina and composite ceramics such as cofired ceramics that are made up of almost equal amounts of alumina and glass. It will be necessary to passivate the substrate surface using a surfactant such as bovine serum albumin or polyethylene glycol. Ideally, it may be effective to draw the albumin pattern on a layer of PDMS that has undergone activation via ozone. By this mechanism one could avoid passivation.

Each of these avenues needs to be explored. Ultimately, after all the experiments are performed it may happen that SU-8 is still the champion. Only time, experiments, and a working LTCC process will tell the tale.

Chuck Glasser

Chuck Glasser

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.