The machine also uses image processing to check if the components have been picked up properly, and also makes corrections if they've been picked up with slight rotation or an offset.

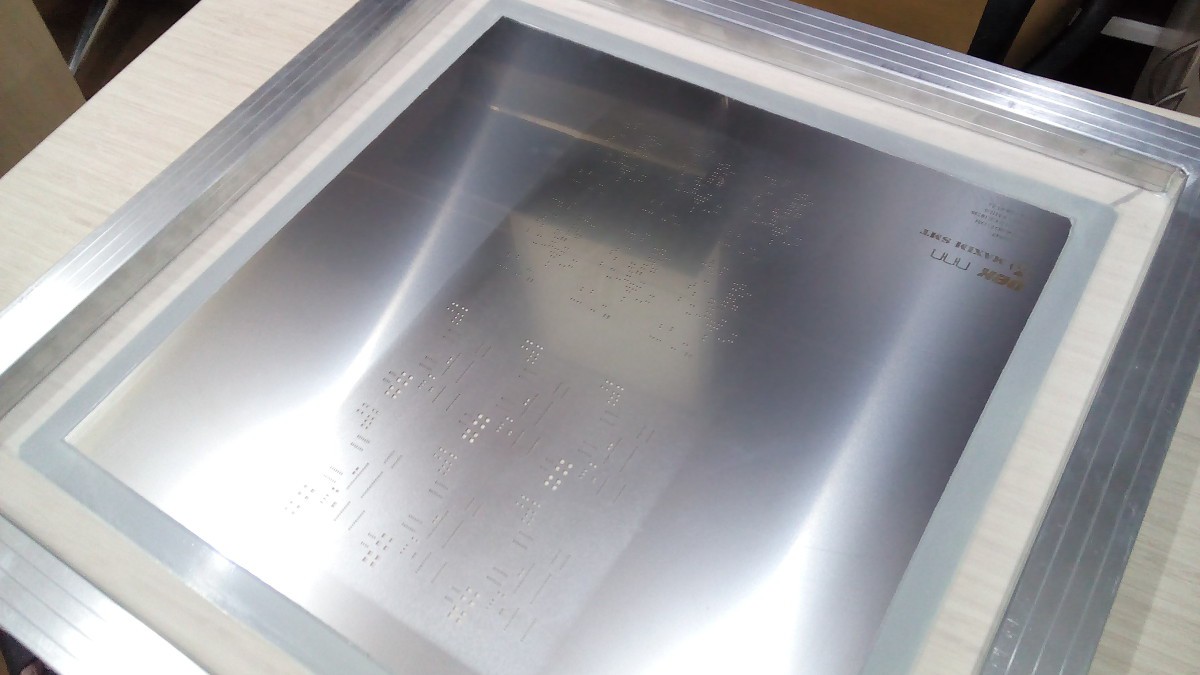

Figure : applying the paste. and the stencil for the panel.

Figure : The pick and place machine. I didn't order the PCBs in panel form with margins , so a custom rig had to be designed in order to feed the PCB into the Machine. It's much easier with panels though.

Figure : static reflow process. The oven's temperature follows a preset curve, and a batch of PCBs(whatever you can fit inside it, avoiding the extremities) reflow in about two minutes.

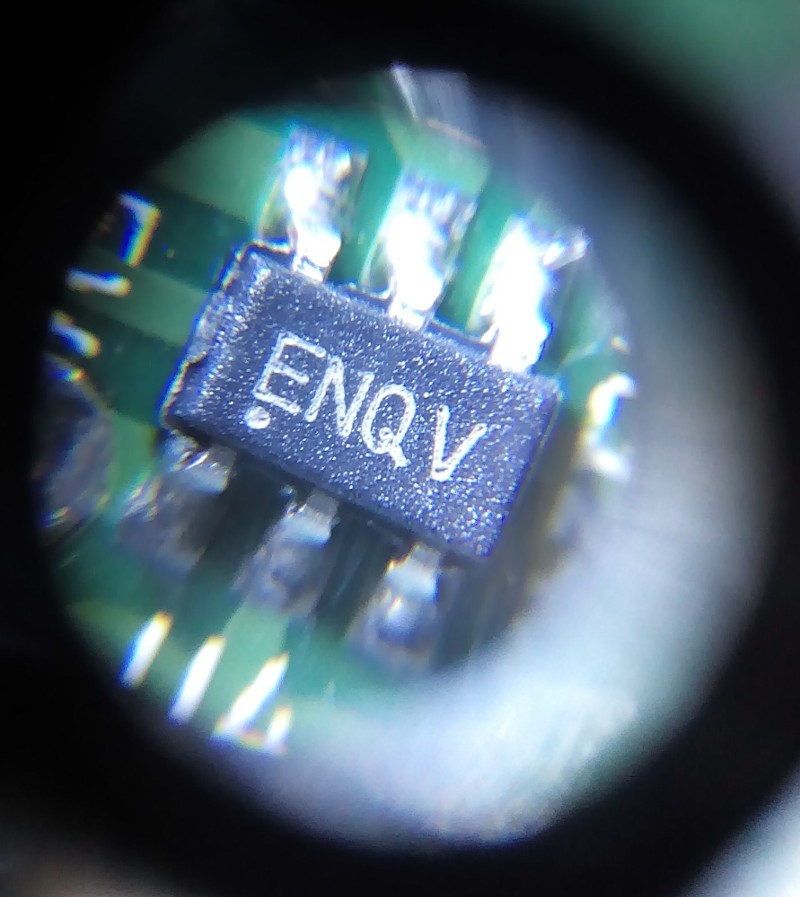

Photograph of a reflowed component( voltage doubler ) taken with a phone camera attached to a microscope lens.

