It took over a year to make the first working prototype of the personal robot. During that time, I 3D printed and experimented with over 240 designs for artificial muscles. The most powerful muscles with the minimum volume were eventually used to power the arms and gripper. Pic shows a few of the designs that were tried.

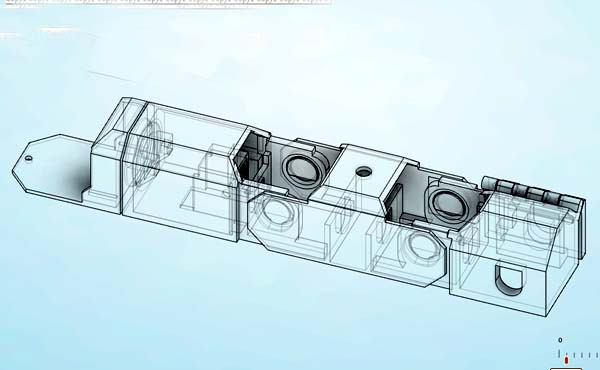

3D Printing Valves

Solenoid air valves are quite expensive and heavy. They also take up too much volume to fit in a small robot. So I also experimented with 3d printing servo controlled valves using micro-servos. One servo can control 3 valves.

You can download ready to print STLs and see details on making the valves here: http://www.instructables.com/id/3d-Printing-Servo-Controlled-and-Other-Valves/

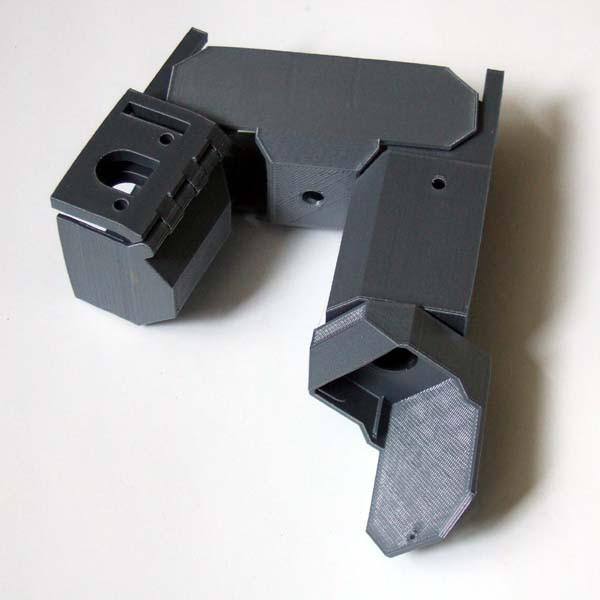

3D printing the arms and body

The robot arm is printed in one piece using PLA. It contains four built-in hinge joints. The air powered artificial muscles are printed in Ninjaflex and after they are sealed, they simply pop into the sockets built into the arms. One bolt holds a micro servo in place to rotate the wrist joint.

Michael Roybal

Michael Roybal

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.