After designing the watch in Fusion360, I had to print the parts with a 3D printer, in my case the bq Prusa i3 Hephestos. As a material I am using PLA, mainly because it doesn't smell as bad as ABS. The main challenge was getting the case printed with a smooth surface. As there is only one main part for it, supports are crucial. I started with Slic3r, but soon switched to Simplify3D because of its adjustable supports. Still, it took a lot of failed attempts to get all the settings right.

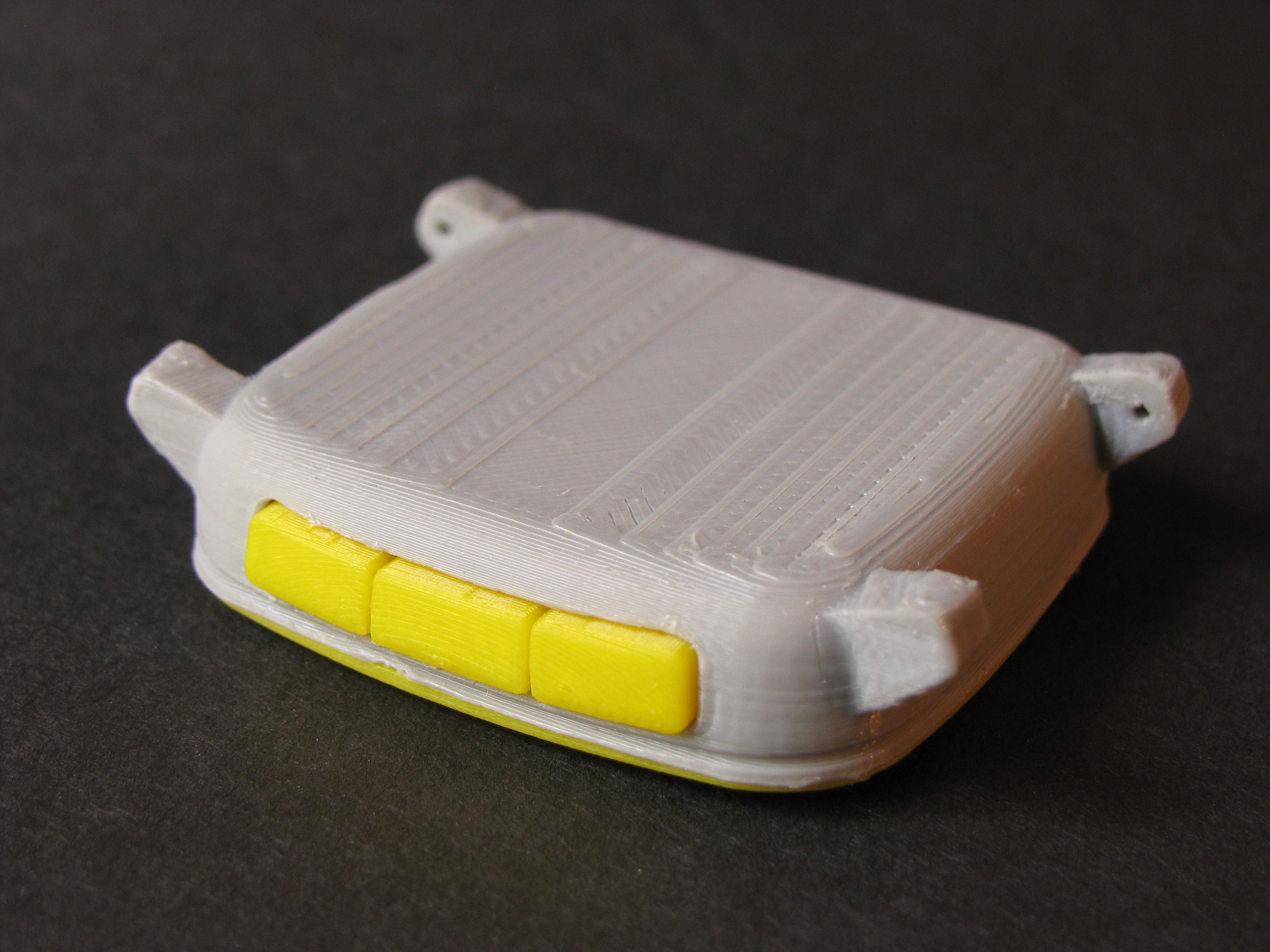

This is what the parts looks like after printing:

For the buttons and cover I lowered the layer thickness to 50 um. This is because these parts are really small and only slightly curved. It's ok if the they are recognizable as 3D prints but they should not look too edgy.

The last part is the "spine". There are no high demands to it, as it will not be visible from looking at the watch.

To explain how the individual parts are assembled, I played around in Fusion360 and created this GIF: Basically, all components apart from the buttons and case are supposed to be glued together. Then this assembly is placed in the case with the buttons, where it will snap in on one side. A small screw will then secure it from falling out of the case. I ended up using double sided tape for the whole process and tiny drops of superglue to secure the display. Attaching an 22mm Casio watchband was the last and easiest step.

Basically, all components apart from the buttons and case are supposed to be glued together. Then this assembly is placed in the case with the buttons, where it will snap in on one side. A small screw will then secure it from falling out of the case. I ended up using double sided tape for the whole process and tiny drops of superglue to secure the display. Attaching an 22mm Casio watchband was the last and easiest step.

The end result turned out really well in my opinion. It is obviously not nearly as usable and durable as a industrially manufactured Pebble watch. But it can definitely be worn as a watch and the battery life almost justifies that you have to open the case to replace the coin cell every few months.

Max.K

Max.K

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.