I decided to go with a hall effect switch to do the homing for the carousel. Obviously vendotron needs to know exactly where "zero" is so that when a purchase is made, it can accurately spin the carousel to the correct column.

I decided to go with an off the shelf hall effect sensor that can be purchases on a breakout board and with a wire connector to simplify the design. The one I went with is the SunFounder module:

https://www.amazon.com/SunFounder-Switch-Sensor-Arduino-Raspberry/dp/B013G5N03O

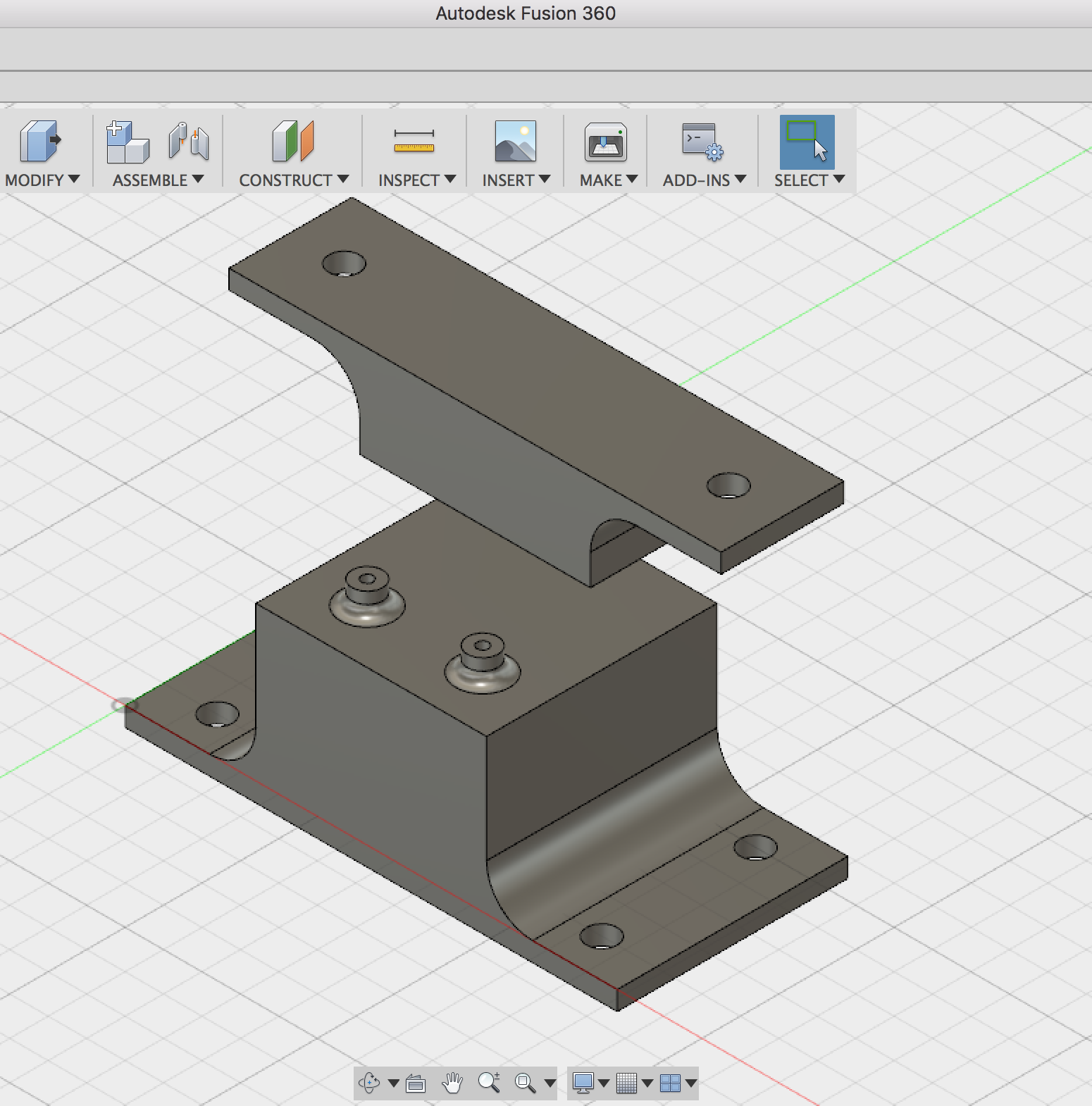

I designed a stand for this sensor that will go under the carousel, with a bracket holding a 6mm magnet attached to the carousel:

Example magnets that fit into the bracket:

https://www.amazon.com/gp/product/B01I79ONIU

The hall effect module will be wired into the 'home' port on the PCB, and code will be written so that when the machine is first powered on, it will slowly spin the carousel until the hall effect sensor detects the magnet. At that point, the software will know exactly where each column on the carousel is relative to the doors.