Photograph of a reflowed component( voltage doubler ) taken with a phone camera attached to a microscope lens.

Reflowed boards. The PicKit 3 has a Programmer-to-go option where a HEX file can be downloaded onto it once, and the computer+IDE is no longer required. It can be powered from any source, and the code can be downloaded by pressing a physical button. Came in handy for preliminary testing.

Reflowed boards. The PicKit 3 has a Programmer-to-go option where a HEX file can be downloaded onto it once, and the computer+IDE is no longer required. It can be powered from any source, and the code can be downloaded by pressing a physical button. Came in handy for preliminary testing.

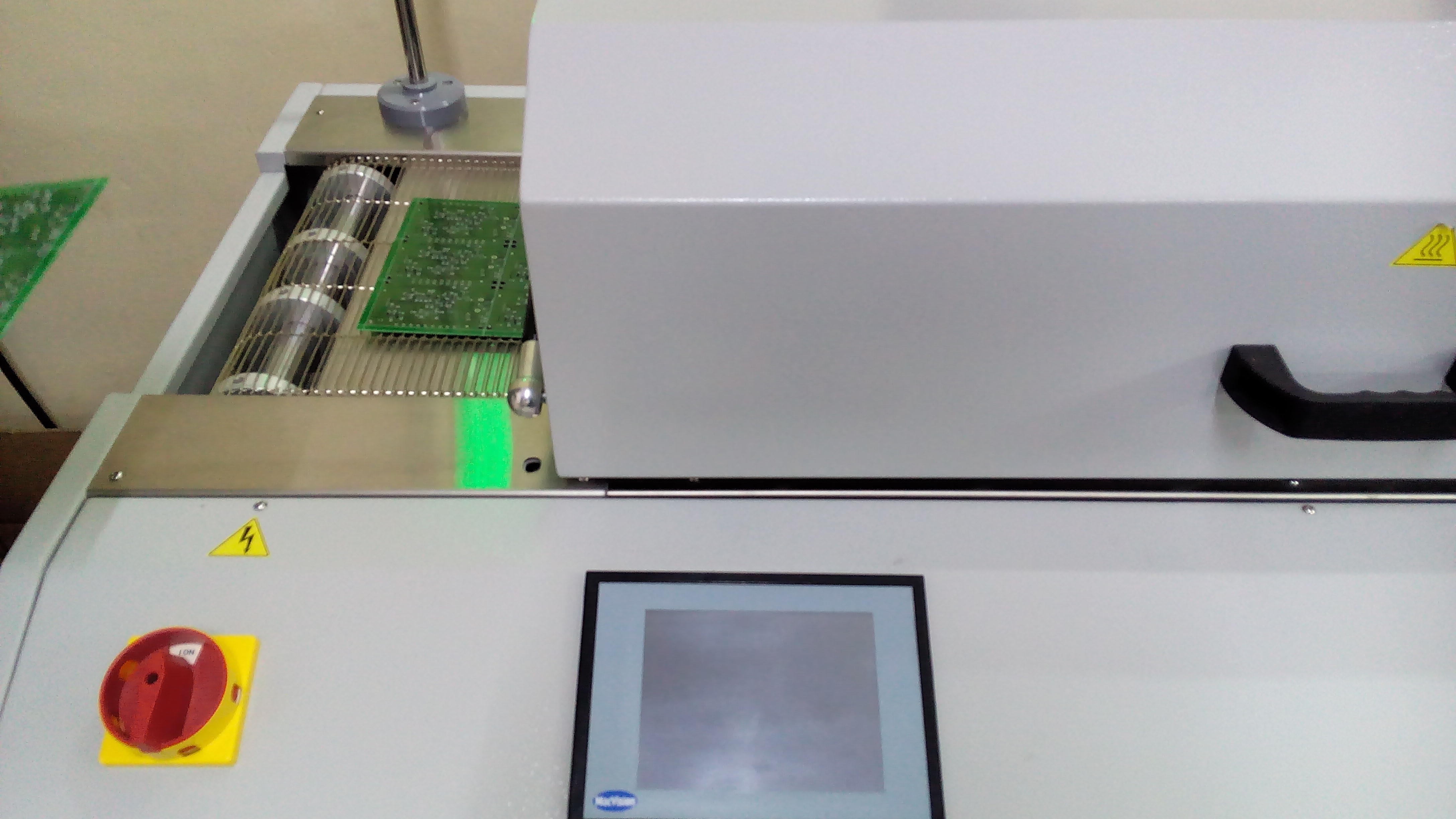

Figure : A conveyor based reflow oven. The boards travel slowly through various temperature ranges maintained inside the tunnel, and the reflow happens as it moves.

A manual assembly line at the workshop!

Jithin

Jithin

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.