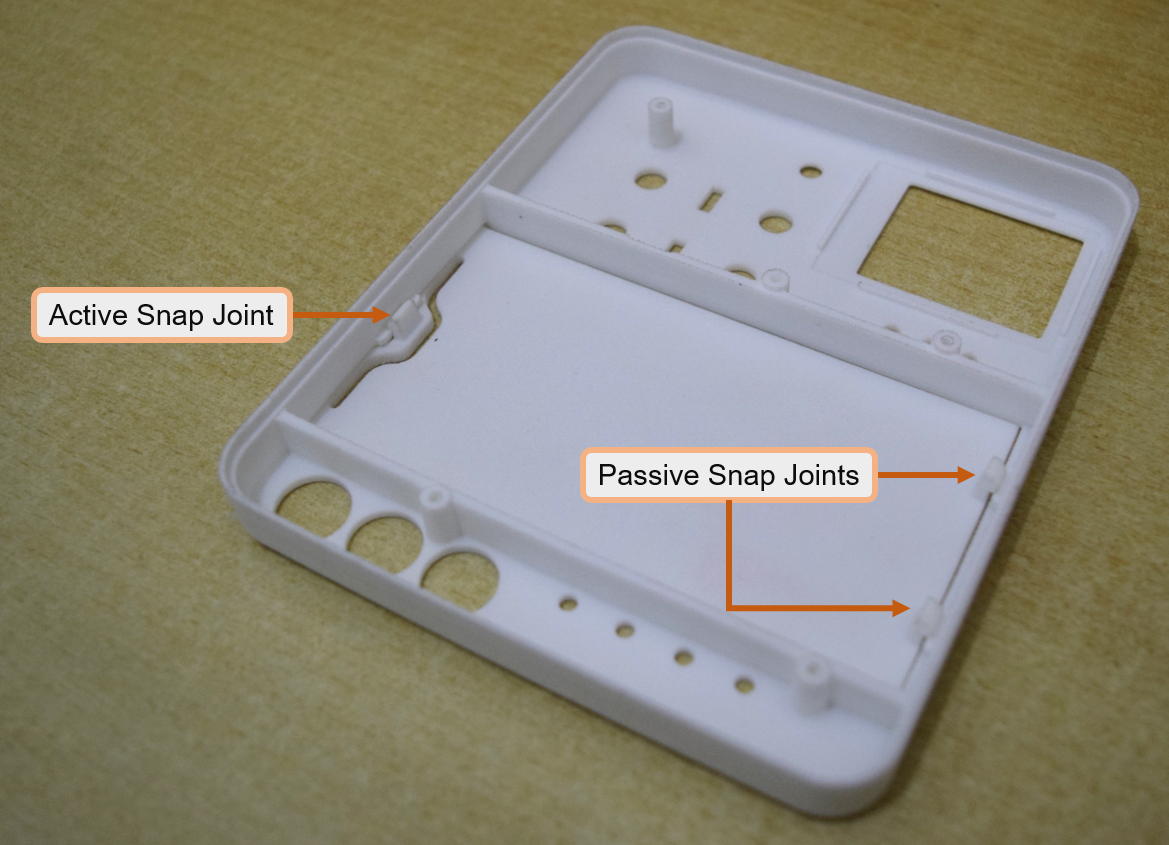

evive has a "magic lid" which enclose arduino shield stack space, IoT hub (Bluetooth, XBee and ESP8266 ESP 12e) and prototyping area. The lid has been provided with one snap joint from where the user will open and other two passive snaps for locking. Designing the snap joint took multiple iterations before the final Plastic Injection Molding using SLS 3D printing.

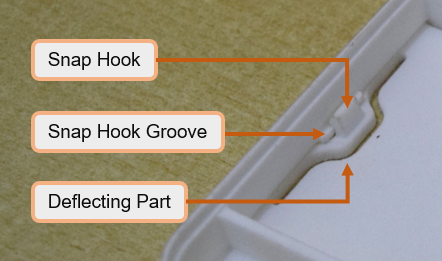

Snap joints are compliant mechanisms. A beginners guide for snap joint design can be found here.

The design parameters depends mostly on how easily/frequently we want to open the snap joint, the number of snap joints provided, material used and manufacturability.

A snap have two basic parts, Snap Hook and Snap Hook Groove. Usually snap hook are made flexible to get deflected and hence snapped. But in our design we have made the lid flexible (Deflecting Part), as the snaps are small in size as compared to the thickness of the case.

The problems faced by us includes interference of passive snap while removing the lid and hence wearing of groove in first iteration. It was corrected by providing proper clearance and fillets. Iterations helps us for reaching the final design of snaps.

Dhrupal R Shah

Dhrupal R Shah

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.