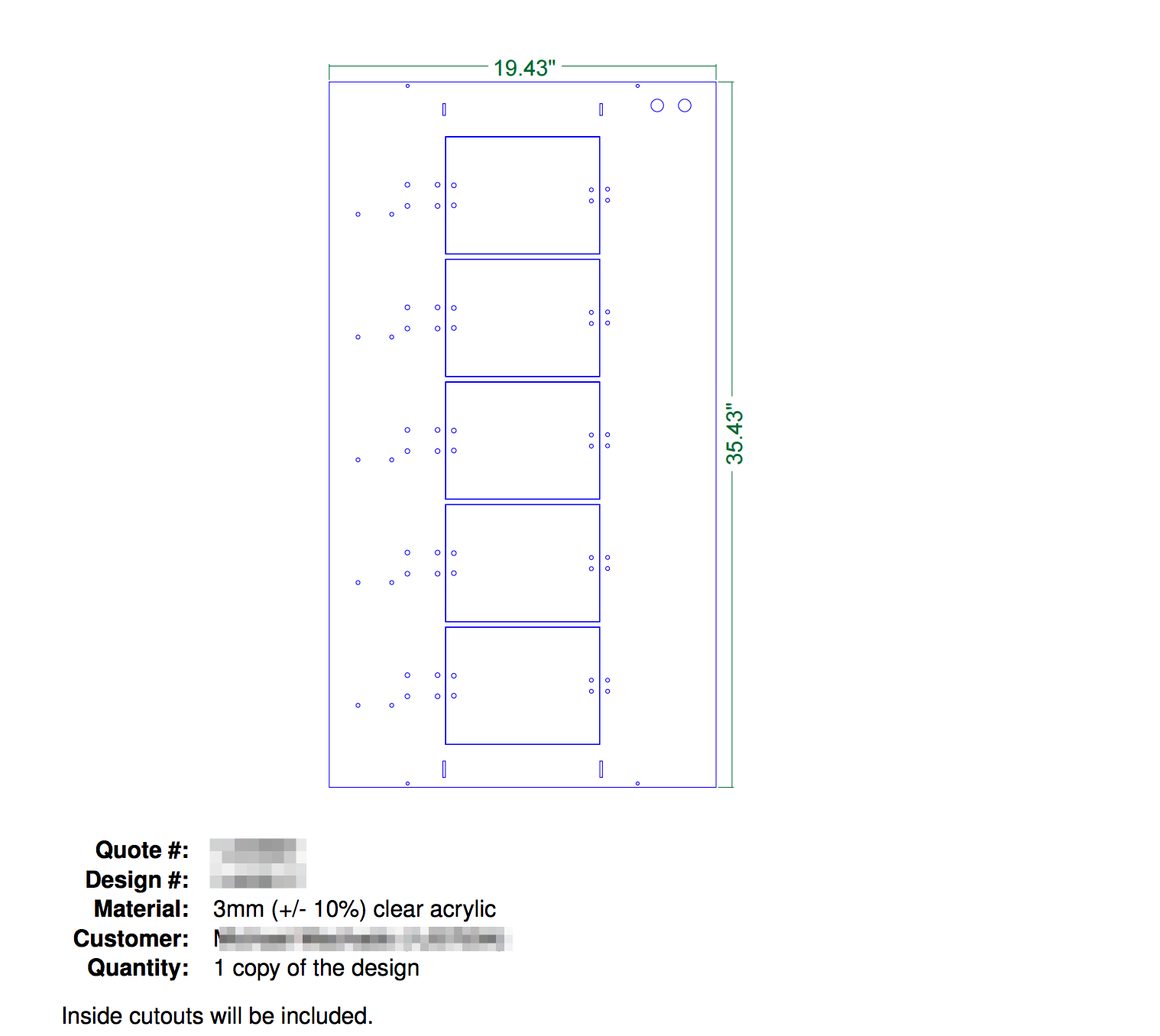

The front panel acrylic has also been ordered. At MakerHQ we only have a 20"x12" bed on our laser cutter, so we can't do larger jobs in house. When we need to cut larger panels, we use Pololu Laser Cutting Service, because they are fast, high quality and an awesome company to support. Here is an example of the digital proof you get when submitting a job. It looked great, so I ordered it and it should be here in about a week!

Mike Machado

Mike Machado

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.