The plasma torch needs to fire and start an arc before moving or a detail can be missed or a drop out doesn't drop out. That was the case that I ran into. Thinking that it was a GRBL issue, I posted an issue on the github grbl page here. The thought was the G4P1.2 was not dwelling the proper about of time the first time it was called, but would work fine in successive calls. The program below was made to help with diagnosing the problem.

G21 G90 G64 G54 G0X0Y0 G0 Z1.0 G38.2Z-300F1000 G92Z-17 G90G0Z1 M3S10000 G4P1.2 G1 Z1.0 F1000.0 G1 F1200.0 X10 Y0 M5 G0 Z10.0 G0 X0 Y10 G1F1000.0 Z1.0 G38.2Z-300F1000 G92Z-17 G90G0Z1 M3S10000 G4P1.2 G1 Z1.0 F1000.0 G1 F1200.0 X10 Y10 M5 G0 Z10.0 G0 X0 Y20 G1F1000.0 Z1.0 G38.2Z-300F1000 G92Z-17 G90G0Z1 M3S10000 G4P1.2 G1 Z1.0 F1000.0 G1 F1200.0 X10 Y20 M5 G0 Z10.0 M30

This code produced the following cuts:

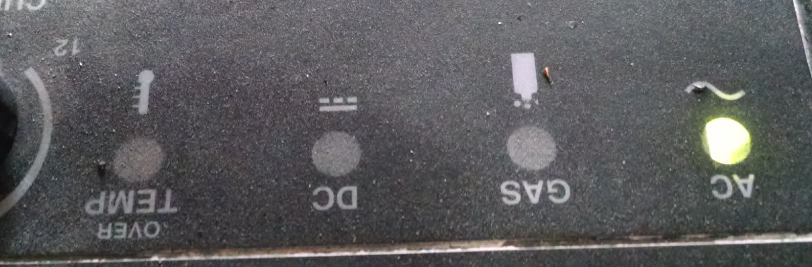

For the first cut, the relay kicks in to turn on the plasma torch, but there is hesitation before the DC light turns on along with the plasma torch fire. After the relay shuts off, the DC light stays on for a short time.

The way that would be nice is if M66 was implemented in grbl (may have to dive into this, if its priority goes up). For now a cut elsewhere on the material will charge the DC side and allow the next cut to come out ok.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.