So after I was sure that all the connections were correct it was time to put the firmware into the machine.

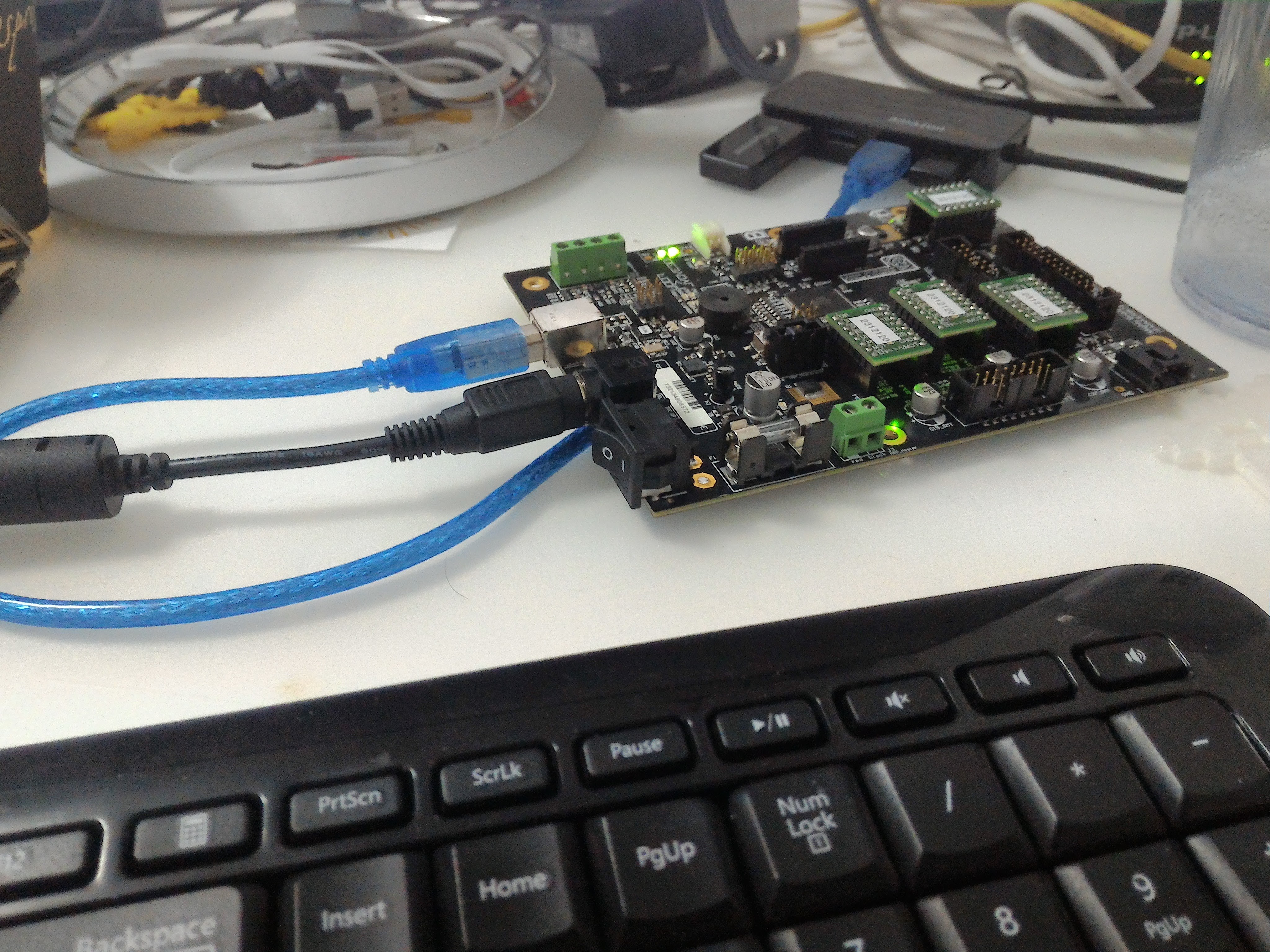

I forgot to get the configuration values before taking out the original board so I hooked the board to the power supply (soldered the original connector so I can use the board) and connected via USB to ReplicatorG:

After I got the information from the board I proceed to editing Configuration.h - the file can be found in the files section.

I guessed the values of the PID based on stuff that I found online so the next thing was to get the correct PID values, that can be done using PID autotuning feature of Marlin.

After few tries I succeeded in printing something!

But after few prints my nozzle got clogged, so I declogged and after few more prints it got clogged again.

The issue was that once it finished printing the fan would stop! now I was used to the fan running while the hotend was hot so digging a bit in Marlin source revealed that there is an option to control the fan automatically based on the temperature.

The change needed was in configuration_adv.h (can be found in the files section) file - settings EXTRUDER_0_AUTO_FAN_PIN to 9 which means it will use D9 pin (which I connected the fan to) for controlling the fan based on the temperature.

Now since it uses pin 9 we can't use it for the "regular" fan pin so a change in pins.h (Also in the files section) was needed to set FAN_PIN to -1.

With this fix I been printing for serval hours with breaks between them and the nozzle doesn't clog anymore.

Next up: printing adapters for RAMPS1.4 board and LCD controller.

Uriel Katz

Uriel Katz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.